Patents

Literature

52results about How to "Reduce granulation" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

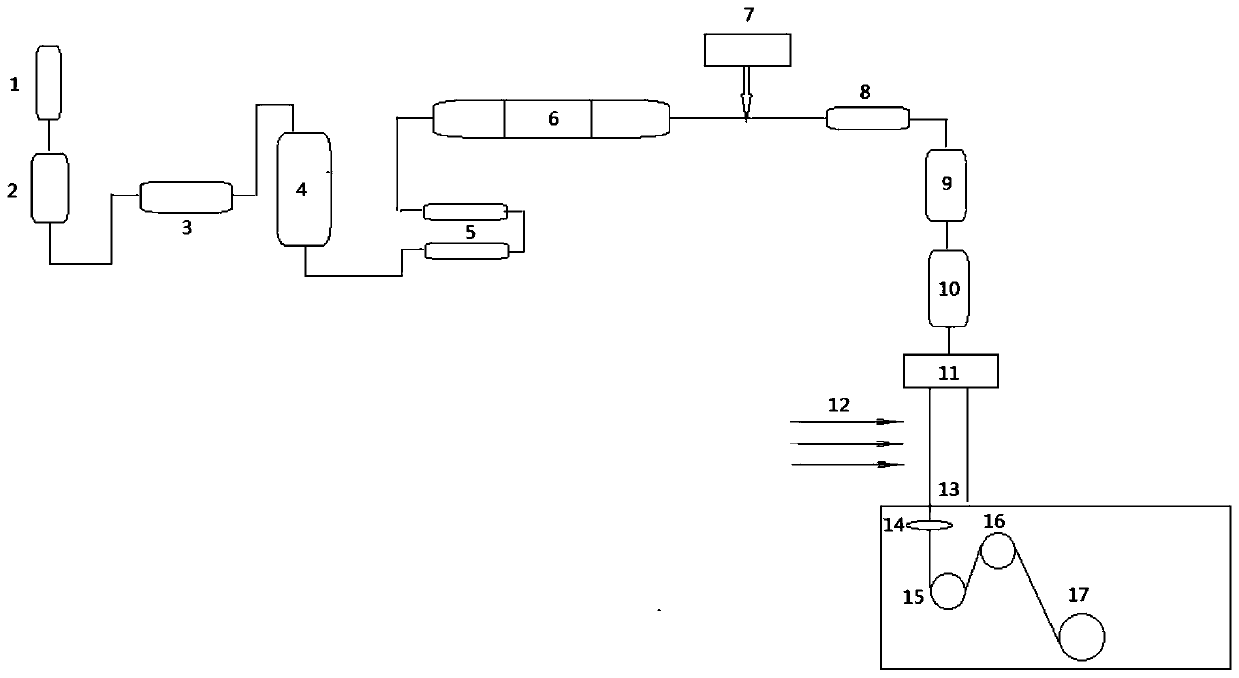

Nylon fibers and preparation method thereof

ActiveCN104562271AEmission reductionReduce pollutionFilament manufactureMonocomponent copolyamides artificial filamentYarnPolymer science

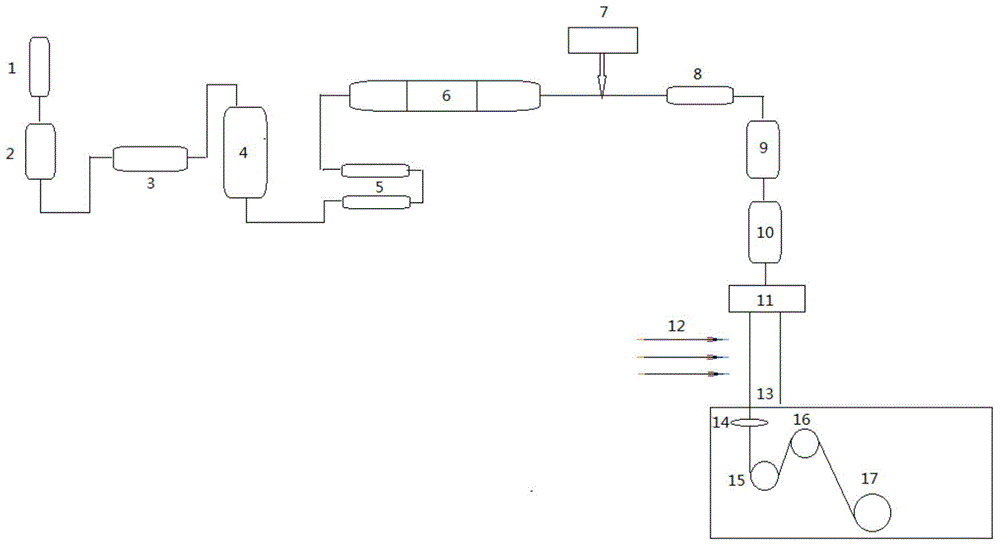

The invention discloses a preparation method of nylon fibers. The preparation method comprises the following steps: directly spinning after taking raw materials containing 1,5-pentamethylene diamine and adipic acid to react. The invention further provides the nylon fibers prepared by the method. The method adopts a manner of combining nylon polymerization and fusion direct spinning to prepare nylon 56 wires so that the production cost is reduced, the waste gas is reduced and the pollution to the environment is reduced. The high-performance nylon fibers prepared by the method can be further used for preparing textile materials including yarns, woven fabrics, knitted fabrics or non-woven fabrics, can be widely applied to the fields of clothing material industries, decoration carpets and the like, and has a wide industrial application prospect.

Owner:CATHAY R&D CENT CO LTD +1

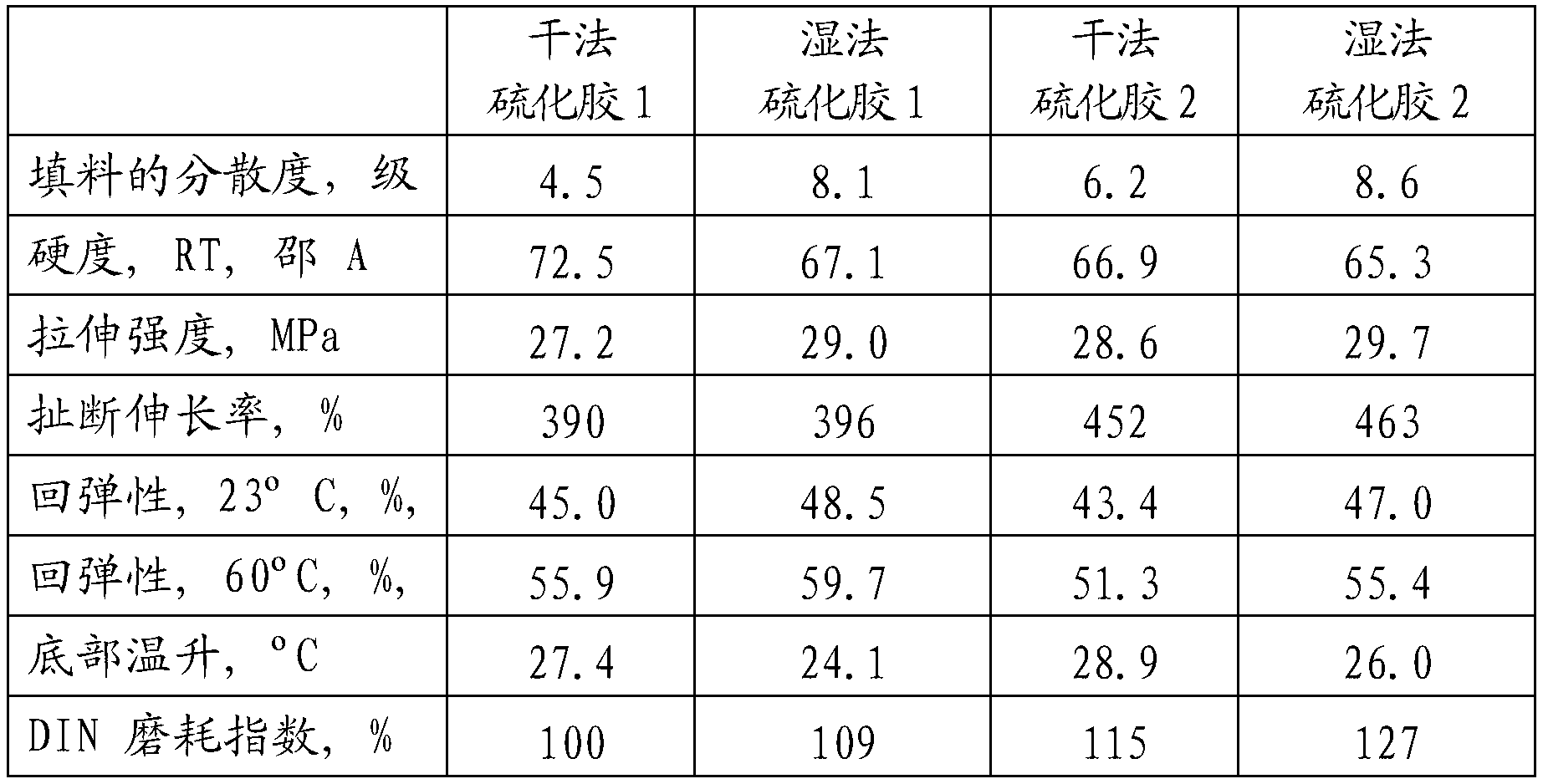

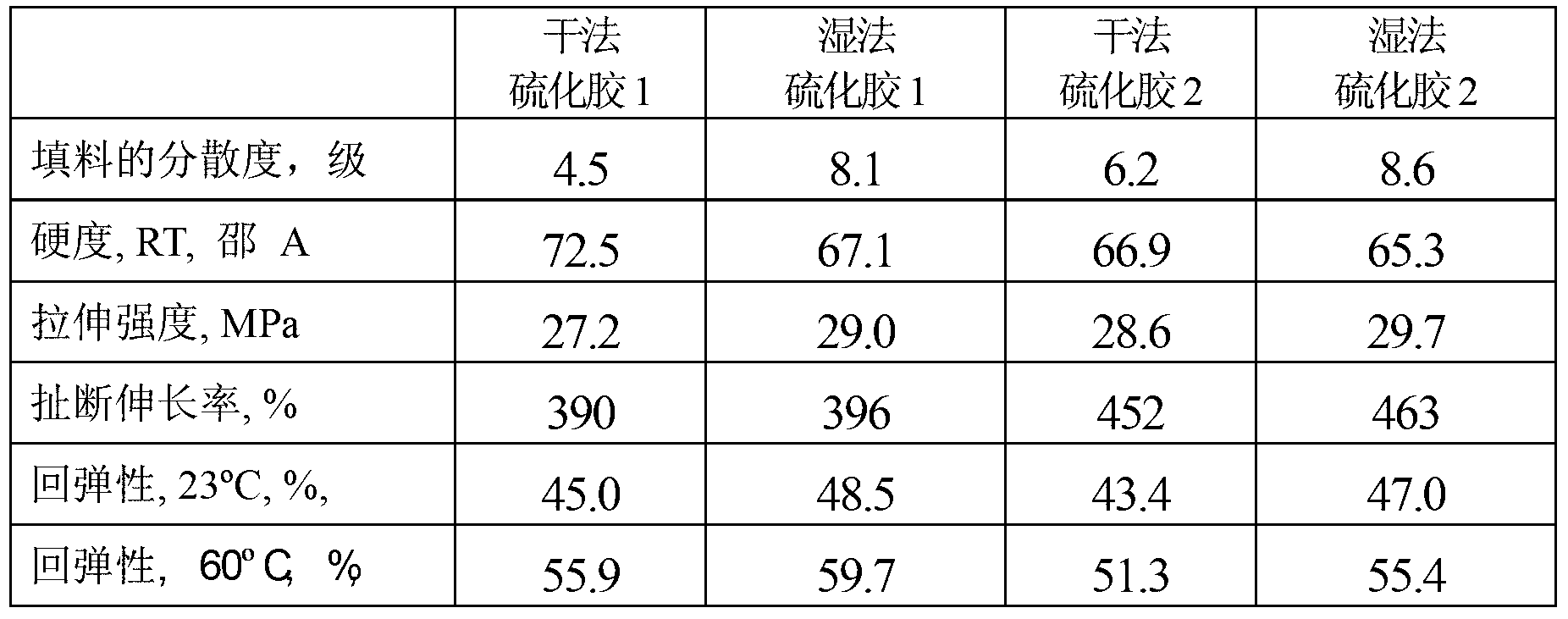

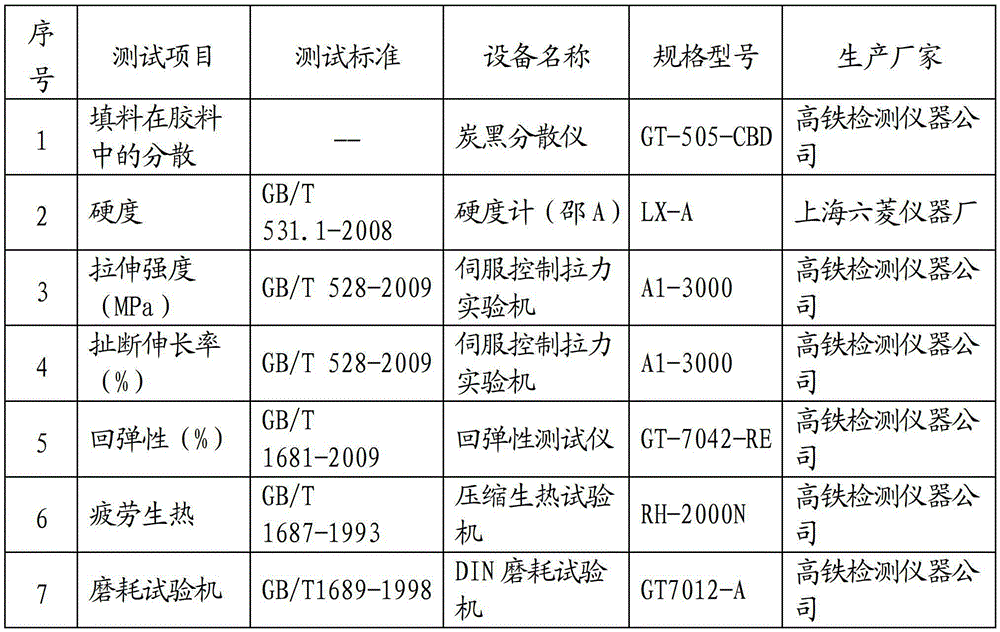

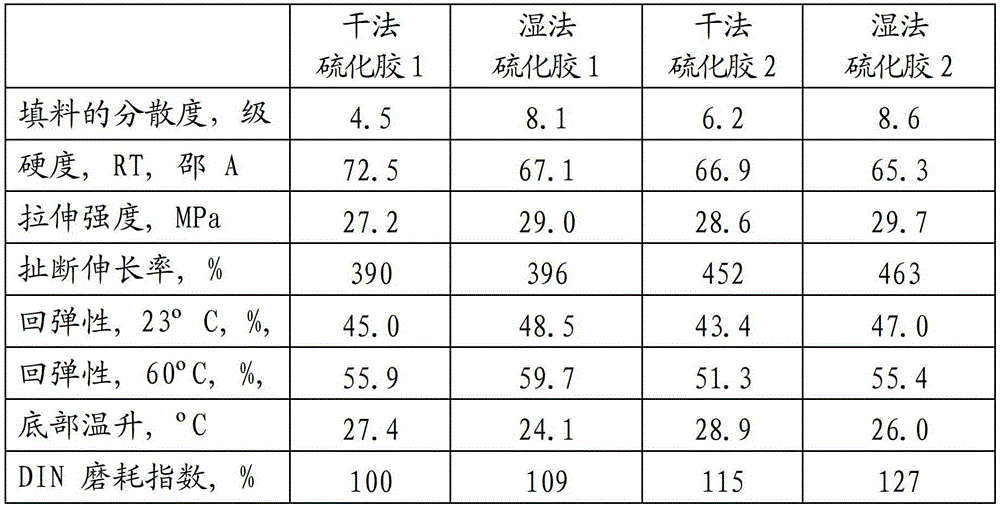

Filler, synthetic rubber and wet rubber compound integrated production method

ActiveCN103224659ABreakthrough applicabilityBreakthrough performancePigmenting treatmentSilicon oxidesSynthetic rubberIntegrated production

The invention discloses a filler, synthetic rubber and wet rubber compound integrated production method. A filler is selected from carbon black, white carbon black or a combination of the carbon black and the white carbon black. Compared with traditional and respective independent technologies, the method disclosed in the invention has the advantages of omitting of the post-treatment technologies of the filler and a synthetic rubber, realization of the cycle of sodium carbonate, and full utilization of carbon dioxide and heat generated in a traditional carbon black production technology. So the method can reduce production equipment and simultaneously realize the low carbon and low pollution discharge through the integrated optimization of the process flow in order to reach the recycle purpose.

Owner:EVE RUBBER RES INST

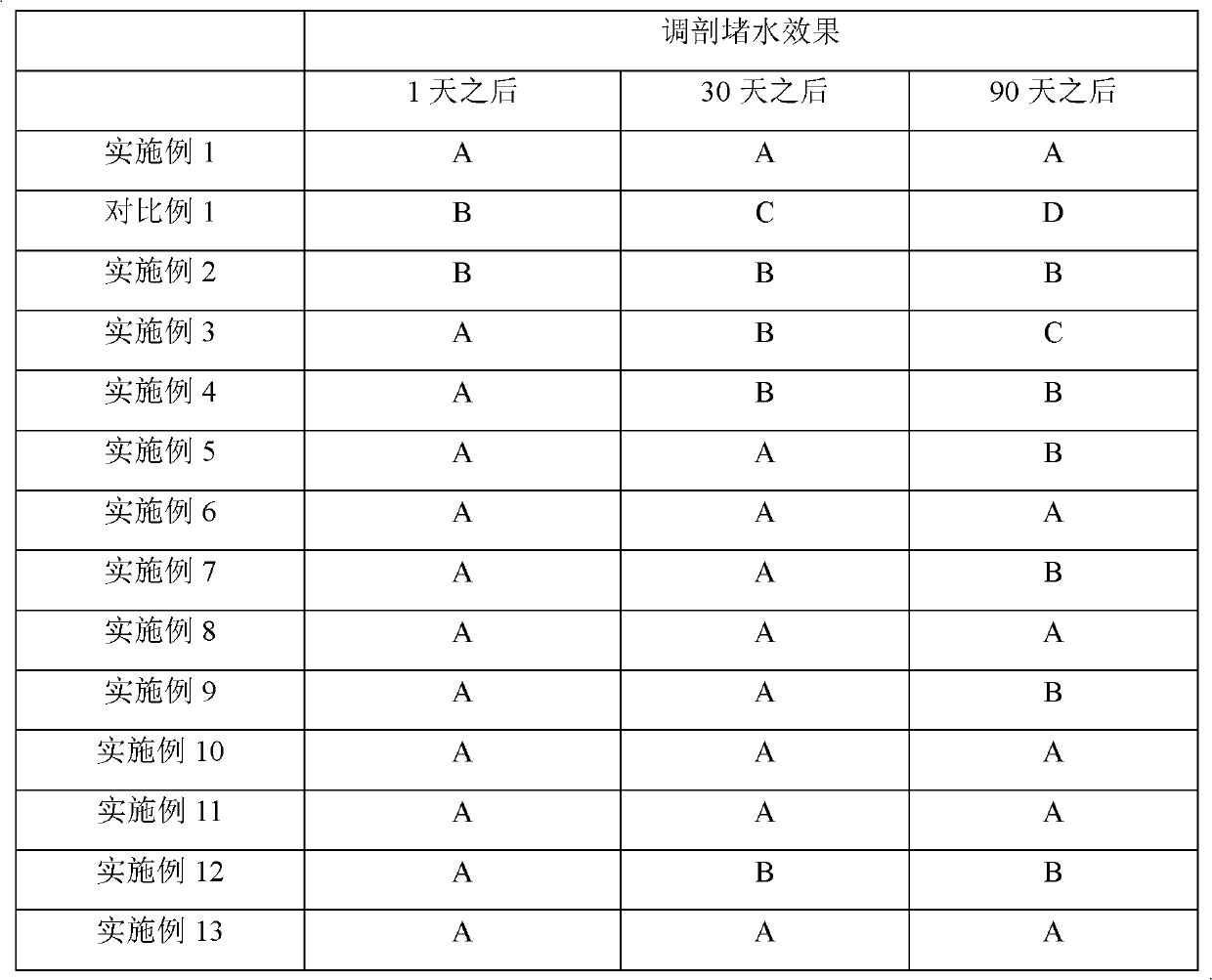

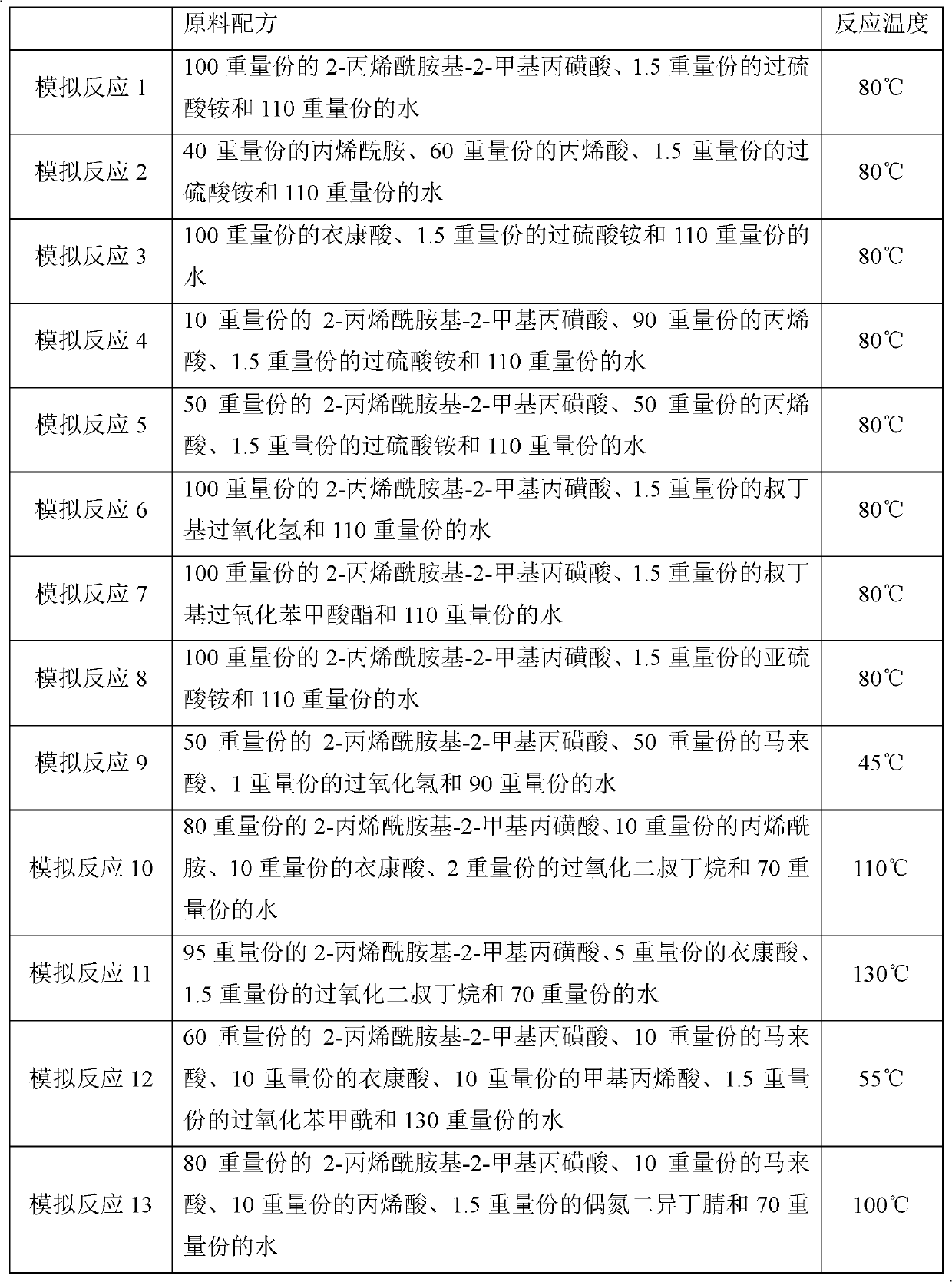

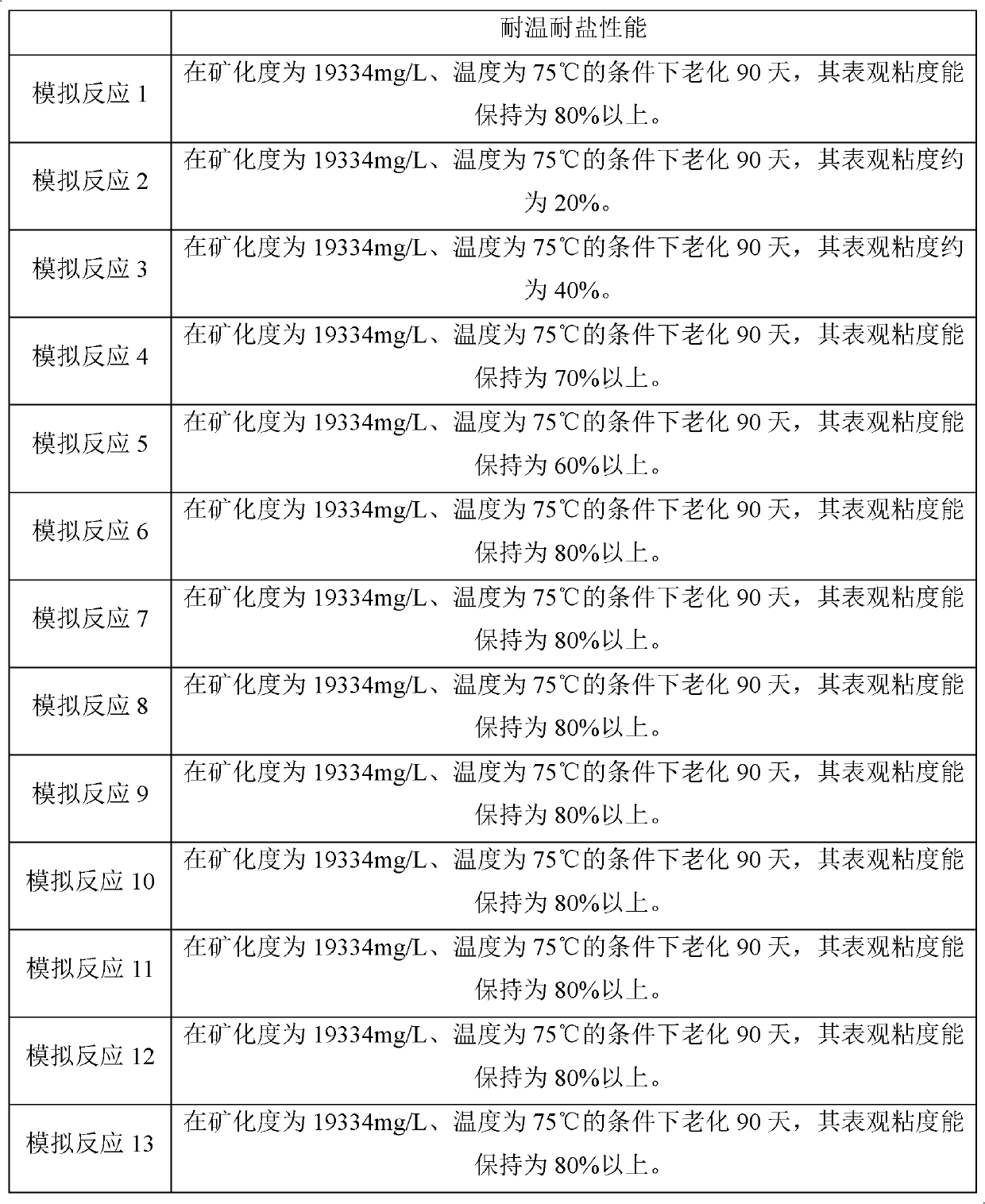

Oil field profile control and water shutoff method

InactiveCN103375153AReduce granulationLittle influence on formation salinityFluid removalDrilling compositionPolymer scienceItaconic acid

The invention discloses an oil field profile control and water shutoff method. The method includes injecting polymerizable polymer monomers and initiators into a stratum which needs profile control and water shutoff, and initiating polymerization reaction at the temperature of the stratum, wherein the polymerizable polymer monomers contain at least one of maleic acid, itaconic acid and 2-acrylamide-2- methyl propanesulfonic acid. According to the oil field profile control and water shutoff method, good profile control and water shutoff effects can be acquired.

Owner:CHINA PETROLEUM & CHEM CORP +1

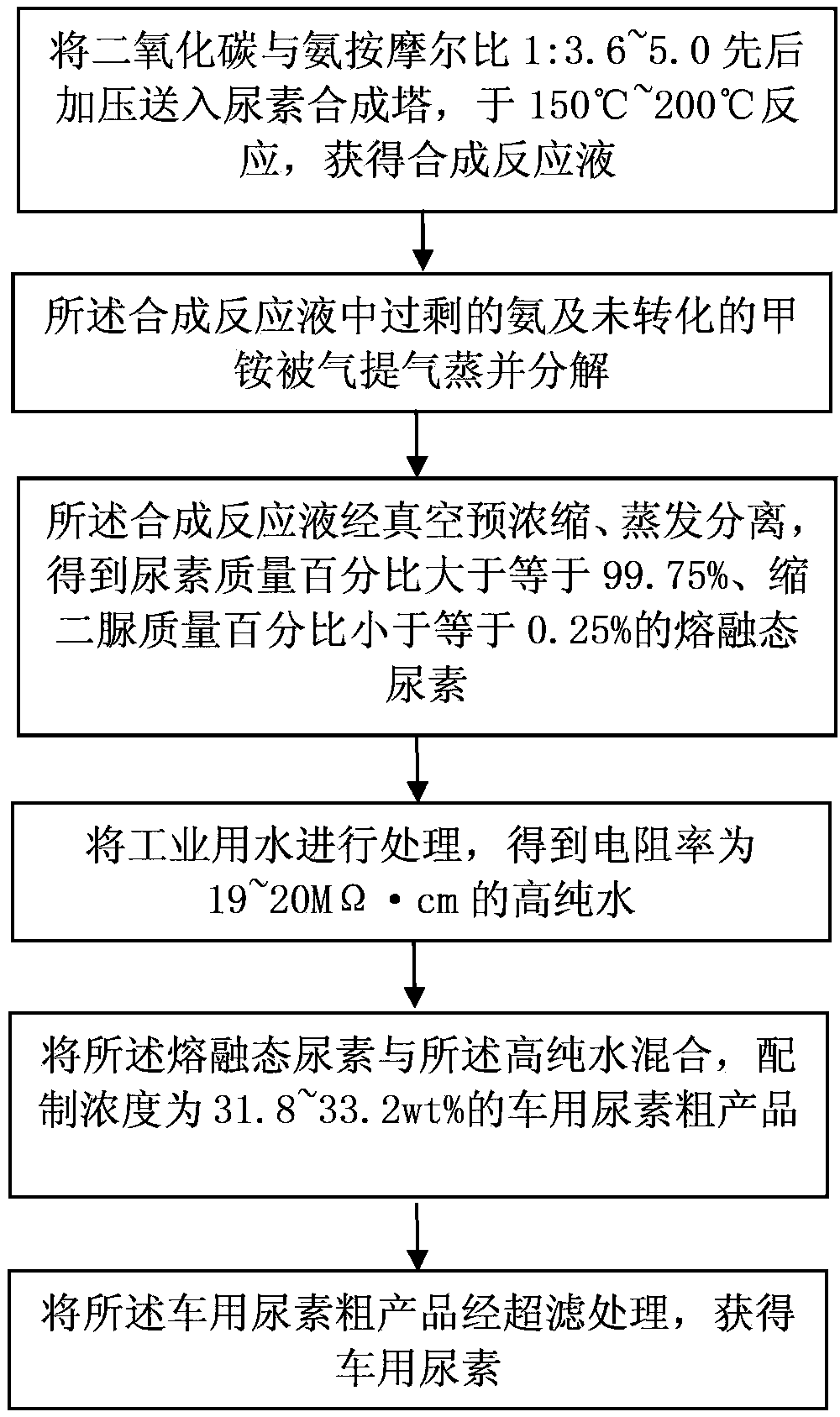

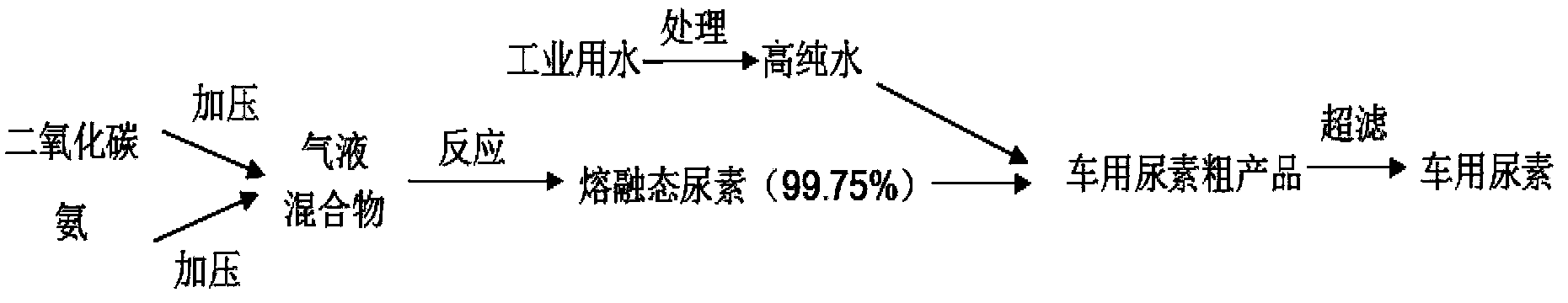

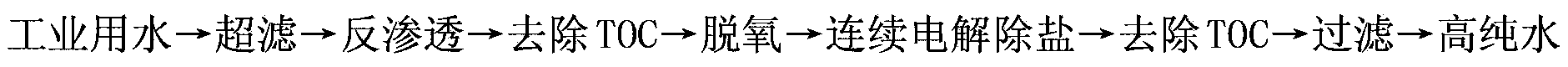

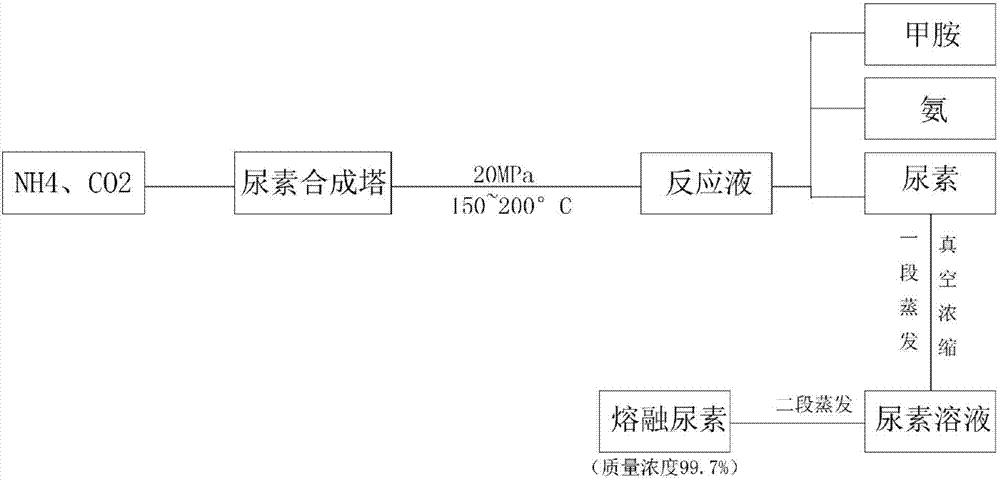

Preparation method of AdBlue

InactiveCN104341321AQuality assuranceReduce environmental pollutionUrea derivatives preparationProductsUltrafiltrationUrea

The invention relates to a preparation method of AdBlue. The method comprises the following steps: 1, carrying out pressurizing sending on carbon dioxide and ammonia into a urea synthesis tower, and reacting at 150-200DEG C to obtain a synthetic reaction solution; 2, carrying out stripping, steaming and decomposition on excess ammonia and unconverted methylamine; 3, carrying out vacuum pre-concentration and evaporation separation on the synthetic reaction solution to obtain molten urea; 4, treating industrial water to obtain highly pure water; 5, mixing the molten urea with the highly pure water to prepare crude AdBlue; and 6, carrying out ultrafiltration treatment on the crude AdBlue to obtain the AdBlue. The method simplifies present production technologies, allows the AdBlue with high added values to be produced through original production technologies, allows the quality level of theobtained AdBlue to meet or exceed all present quality standards of AdBlue, reduces the cost, and reduces the environmental pollution.

Owner:INNOVATIVE COAL CHEMICAL DESIGN INSTITUTE (SHANGHAI) CO LTD

Preparation method of porous ZnO block material

The invention discloses a preparation method of a porous ZnO block material. The method comprises the following steps: dissolving a raw material zinc acetate in an ammonia water solution of citric acid, adding a certain concentration of a compounded dispersant, carrying out a gelatinizing process to form a spatial network structure in order to make zinc ions uniformly exist in the network structure, gelatinizing the obtained material, carrying out dry gelatinization, carrying out direct compaction molding, and sintering obtained blocks to obtain the porous ZnO block material. The method has the advantages of short preparation period, simple technology and device, low cost, and realization of uniform dimensions and uniform distribution of apertures of the obtained porous material through a proper dispersant formula.

Owner:SHAANXI UNIV OF SCI & TECH

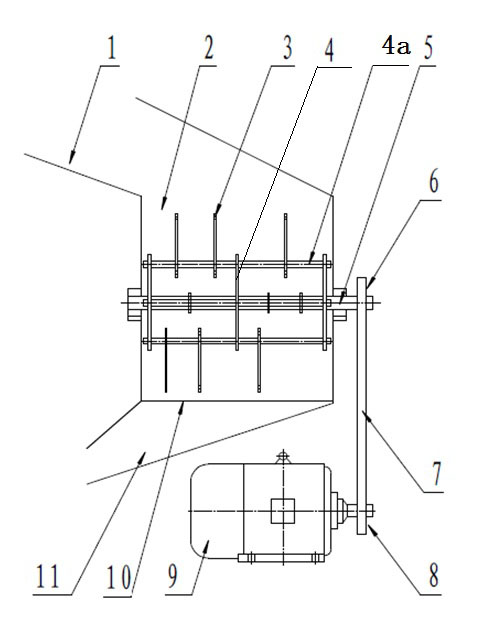

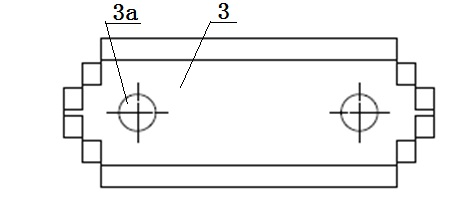

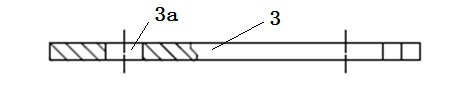

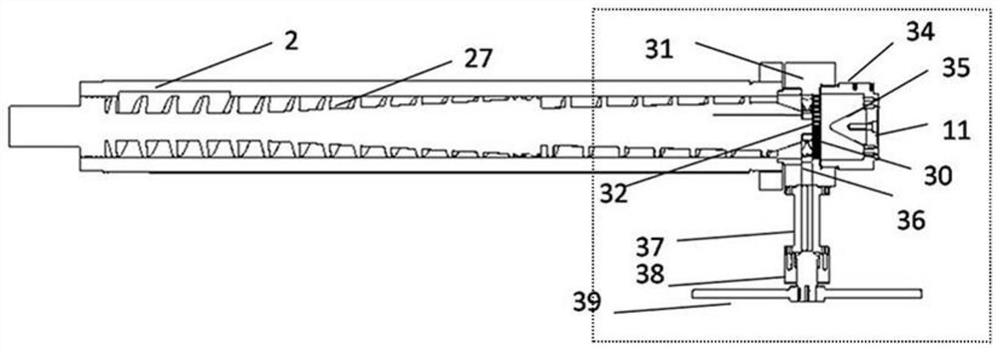

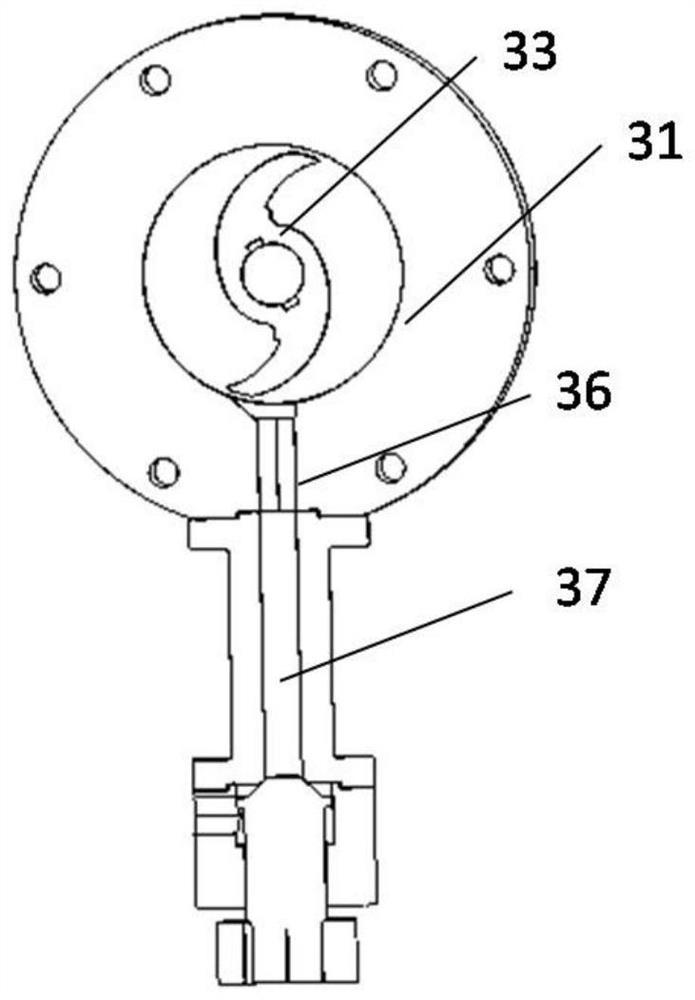

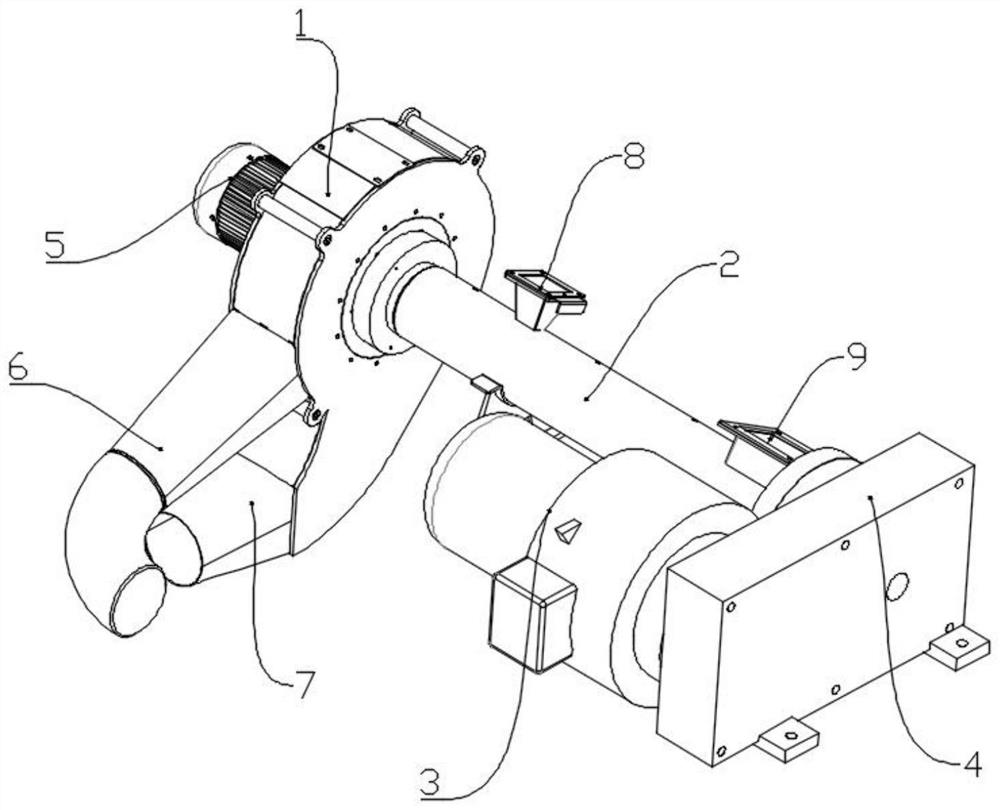

Hammer type shearing granulator

A hammer type shearing granulator comprises a granulating cabin (2) provided with a feeding port (1) and a discharging port (11), a blade support (4) and shearing blades (3) installed on the blade support, wherein the blade support (4) is installed in the granulating cabin and can rotate around a horizontal central shaft (5). The outer end of the central shaft of the blade support is connected with a power transmission device. The blade support is of a transversely arranged cylindrical-cage-shaped structure, cylindrical-cage-shaped strips (4a) are evenly distributed on the outer circumferential face of the blade support, each blade is of a structure with a single side or double sides provided with edges, installation holes (3a) capable of being freely sleeved on the cage strips (4a) are arranged at one ends or two ends of the blades, at least two blades are evenly installed on each cage strip, the blades on two adjacent cage strips are arranged in staggered mode, and a screen net (10) is arranged at the position of the discharging port of the granulating cabin. Expansion tobacco stalk granulation is performed by means of the hammer type shearing granulator, particle shape of ternary porous particles of expansion tobacco stalk is changed, production yield is improved, a product filling value is improved, and service life of the blades is prolonged.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

Method for integrated production of carbon black and white carbon black

ActiveCN103289449AExtreme Performance BreakthroughBreakthrough in processing performancePigmenting treatmentSilicaSodium carbonateChemistry

The invention discloses a method for the integrated production of carbon black and white carbon black. Compared with the traditional mutually-independent processes, the method has the effects that the cyclic utilization of sodium carbonate is realized; and carbon dioxide and heat which are generated in the traditional carbon black production process are utilized fully. Thus, by integrating and optimizing the process flows, the purposes of low carbon emission, low pollution emission and cyclic utilization are realized.

Owner:EVE RUBBER RES INST

Integrated energy-saving processing process for modified reprocessed plastic

InactiveCN103928726AReduce drawingReduce coolingWaste accumulators reclaimingBattery recyclingEngineeringCrusher

The invention provides an integrated energy-saving processing process for modified reprocessed plastic, relating to the technical field of resource reutilization. The integrated energy-saving processing process comprises the following process steps: (1) cutting waste storage batteries and sequentially separating plastic pieces, grids, lead plaster, lead powder and the like in the waste storage batteries out; (2) putting the separated plastic pieces into washing equipment and washing; after the washing, leaching and conveying the separated plastic pieces into disinfection equipment and disinfecting the separated plastic pieces; (3) putting the disinfected plastic pieces into a crusher, crushing the disinfected plastic pieces into grains and quantitatively adding the plastic grains into an extruder and adding other auxiliary materials according to the requirements on preparation of a product; extruding by the extruder; and (4) directly putting plastic strips extruded by the extruder into a molding mould, and de-molding to directly obtain a finished product; and carrying out surface treatment on the finished product. According to the integrated energy-saving processing process, four links of drawing wires, cooling, granulating and refusing are reduced; compared with a traditional process, the integrated energy-saving processing process has the advantages that energy-saving and environment-friendly effects are achieved; the processing efficiency is improved and the cost is saved.

Owner:JIESHOU SHUANGTE NEW MATERIAL TECH

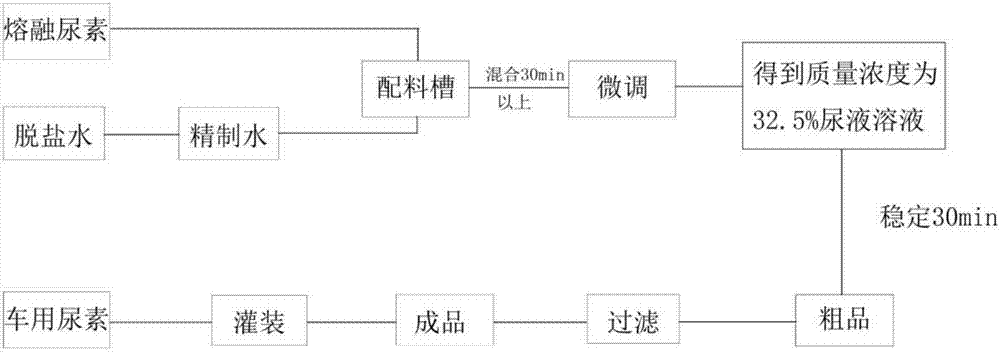

Preparation method of vehicle urea

InactiveCN107417576ASimple production processImprove yieldUrea derivatives preparationProductsUreaChemistry

The invention discloses a preparation method of vehicle urea. The preparation method comprises the following steps: (S1) synthesizing ammonia and carbon dioxide so as to obtain fused urea, wherein the mass concentration of the fused urea is 80%, and the mass percentage of biuret is less than or equal to 0.25%; (S2) treating desalted water by virtue of water refining equipment, so as to obtain refined water with a resistivity of 18Mohm.cm-20Mohm.cm; (S3) simultaneously adding the fused urea obtained in the step (S1) and the refined water obtained in the step (S2) into a batching tank in a proportion of 1 to 1.5, stirring for 30 minutes or longer, so as to obtain a urea solution with a mass concentration of 31.5%-32%; (S4) finely adjusting the amount of the fused urea or the refined water, so as to obtain the urea solution with a mass concentration of 32.5%, namely crude urea; (S5) filtering the crude urea so as to obtain vehicle urea; and (S6) conveying the vehicle urea into a finished product tank, and pumping the vehicle urea into a filling machine by virtue of a finished product pump, so as to obtain the finished vehicle urea. By utilizing the fused urea as the raw material, the vehicle urea with relatively high quality is obtained.

Owner:四川金素环保科技有限公司

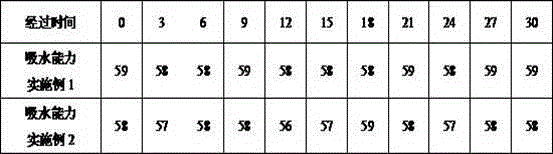

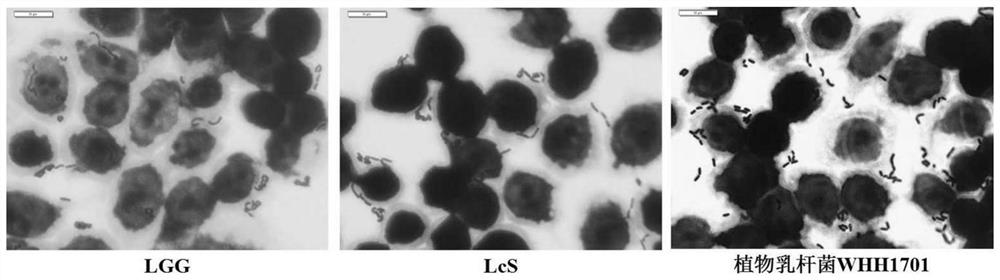

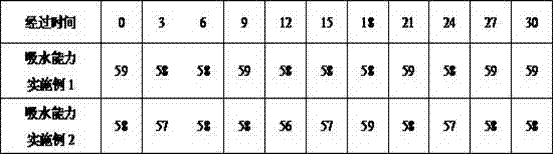

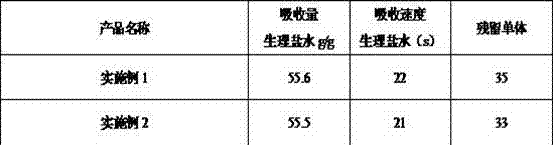

Preparation method of high-water-absorption polymer

The invention discloses a preparation method of a high-water-absorption polymer. The polymer comprises the following components (in parts by weight): 40g to 45g of acrylic acid, 55g to 60g of water, 19.28g to 20.5g of sodium hydroxide, 0.01g to 0.02g of N, N' methylene bis-alkenyl amide, 1g to 2g of 3% potassium persulfate aqueous solution, 0.05g to 0.1g of sorbide glycerinum-laurate and 1g to 2g of 3% potassium persulfate aqueous solution. The preparation method comprises the following steps: preparing the acrylic acid aqueous solution with concentration of 55 to 60 percent; adding a cross-linking agent, a surface active agent and a polymerization initiator into the acrylic acid aqueous solution, blowing nitrogen, sending the solution into a blender at a feed speed of 250g / min, sending the 3% sodium bisulfate aqueous solution into the blender at a feed speed of 6 to 10 g / min, enabling the material mixed by the blender to rapidly flow into a screw squeezing device to be polymerized, controlling the temperature at 103 DEG C, discharging the hydrogel polymer out of the squeezing device, drying by virtue of hot air at 160 DEG C, and crushing to obtain the high-water-absorption polymer. The preparation method is stable in product quality, high in yield, labor-saving and high in efficiency.

Owner:欧阳晨曦

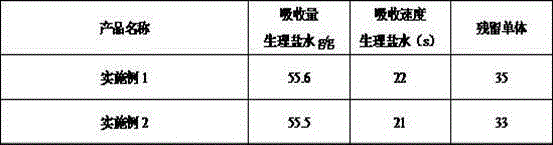

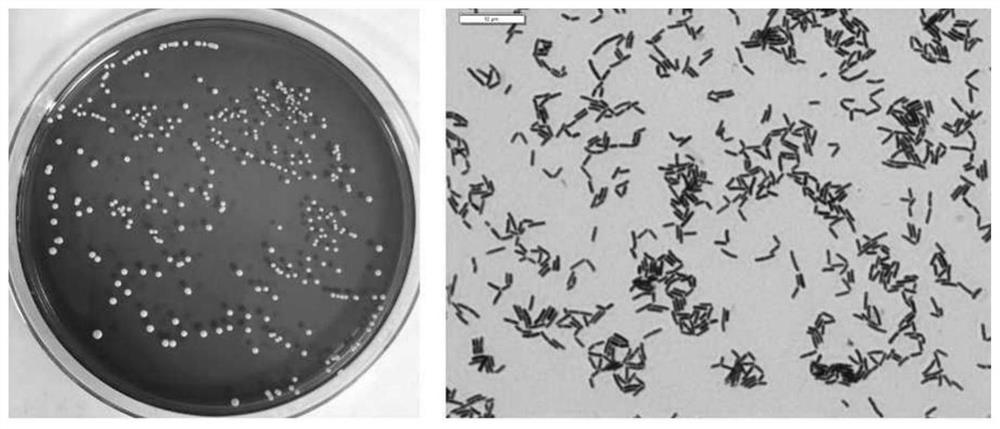

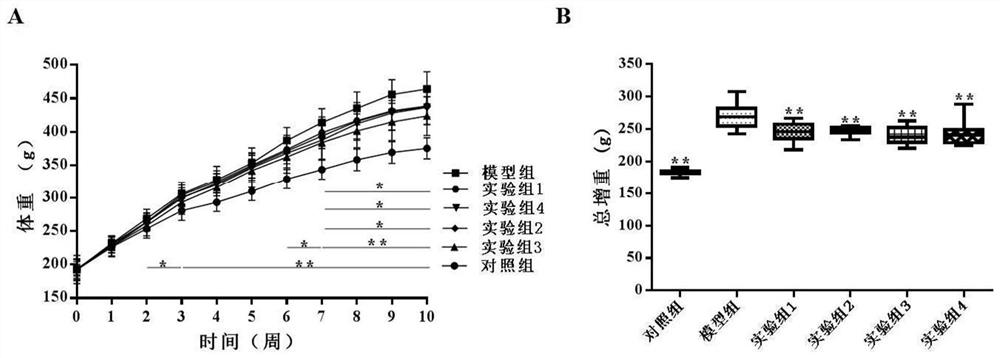

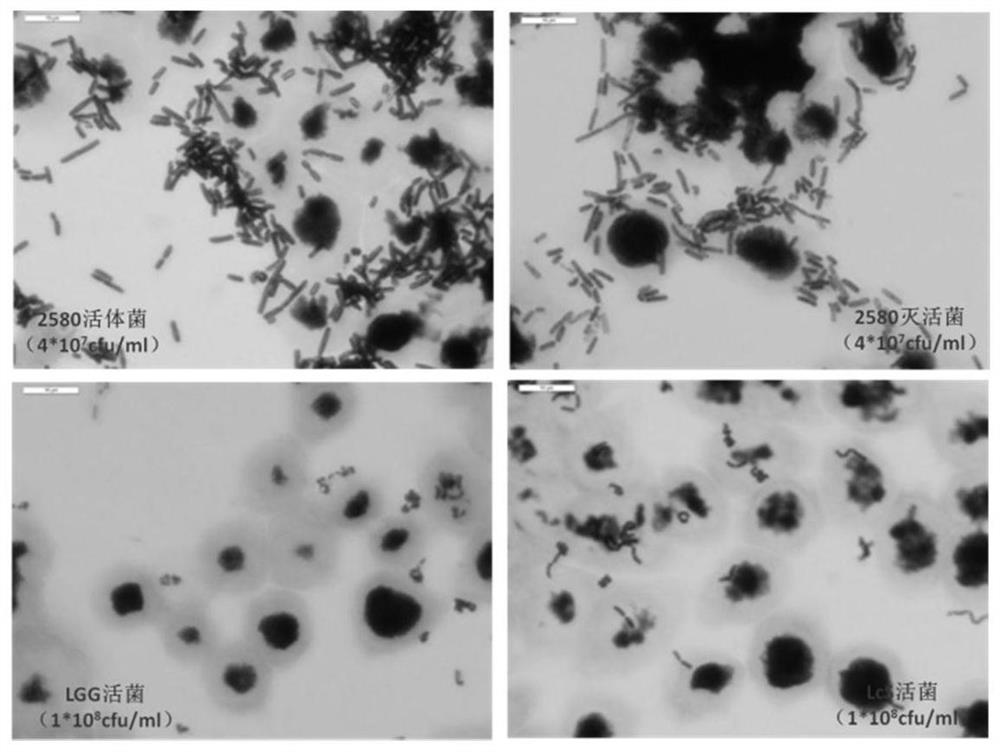

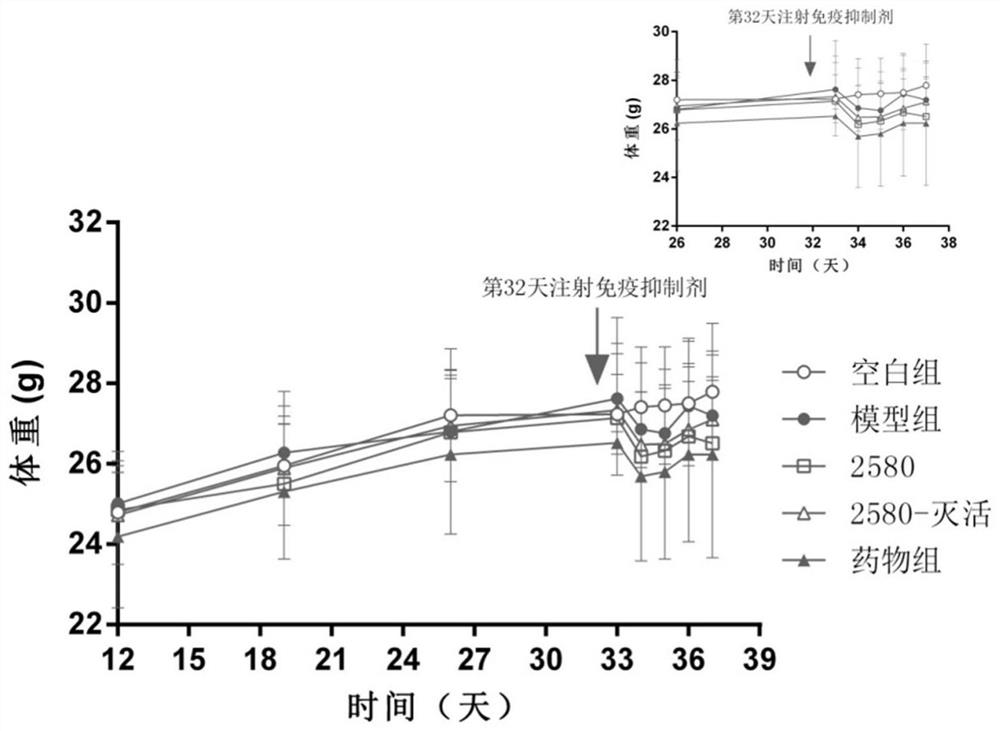

Probiotic tablets based on lactobacillus plantarum and preparation method of probiotic tablets

PendingCN111714572AGood acid and bile salt resistanceWide pH rangeOrganic active ingredientsBacteriaBiotechnologyVitamin C

The invention relates to the field of foods, and discloses probiotic tablets based on lactobacillus plantarum and a preparation method of the probiotic tablets. Lactobacillus plantarum freeze-dried powder, tea leaf theanine, konjaku flour, direct compression auxiliary materials, vitamin C and magnesium stearate are compounded, the direct compression auxiliary materials are adopted, and a direct compression technique is adopted, so that process flows for granulation and the like can be omitted, and the energy consumption can be reduced, the productivity can be increased, and the properties of the tablets can also be improved notably. The probiotic tablets can reduce weight, reduce in vivo fat accumulation, reduce ratio of internal organs of the body and body fat ratio, reduce leptin level and reduce blood lipid, and can be used for preventing and treating obesity. In addition, lactobacillus plantarum 1701 contained in the tablets also has favorable tolerance and adhesion property. The bacterial strains after being inactivated also have the function of reducing weight, so that products containing the bacterial strains are good in stability and long in quality guarantee period.

Owner:HANGZHOU WAHAHA TECH +1

Nylon fiber and its preparation method

ActiveCN104562271BEmission reductionReduce pollutionFilament manufactureMonocomponent copolyamides artificial filamentYarnExhaust gas emissions

The invention discloses a method for preparing nylon fibers, which comprises the steps of performing polymerization reaction on raw materials containing 1,5-pentamethylenediamine and adipic acid and then directly spinning them. The present invention also provides a nylon fiber prepared by the aforementioned method. The method of the invention prepares nylon 56 yarn by combining nylon polymerization and melt direct spinning, which reduces production cost, waste gas discharge and environmental pollution. The high-performance nylon fiber prepared by the present invention can be further used to make textile materials such as yarn, woven fabric, knitted fabric or non-woven fabric, and can be applied to the fields of clothing, industry, decorative carpets, etc., and has a wide range of industrial applications. Application prospect.

Owner:CATHAY R&D CENT CO LTD +1

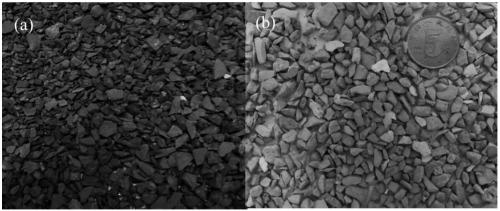

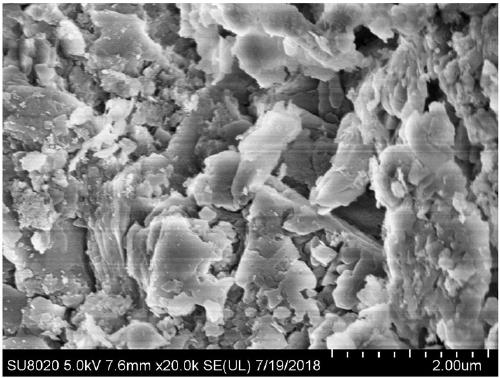

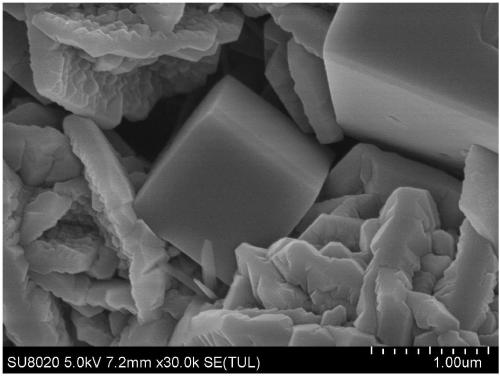

Method for preparing zeolitic particulate material from washed coal gangue

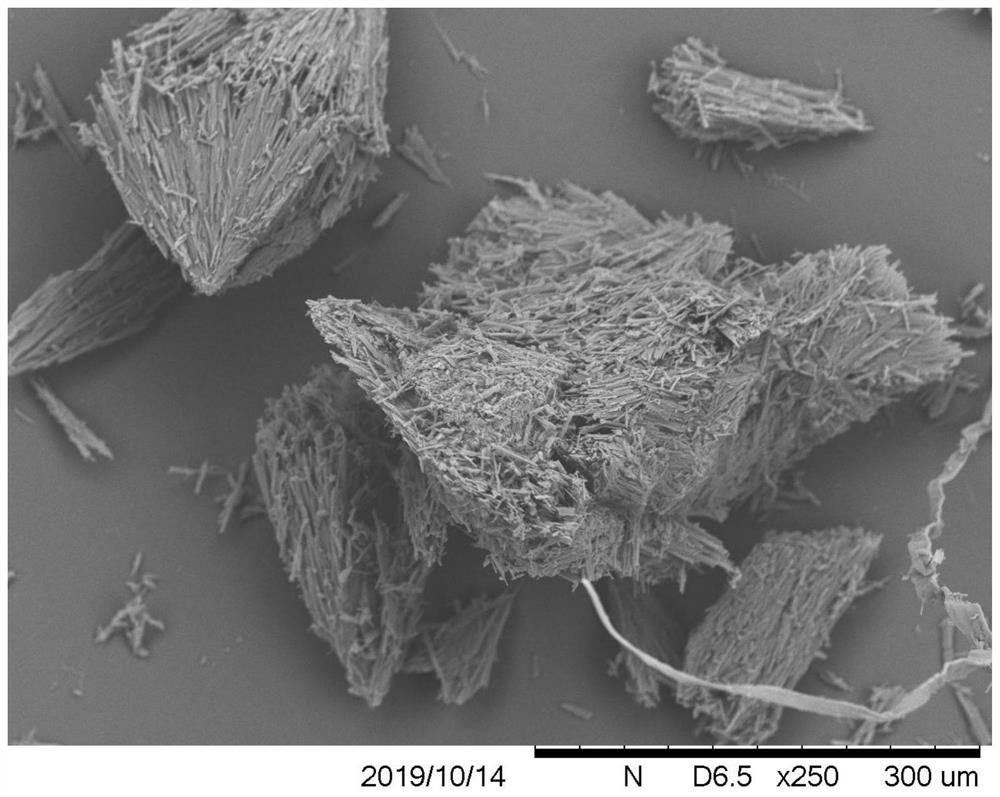

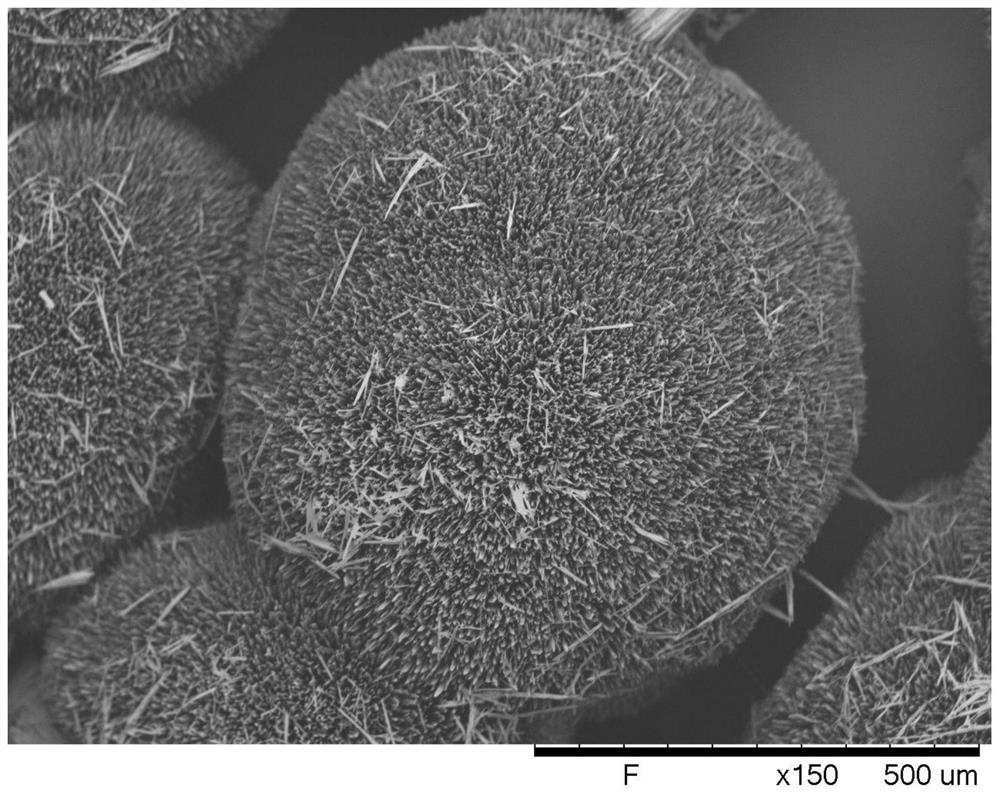

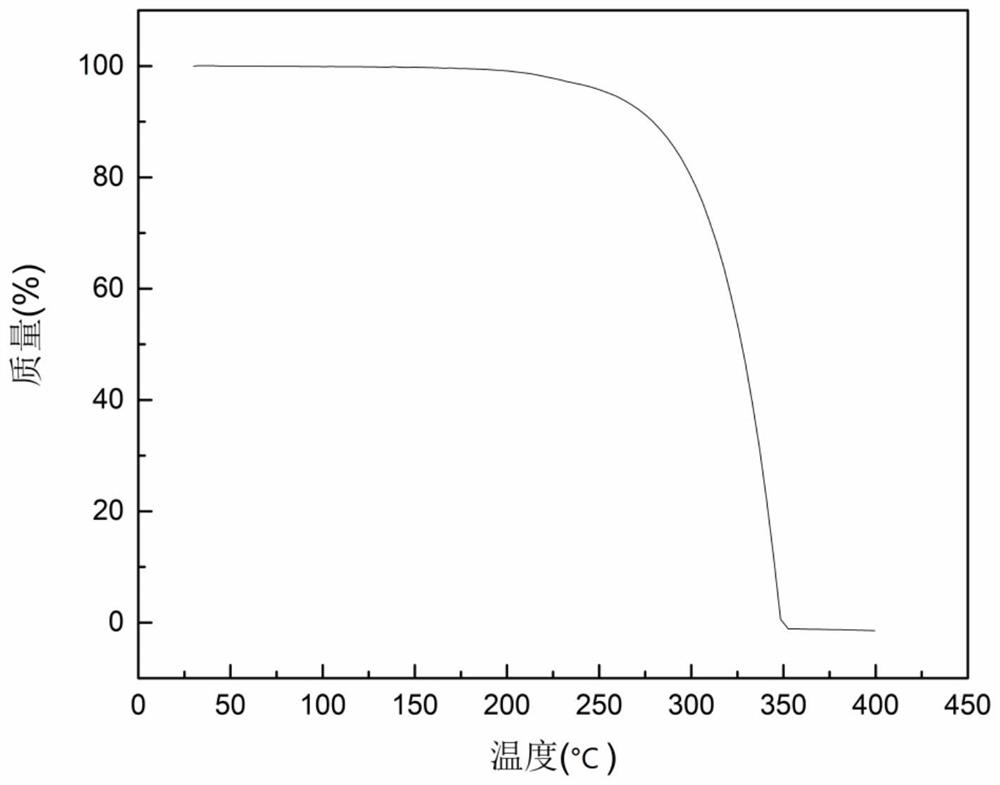

ActiveCN109205640AFast adsorption of pollutantsReduce manufacturing costAluminosilicate zeolite type-AParticulatesConstructed wetland

The invention discloses a method for preparing a zeolitic particulate material from washed coal gangue. The method comprises the following steps: crushing and sieving the ash residue obtained after the washed coal gangue is calcinated at a temperature of 650 to 900 DEG C, and adding the obtained particulate matter to a sodium hydroxide solution, so that an active silicon aluminum component in theparticulate matter is reacted with sodium hydroxide to crystallize and grow zeolite 4A on the surface of the particulate matter, namely, the zeolitic particulate material. The zeolitic granular material prepared from the washed coal gangue disclosed by the invention has the advantages of wide source of raw materials, comprehensive utilization of waste, and low preparation cost, the synthetic zeolite is mainly distributed on the surface of the particulate matter, the speed of adsorbing a pollutant is fast, and the zeolitic particulate material can be widely applied to a percolation material forpolluted rainwater treatment in the construction of the sponge city, and a percolation material for the constructed wetland.

Owner:中科华鹿(合肥)环保科技有限公司

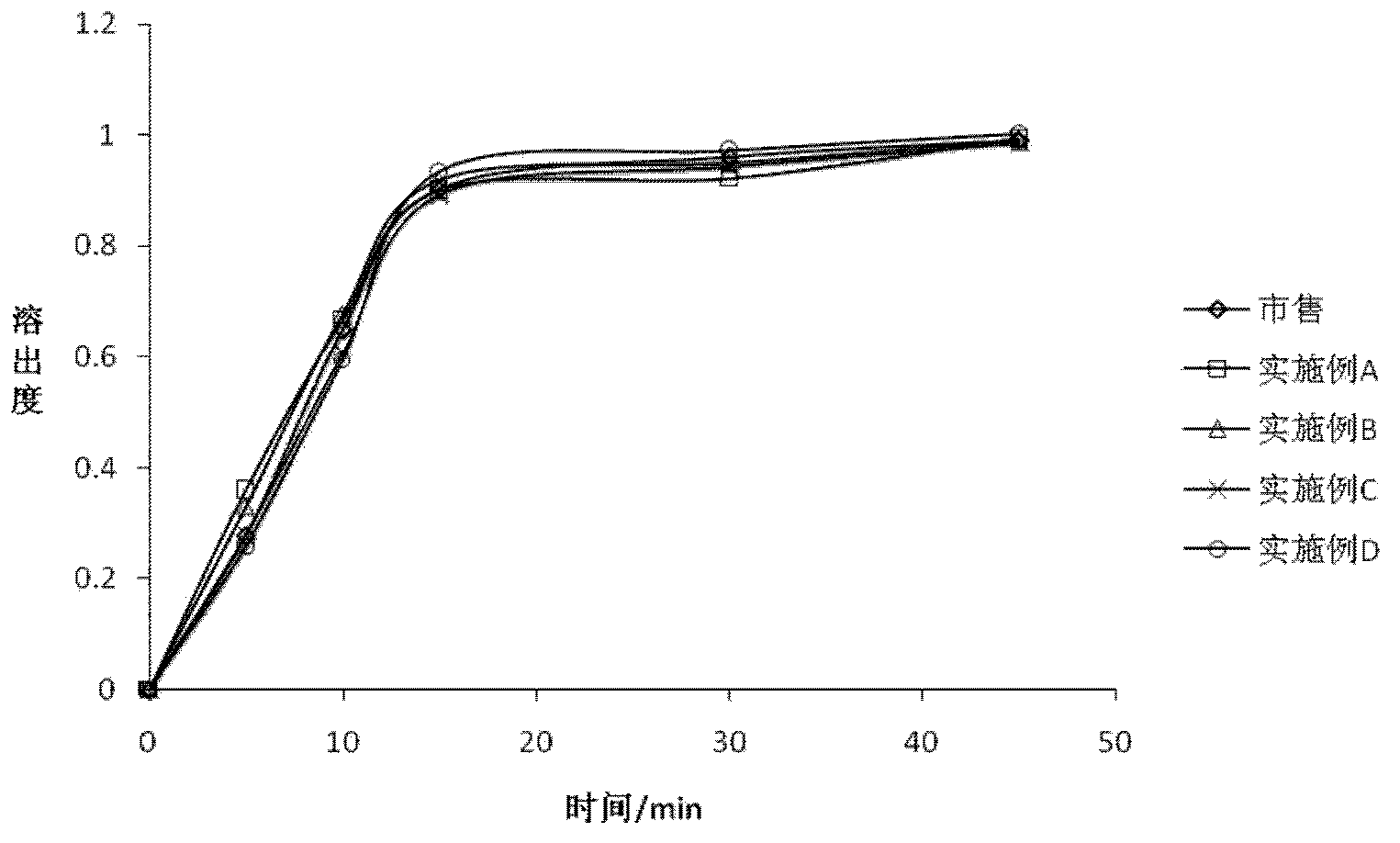

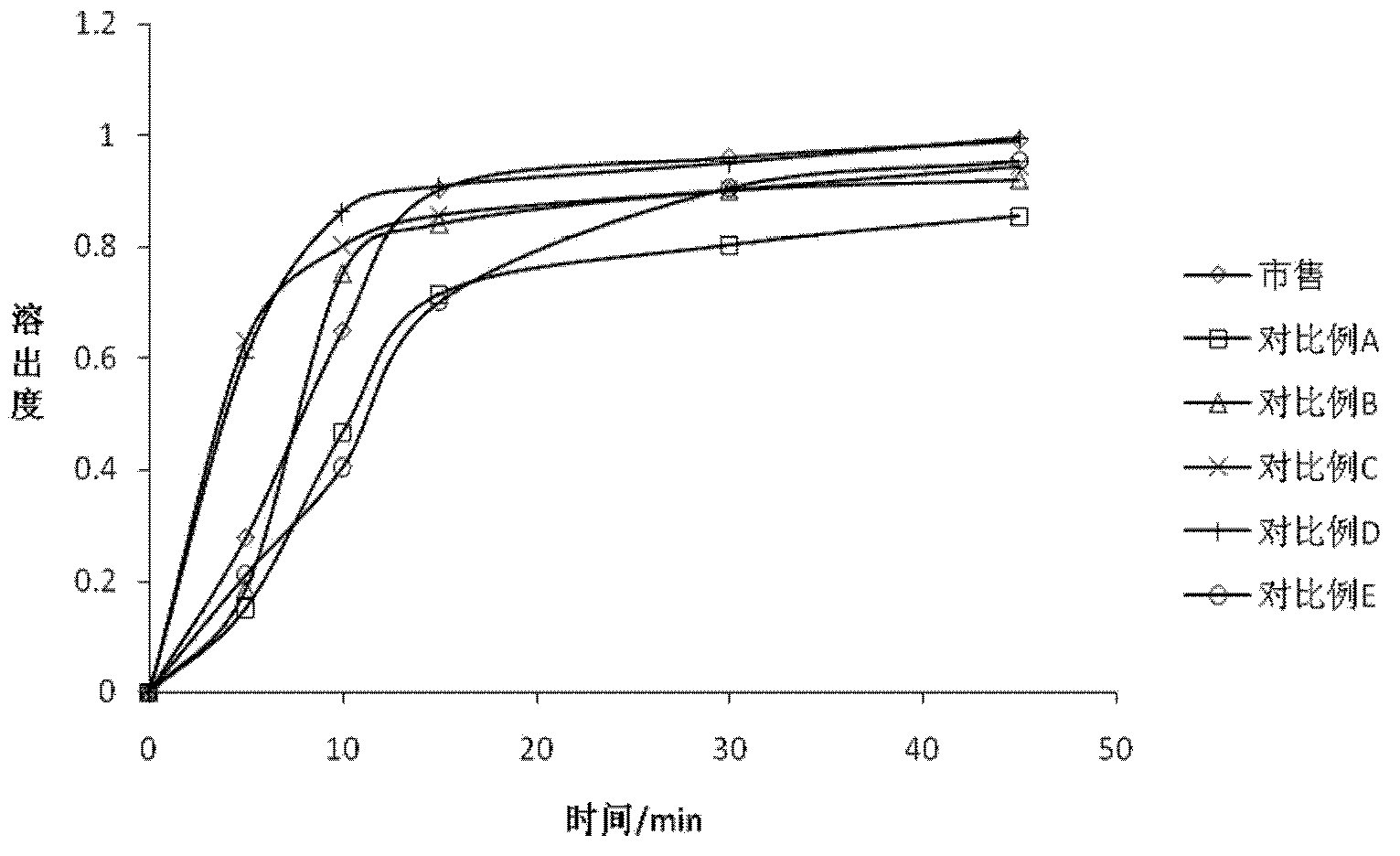

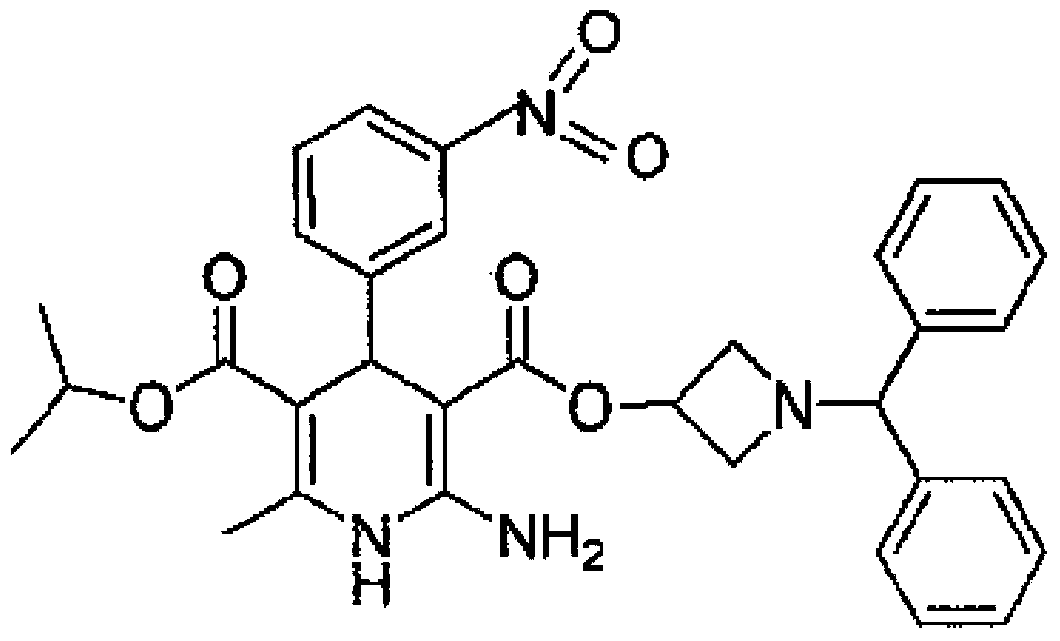

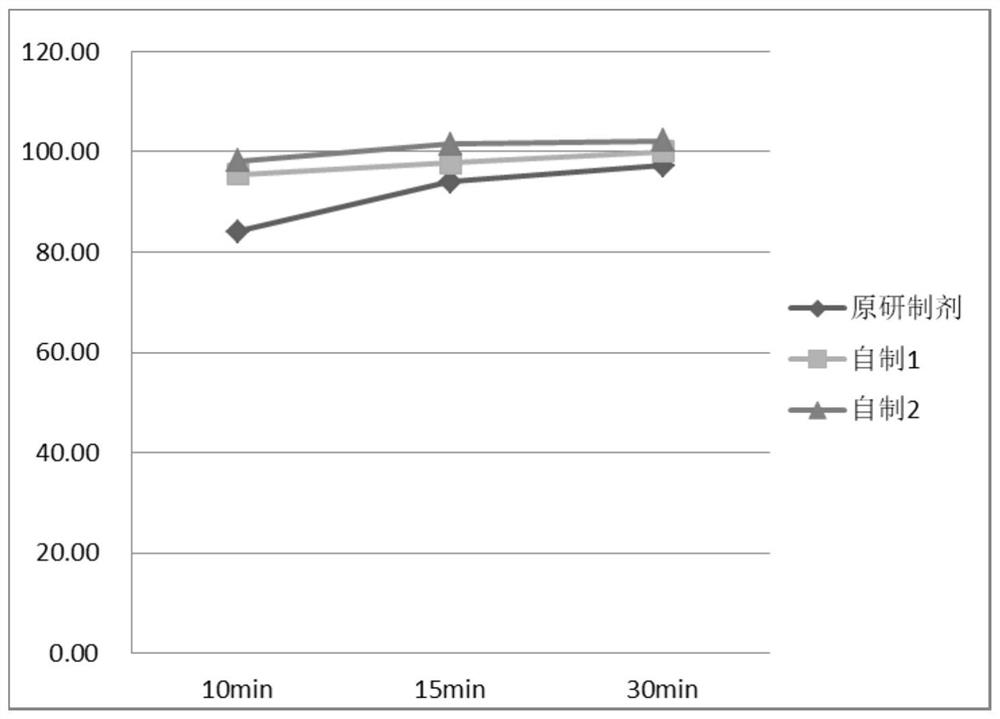

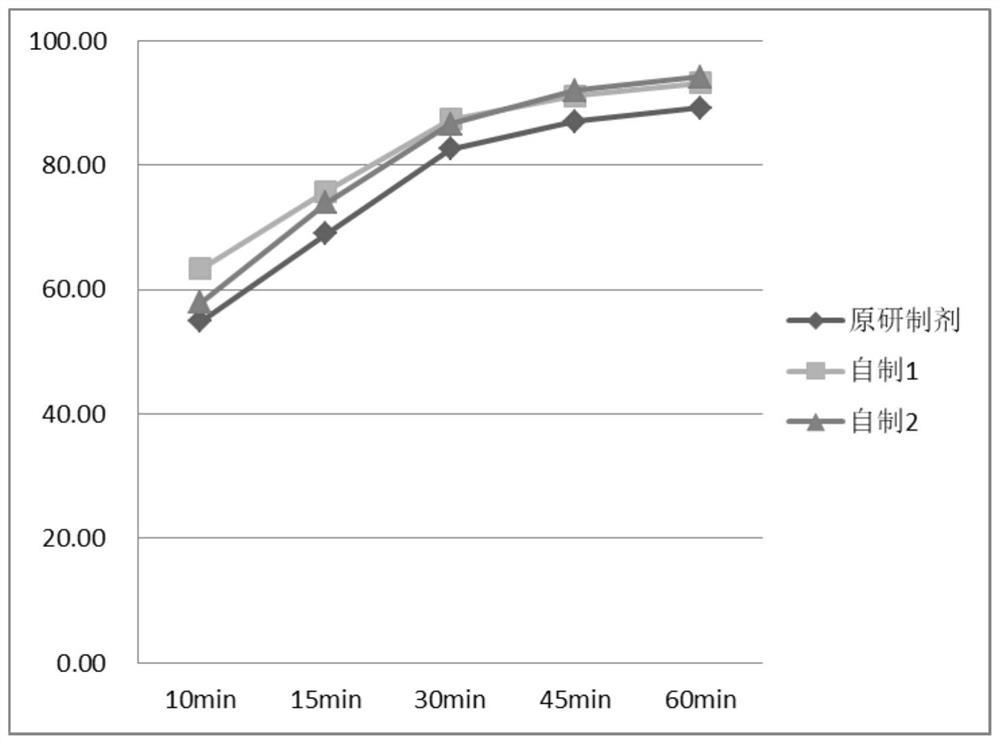

Azelnidipine preparation with combination of two disintegrating agents and preparation method of azelnidipine preparation

ActiveCN103520732APromote dissolutionReduce granulationOrganic active ingredientsPill deliveryBioequivalenceSodium carboxymethylcellulose

The invention provides an azelnidipine preparation with combination of two disintegrating agents. The azelnidipine preparation is prepared from azelnidipine, two combined disintegrating agents in different proportions and other pharmaceutic adjuvants, wherein the combined disintegrating agents are prepared from calcium carboxymethyl celluloses and low-substituted hydroxypropyl celluloses; the adding amount of the calcium carboxymethyl celluloses accounts for 13% to 120% of that of the low-substituted hydroxypropyl celluloses; the other pharmaceutic adjuvants contain one or multiple types of filling agents, adhesives or lubricants. The azelnidipine preparation is simple in preparation method and controllable in quality, and has the high fitting degree with the in-vitro stripping curve of a product prepared by a specified pharmaceutical factory while having the bioequivalence at the same time. Thus, the efficacy and safety of the azelnidipine preparation in clinical applications are ensured.

Owner:NANJING CHIA TAI TIANQING PHARMA

Filler, synthetic rubber and wet rubber compound integrated production method

ActiveCN103224659BPromote lysisTake advantage ofPigmenting treatmentSilicon oxidesSynthetic rubberPollution

The invention discloses a filler, synthetic rubber and wet rubber compound integrated production method. A filler is selected from carbon black, white carbon black or a combination of the carbon black and the white carbon black. Compared with traditional and respective independent technologies, the method disclosed in the invention has the advantages of omitting of the post-treatment technologies of the filler and a synthetic rubber, realization of the cycle of sodium carbonate, and full utilization of carbon dioxide and heat generated in a traditional carbon black production technology. So the method can reduce production equipment and simultaneously realize the low carbon and low pollution discharge through the integrated optimization of the process flow in order to reach the recycle purpose.

Owner:EVE RUBBER RES INST

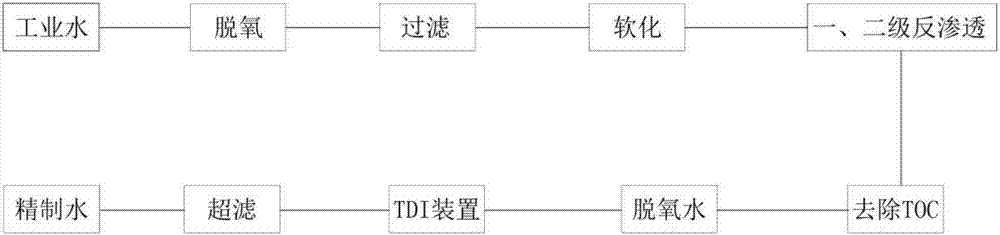

A preparing method of a urea solution used for vehicles

InactiveCN106621867AReduce environmental pollutionSave waterUrea derivatives preparationProductsMacromolecular SubstancesUrea

The invention relates to a crystallizing method of a urea solution and particularly relates to a producing method of urea that is a raw material of a diesel vehicle exhaust treating liquid. The method includes (1) a step of preparing urea, namely a step of conveying a urea synthesis reaction solution in a synthesis stage of a urea production device into a urea solution tank to obtain an initial urea solution, (2) a step of removing excessive ammonium and carbon dioxide from the initial urea solution through flash evaporation, (3) a step of conveying the urea synthesis reaction solution into a vacuum flash evaporation crystallization kettle and performing vacuum flash evaporation crystallization, (4) a step of preparing high-purity water, namely a step of desalting industrial water, filtering the water with activated carbon, removing macro-molecule substances through a reverse osmosis membrane apparatus, removing TOC, deoxygenizing the water, disinfecting the water and filtering the water, and (5) a step of mixing crystallized urea and the high-purity water, and fully stirring the crystallized urea and the high-purity water to obtain the urea solution used for vehicles. The urea solution used for vehicles can reduce environment pollution, saves a cost and is of great significance for environment protection.

Owner:青岛鹏通瑞德电气科技有限公司

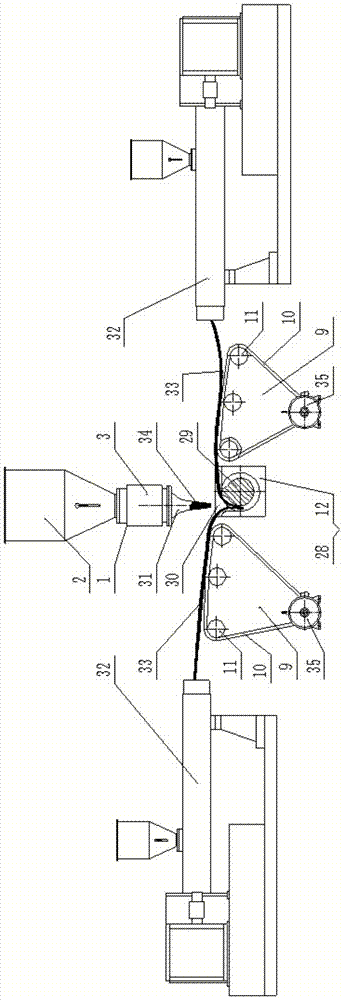

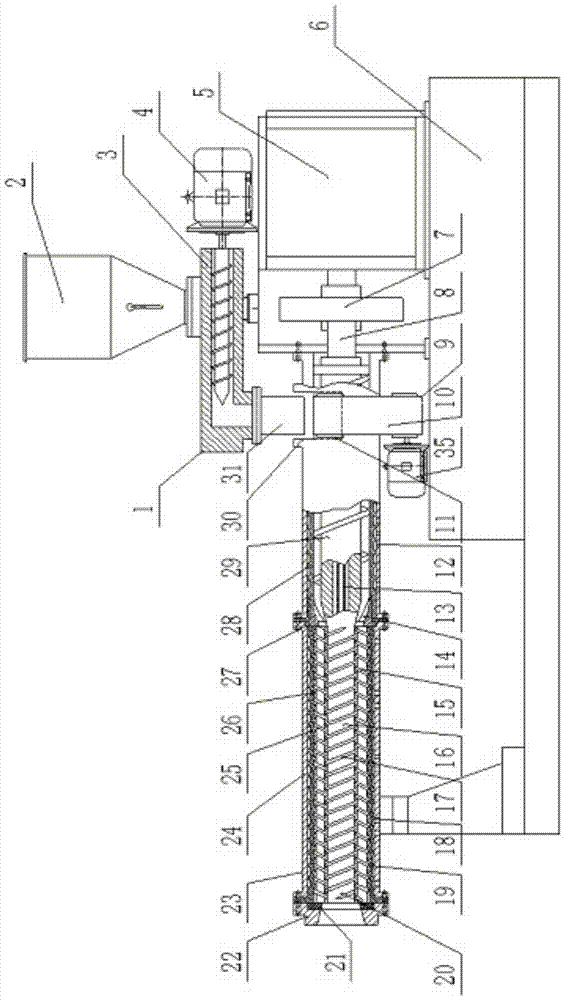

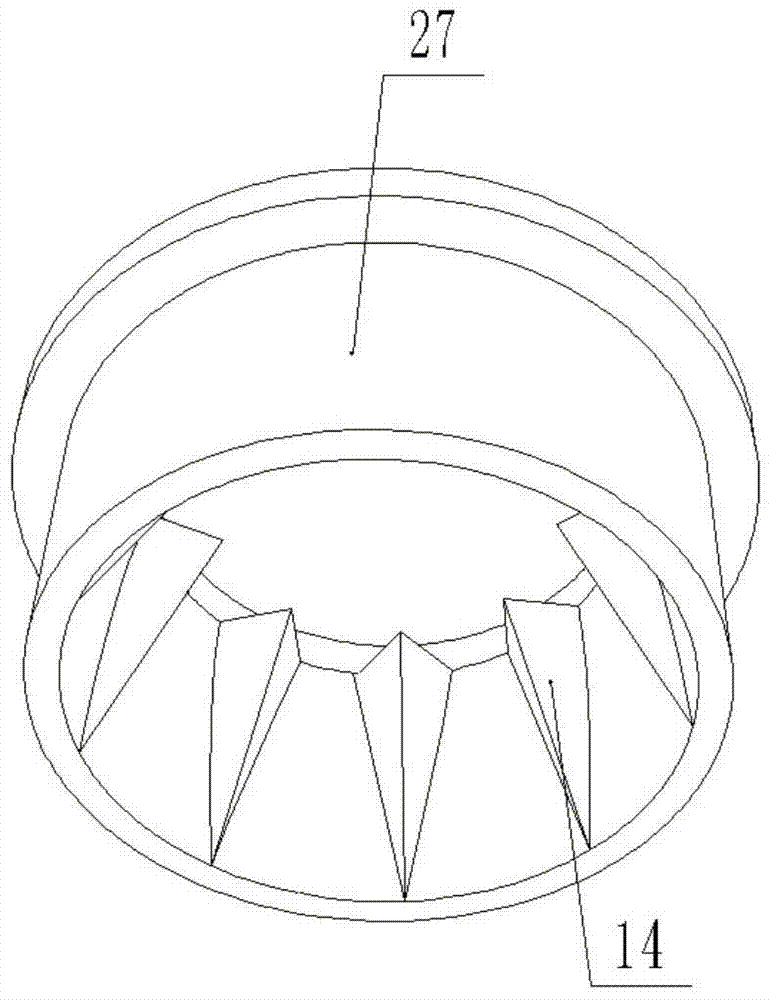

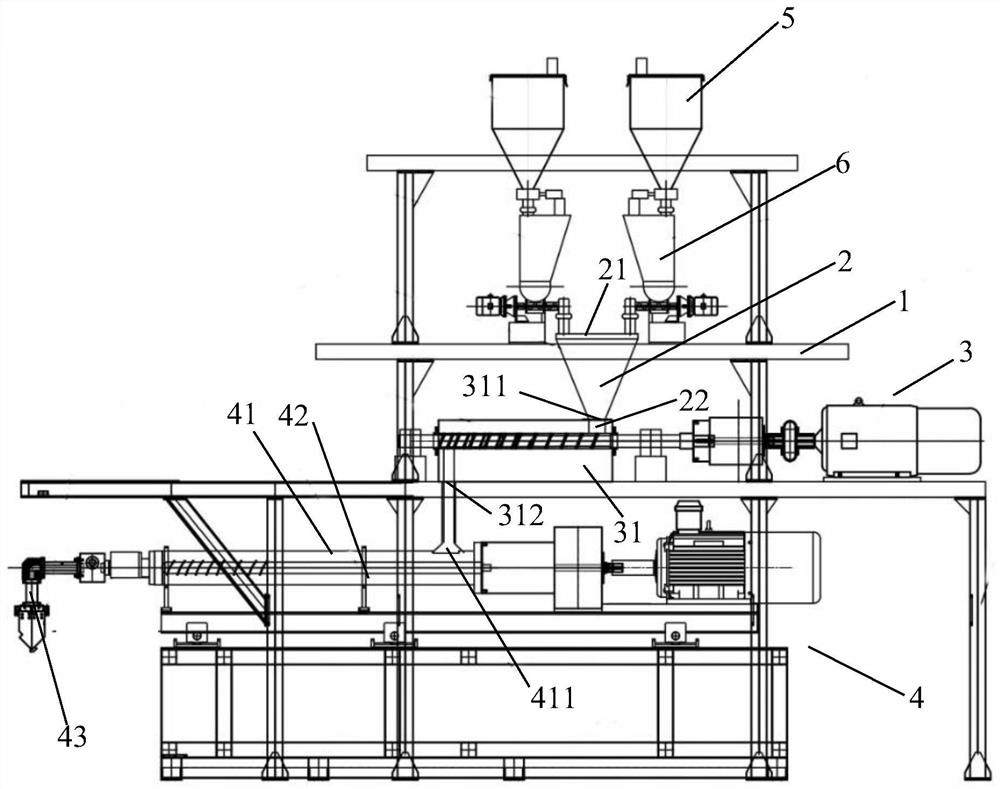

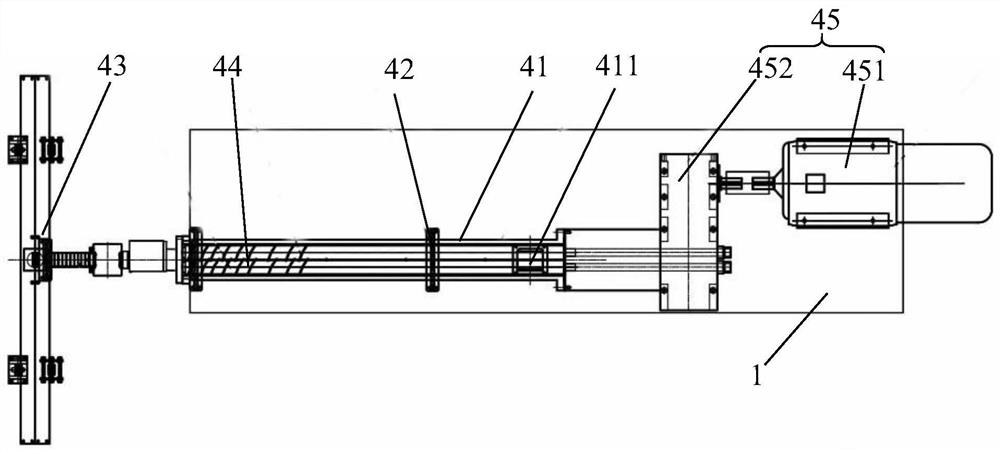

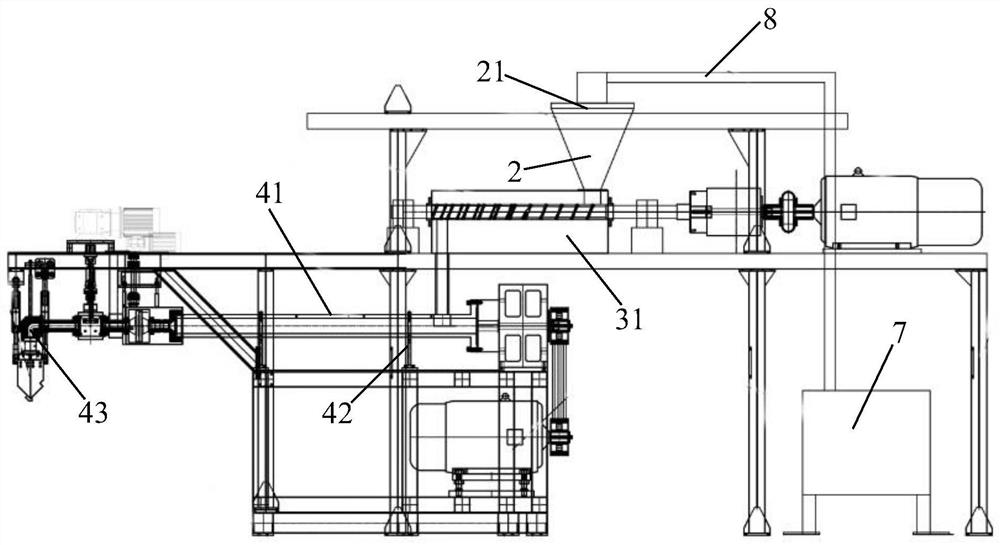

A continuous rubber mixing device

ActiveCN105034187BSimplify the mixing process stepsRealize continuous productionMixing effectMechanical engineering

The invention belongs to the field of polymer molding processing, in particular to a rubber continuous mixing device, which mainly consists of a compounding agent metering supply device, a film metering and conveying device, a machine barrel, a main screw, a planetary screw, a brake ring, a die, and a transmission device The film metering and conveying device is located on both sides of the barrel, and the film is metered and delivered to the feeding port, and the compounding agent metering and supplying device is metered and delivered to the feeding port. In the barrel, it advances with the rotation of the screw, and is cut horizontally by the blade, so that the proportion of the material entering the gap of the planetary screw is basically the same, avoiding the poor dispersion caused by the light weight of the silica when the granular rubber is mixed with the silica. The uniform phenomenon enhances the mixing effect.

Owner:BEIJING UNIV OF CHEM TECH

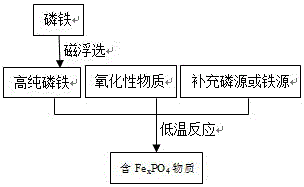

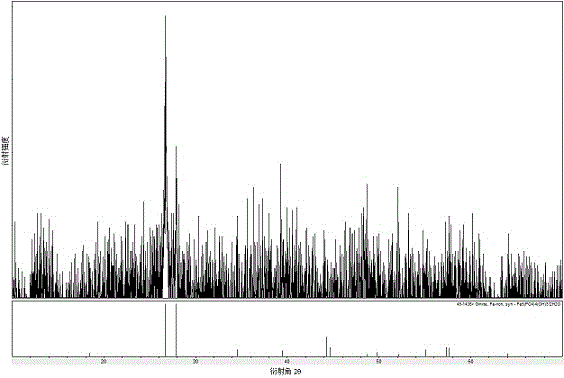

Method for preparing FexPO4-containing substances from ferrophosphorus at low temperature

The invention relates to a method for preparing FexPO4-containing substances from ferrophosphorus at a low temperature. The ferrophosphorus is mixed with oxidizing substances; then, low-temperature reaction is performed to obtain FexPO4-containing substances; phosphorus sources or iron sources are supplemented according to the ferrophosphorus composition; the influence of impurities in the ferrophosphorus on products is eliminated by physical or chemical measures; the reaction process is enhanced; the fully sealed harm-byproduct-free green and clean production can be realized through regulating and controlling raw materials and process parameters; the generated products can be subjected to concentration granulation or controlled crystallization; the granularity and the appearance are controllable. The method has the advantages that the cheap ferrophosphorus waste slag is converted into high-value FexPO4-containing substances at low temperature; the ferrophosphorus resources are not limited; the influence of impurity elements on products can be eliminated; the granulation treatment can also be performed on products; the appearance and the granularity are controlled; the obtained finished product has high purity and high value; the granularity and the appearance can be easily controlled; the water consumption is low; the energy consumption is low; the preparation method and the process are simple; the resource utilization rate is high; the cost is low; the investment is low; the benefits are good; cleanness and environment protection are realized.

Owner:SICHUAN UNIV

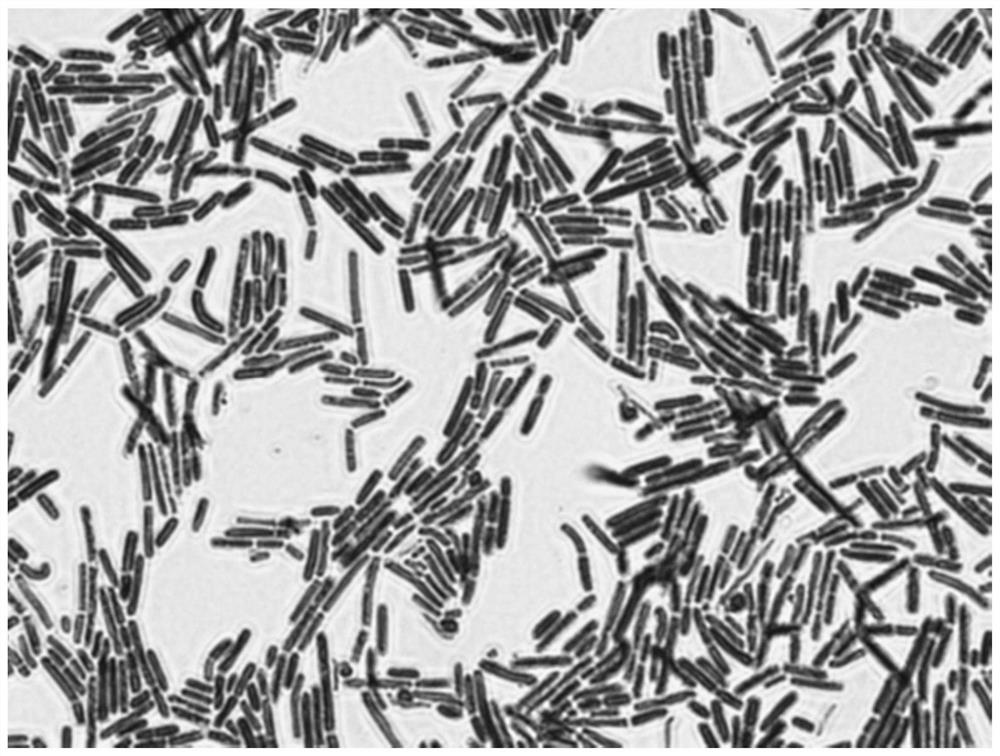

Probiotic tablet with immunity enhancing function and preparation method thereof

ActiveCN111743158AGood compressibilityImprove liquidityBacteriaMicroorganism based processesWhite blood cellSpecific immunity

The invention relates to the field of foods, and discloses a probiotic tablet with an immunity enhancing function and a preparation method of the probiotic tablet. The tablet comprises lactobacillus helveticus freeze-dried powder, acerola cherry powder, a direct-compression auxiliary material and magnesium stearate, can improve in-vitro splenic lymphocyte proliferation and interleukin IL-12 secretion of splenic lymphocytes, promotes human colon cancer epithelial cells HT-29 to secrete interleukin IL-8, and can be used for enhancing immunity. The selected lactobacillus helveticus WHH2580 strainhas excellent acid resistance, cholate resistance and adhesion performance; after the strain is inactivated, the immunity of the organism can still be improved by improving and regulating the organ index, the non-specific immunity and the specific immune response of the organism, so that the product stability and the shelf life of the strain are longer.

Owner:HANGZHOU WAHAHA TECH +1

Preparation method of titanium dioxide porous material

The invention discloses a preparation method of a titanium dioxide porous material. The method comprises the following steps: synthesizing xerogel powder from titanium sulfate by adopting anhydrous ethanol and deionized water as solvents and ethylene diamine tetraacetic acid, citric acid, diethylenetriaminepentacarboxylic acid, tartaric acid, ethylene glycol and polyethylene glycol as dispersants, carrying out direct dry press molding on the xerogel powder to obtain a block material, and carrying out heat treatment to obtain the titanium dioxide porous material. The method has the advantages of simple technology, short period, simple device, low cost, and realization of high controllability of the dimensions and the distribution of apertures of the obtained porous material.

Owner:SHAANXI UNIV OF SCI & TECH

Granulation process for high-compaction microcrystalline graphite negative electrode material

The invention discloses a granulation process for a high-compaction microcrystalline graphite negative electrode material. The preparation method comprises the following steps of putting small-granularity microcrystalline graphite powder and a large-granularity adhesive into a fusion machine for mixing, heating the fusion machine to a temperature 2-4 DEG C lower than the softening point of the adhesive, and carrying out fusion granulation for 60-120 minutes to obtain softened composite particles of microcrystalline graphite and the adhesive, and heating the fusion machine to 500-700 DEG C, keeping the temperature for 1-3 hours, cooling the material to room temperature, graphitizing, screening, demagnetizing and packaging to obtain the secondary composite particles for the high-compaction microcrystalline graphite negative electrode material. The method disclosed by the invention solves the problems that granulation equipment is overloaded and abraded due to high adhesive content, and faults are easy to occur.

Owner:HUNAN SHINZOOM TECH

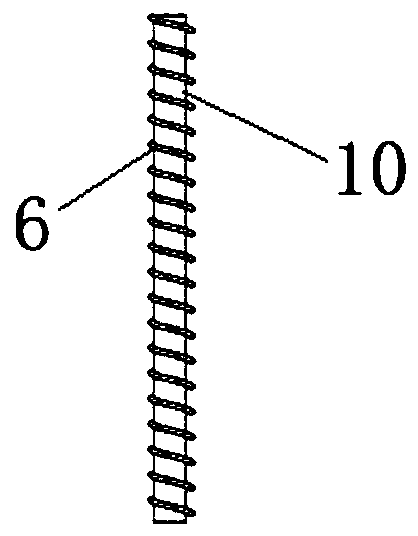

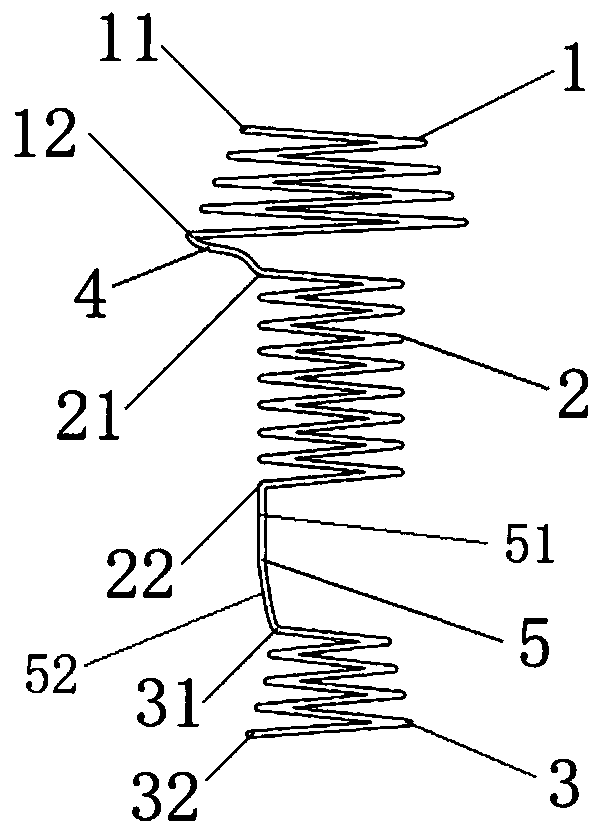

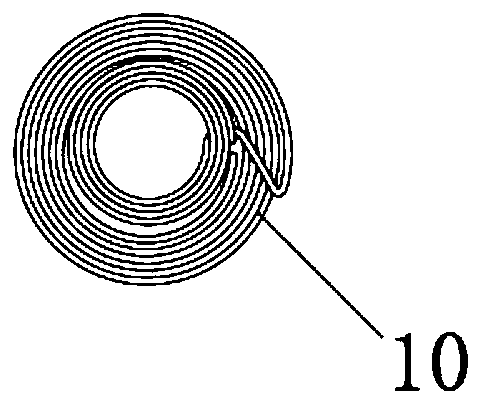

Urethral stent for non-invasive surgery and preparation method thereof

ActiveCN110974500AReduce the difficulty of surgeryImprove comfortStentsSurgeryUrethral stentsInvasive surgery

The invention provides a urethral stent for non-invasive surgery. The urethral stent comprises a main body structure made of a polydodecyl glyceride (PGD) material and a degradable alloy wire, whereinthe main body structure is in a thin strip shape at normal temperature and is converted into a spiral structure after being implanted into a human body; and the degradable alloy wire is coiled on theouter surface of the main body structure. The main body structure of the stent is made of polydodecyl glyceride, and the main body structure is in a slender strip shape at normal temperature, so thatthe main body structure is convenient to insert into a urethra in an operation process; and the polydodecyl glyceride has a memory effect at body temperature, can deform after being implanted into ahuman body to become a spiral structure, and plays a role in expanding the urethra, so that operation difficulty is obviously reduced, and comfort of the implanted stent is improved. According to theinvention, the degradable alloy wire rod is coiled on the main body structure, so that the stent structure can be supported, and meanwhile, the stent structure can be deformed together with the PGD material to play a role in expanding the urethra.

Owner:BEIHANG UNIV

Filter for granulator

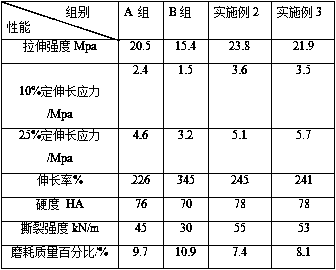

ActiveCN113211675AEfficient separationSeparation does not affectCoatingsUltimate tensile strengthMechanical engineering

The invention discloses a filter for a granulator. The filter comprises a screen plate, an ox horn scraper, a porous flange, a discharging part and a granule discharging flange. The ox horn scraper is matched with a screen plate impurity removal notch, so that impurities and molten materials are effectively separated, and separation of the molten materials is not affected; the ox horn scraper tightly attached to the screen plate to rotate anticlockwise, normal materials are extruded through the screen plate under the extrusion and ox horn scraping and pressing effects, the materials are conveyed, the materials which are not completely molten can be further extruded and molten, the impurities in the materials are separated from the molten materials, and the effect of auxiliary extrusion and melting is achieved; and complete material melting is ensured, the material compactness is good, a good granulating mechanical property is achieved, the strength is high, the purity of a granulated material and the granulating quality are improved, and practicability is good.

Owner:柏建国

Preparing method for porous metastable stable Bi2SiO5 block

The invention discloses a preparing method for a porous metastable stable Bi2SiO5 block. Absolute ethyl alcohol and deionized water serve as solvents, ethylenediaminetetraacetic acid, citric acid, diethylenetriamine pentabasic acid, tartaric acid, ethylene glycol, polyethylene glycol and the like serve as dispersing agents, gelatinization is carried out at a certain temperature, and dried gel powder is obtained after drying; then, the dried gel powder is directly subjected to dry pressing forming, a block material is formed and subjected to heat treatment, and the porous metastable stable Bi2SiO5 block can be obtained. The method is simple in process, short in period, simple in equipment and low in cost, and the obtained porous material is high in controllability over the pore size and distribution.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of porous titanium dioxide-silica block

ActiveCN105964235AUniform crystallizationComposite uniformPhysical/chemical process catalystsWater bathsAnhydrous ethanol

The invention discloses a preparation method of a porous titanium dioxide-silica block. The preparation method comprises respectively adding butyl titanate and ethyl orthosilicate as raw materials into a specific dispersant-containing anhydrous ethanol-deionized water mixed solution, carrying out a water bath reaction process on the butyl titanate solution to obtain butyl titanate semigel, adding the ethyl orthosilicate solution into the semigel, carrying out a stirring reaction process until gelation, directly molding the dried powder and carrying out sintering to obtain the porous titanium dioxide-silica block. The preparation method has the characteristics of simple device, short period and low cost.

Owner:SHAANXI UNIV OF SCI & TECH

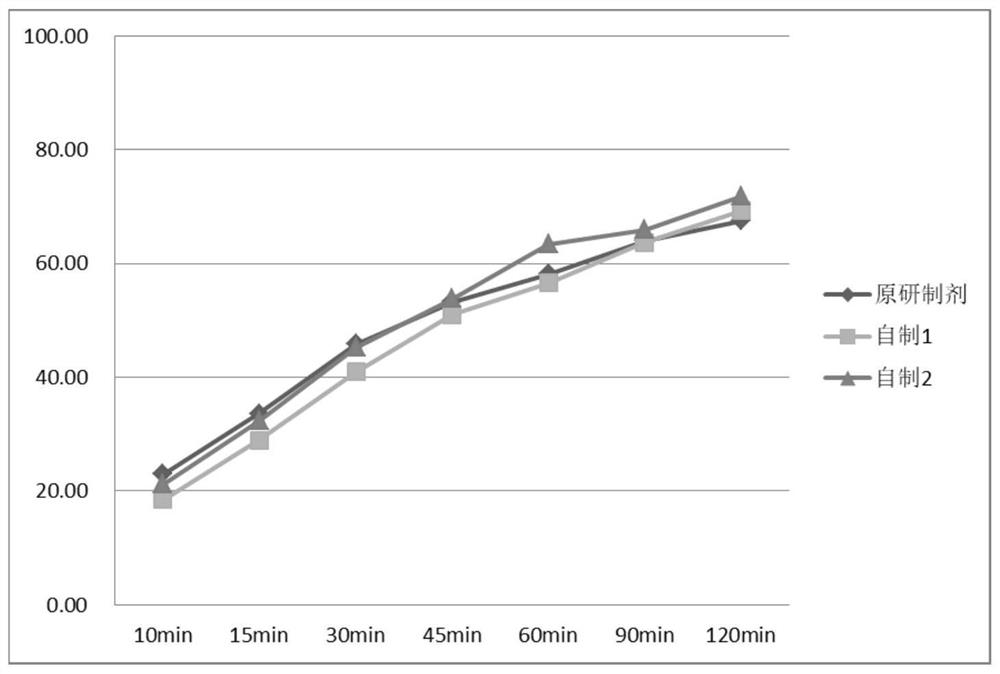

Flunarizine hydrochloride capsule preparation and preparation method thereof

ActiveCN113262207AReduce granulationReduce drynessOrganic active ingredientsNervous disorderFlunarizine HydrochlorideLactose

The invention discloses a flunarizine hydrochloride capsule preparation and a preparation method thereof. The flunarizine hydrochloride capsule preparation is prepared from the following raw materials in parts by weight: 2-10 parts of flunarizine hydrochloride, 100-150 parts of lactose, 10-40 parts of starch, 0.1-1 part of a flow aid and 2-20 parts of a lubricant. The flunarizine hydrochloride capsule prepared by the invention is placed for 3 months under a high-temperature experimental condition, the dissolution curve of the flunarizine hydrochloride capsule in a medium with a pH value of 3.0 has no obvious change, and an f2 value is greater than 50; and the dissolution curve of an original developed preparation is obviously reduced, and the f2 value is 12.7. The in-vitro dissolution curve stability of the flunarizine hydrochloride capsule prepared by the invention is superior to the in-vitro dissolution curve stability of the original preparation.

Owner:CHIATAI QINGCHUNBAO PHARMA

A kind of preparation method of superabsorbent polymer

The invention discloses a preparation method of a high-water-absorption polymer. The polymer comprises the following components (in parts by weight): 40g to 45g of acrylic acid, 55g to 60g of water, 19.28g to 20.5g of sodium hydroxide, 0.01g to 0.02g of N, N' methylene bis-alkenyl amide, 1g to 2g of 3% potassium persulfate aqueous solution, 0.05g to 0.1g of sorbide glycerinum-laurate and 1g to 2g of 3% potassium persulfate aqueous solution. The preparation method comprises the following steps: preparing the acrylic acid aqueous solution with concentration of 55 to 60 percent; adding a cross-linking agent, a surface active agent and a polymerization initiator into the acrylic acid aqueous solution, blowing nitrogen, sending the solution into a blender at a feed speed of 250g / min, sending the 3% sodium bisulfate aqueous solution into the blender at a feed speed of 6 to 10 g / min, enabling the material mixed by the blender to rapidly flow into a screw squeezing device to be polymerized, controlling the temperature at 103 DEG C, discharging the hydrogel polymer out of the squeezing device, drying by virtue of hot air at 160 DEG C, and crushing to obtain the high-water-absorption polymer. The preparation method is stable in product quality, high in yield, labor-saving and high in efficiency.

Owner:欧阳晨曦

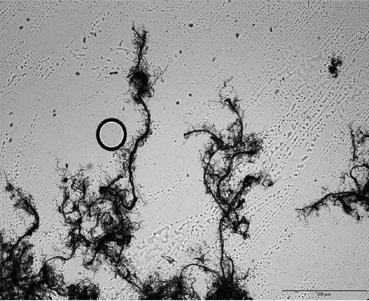

A kind of ultrasonic-assisted preparation spherical praziquantel crystal and method

ActiveCN110790759BHigh purityImprove liquidityOrganic chemistry methodsAgainst vector-borne diseasesPhysical chemistryCrystalline particle

The invention relates to an ultrasonic-assisted preparation of spherical praziquantel crystals and a method thereof. Add crude praziquantel into isopropanol solution, stir and dissolve at 50-60°C, prepare praziquantel-isopropanol solution, cool and crystallize by cooling crystallization, add ultrasound at 30-39.5°C, ultrasonic power 10- 100W / mL solution, ultrasonic time is 5-30min, then continue to cool down to crystallize to 0-5°C, keep the temperature for 30min-60min, filter, wash and dry to obtain spherical crystals of praziquantel. The average roundness value is above 0.85, and the angle of repose is below 11°. Spherical praziquantel crystals have the characteristics of high purity, good fluidity, high bulk density, high yield, small crystal particle size and uniform crystal shape, as well as excellent anti-agglomeration performance and bioavailability. The solvent used in the reaction process can be recovered, and the granulation step is omitted by direct forming into spheres, which is a method with great industrial application prospects.

Owner:TIANJIN UNIV

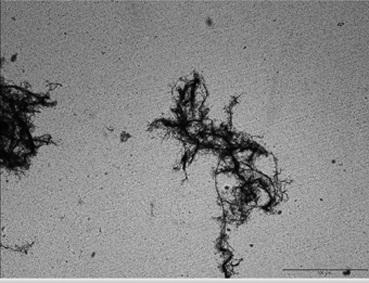

A kind of preparation method of aromatic polyamide fiber rubber premixed masterbatch

The invention provides a preparation method of an aromatic polyamide fiber and rubber premix master batch. The method comprises the following steps: 1, preparing raw materials: weighing 20-80 parts by mass of liquid rubber, 20-80 parts by mass of aromatic polyamide fibers and a dispersion solvent with the mass 1-2 times the total mass of the liquid rubber and the aromatic polyamide fibers; 2, adding the dispersion solvent weighed in step 1 to the aromatic polyamide fibers to pre-disperse the fibers in order to obtain a fiber solvent premix system; and 3, mixing the fiber solvent premix system obtained in step 2 with the liquid rubber, carrying out gradient heating under a vacuum pumping condition to remove the dispersion solvent and system water, and discharging the obtained material when the read value of a vacuum heating mixer pressure meter is stable and no liquid drops from a solvent condensation port in order to obtain the aromatic polyamide fiber and rubber premix master batch. The method has the advantages of simplicity in operation, low production cost, high efficiency, and effective improvement of the performances and the quality of rubber products produced from the aromatic polyamide fiber and rubber premix master batch.

Owner:中蓝晨光化工有限公司

Production equipment and process for preparing breathable film through one-step method

PendingCN111660522AGood mixing and plasticizing effect at low temperatureReduce coke phenomenonMolten statePlasticulture

The invention discloses production equipment and process for preparing a breathable film through an one-step method. The production equipment comprises a rack, a collecting hopper, a double-rotor continuous internal mixer and a casting machine; the collecting hopper is fixedly installed on the rack, a feeding port is formed in the upper end of the collecting hopper, and a first discharging port isformed in the lower end of the collecting hopper; an internal mixing barrel on the double-rotor continuous internal mixer is fixedly installed on the rack, and the internal mixing barrel is located below the material collecting hopper; a first material receiving opening and a second material discharging opening are formed in the internal mixing barrel, and the first material receiving opening communicates with the first material discharging opening; a casting screw cylinder on the casting machine is arranged on the rack through a supporting frame, a second material receiving opening is formedin the casting screw cylinder, and the second material receiving opening communicates with the second discharging opening through a pipeline; and the tail end of the casting screw cylinder is connected with a casting mold. Through the stirring of the internal mixing cylinder, the raw material is fully and uniformly mixed and primarily plasticized, and continuously enters the casting screw cylinder in a semi-molten state in the mixing motion to be plasticized again, so that the raw material low-temperature mixing plasticizing effect is good, and the coke phenomenon in the casting screw cylinder and the casting mold can be reduced.

Owner:佛山市新三合塑料薄膜制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com