Method for decomposing bastnaesite through calcification transformation-leaching

A technology of calcification transformation and bastnaesite, which is applied in the field of calcification transformation-leaching and decomposition of bastnaesite, can solve the problems of rare earth loss, waste of fluorine resources, high energy consumption, etc., achieve efficient separation and comprehensive recovery, reduce fuel consumption, The effect of low firing temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

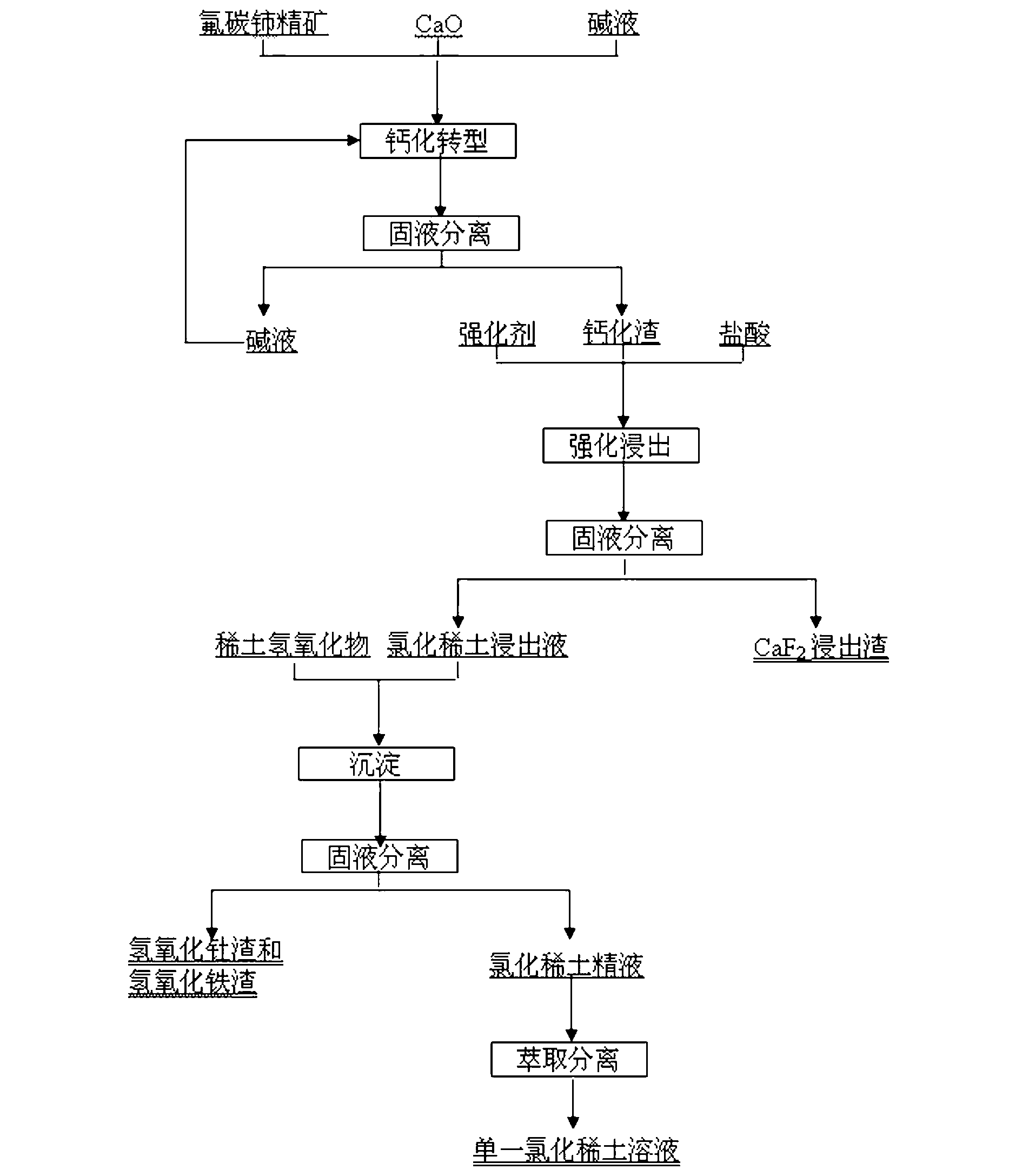

Method used

Image

Examples

Embodiment 1

[0032] (1) Activation pretreatment of rare earth concentrate

[0033] Roast bastnaesite concentrate at 430°C for 3 hours to obtain activated ore;

[0034] (2) Activated ore calcification transition pretreatment

[0035] Mix the activated ore obtained in step (1) with CaO evenly at a mass ratio of 100:70, then mix the mixture with 0.5mol / L NaOH solution according to the solid-to-liquid ratio of 1kg:20L for calcification and fluorine-fixing transition pretreatment, and the transition temperature is 150°C, the transformation time is 3 hours, and then solid-liquid separation is carried out to obtain transformation slag and lye, and the lye is directly recycled;

[0036] (3) Transformation slag acid leaching

[0037] (a) The transformation slag obtained in step (2) and 1 mol / L hydrochloric acid solution are subjected to acid leaching treatment according to the solid-to-liquid ratio of 1 kg : 20L, the leaching temperature is 30°C, the leaching time is 120min, and the mass fraction...

Embodiment 2

[0043] (1) Activation pretreatment of rare earth concentrate

[0044] Roast bastnaesite concentrate at 480°C for 2 hours to obtain activated ore;

[0045] (2) Activated ore calcification transition pretreatment

[0046] Mix the activated ore obtained in step (1) with CaO evenly at a mass ratio of 100:80, then mix the mixture with 0.5mol / L NaOH solution according to the solid-to-liquid ratio of 1kg:15L for calcification and fluorine-fixing transition pretreatment, and the transition temperature is 180°C, the transformation time is 2 hours, and then the solid-liquid separation is carried out to obtain the transformation slag and lye, and the lye is directly recycled;

[0047] (3) Transformation slag acid leaching

[0048] (a) The transformation slag obtained in step (2) and 1.5mol / L hydrochloric acid solution are subjected to acid leaching treatment according to the solid-to-liquid ratio of 1 kg: 20L, the leaching temperature is 50°C, the leaching time is 90min, and the mass f...

Embodiment 3

[0054] (1) Activation pretreatment of rare earth concentrate

[0055] Roast bastnaesite concentrate at 500°C for 1 hour to obtain activated ore;

[0056] (2) Activated ore calcification transition pretreatment

[0057] Mix the activated ore obtained in step (1) with CaO evenly at a mass ratio of 100:100, then mix the mixture with 1.0mol / L NaOH solution according to the solid-to-liquid ratio of 1kg:10L for calcification and fluorine-fixing transition pretreatment, and the transition temperature is 300°C, the transformation time is 2 hours, and then solid-liquid separation is carried out to obtain transformation slag and lye, and the lye is directly recycled;

[0058] (3) Transformation slag acid leaching

[0059] (a) The transformation slag obtained in step (2) and 1.5mol / L hydrochloric acid solution are subjected to acid leaching treatment according to the solid-to-liquid ratio of 1 kg: 20L, the leaching temperature is 90°C, the leaching time is 30min, and the mass fraction ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com