Method for integrated production of carbon black and white carbon black

A production method and white carbon black technology, applied in the directions of silicon oxide, silicon dioxide, fibrous fillers, etc., can solve the problems of complex process flow, no disclosure, reduction of carbon dioxide emissions, etc., and achieve low emissions and limit performance breakthroughs , the effect of reducing the total cost of production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

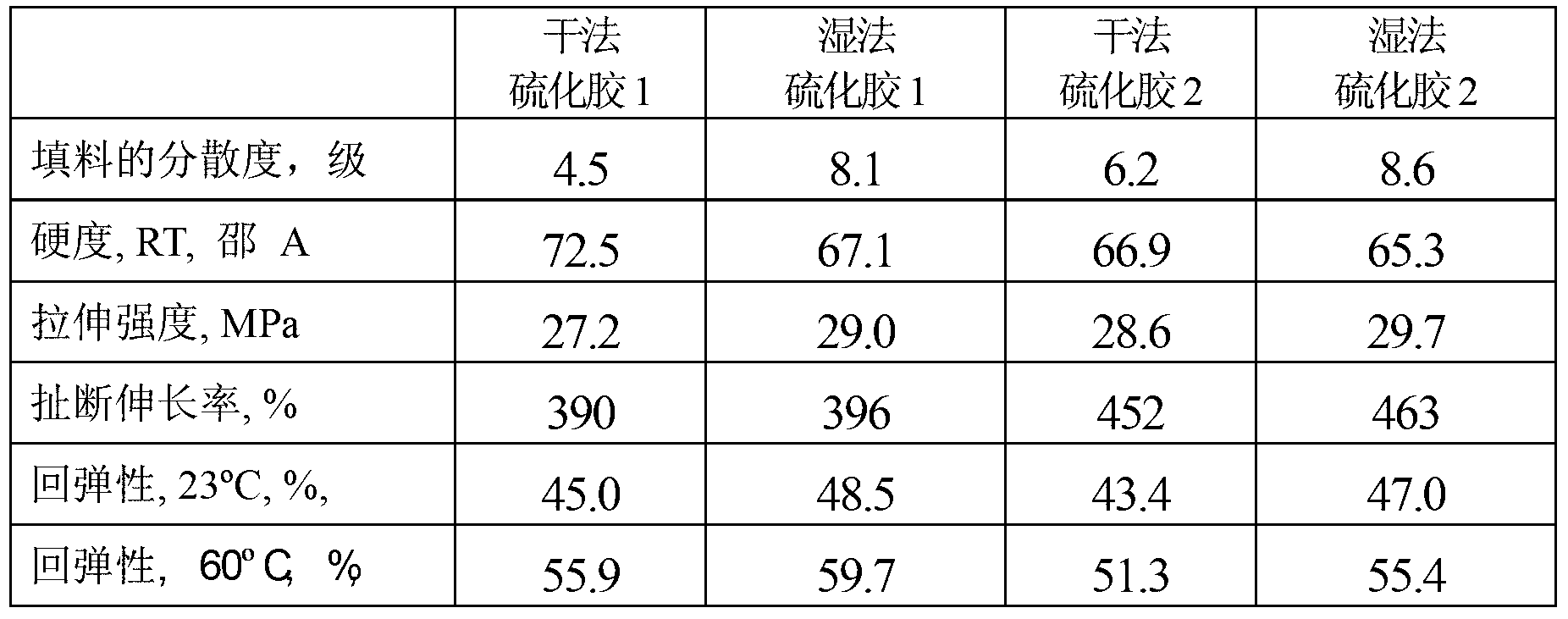

Embodiment 1

[0092] The fuel oil is pumped to be mixed with the air provided by the main supply fan and preheated to 850°C by the air preheater, and then combusted in the combustion section to generate a high-temperature combustion airflow of about 1900°C; the raw oil is preheated to a certain temperature by the preheater After that, it is sprayed into the throat section of the reaction furnace, mixed with the high-temperature combustion airflow, and rapidly cracked to produce carbon black flue gas; then, it is sprayed with quenching water to reduce the temperature of the flue gas to terminate the reaction, and the separated carbon black is sent to the In the process of wet mixing rubber, the carbon dioxide separated from the exhaust gas after combustion is used in the production process of white carbon black, and nitrogen is used in the wet mixing process, and a large amount of heat generated is used in the production process of white carbon black and wet mixing. used in the process.

[0...

Embodiment 2

[0101] The fuel oil is pumped to be mixed with the air provided by the main supply fan and preheated to 850°C by the air preheater, and then combusted in the combustion section to generate a high-temperature combustion airflow of about 1900°C; the raw material oil is preheated to a certain temperature by the preheater After that, it is sprayed into the throat section of the reaction furnace, mixed with the high-temperature combustion airflow, and rapidly cracked to produce carbon black flue gas; then, it is sprayed with quenched water to reduce the temperature of the flue gas to terminate the reaction, and the separated carbon black is used after passing through the bag filter. In the process of wet mixing rubber, the carbon dioxide produced by the combustion of tail gas in the tail gas boiler is used in the production process of white carbon black, and the heat generated is used in the process of white carbon black and wet mixing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com