Preparation method of AdBlue

A technology for vehicle urea and urea, which is applied in the preparation of organic compounds, the preparation of urea derivatives, chemical instruments and methods, etc., can solve the problems of high price and cost of urea, high energy consumption, and disconnected production processes and production processes, and achieve good Application prospect, environmental pollution reduction, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

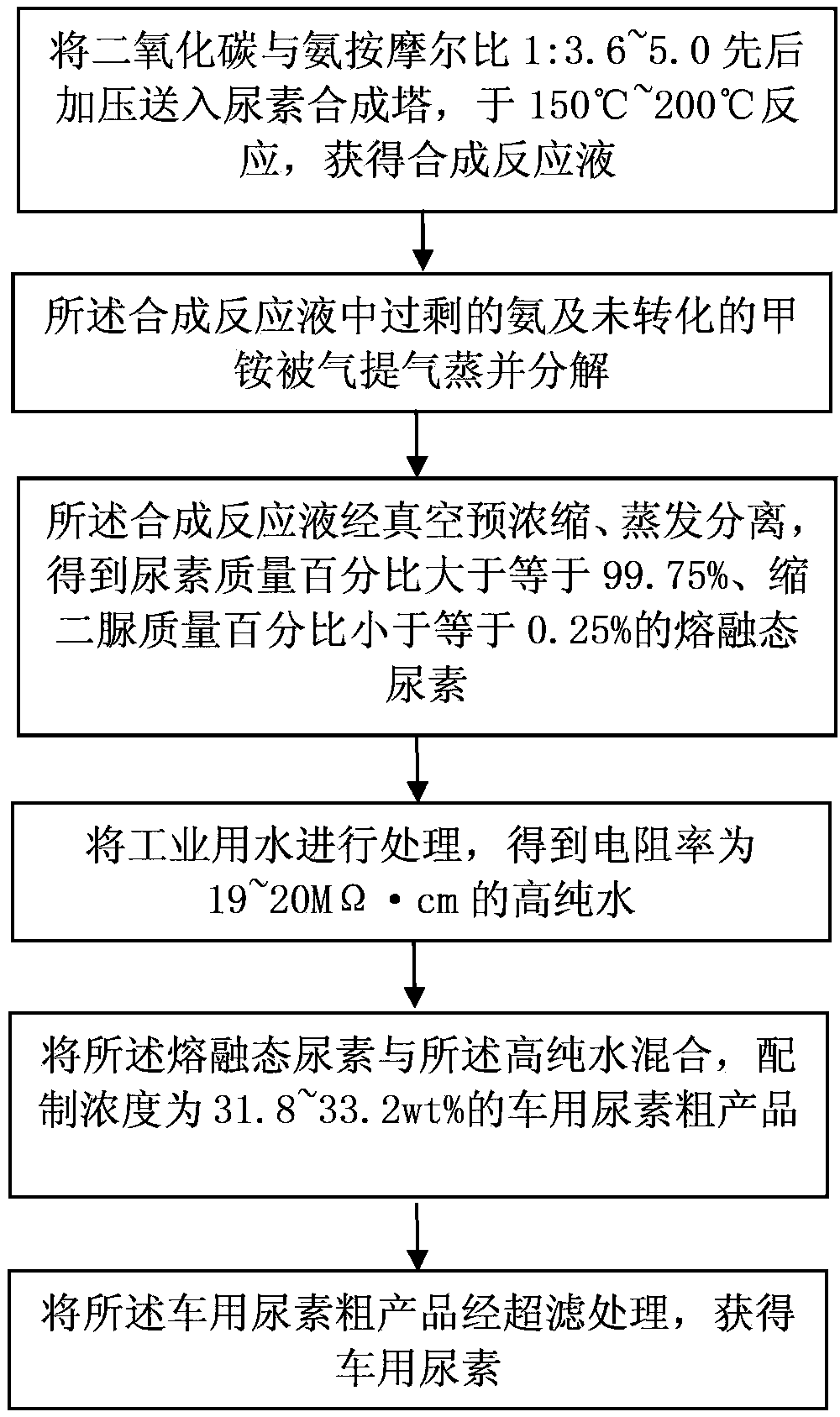

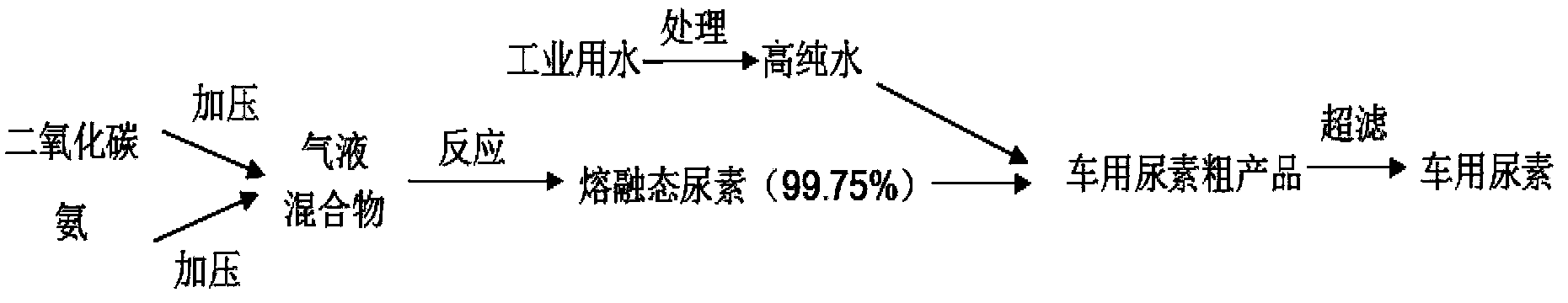

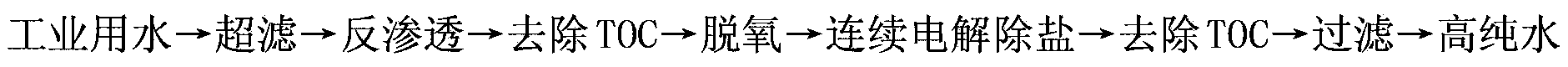

[0033] Such as figure 1 , figure 2 As shown, carbon dioxide and ammonia (10°C, 3MPa) at normal temperature and pressure are sent to the urea synthesis tower under pressure at a molar ratio of 1:3.6, and react at 188°C. The excess ammonia and unconverted formazan in the synthesis reaction liquid The ammonium was stripped and decomposed, and the product was pre-concentrated in vacuum and separated by evaporation to obtain 110 kg of 99.75% (wt.) molten urea (130°C, 1MPa). Such as image 3 Shown is the flow chart of the preparation of high-purity water during the preparation of urea for vehicles. 230 kg of industrial water was subjected to ultrafiltration (ultrafiltration membrane group), reverse osmosis (reverse osmosis membrane group), removal of TOC (total organic carbon remover), deoxidation, continuous electrolytic desalination (EDI), removal of TOC, filtration ( precision filter) to remove ions in the water and obtain 221 kg of high-purity water (main parameters: resist...

Embodiment 2

[0036] The raw material carbon dioxide (40°C, 0.2MPa) and ammonia (0°C, 2.3MPa) are sent to the urea synthesis tower under pressure at a molar ratio of 1:5.0, and react at 195°C. The excess ammonia and unconverted formazan in the synthesis reaction liquid Ammonium was stripped and decomposed, and the product was pre-concentrated in vacuum and separated by evaporation to obtain 1000 kg of 99.75% (wt.) molten urea (140°C, 1.3MPa). 2300 kg of industrial water was subjected to ultrafiltration (ultrafiltration membrane group), reverse osmosis (reverse osmosis membrane group), removal of TOC (total organic carbon remover), deoxidation, continuous electrolytic desalination (EDI), removal of TOC, filtration ( precision filter) to remove ions in the water and obtain 2145 kg of high-purity water (main parameters: resistivity 20MΩ cm, copper<0.2μg / L, zinc<0.2μg / L, potassium<0.5μg / L, phosphate <1μg / L , refer to the national standard GB / T11446.1-1997 for parameter standards); then 2145 kg ...

Embodiment 3

[0039]The raw material carbon dioxide (20°C, 1MPa) and ammonia (-15°C, 3MPa) are sent to the urea synthesis tower under pressure at a molar ratio of 1:4.0, and react at 160°C to synthesize excess ammonia and unconverted methylammonium in the reaction liquid It was stripped and decomposed, and the product was pre-concentrated in vacuum and separated by evaporation to obtain 300 kg of 99.75% (wt.) molten urea (120°C, 1.8MPa). 650 kg of industrial water was subjected to ultrafiltration (ultrafiltration membrane group), reverse osmosis (reverse osmosis membrane group), removal of TOC (total organic carbon remover), deoxidation, continuous electrolytic desalination (EDI), removal of TOC, filtration ( precision filter), remove ions in water, and obtain 632 kg of high-purity water (main parameters: resistivity 20MΩ cm, copper-1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com