Method for preparing FexPO4 by electrolyzing ferrophosphorus

A technology for electrolysis of ferrophosphorus and electrolysis, which is applied in the electrolysis process, electrolysis components, electrodes, etc., and can solve the problem of the type and content of impurities, the difficulty in controlling the particle size and morphology of the product, the different types and contents of ferrophosphorus impurities, and the influence of the particle size of ferrophosphorus raw materials. Larger problems such as overcoming the difficulty of raw material ratio, reducing the influence of impurity elements, and eliminating the easy corrosion of equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

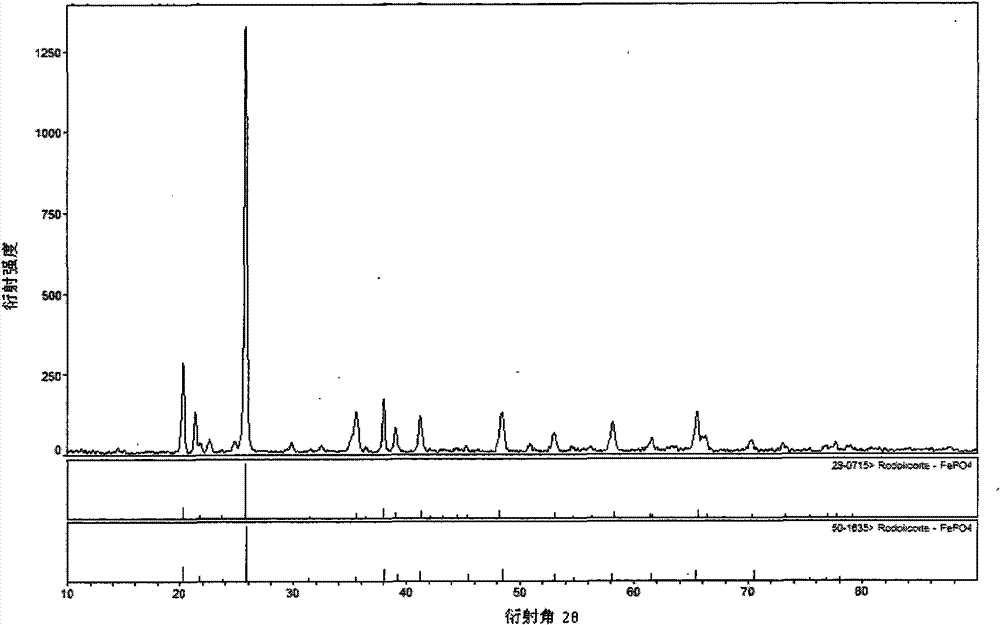

Embodiment 1

[0028] Preparation of iron phosphate from iron phosphorus by electrolysis, and preparation of FePO by iron phosphorus FeP 4 , the electrolytic device is composed of ferrophosphorus and graphite, ferrophosphorus is used as anode, placed in the anode bag, graphite is used as cathode, tap water is used as electrolyte, 1% phosphoric acid is added to increase conductivity, electrolysis is performed on a DC power supply, and the voltage is 5-7V , the current is 1.5-2A, the electrolysis time is 50-60h, adding ammonia water to the electrolyzed solution to adjust the pH=5-6, after filtering, washing and drying, the finished product of ferric phosphate is obtained.

[0029] In this reaction, ammonia water is added to adjust the pH value, and the remaining solution after filtration is ammonium phosphate, which can be used as chemical fertilizer, realizing green and clean production.

Embodiment 2

[0031] Ferrophosphorus Fe by electrolysis 2 Preparation of iron phosphate by P, preparation of FePO with ferrophosphorus as iron source and part of phosphorus source 4 , the electrolysis device is composed of iron phosphorus and graphite, iron phosphorus is used as anode, graphite is used as cathode, aqueous solution is used as electrolyte, phosphoric acid is used as a supplementary phosphorus source, and the conductivity of the aqueous solution is also improved. Electrolyzed on a DC power supply, the voltage is 4~ 6V, current 1.5-2A, electrolysis time 30-40h, add ammonium carbonate to the electrolyzed solution to adjust pH=4-5, filter, wash and dry to obtain finished iron phosphate.

[0032] In this reaction, ammonium carbonate is added to adjust the pH, and the remaining solution after filtration is ammonium phosphate, which can be used as chemical fertilizer, realizing green and clean production.

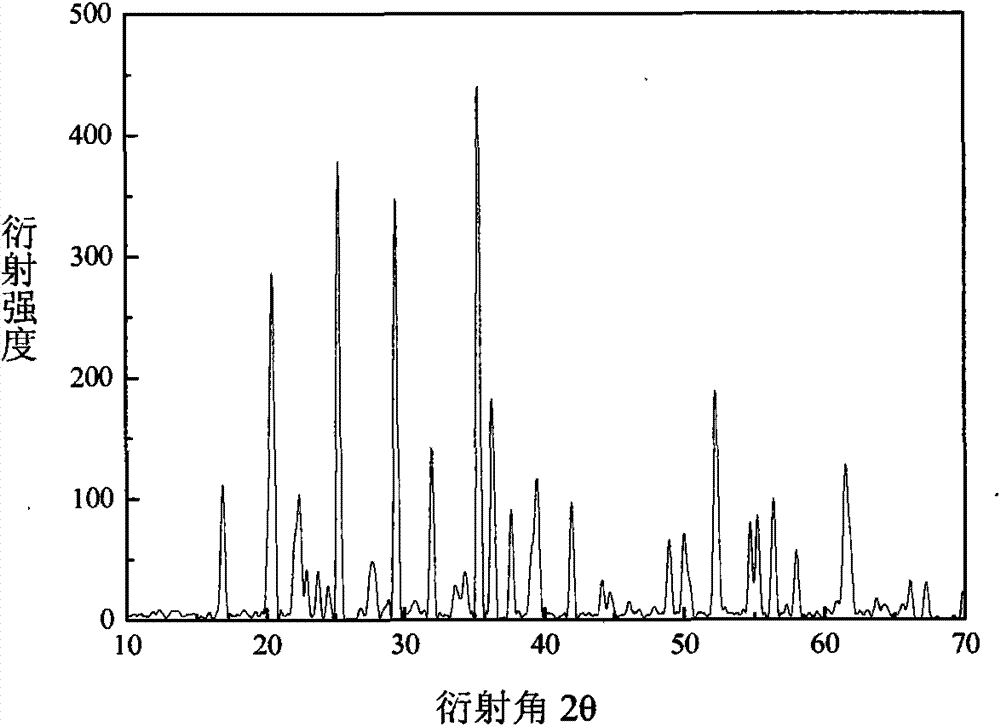

Embodiment 3

[0034] Ferrophosphorus Fe by electrolysis 1.5 P prepares ferrous phosphate, and prepares Fe with ferrophosphorus as iron source and part of phosphorus source 3 (PO 4 ) 2 , the electrolytic device is composed of ferrophosphorus and graphite, ferrophosphorus is used as the anode, placed in the anode bag, graphite is used as the cathode, the aqueous solution is used as the electrolyte, and ammonium phosphate is used as the supplementary phosphorus source, which also improves the conductivity of the aqueous solution. On electrolysis, the voltage is 5-7V, the current is 1.8-2A, and the electrolysis time is 40-45h. Ammonium bicarbonate is added to the electrolyzed solution to adjust the pH to 6-7. After filtering, washing and drying, phosphite Iron products.

[0035] In this reaction, ammonia water is added to adjust the pH, and the remaining solution (ammonium phosphate) after filtration can be used as fertilizer. Realized green and clean production.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com