A kind of preparation method of aromatic polyamide fiber rubber premixed masterbatch

An aromatic polyamide and fiber technology is applied in the field of preparation of an aromatic polyamide fiber-rubber premix masterbatch, and can solve the problems of poor abrasion resistance and tear resistance, complex composition and preparation method, and high cost of raw materials, Achieve the effect of accelerating the removal of solvent and moisture, reducing production costs, and reducing drying steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

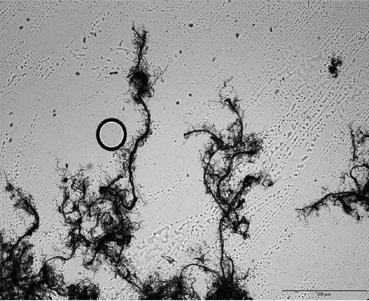

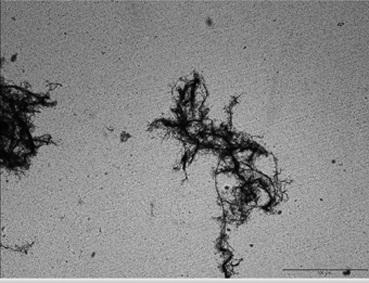

Image

Examples

Embodiment 1

[0035] A kind of preparation method of aromatic polyamide fiber rubber premixed masterbatch, comprises the steps:

[0036] A. Raw material preparation: Weigh 20 parts of liquid rubber, 40 parts of aromatic polyamide fiber, and 80 parts of dispersing solvent by mass percent, and set aside, wherein the aromatic polyamide fiber includes aromatic polyamide pulp and aromatic polyamide pulp. Amide chopped fiber, the aromatic polyamide pulp is the pulp formed by beating and grinding aromatic polyamide chopped fiber in water through a beater;

[0037] B. Fiber pre-dispersion: adding the dispersing solvent weighed in step A to the aramid fiber to pre-disperse the fiber to obtain a fiber solvent premixing system;

[0038] C. Material mixing and granulation: mix the fiber solvent premixed system obtained in step B with the liquid rubber weighed in step A, and then gradually increase the temperature under vacuum conditions to remove the dispersion solvent and system moisture, see vacuum h...

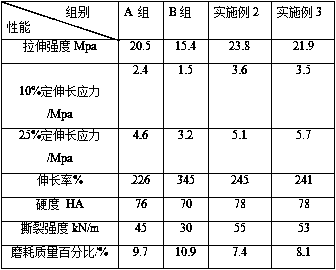

Embodiment 2

[0044] The difference between this embodiment and Example 1 is that the raw material ratio of this embodiment is: 40 parts of liquid rubber, 70 parts of aramid fiber and 110 parts of solvent, except that the above raw material ratio is different from that of Example 1, this implementation Example and embodiment 1 also have the following differences:

[0045] In this embodiment, in step B, the fiber pre-dispersion is carried out under stirring conditions, the stirring speed is 600rpm, and the time is 15min. In step C, the gradient temperature rise to remove the dispersion solvent and the water in the system is to remove the dispersion solvent at 76-80°C, and remove the water in the system at 96-100°C. In this embodiment, the water content of the pulp is controlled to 65 %.

[0046] The polar liquid rubber used in this embodiment is liquid nitrile rubber; specifically, liquid nitrile rubber Nipol1312 is used. The dispersion solvent of the present embodiment adopts acetone;

Embodiment 3

[0048] The difference between this embodiment and Example 1 is that the ratio of raw materials in this embodiment is: 50 parts of liquid rubber, 80 parts of aromatic polyamide fibers, and 130 parts of dispersing solvent. Embodiment and embodiment 1 also have following difference:

[0049] In this embodiment, in step B, the fiber pre-dispersion is carried out under stirring conditions, the stirring speed is 700rpm, and the time is 10min. In step C, the gradient temperature rise to remove the dispersion solvent and the water in the system is to remove the dispersion solvent at 85-90°C, and remove the water in the system at 105-110°C. In this embodiment, the water content of the pulp is controlled to 70 %.

[0050] The liquid rubber in this embodiment is non-polar liquid rubber, and EPDM is used; specifically, Trilene 65 is used as liquid EPDM; the dispersion solvent is 120# solvent naphtha.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com