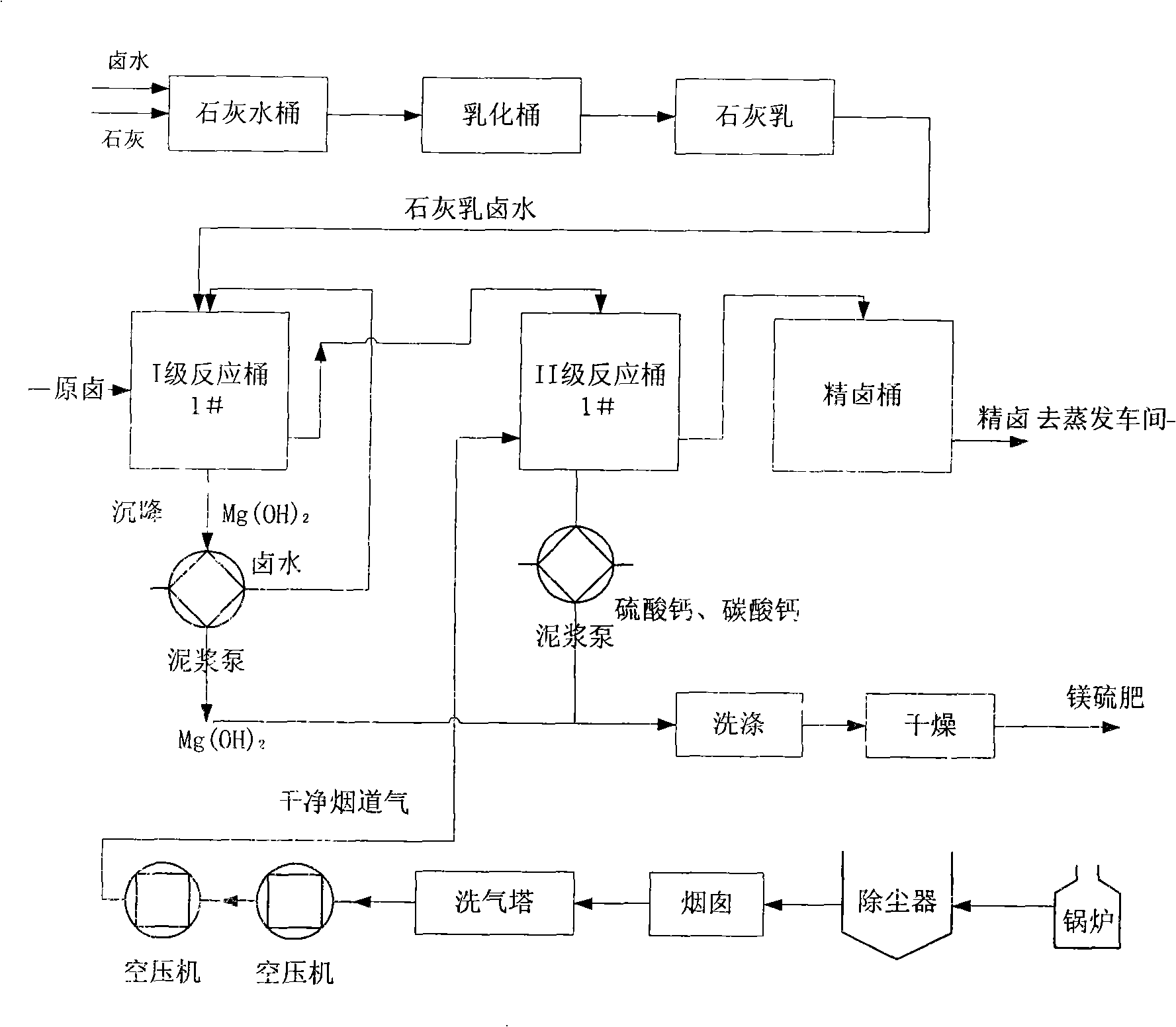

Technological process for purifying bittern

A process method and brine purification technology, applied in the direction of alkali metal chlorides, etc., can solve the problems of increasing the energy consumption of circulating pumps and water, rising brine purification costs, and less construction investment, so as to reduce brine purification costs, and the reaction process is safe and stable. , scientific and reasonable effect of process design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0026] Purify brine 458m per hour 3 As an example, the indicator after brine treatment: Ca 2+ , Mg 2+ The total content is 10mg / l, NaCl≥287g / l.

[0027] When purifying the brine of this scale, first prepare emulsified lime water, that is, 660kg of lime (Ca(OH) 2 ), (lime purity by 100%) was added to the purified 1.6m 3 In the brine, stir evenly under normal temperature and pressure to make a lime emulsion. The active calcium oxide in the lime emulsion is measured to be 320g / l by acid-base titration. The prepared lime emulsion is pumped into the reaction tank, and mixed with the The saturated brine of calcium and magnesium ions carries out the first step reaction, and the sampling adopts the acid-base titration method to detect, and the P value is 15 to 50ml, and the present embodiment selects the P value as 15ml, and reacts at normal temperature for 2 hours; half an hour before the end of the reaction, Add flocculant polyacrylamide, the usage amount of polyacrylamide is 1 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com