Hammer type shearing granulator

A granulator and granulation technology, applied in the direction of grain processing, etc., can solve the problems of reducing the filling value of ternary porous particles, reducing product production yield, reducing the service life of blades, etc., achieving small crushing, prolonging service life, Improve fill value effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

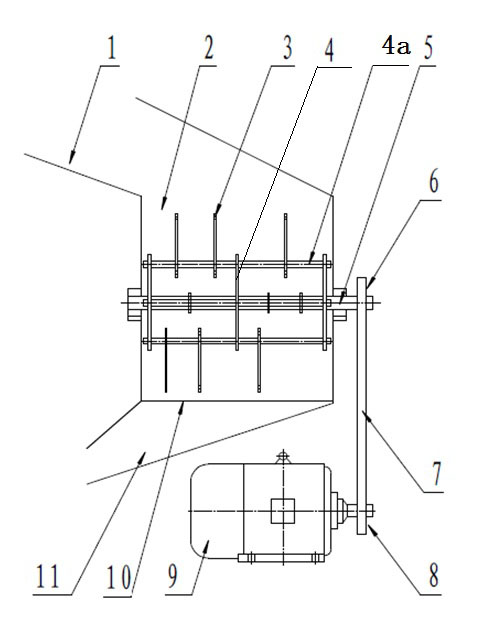

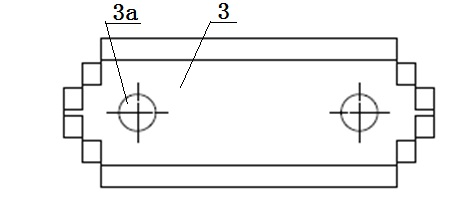

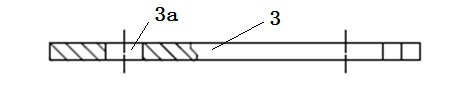

[0017] Such as figure 1 As shown, the hammer shear granulator of the present invention includes a granulation bin 2 with a feed port 1 and a discharge port 11, a blade holder 4 installed in the granulation bin that can rotate around a central axis 5, The shearing blade 3 installed on the blade support, the central shaft outer end of the blade support is connected with the power transmission device. Power transmission device comprises the granulator belt pulley 6 that is sleeved on the outer end of blade support center shaft 5, drive motor 9, the motor belt pulley 8 that is sleeved on the drive motor output shaft, the transmission belt 7 that connects granulator belt pulley 6 and motor belt pulley 8. Such as Figure 3-1 and Figure 3-2 As shown, the blade holder 4 is a horizontal cylindrical cage structure, and the cylindrical cage bars 4a are evenly distributed on the outer surface of the blade holder. Such as diagram 2-1 , Figure 2-2 , Figure 2-3 As shown, the blade ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com