Water-based printing ink resin and preparation method thereof

A technology of water-based ink and resin, which is applied in the field of paint and ink, can solve the problems of poor adhesion of water-based rosin resin, achieve the effects of improving bonding performance, high bonding strength, and reducing environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

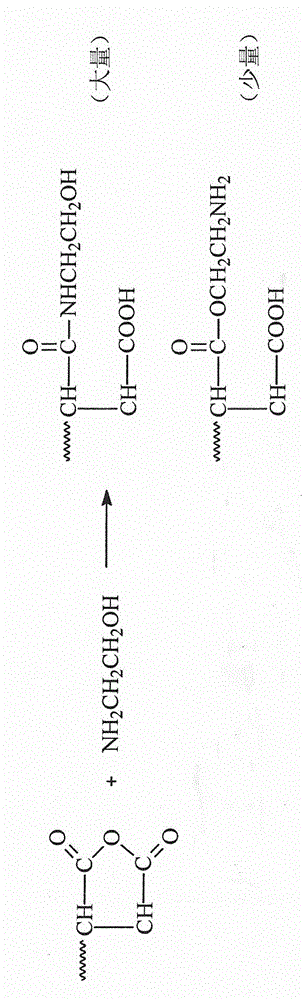

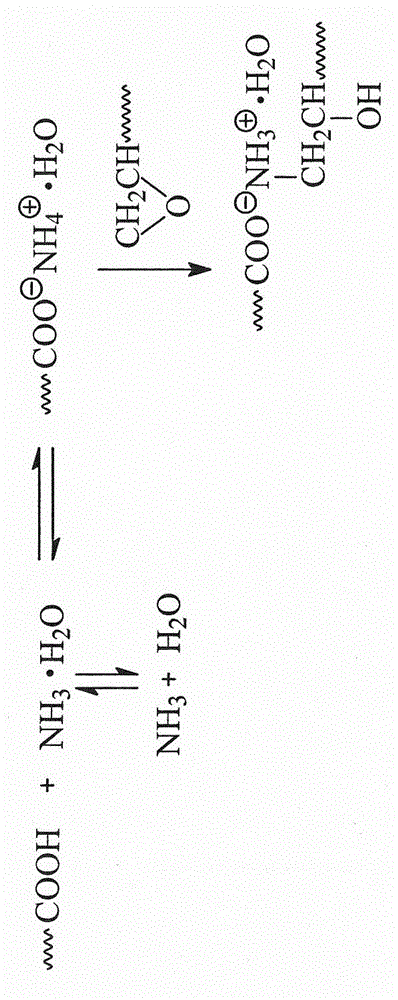

Method used

Image

Examples

Embodiment 1

[0024] Embodiment 1. A water-based ink resin, the weight percentage of each component is: rosin resin: 30.0-32.0%, maleic anhydride: 8.0-10.0%, pentaerythritol: 1.0-3.0%, zinc oxide: 0.02- 0.03%, tung oil: 8.0~10.0%, ethanolamine: 2.0~4.0%, butyl acetate: 2.0~4.0%, mixed alcohol: 8.0~10.0%, amine stabilizer: 12.0~15.0%, ethyl acetate: 17.0~23.0 %.

[0025] The mixed alcohol is a mixed solution of ethanol and isopropanol in a weight ratio of 1:1.

[0026] The amine stabilizing solution is a mixed resin solution of ammonia water and epoxy resin solution in a weight ratio of 1.5 to 2:1, the epoxy resin solution is an acetone solution containing 50.0% of epoxy resin, and the epoxy resin has a softening point greater than 85°C. oxygen resin.

[0027] Its preparation method is as follows:

[0028] A. First add rosin resin in the reaction kettle, heat up to 130-140°C to melt, add maleic anhydride after stirring, heat up to 180°C, keep warm for 1.5 hours, then add zinc oxide and pe...

Embodiment 2

[0038] Embodiment 2. A water-based ink resin, the weight percentage of each component is: rosin resin: 32.0-35.0%, maleic anhydride: 6.0-8.0%, pentaerythritol: 3.0-5.0%, zinc oxide: 0.03- 0.04%, tung oil: 6.0-8.0%, ethanolamine: 2.0-4.0%, butyl acetate: 2.0-4.0%, mixed alcohol: 10.0-12.0%, amine stabilizer: 10.0-12.0%, ethyl acetate: 17.0-23.0 %.

[0039] The mixed alcohol is a mixed solution of ethanol and isopropanol in a weight ratio of 1:1.

[0040] The amine stabilizing solution is a mixed resin solution of ammonia water and epoxy resin solution in a weight ratio of 1 to 1.5:1, the epoxy resin solution is an acetone solution containing 50.0% of epoxy resin, and the epoxy resin has a softening point greater than 85°C. oxygen resin.

[0041] Its preparation method is as follows:

[0042] A. First add rosin resin in the reaction kettle, heat up to 130-140°C to melt, add maleic anhydride after stirring, heat up to 180°C, keep warm for 1 hour, then add zinc oxide and pentae...

Embodiment 3

[0052] Embodiment 3, a water-based ink resin, the weight percentage of each component is: rosin resin: 30.0-32.0%, maleic anhydride: 8.0-10.0%, pentaerythritol: 3.0-5.0%, zinc oxide: 0.03- 0.04%, tung oil: 8.0~10.0%, ethanolamine: 2.0~4.0%, butyl acetate: 2.0~4.0%, mixed alcohol: 10.0~12.0%, amine stabilizer: 10.0~12.0%, ethyl acetate: 17.0~23.0 %.

[0053] The mixed alcohol is a mixed solution of ethanol and isopropanol in a weight ratio of 1:1.

[0054] The amine stabilizing solution is a mixed resin solution of ammonia water and epoxy resin solution in a weight ratio of 1 to 1.5:1, the epoxy resin solution is an acetone solution containing 50.0% of epoxy resin, and the epoxy resin has a softening point greater than 85°C. oxygen resin.

[0055] Its preparation method is as follows:

[0056] A. First add rosin resin in the reaction kettle, heat up to 130-140°C to melt, add maleic anhydride after stirring, heat up to 180°C, keep warm for 1 hour, then add zinc oxide and pent...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com