Patents

Literature

240results about How to "Uniform crystallization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

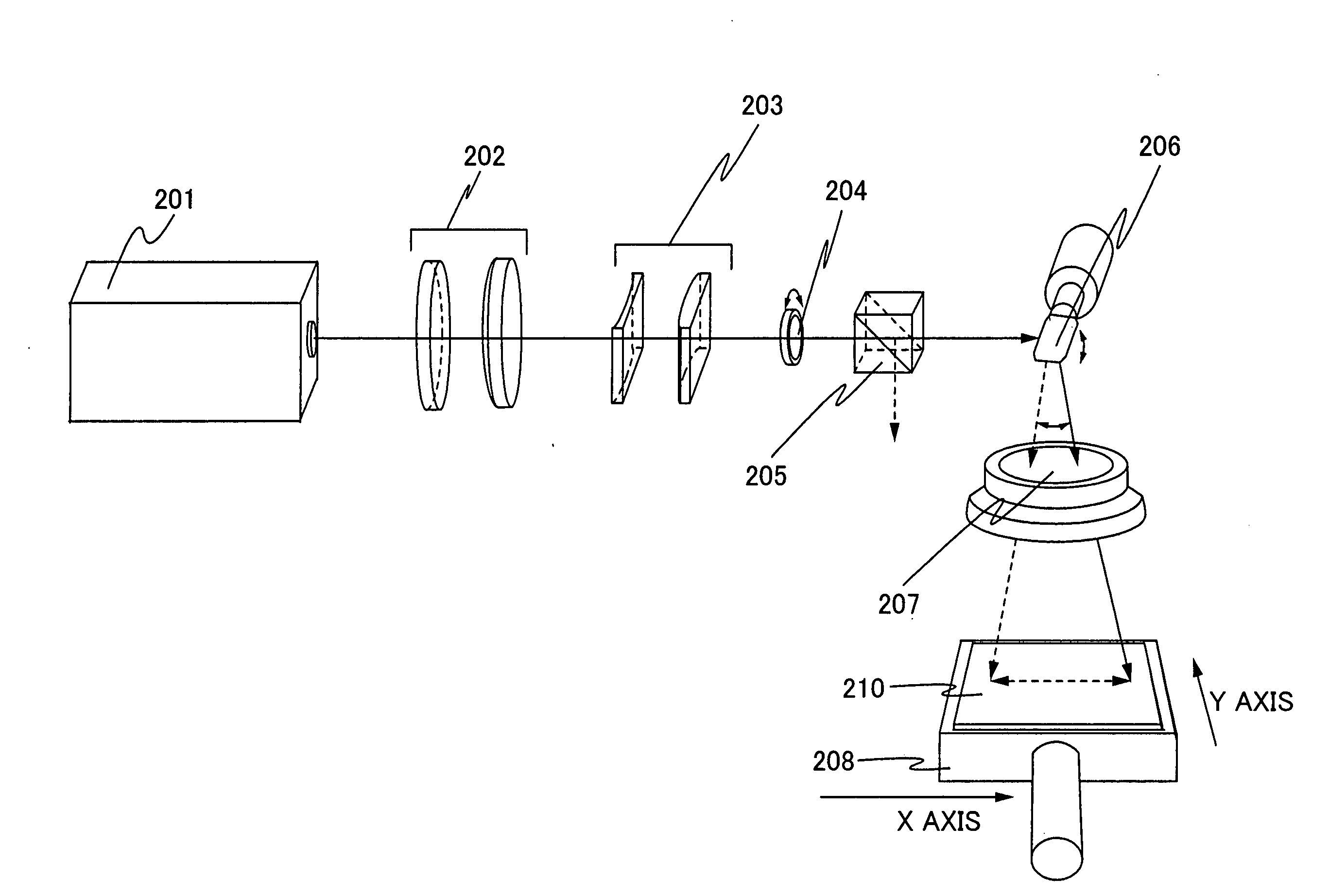

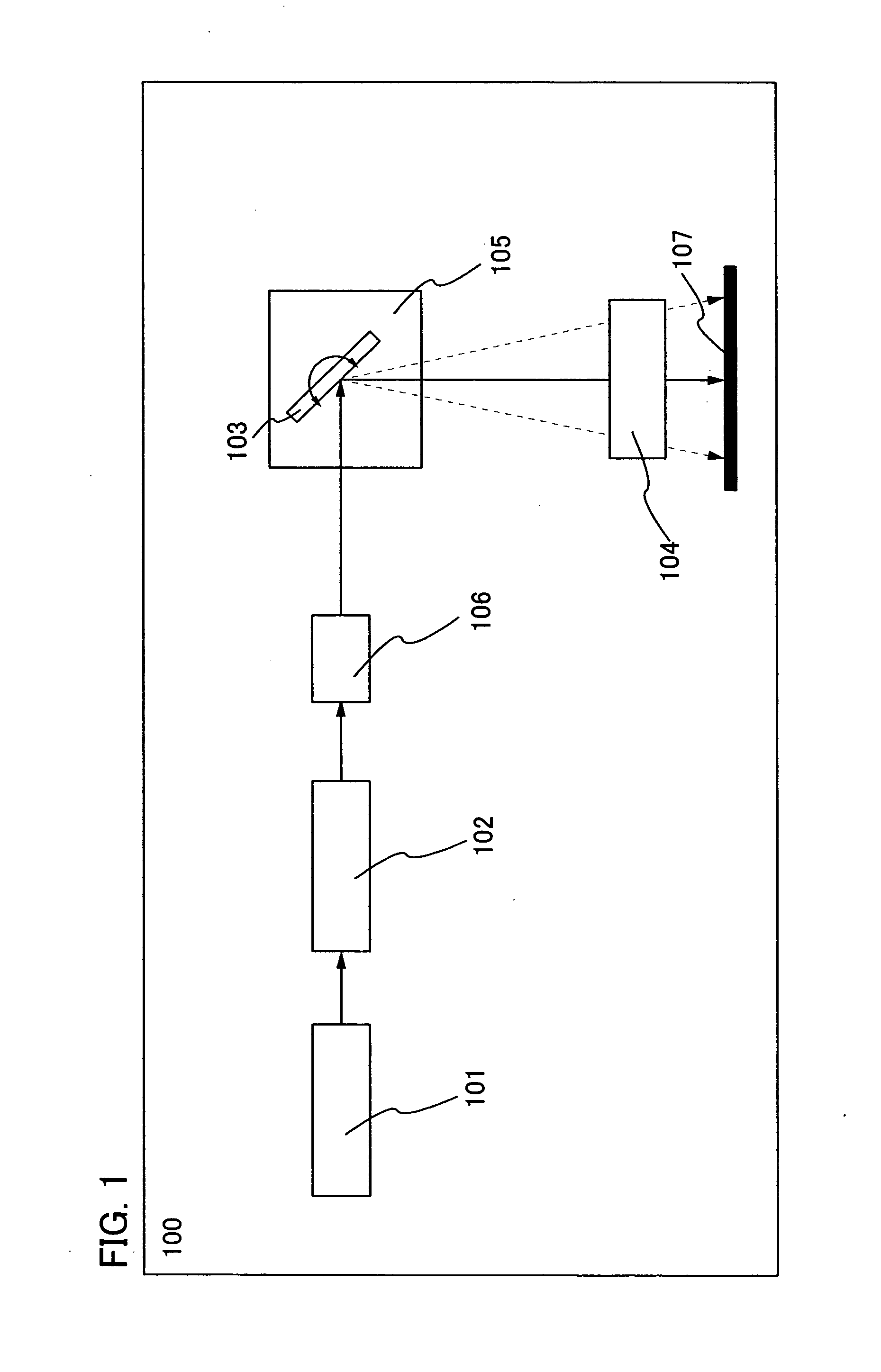

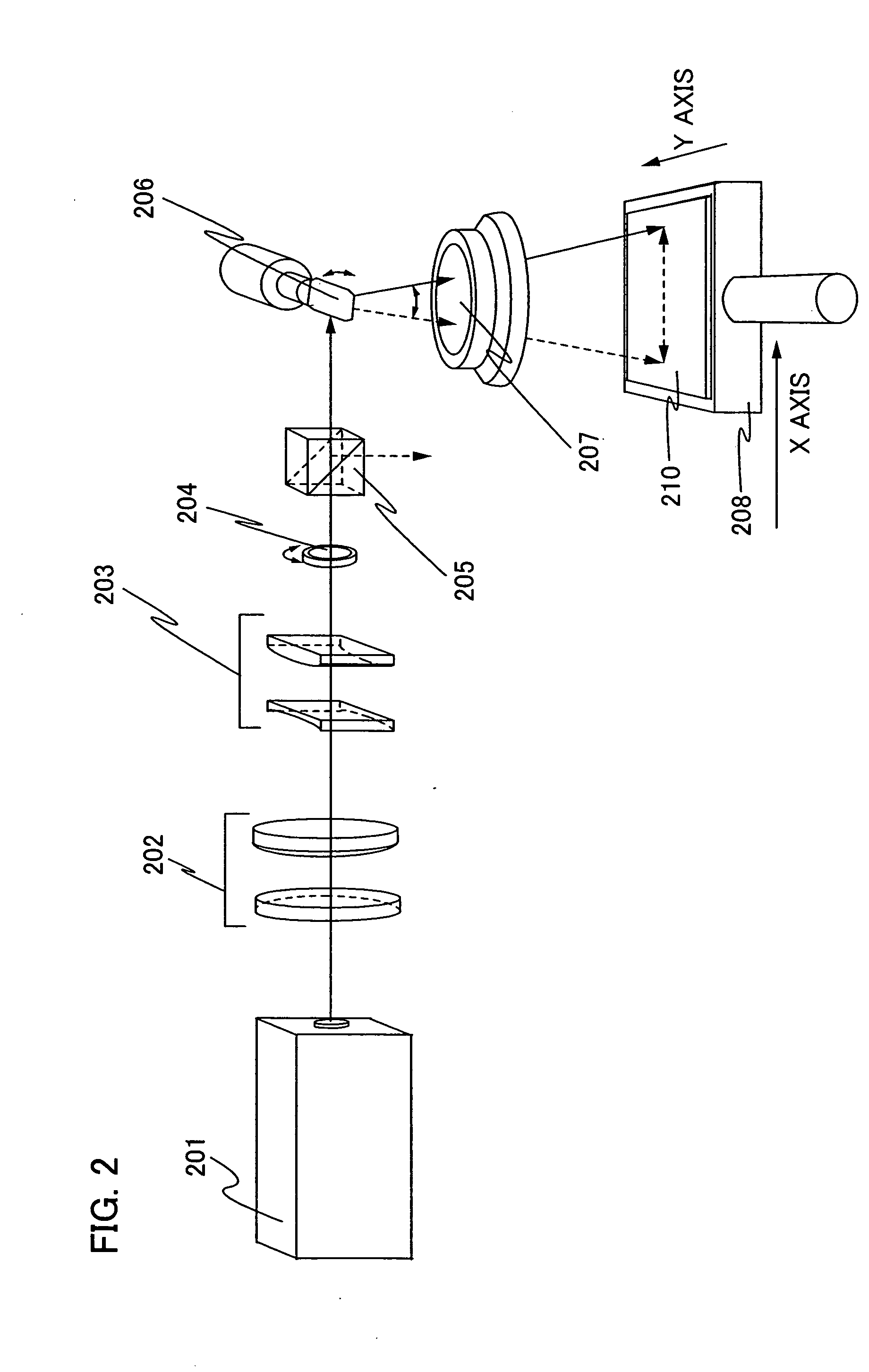

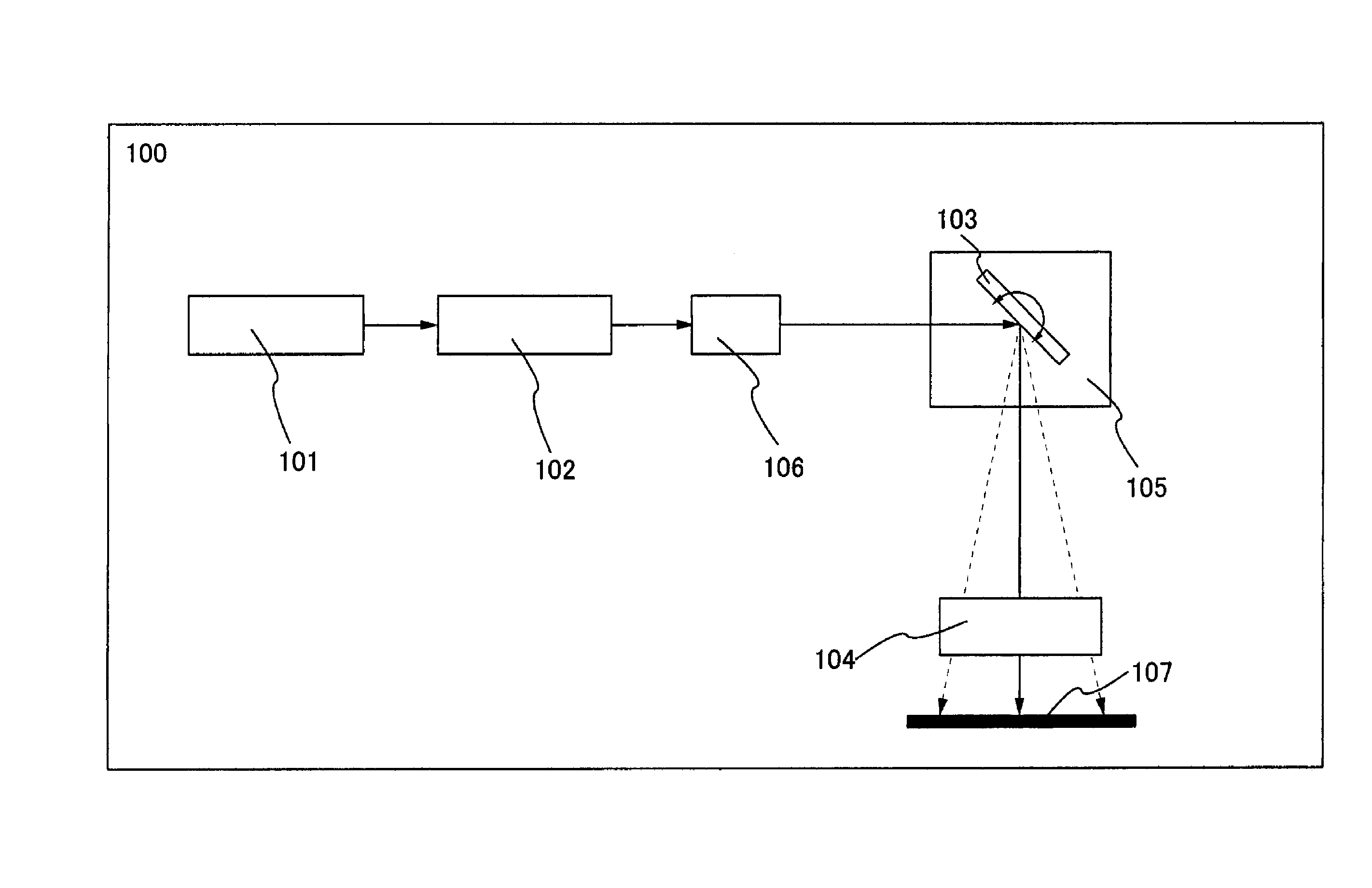

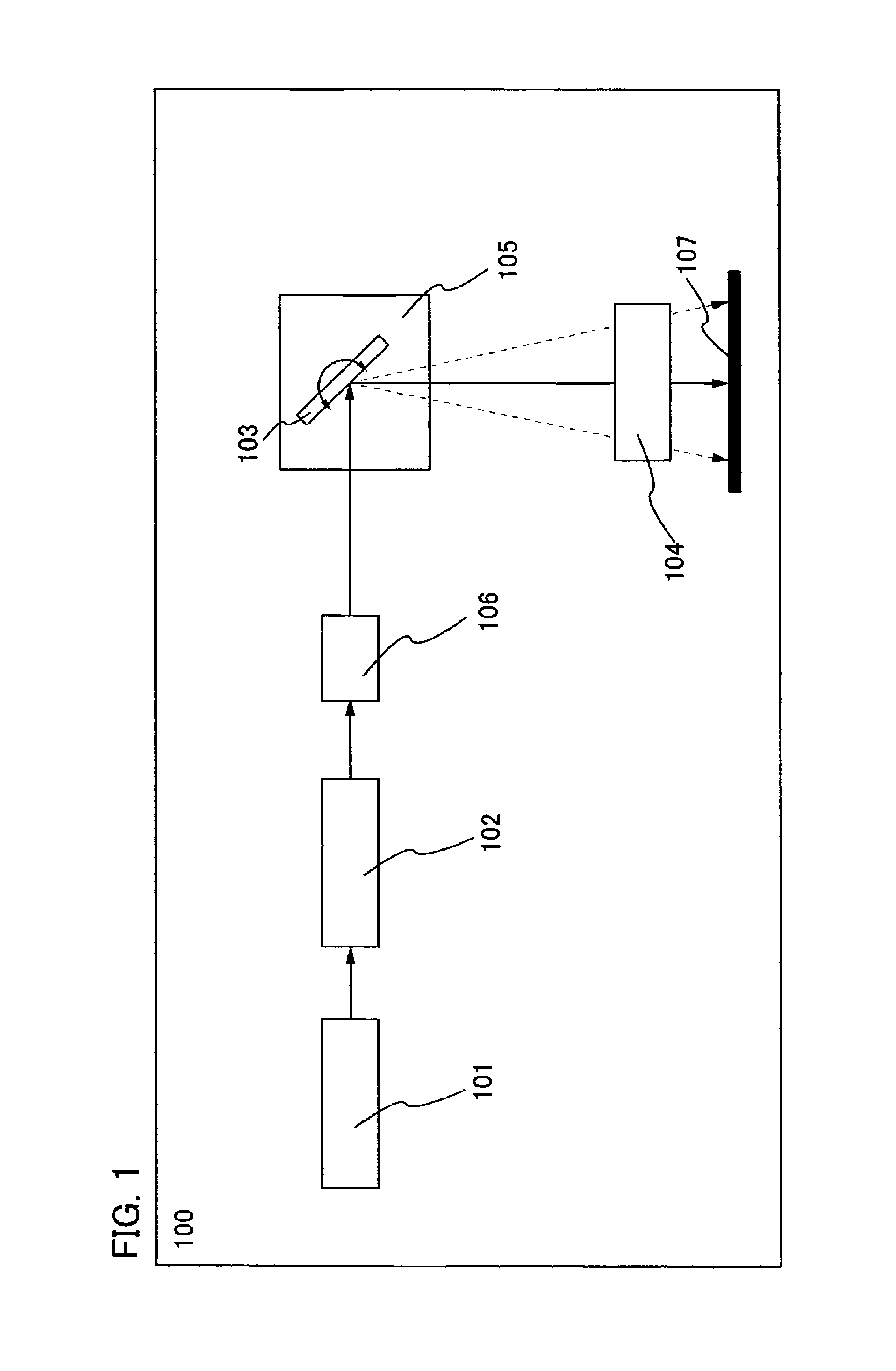

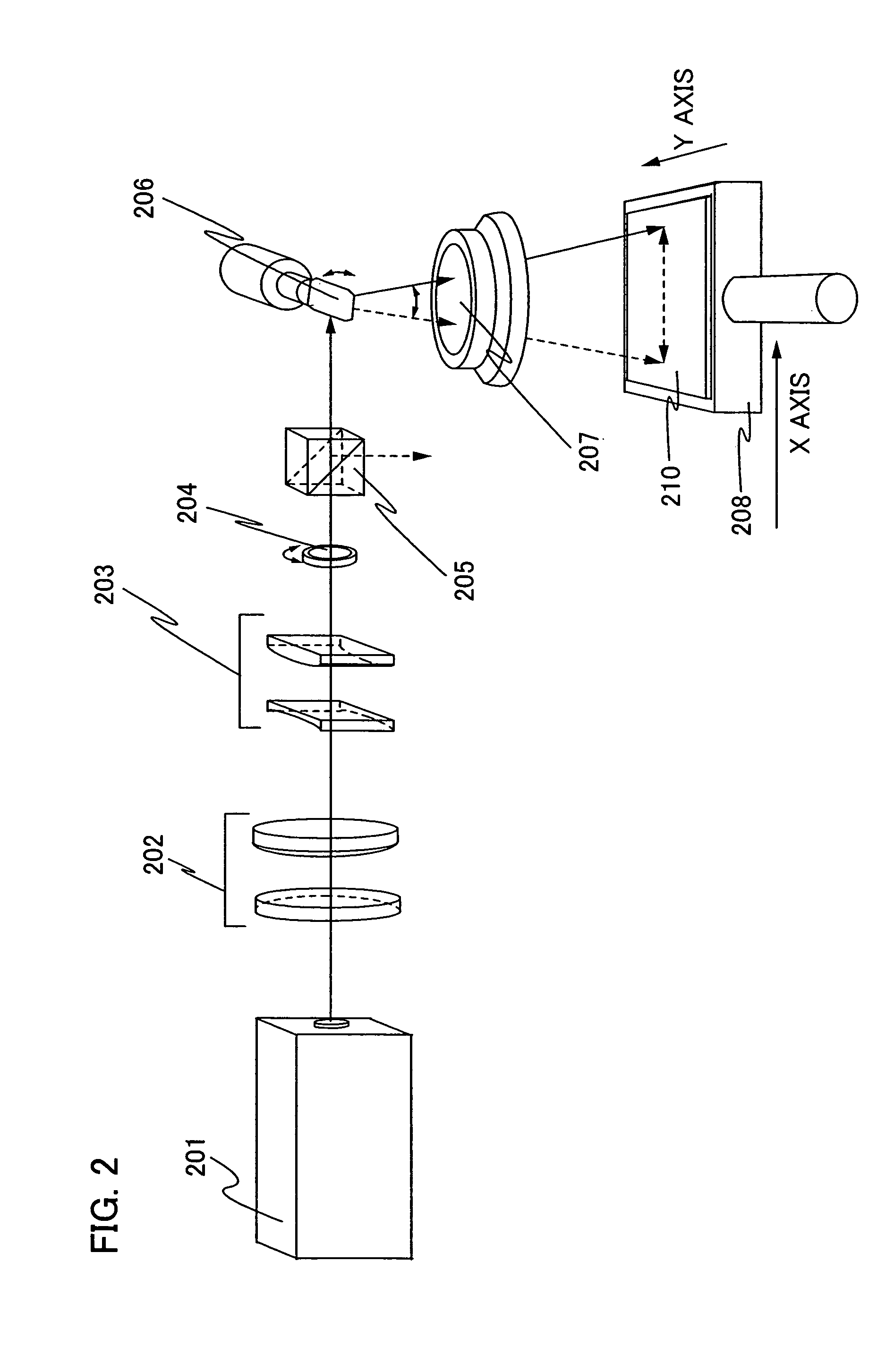

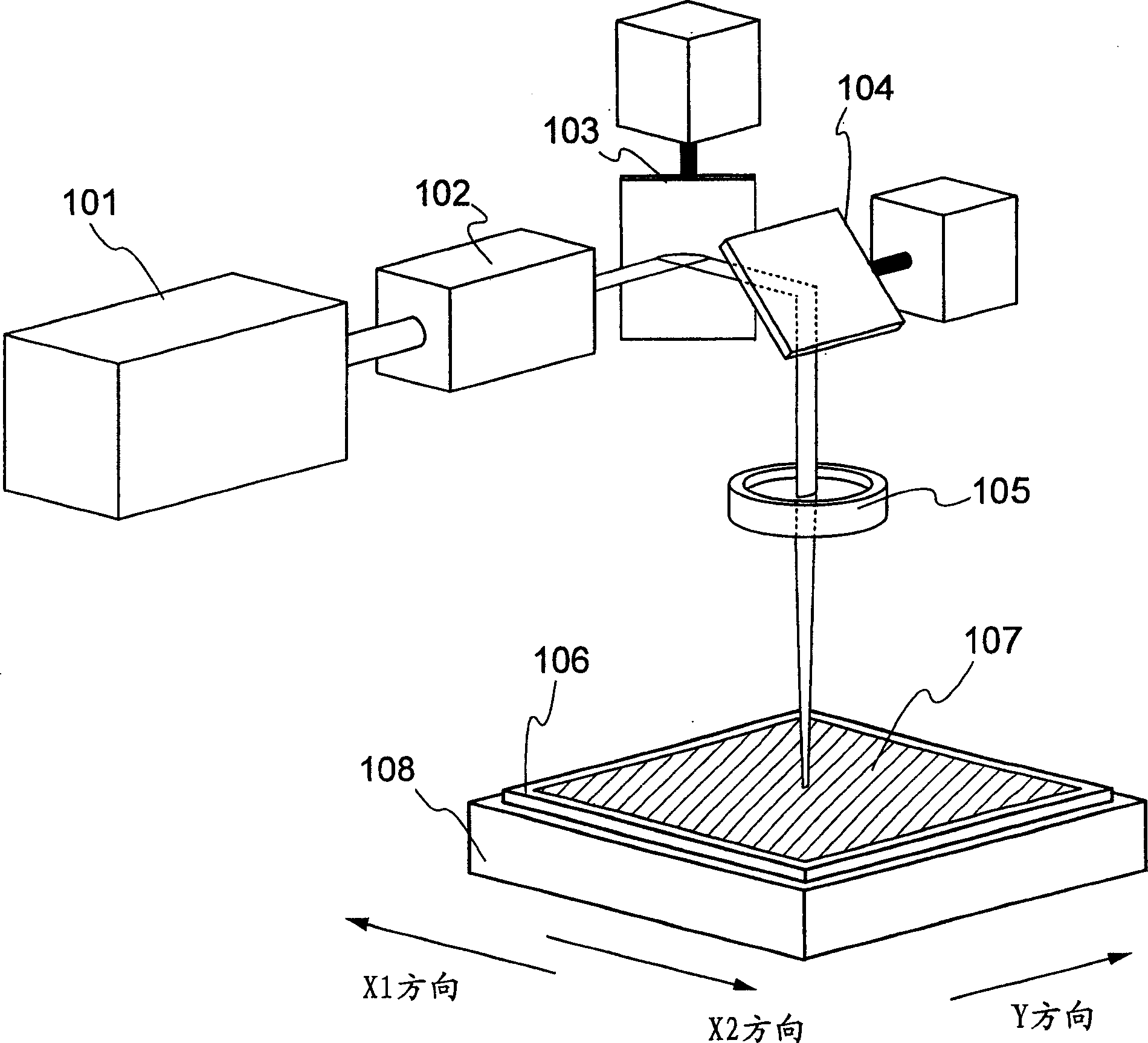

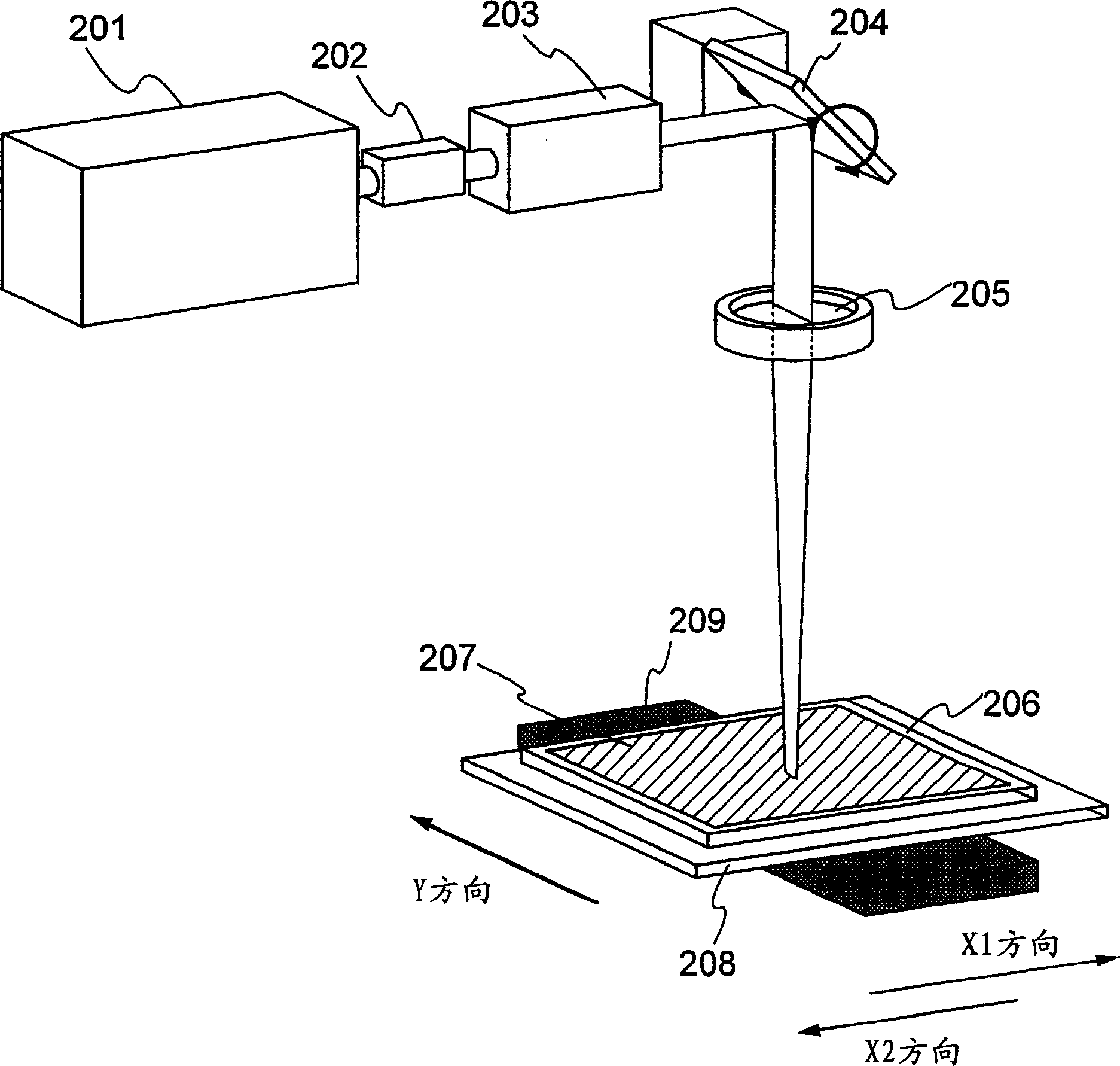

Laser irradiation apparatus and method of manufacturing semiconductor device by using the laser irradiation apparatus

InactiveUS20040074881A1Offset changeSuppress fluctuationsTransistorSolid-state devicesEnergy variationLight beam

The present invention provides the laser irradiation apparatus that has a galvanometer mirror and an f-theta lens optical system, can offset the change of the energy due to the transmittance change of the f-theta lens, and can scan a laser beam while the change of the energy on a substrate is suppressed. Further, the laser beam energy that is incident on the lens is controlled in advance by combining the optical system changing the branching ratio of polarization of the laser beam and the optical system having dependence on direction of polarization of the laser beam and changed continuously according to the transmittance of the lens on which the laser beam is incident. The laser energy is controlled to offset the transmittance of the lens, and thereby energy fluctuation of the laser beam irradiation of a substrate can be prevented.

Owner:SEMICON ENERGY LAB CO LTD

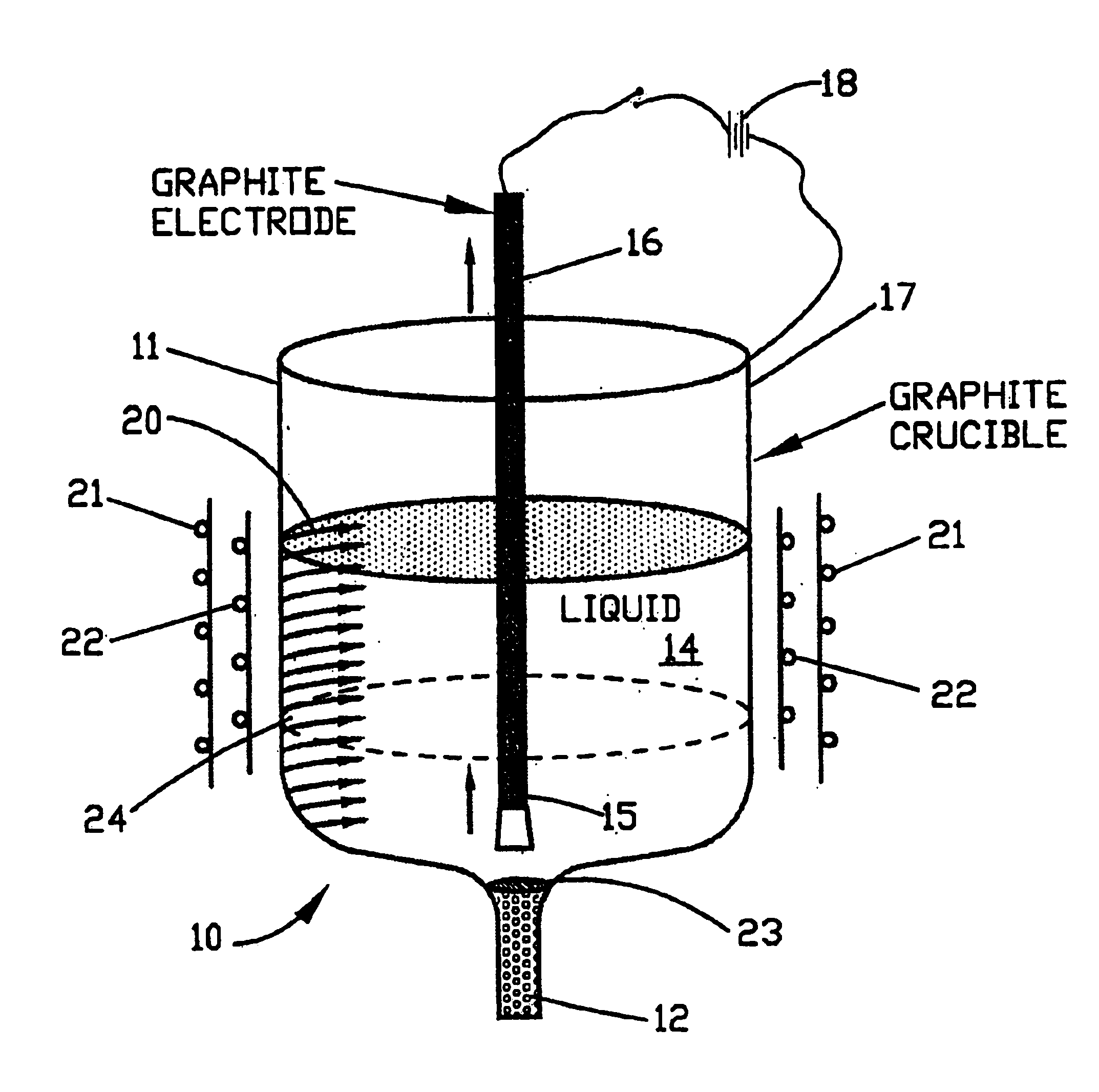

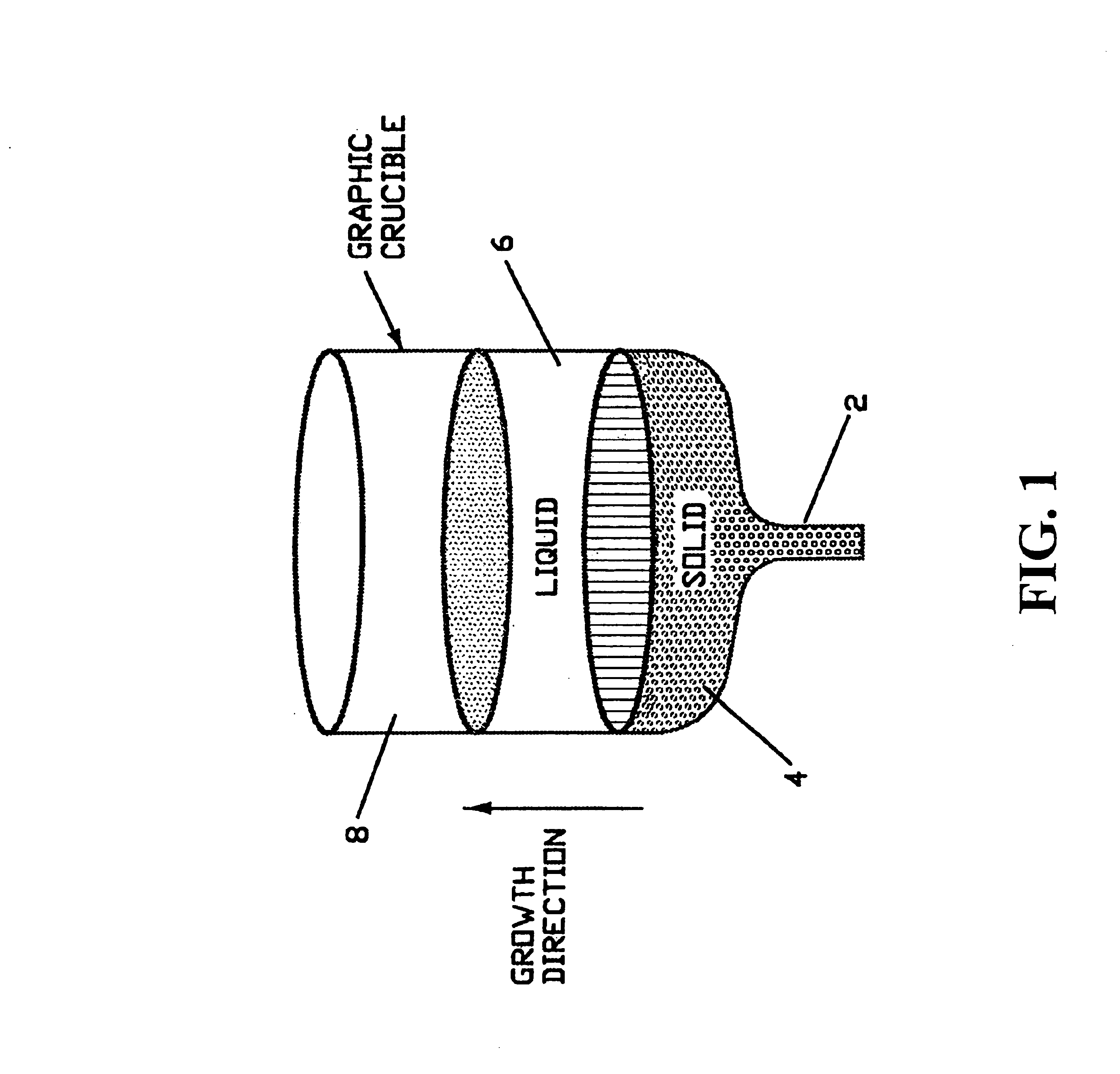

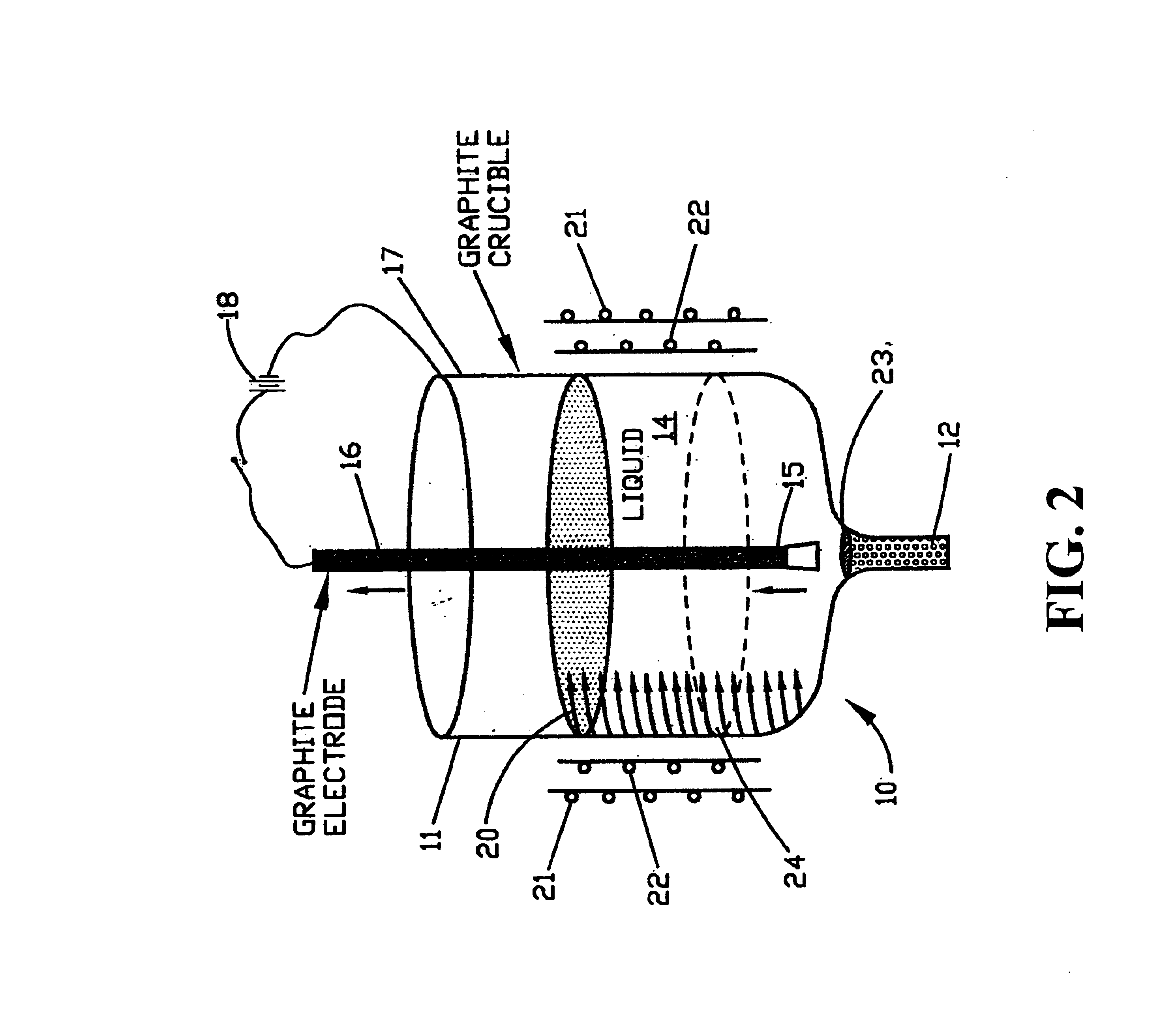

Growth of uniform crystals

InactiveUS6849121B1Easy to unifyLower melting temperaturePolycrystalline material growthFrom melt solutionsMolten stateSeed crystal

The invention provides for growing semiconductor and other crystals by loading a vessel in its lower portion with a seed crystal, loading a charge thereon in the vessel, heating the charge to a molten state and electromagnetically stirring the melt using magnetic and electric fields to obtain a more uniform composition of melt and slowly reducing the temperature of the melt over the crystal to grow a more uniform crystal from such stirred melt.

Owner:AIR FORCE UNITED STATES OF AMERICA AS REPRESENTED BY THE SEC OF

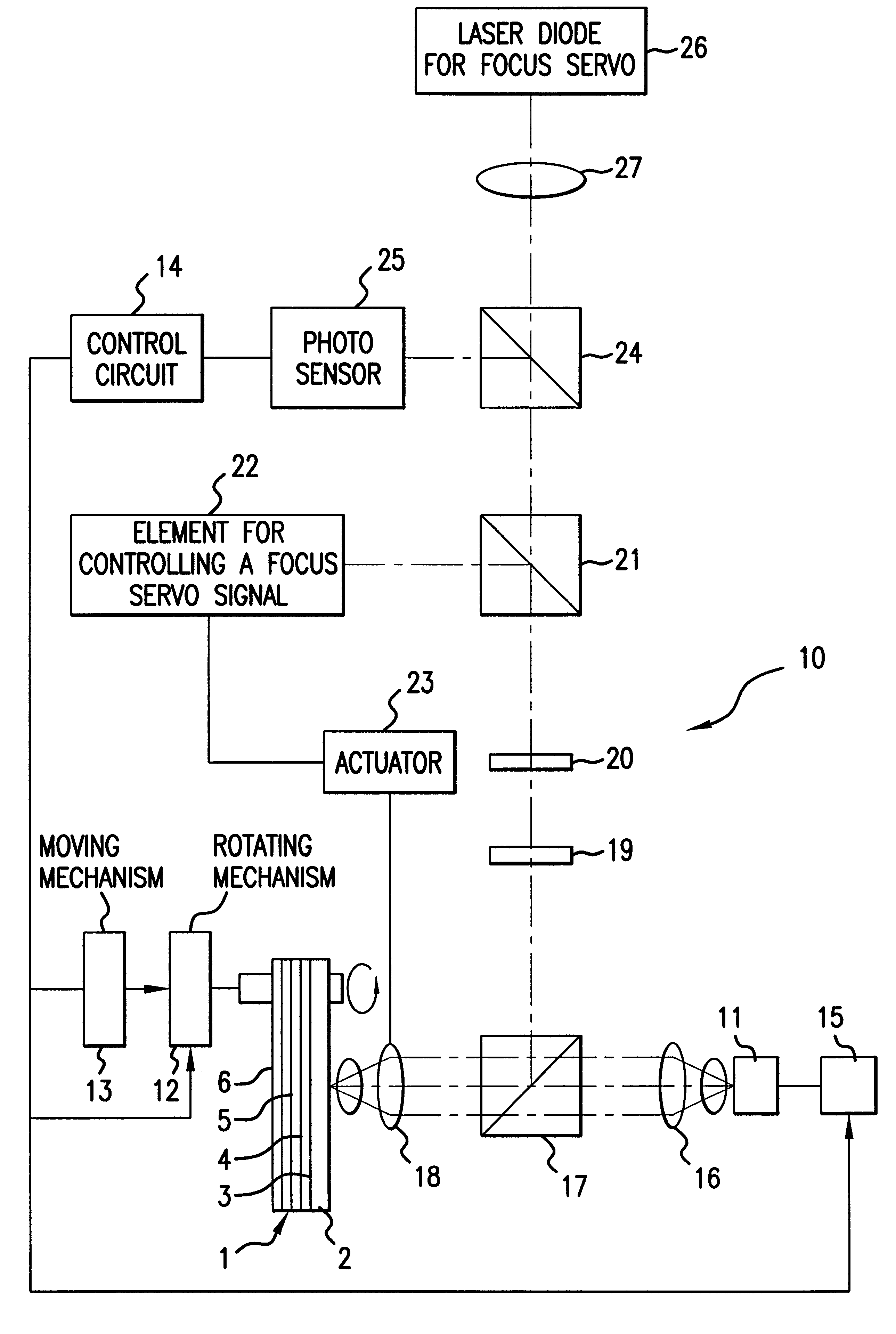

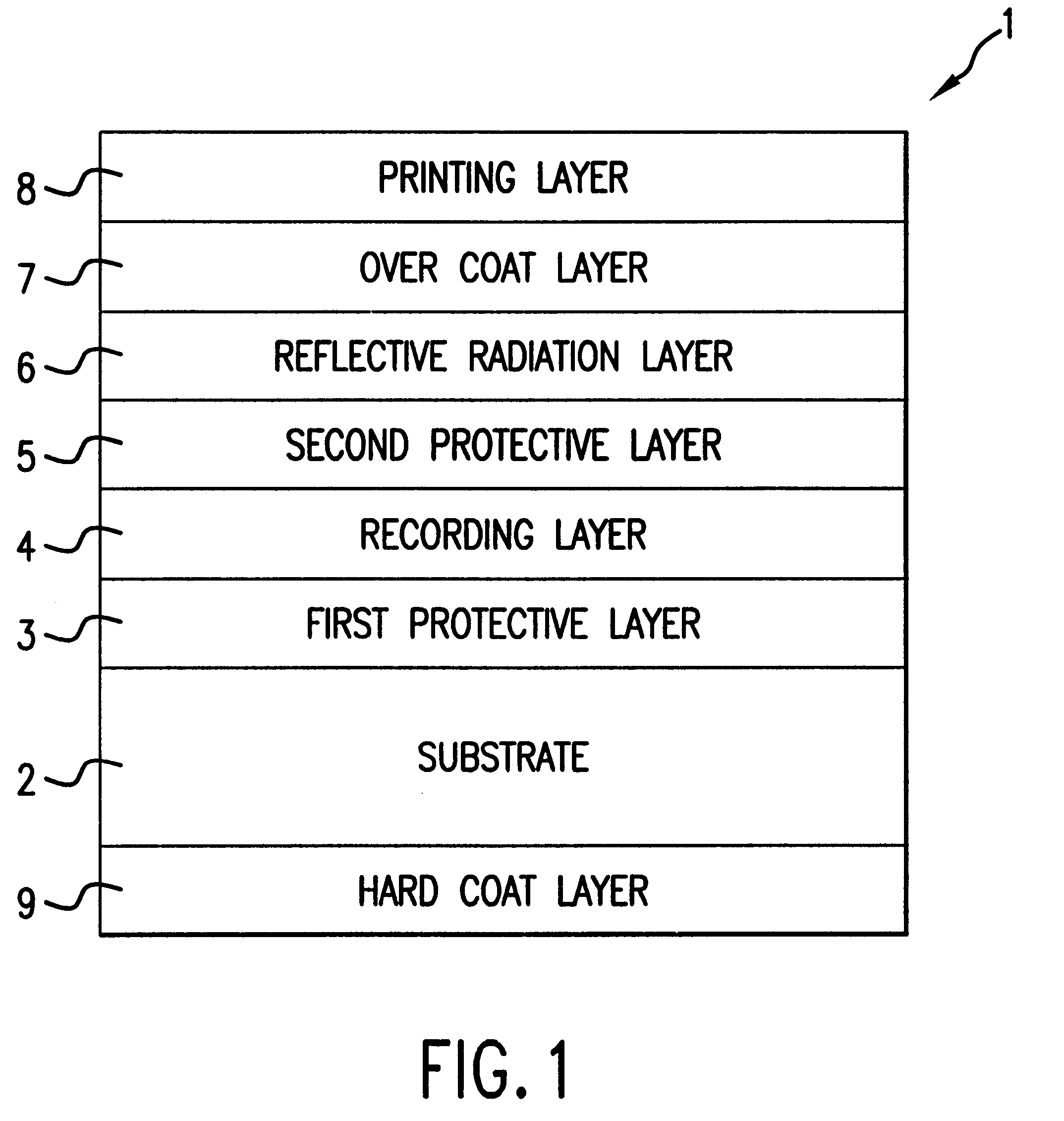

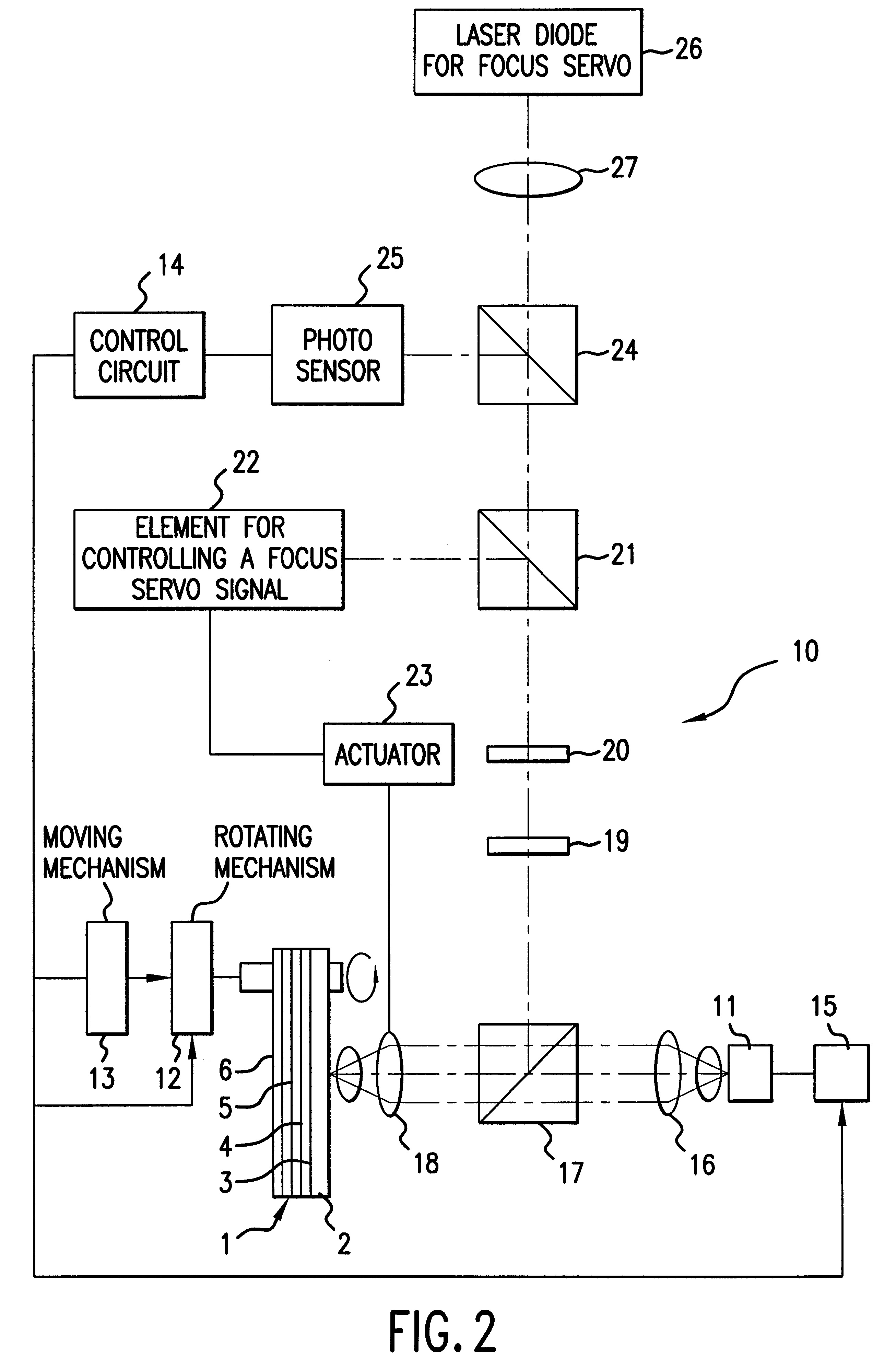

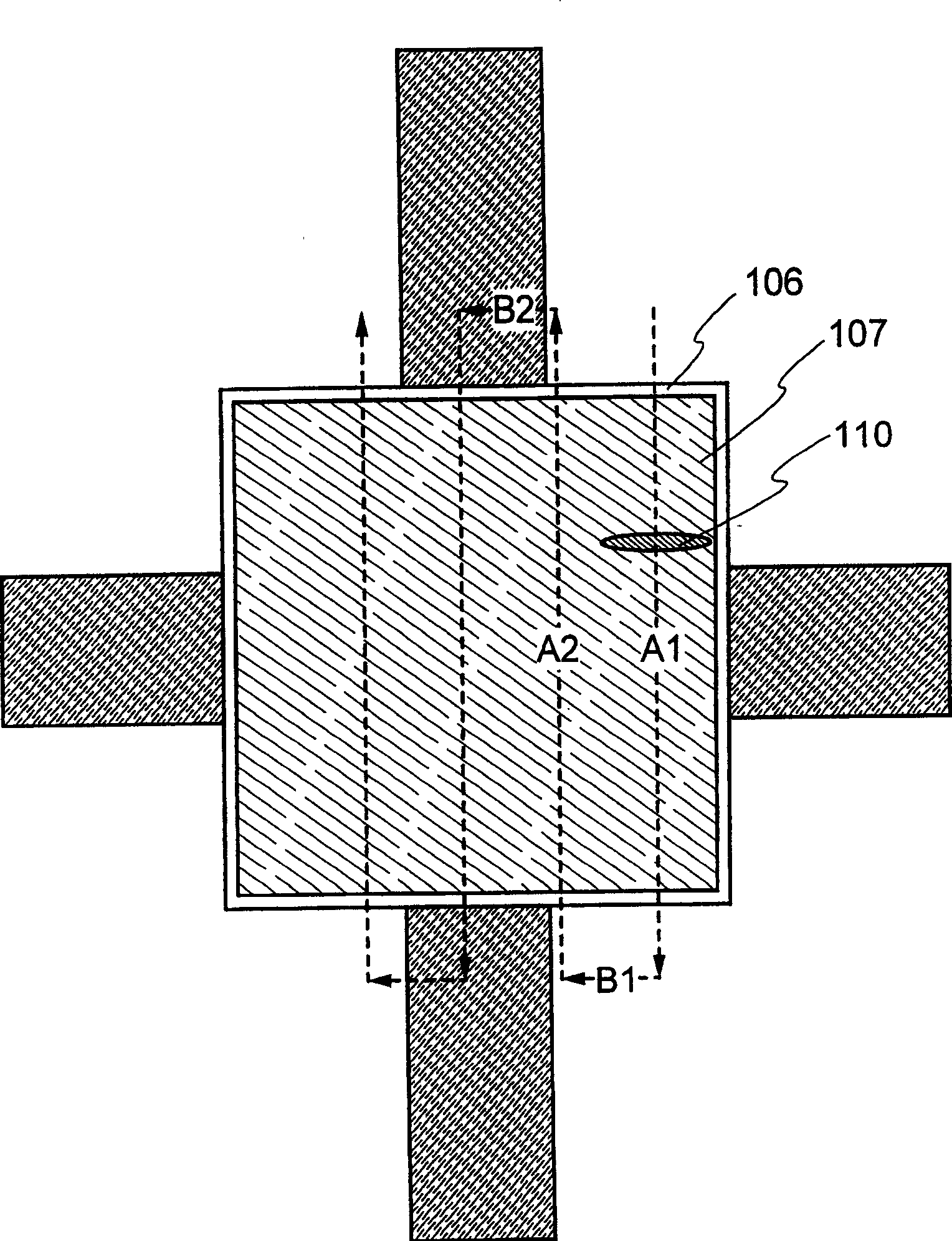

Method and apparatus for initializing optical recording media

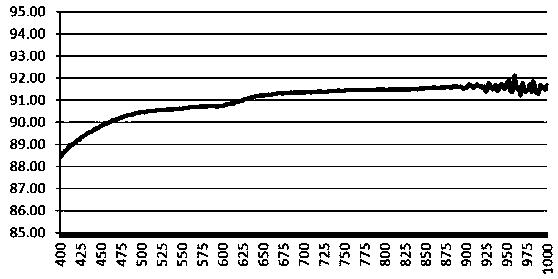

InactiveUS6373802B1Prevent poor initializing conditionUniform crystallizationCombination recordingDisposition/mounting of recording headsPhase changeOptical recording

A method and apparatus for initializing optical recording media is provided that detects the intensity of a reflective light off of an optical recording media and analyzes the initializing condition based on the detected intensity during an initializing process. The light is radiated on a rotating phase-change optical recording medium. The light may be moved in a radial direction of the optical recording medium. The detected intensity of the reflected light may be used to identify crystallized portions and amorphous portions of the optical media. The initialization process can be adaptively controlled to ensure proper initialization. If desired, re-initialization can be limited to those areas detected to be outside of the predetermined parameters.

Owner:RICOH KK

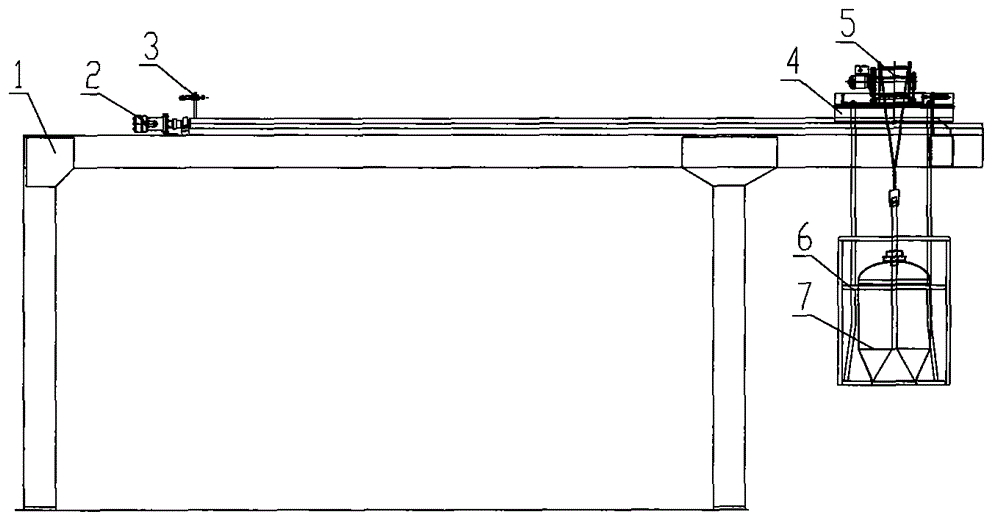

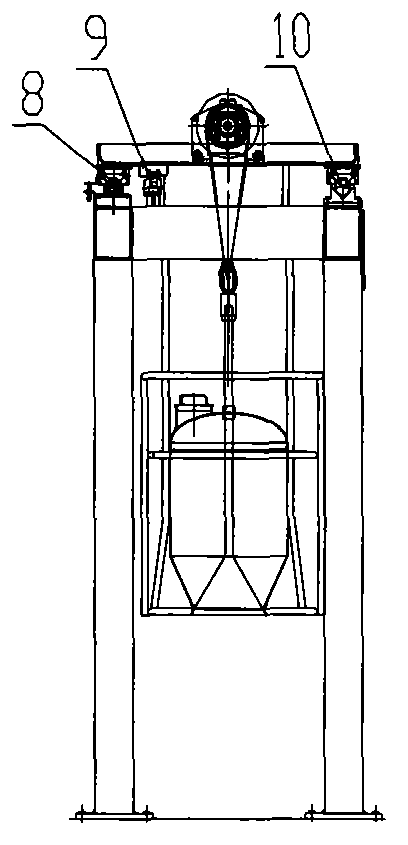

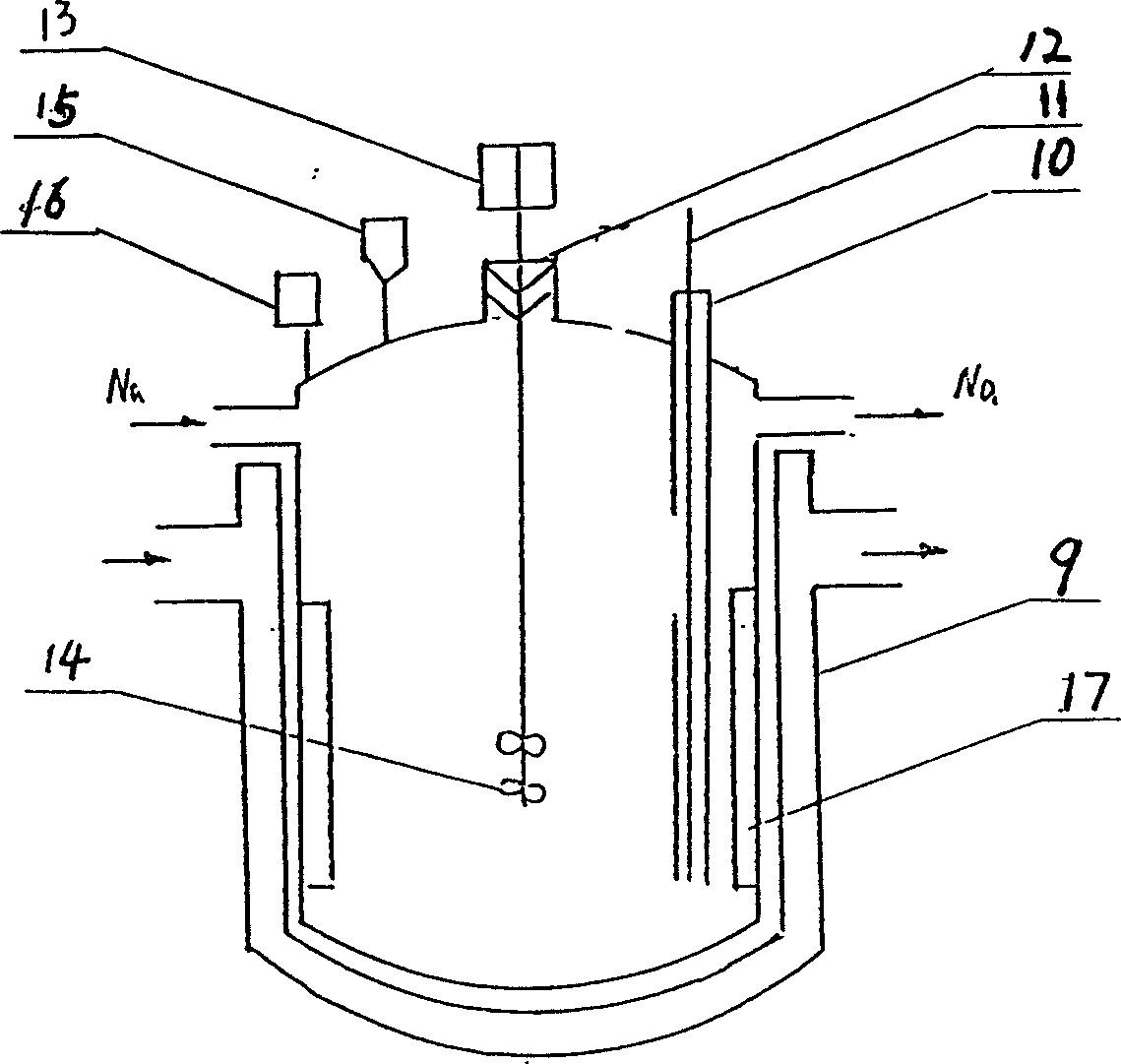

Detonating tool explosive casting automatic production technology and equipment

ActiveCN102944139ASolve technical bottlenecksIncrease production capacityBlasting cartridgesDetonatorSolid particle

The invention belongs to the technical field of production of detonators in civil explosion industry, and particularly relates to a detonating tool explosive casting automatic production technology and equipment. The technology comprises the following steps of removing impurities from raw materials, weighing the raw materials, putting the materials into a melting device by a lifting and delivery device to melt, putting the melted materials in a mixing tank, adding solid particles into the melted materials to mix, carrying out riser assembly on a riser and other assemblies, carrying out one-time multiple-mold quantitative casting in the explosive casting procedure after uniform mixing of the materials, delivering the cast grain to the treatment procedure by a delivery machine to carry out gradient cooling treatment, then delivering the cast grain to a stripping procedure to carry out integral stripping, removing the riser, separating the riser from the explosive, cleaning the riser for repetitive use, inspecting the grain, and directly packing the finished grain. The technology and the equipment have the advantages that the flow process is simple, safe and reliable; the one-time multiple-mold casting of the riser is adopted, so the automatic and continuous production is realized, the energy consumption is reduced, the labor and the material are saved, and the production efficiency and the product quality are improved.

Owner:CHINA WUZHOU ENG GRP +2

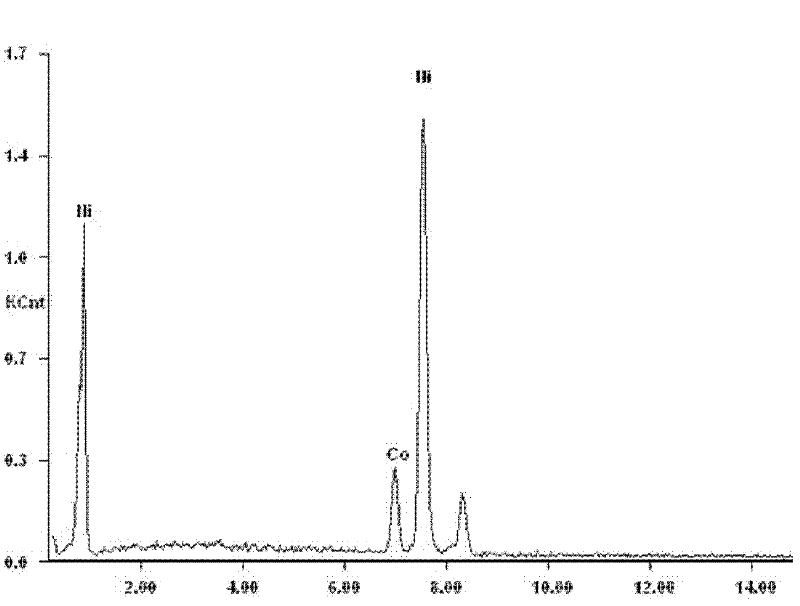

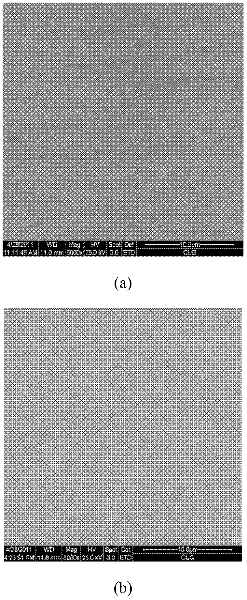

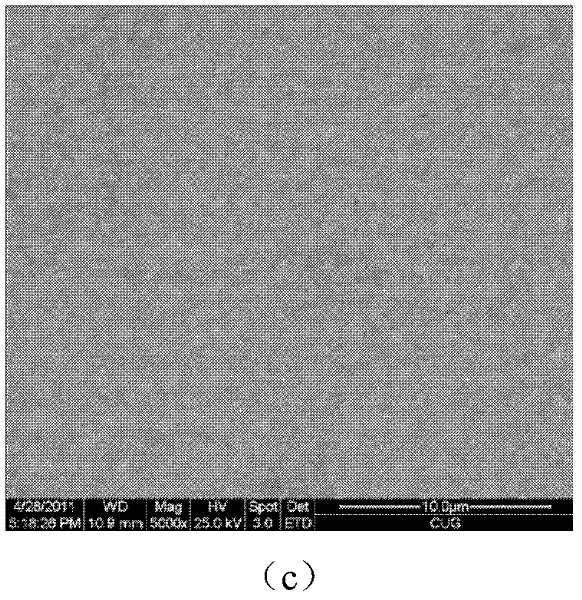

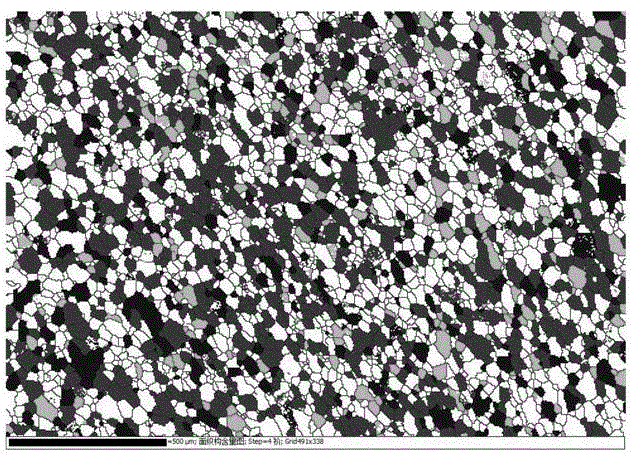

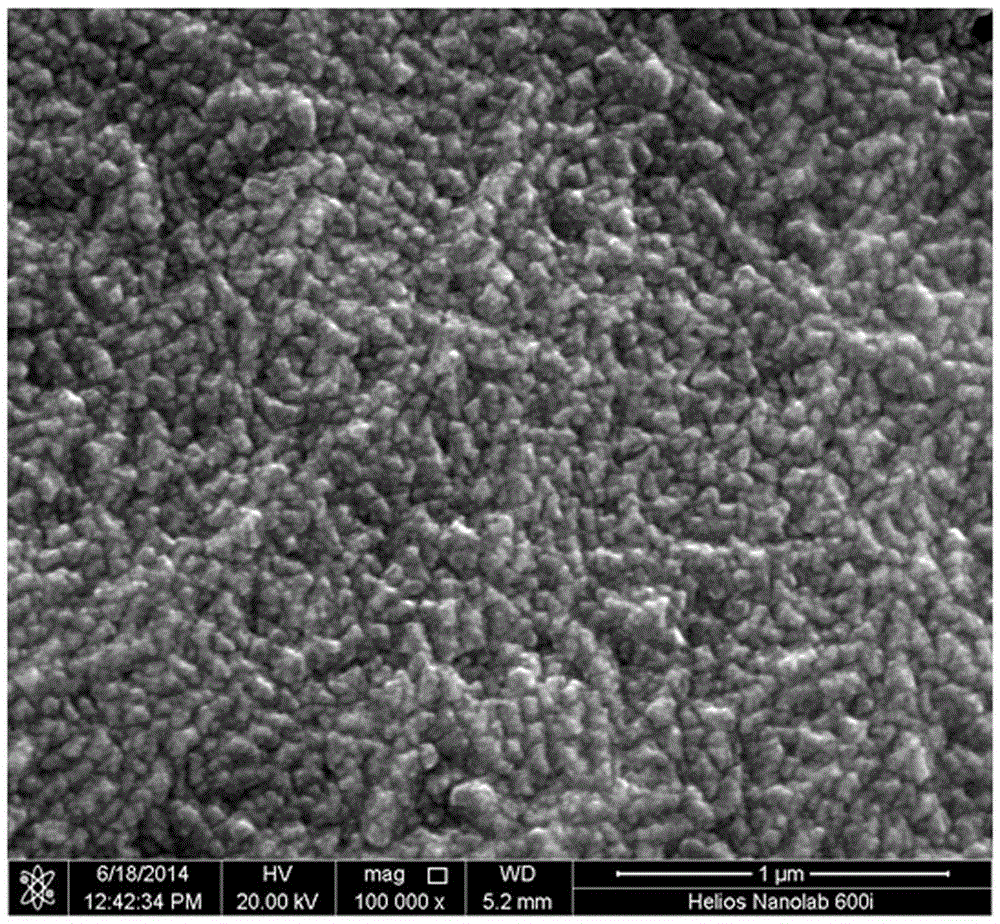

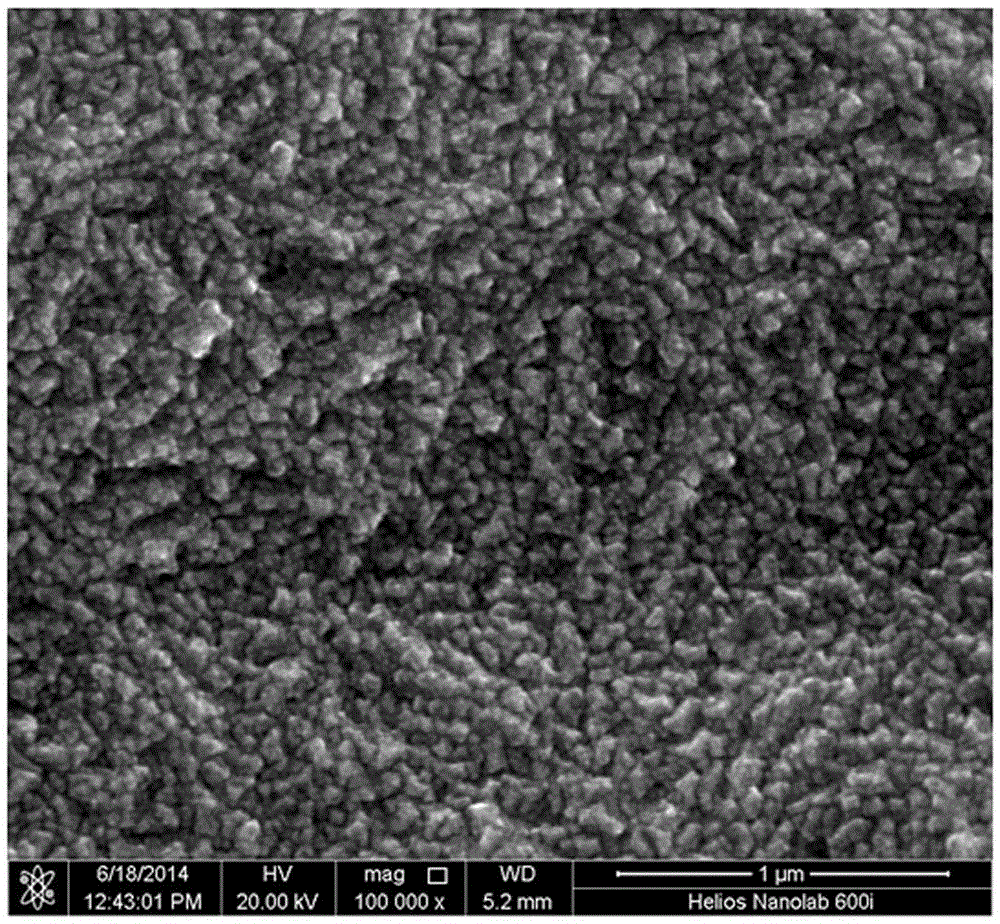

Method for double-pulse electrodeposition of nanocrystalline nickel-cobalt alloy

InactiveCN102260891AUniform crystallizationCrystal fineMaterial nanotechnologyPhotography auxillary processesElectroplatingNickel ions

The invention relates to a method for electrodepositing a nanocrystalline nickel-cobalt alloy by double-pulse. The method for electrodepositing the nanocrystalline nickel-cobalt alloy by double-pulse is characterized by comprising the following processing steps: in a plating solution with a pH value of 5-6, a nickel ion concentration of 0.68-0.95 mol / L and a cobalt ion concentration of 1.9*10<-2>to 3.8*10<-2> mol / L, taking a soluble nickel plate after the soluble nickel plate is subjected to surface treating as a anode, taking an iron sheet after the iron sheet is subjected to surface treating as a cathode and electroplating a nanocrystalline nickel-cobalt alloy layer by using double-pulse electrodepositing technology, wherein the time for electrodepositing is 15-20 min, the positive-going pulse current density is 1.0-2.0 A / dm<2>, the positive-going duty ratio is 60-80%, the working time of the positive-going pulse is 50-100 ms and the positive-going cycle is 40-60 ms; and the negative-going pulse current density is 0.1-0.2 A / dm<2>, the negative-going duty ratio is 60-80%, the working time of the negative-going pulse is 10-20 ms, the negative-going cycle is 1-2 ms and the workingtime of the positive-going pulse is 5-10 times of that of the negative-going pulse. The nickel-cobalt alloy coating prepared by the method has the advantages of smooth surface, compact structure, fine and even crystal, good smoothness, no crack and excellent corrosion resistance.

Owner:CHINA UNIV OF GEOSCIENCES (WUHAN)

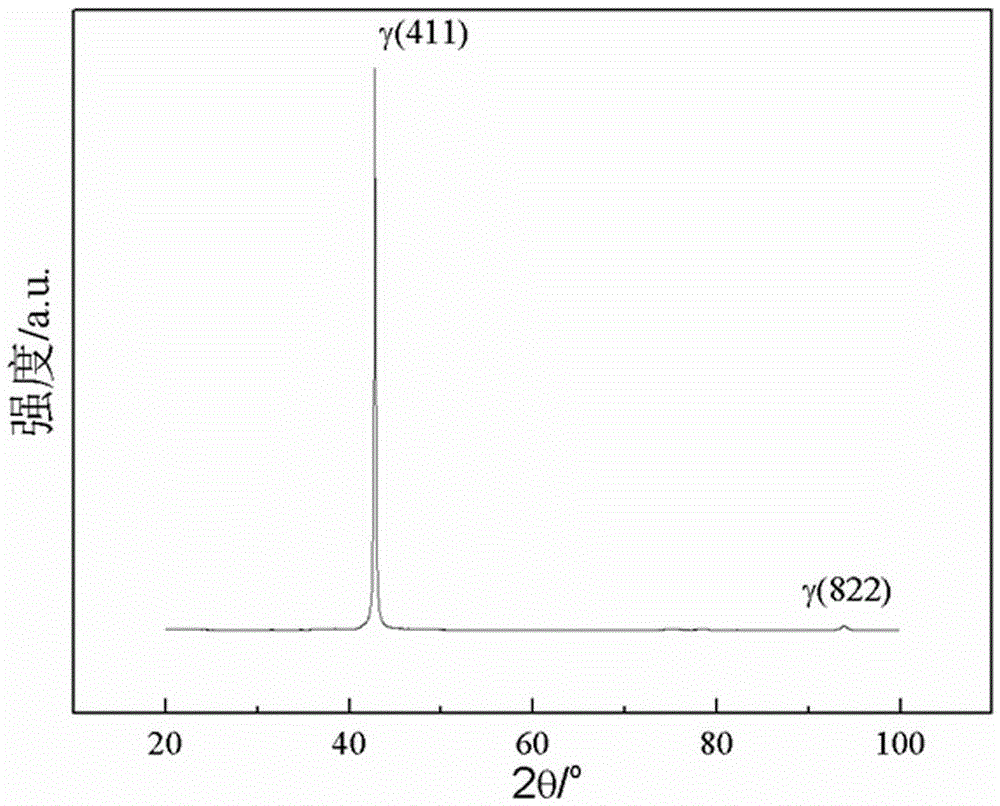

Tantalum target and manufacturing method thereof

ActiveCN104451567AFully brokenUniform deformationVacuum evaporation coatingSputtering coatingIngotThermal treatment

The invention provides a tantalum target and a manufacturing method thereof; the manufacturing method comprises the steps: firstly, performing a first forging to a tantalum ingot and obtaining a primary forged blank; performing a second forging and a first thermal treatment to the primary forged blank obtained in the previous step and obtaining a secondary forged blank; performing a third forging and a second thermal treatment to the secondary forged blank obtained in the previous step and obtaining a tertiary forged blank; performing a fourth forging and a third thermal treatment to the tertiary forged blank obtained in the previous step and obtaining a quartus forged blank; and finally, rolling and performing a fourth thermal treatment to the quartus forged blank obtained in the previous step and obtaining the tantalum target; the first forging is a rotary forging; the temperature of the first forging is 800-1400 degrees centigrade. The prepared tantalum target is uniform in texture distribution, small in grain size and capable of satisfying usage requirements in high-level semiconductor film-coating industries.

Owner:NINGXIA ORIENT TANTALUM IND

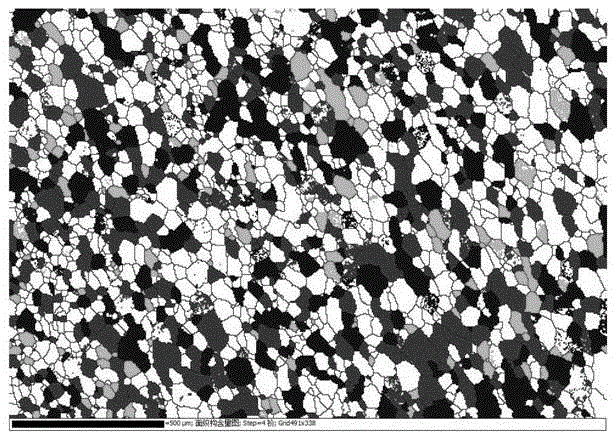

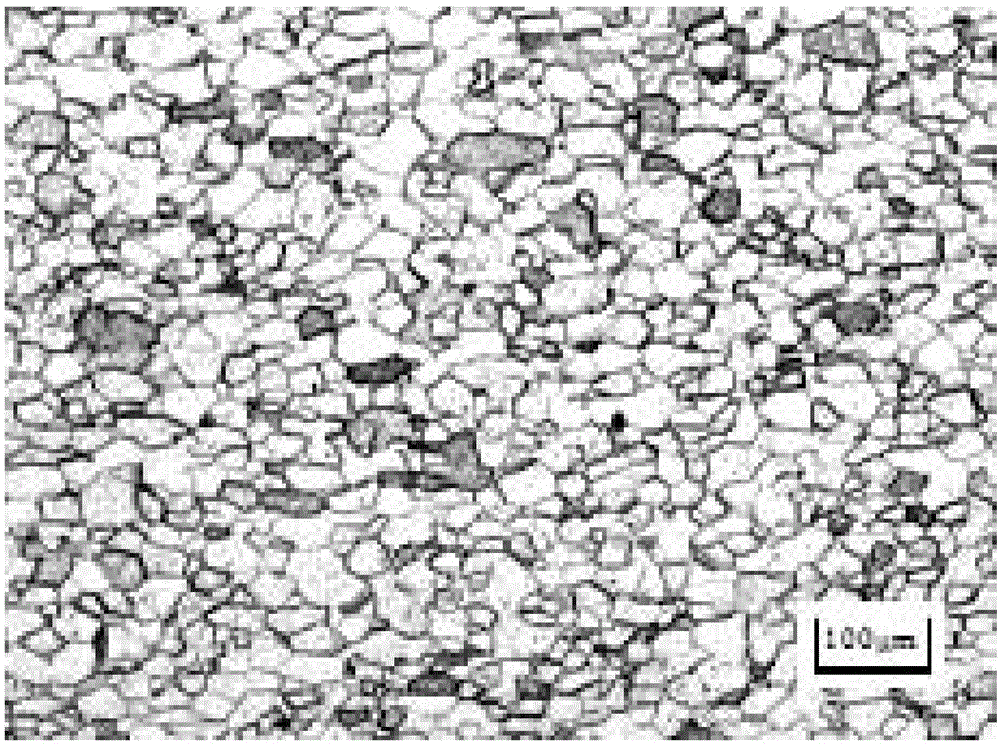

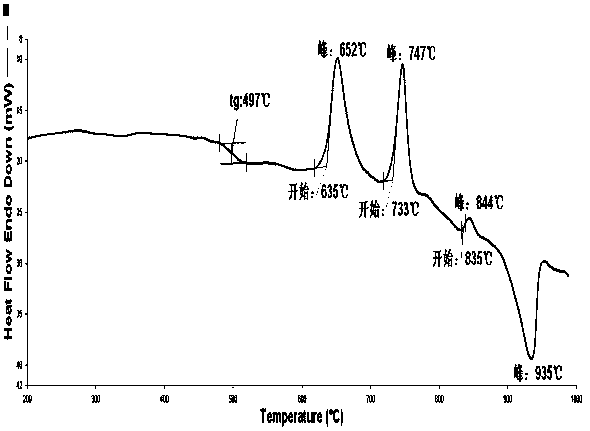

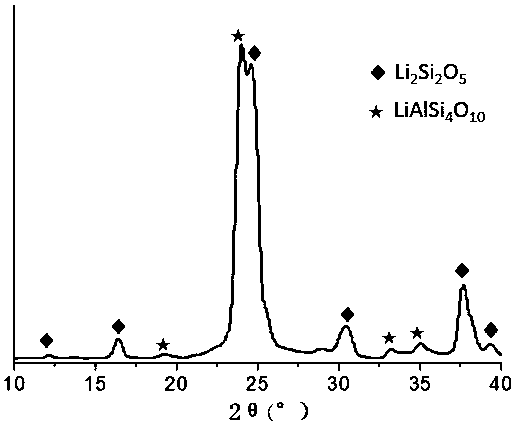

High-strength transparent glass ceramic

The invention belongs to the technical field of glass ceramic materials, and concretely relates to a high-strength transparent glass ceramic. The glass ceramic comprises, by mass, 65-73% of SiO2, 3-10% of Al2O3, 1.5-4% of Na2O, 10-14% of Li2O, 1.5-4% of P2O5, 1.5-5% of Zr2O and 0-1% of a clarifier, a ratio of (Al2O3+ZrO2) to P2O5 is equal to or more than 2 and equal to or less than 6; and a ratioof P2O5 to (Na2O + K2O) is more than -0.5 and less than 0.5, and the crystal phase of the high-strength transparent glass ceramic contains Li2Si2O5 or LiAlSi4O10. The glass ceramic of the present invention has a transmittance of at least 88% and the surface Vickers hardness after reinforcement is at least 750 kgf / mm<2>.

Owner:KORNERSTONE MATERIALS TECH

Polypropylene composite capable of resisting thermal oxidizing aging

InactiveCN102408630AImprove interface bonding performancePrevent free diffusionPolypropylene compositesPolymer science

The invention discloses a polypropylene composite capable of resisting thermal oxidizing aging, comprising the following components based on weight percentages: 40-82% of polypropylene resin, 2-10% of compatilizer, 10-40% of filler, 0.2-0.5% of nucleating agent, 2-10% of anti-oxidant synergistic agent, 0.2-1.0% of anti-oxidant and 0.2-1.0% of processing agent, wherein the polypropylene resin is a mixture of homopolymerized polypropylene and block copolymerization polypropylene; the compatilizer is graft polymer of polypropylene and unsaturated carboxylic acid or its anhydride. The advantages are as follows: the nucleating agent is a substance which makes the sphaerocrystal of the polypropylene more refine, the crystallization more homogenized and regularized, and increases the crystallinity; the anti-oxidant synergistic agent is one of or a mixture of fluoropolymer and polysiloxane. The composite has both mechanics performance and performance of resisting thermal oxidizing aging. In addition, the anti-oxidant synergistic agent has a very low surface tension and has a trend of migrating and assigning to the surface of the composite during the forming and use process. The configuration of the anti-oxidant synergistic agent has an effect of separating oxygen molecules, and can lower the ratio of the oxygen entering the base body through the surface of the composite such that the performance of resisting thermal oxidizing aging for the polypropylene is increased.

Owner:KINGFA SCI & TECH CO LTD +1

Acid cleaning and phosphorizing method of electromobile frame

InactiveCN103243338AReduce labor intensityModerate thicknessMetallic material coating processesSurface conditionsDisposal Technique

The invention relates to an acid cleaning and phosphorizing method of an electromobile frame, belonging to the technical field of metal surface treatment. The method comprises the following steps: (1) degreasing the metal frame; (2) cleaning with water; (3) immersing the metal frame in an acid cleaning solution to carry out acid cleaning; (4) flushing with water; (5) immersing in a surface conditioning tank to carry out surface conditioning; (6) immersing in a phosphorizing tank to carry out phosphorization and film formation; (7) cleaning in a clean water tank; and (8) drying in a phosphorizing line baking oven. The invention has the advantages of low technical difficulty, strong operability, simple technique, low deposit amount, high film formation speed, is simple and convenient for maintenance, greatly lowers the labor intensity of workers, and reduces the technical pollution; and the finally obtained grey phosphorized film has the advantages of uniform crystallization and moderate thickness, and greatly prolongs the service life of the electromobile metal frame.

Owner:山东威斯特车业有限公司

Manufacture method of fused cast zirconia-alumina brick

InactiveCN101648811AImprove high temperature resistanceImprove corrosion resistanceBrickEconomic benefits

The invention discloses a manufacture method of a fused cast zirconia-alumina brick. The brick is prepared from 35.69% of zircon sand, 15.3% of zirconia, 47.01% of powdered alumina and 2% of sodium carbonate. The manufacture method comprises the following steps: 1. weighing the raw materials in weight percent and then evenly mixing; 2. adding the mixed raw materials after the furnace temperature rises to 1850 DEG C, and then heating up to melt for 90 minutes; 3. keeping the temperature for 30 minutes after the furnace temperature rises to 2780-2800 DEG C, and then carrying out secondary oxygenblowing; 4. lowering the furnace temperature to 1860-1880 DEG C for casting after the oxygen blowing, and carrying out deep gas discharge and afterteeming of a casting solution in a mouldboard; 5. and annealing. The brick has obvious high temperature resistance and erosion-resistant performance when being used on a glass kiln; compared with the original zircon corundum bricks, the service life ofthe fused cast zirconia-alumina brick is prolonged by two years, thereby bringing considerable economic benefits to users. The fused cast zirconia-alumina brick receives authorization and trust fromexperts and clients of dozens of countries, such as Japan, Britain, France, India and the like.

Owner:ZHENGZHOU XINGUANGSE REFRACTORY

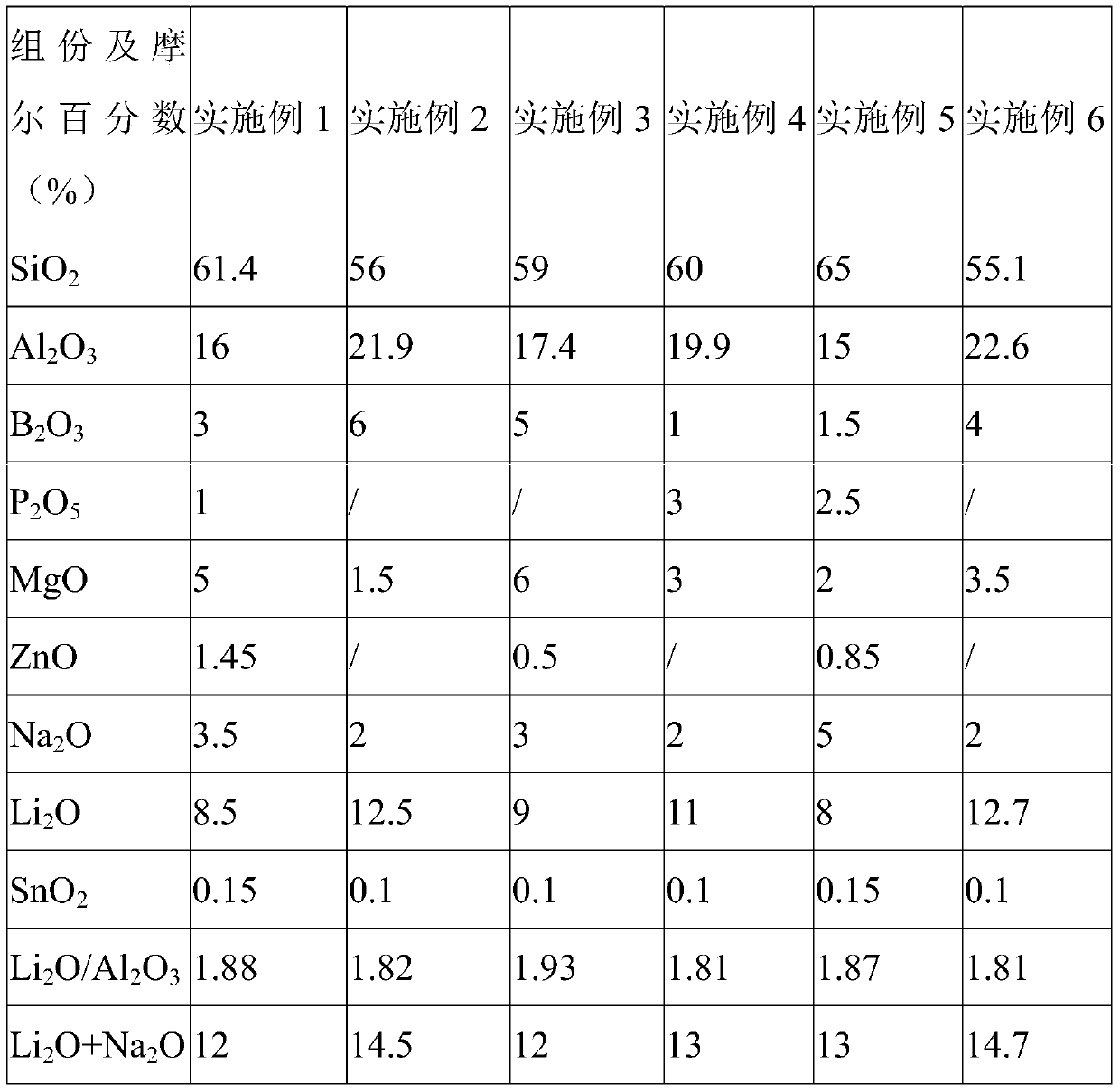

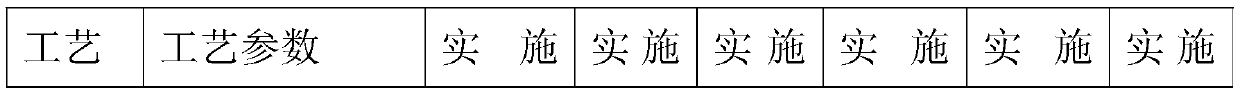

Chemically strengthenable self-crystallizing glass ceramic and preparation method thereof

ActiveCN110104955AFasten the network structureHigh mechanical strengthGlass forming apparatusGlass rolling apparatusLithiumQuartz

The invention discloses a chemically strengthenable self-crystallizing glass ceramic and a preparation method thereof. The glass ceramic has crystals with the average crystal size ranging from 5 nm to60 nm, a main crystal phase of the crystals is at least one of a beta quartz solid solution, nepheline and a nepheline solid solution, the crystals account for 30%-90% by mass of the glass ceramic, and the glass ceramic contains 8%-13% of Li2O by mole, the content ratio of Al2O3 to Li2O is greater than or equal to 1.8, the sum of the content of the Li2O and the content of the Na2O is 10% to 15%,and nucleating agents ZrO2, TiO2 and fluoride are not added in the glass ceramic. The glass ceramic has the advantages of high aluminum content, high lithium content and low sodium content in composition, and contains no nucleating agent; the high lithium content increases the crystallization tendency of the glass substrate to realize uniform crystallization; the crystal growth speed can be controlled by the high aluminum content, so that the glass ceramic network structure is firm, and the mechanical strength is improved; the low nano content can reduce the dielectric constant of the glass ceramic.

Owner:CHONGQING XINJING SPECIAL GLASS CO LTD +1

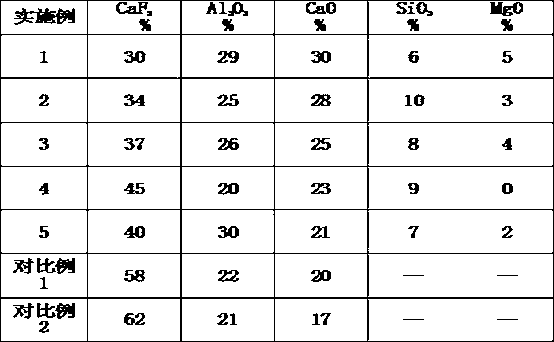

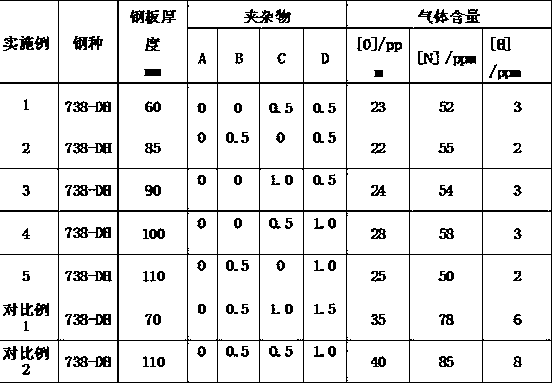

Electroslag remelting slag for smelting plastic mould steel and preparation method thereof

The invention discloses an electroslag remelting slag for smelting plastic mould steel. The slag comprises the following raw materials by mass percent: 30-45% of CaF2, 20-30% of Al2O3, 20-30% of CaO and 5-10% of SiO2. A preparation method comprises steps of: uniformly mixing the added raw materials; roasting; slugging; and standby applying. The viscosity of the electroslag remelting slag can be increased, the air permeability of the electroslag remelting slag can be lowered, moreover, the environmental pollution can be reduced, and the thermal efficiency and electrical efficiency of electroslag remelting are increased; and the plastic mould steel is remolten by an electric furnace and an electroslag furnace, has the thickness of 100-300 millimeters, has high purity, low sulphur content, less non-metallic inclusions, smooth steel ingot surface, uniform and dense crystallization and uniform metal tissue and chemical ingredients, and can fully satisfy market requirements.

Owner:武钢集团有限公司

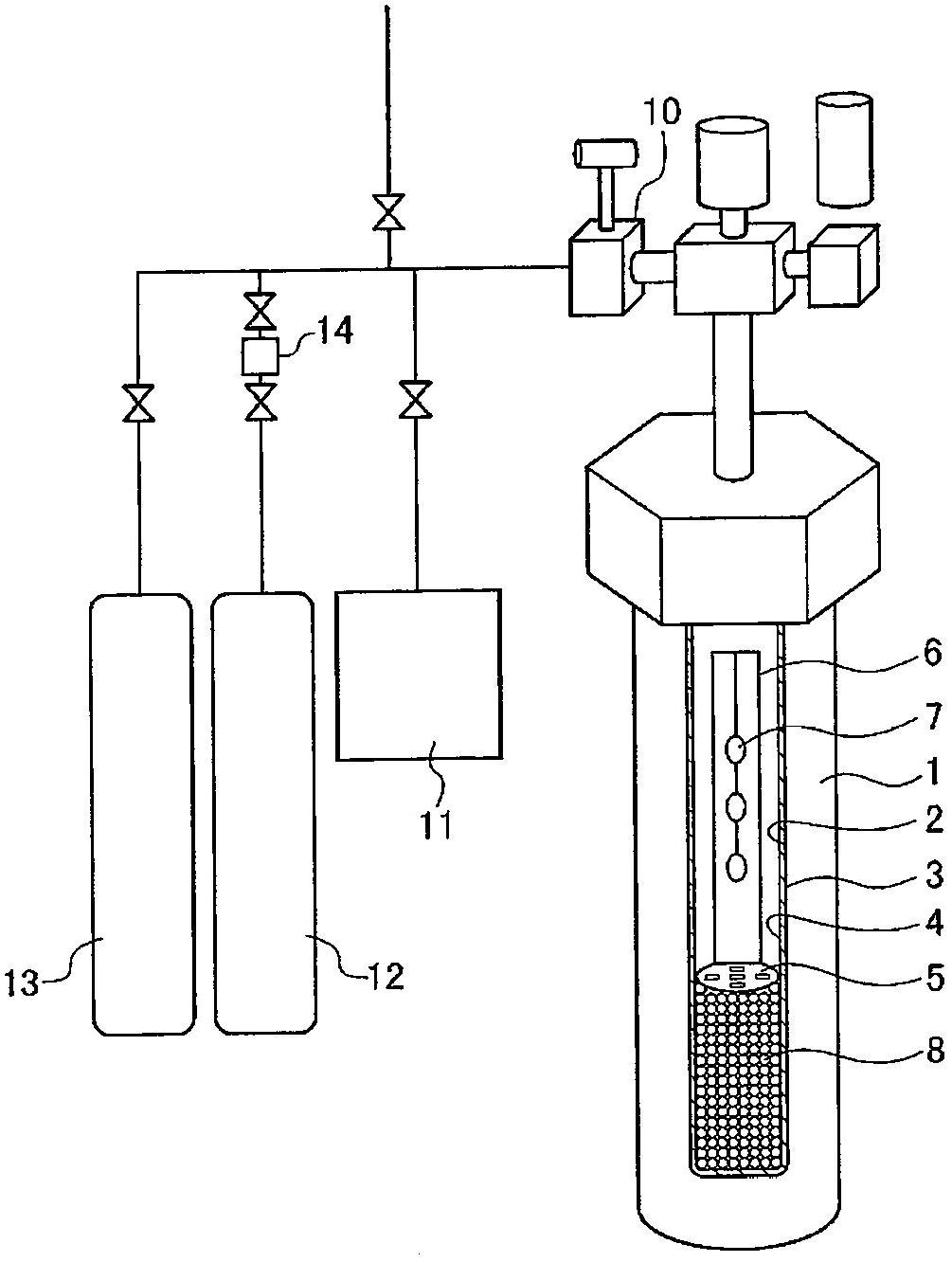

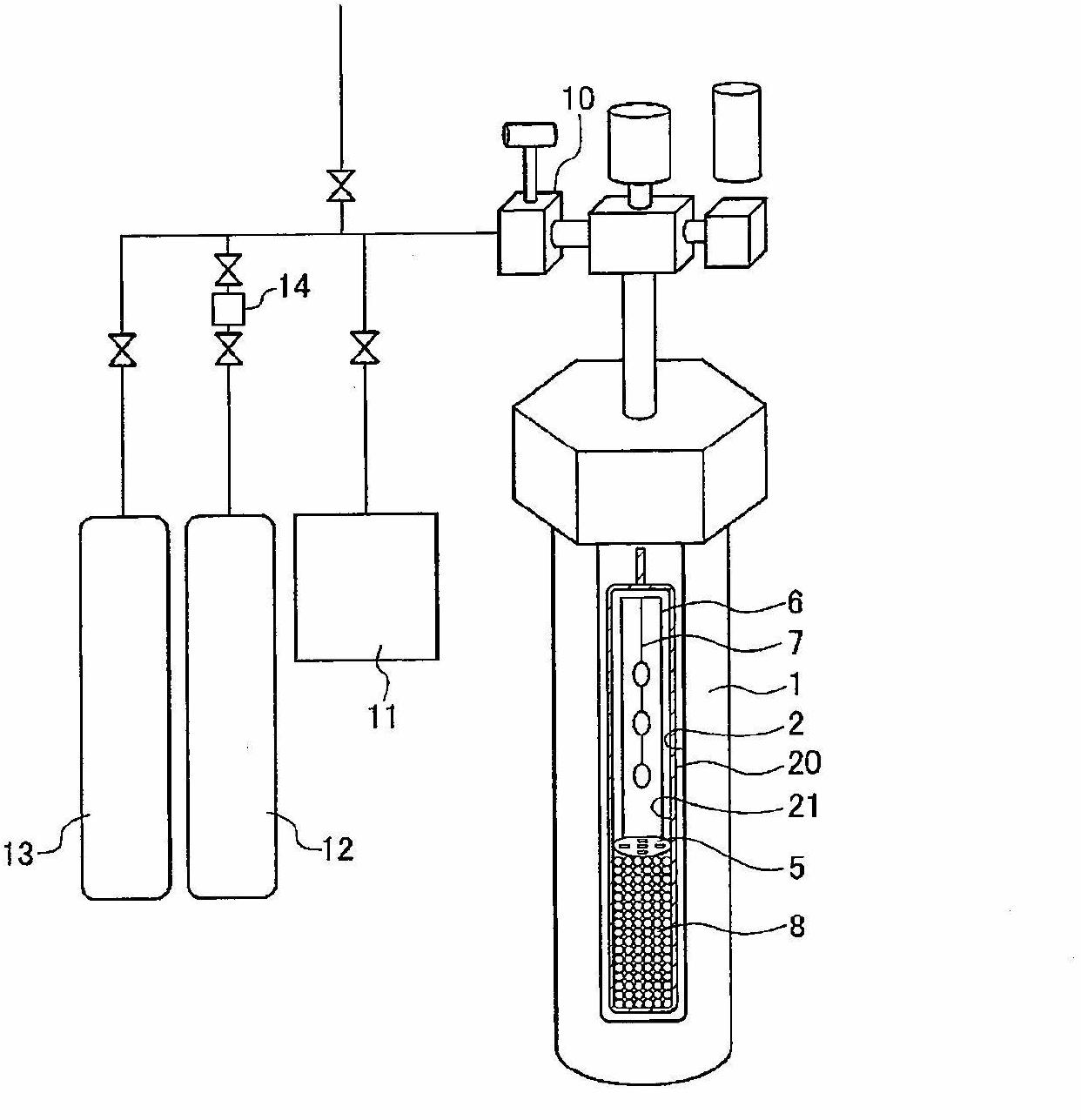

Laser irradiation apparatus and method of manufacturing semiconductor device

InactiveUS7405114B2Efficiently and uniformlySuppress fluctuationsTransistorSolid-state devicesEnergy variationGalvanometer

The present invention provides the laser irradiation apparatus that has a galvanometer mirror and an f-θ lens optical system, can offset the change of the energy due to the transmittance change of the f-θ lens, and can scan a laser beam while the change of the energy on a substrate is suppressed. Further, the laser beam energy that is incident on the lens is controlled in advance by combining the optical system changing the branching ratio of polarization of the laser beam and the optical system having dependence on direction of polarization of the laser beam and changed continuously according to the transmittance of the lens on which the laser beam is incident. The laser energy is controlled to offset the transmittance of the lens, and thereby energy fluctuation of the laser beam irradiation of a substrate can be prevented.

Owner:SEMICON ENERGY LAB CO LTD

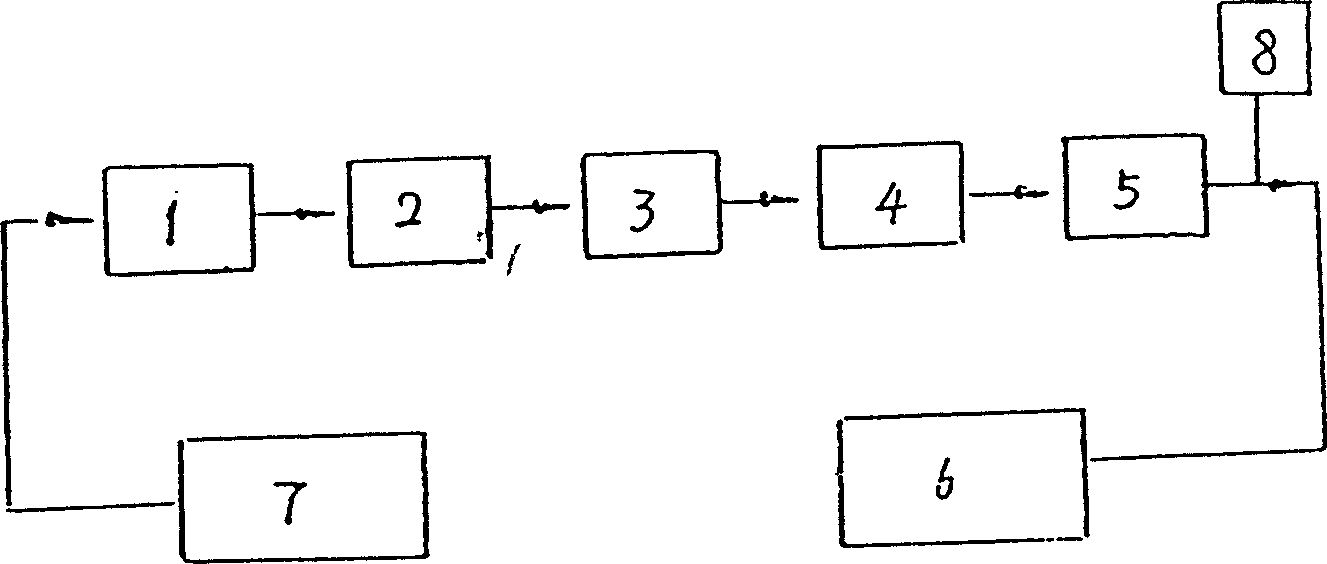

Sodium purifying process and purification system thereof

The invention belongs to alkali metals refinement field, more specificly it relates to the nucleus-grade sodium refinement process and its refinement system for reactor. The process comprises calcium reaction, two stage precipitation and two stage filtering. The refinement system mainly comprises sodium receiving tank, calcium removing reactor, first stage precipitator, first stage filter, second stage precipitator, second stage filter, sodium storage tank and spare cold trap purging loop. The refinement process can make calcium content reduce to below 0.001% from 0.045% of industrial sodium, oxygen content reduce to below 0.003% from 0.025%.

Owner:CHINA INSTITUTE OF ATOMIC ENERGY

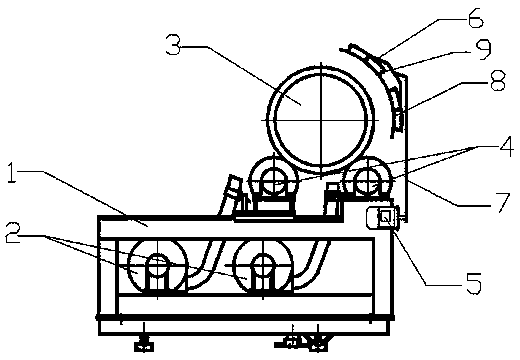

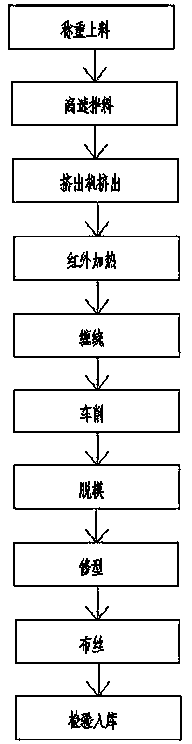

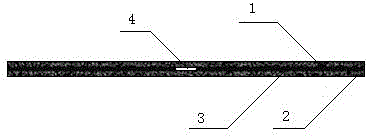

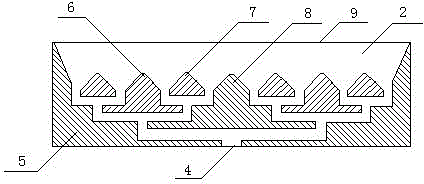

Production equipment and production technology for HDPE (high density polyethylene)spirally enwound structure-wall pipe (Krah pipe)

ActiveCN103963325AReduce manufacturing costImprove heating efficiencyTubular articlesElectric fusesProcess engineering

The invention discloses production equipment and a production technology for an HDPE (high density polyethylene) spirally enwound structure-wall pipe (Krah pipe).The equipment comprises a base trolley, cooling fans, a mold roller, rolling wheels, a servo motor, an infrared heating device and a rotating rod. The technology comprises material mixing, feeding, vacuum feeding, extrusion, enwinding, turning, demolding, modification, electric fuse distribution, inspection and storage. According to the production equipment and the production technology, infrared high-frequency heating is adopted, the heating efficiency is high, the cost is low, and the operation is simple and convenient; the ring stiffness is increased by above 30% due to addition of short-glass-fiber master batches; characteristics of HDPE are adopted, so that the comprehensive performance of the pipe is improved; the weld seam quality of the pipe is guaranteed, and the weld seam quality and the overall external pressure resistance of the pipe are also improved.

Owner:HUNAN QIANYUAN NEW MATERIAL

Alkaline non-cyanide zinc plating nickel alloy plating solution and electroplating process thereof

The invention discloses an alkaline non-cyanide zinc plating nickel alloy plating solution and an electroplating process thereof. The plating solution is prepared with hydantoin or a hydantoin derivative as a main coordination agent by adding an auxiliary coordination agent, zinc sulfate, nickel sulfate, potassium carbonate and water. The plating solution comprises 20 g-400 g / L of the main coordination agent, 5 g-300 g / L of the auxiliary coordination agent, 5 g-200 g / L of the zinc sulfate, 1 g-150 g / L of the nickel sulfate and 5 g-435 g / L of the potassium carbonate. The electroplating process of the plating solution comprises the steps of substrate pretreatment and zinc-nickel alloy electroplating. A constant current electroplating mode is adopted for zinc-nickel alloy electroplating. The electric current density is 0.5 A-5 A / dm2. The temperature of the plating solution is 30 DEG C-60 DEG C. The distance between a cathode and an anode is 0.5 cm-25 cm. The stirring speed of the plating solution is 0 rpm-3000 rpm. The electroplating time is 1 min-120 min. According to the plating solution and the electroplating process thereof, the hydantoin or the hydantoin derivative serves as the main coordination agent for the first time, and zinc-nickel alloy with the nickel content of 10 wt.%-13 wt.% is obtained through electro-deposition by using the main coordination agent and the auxiliary coordination agent in a combination mode. An obtained coating is good in corrosion resistance. The stability of the plating solution is improved immensely compared with using of a single coordination agent.

Owner:宏正(福建)化学品有限公司

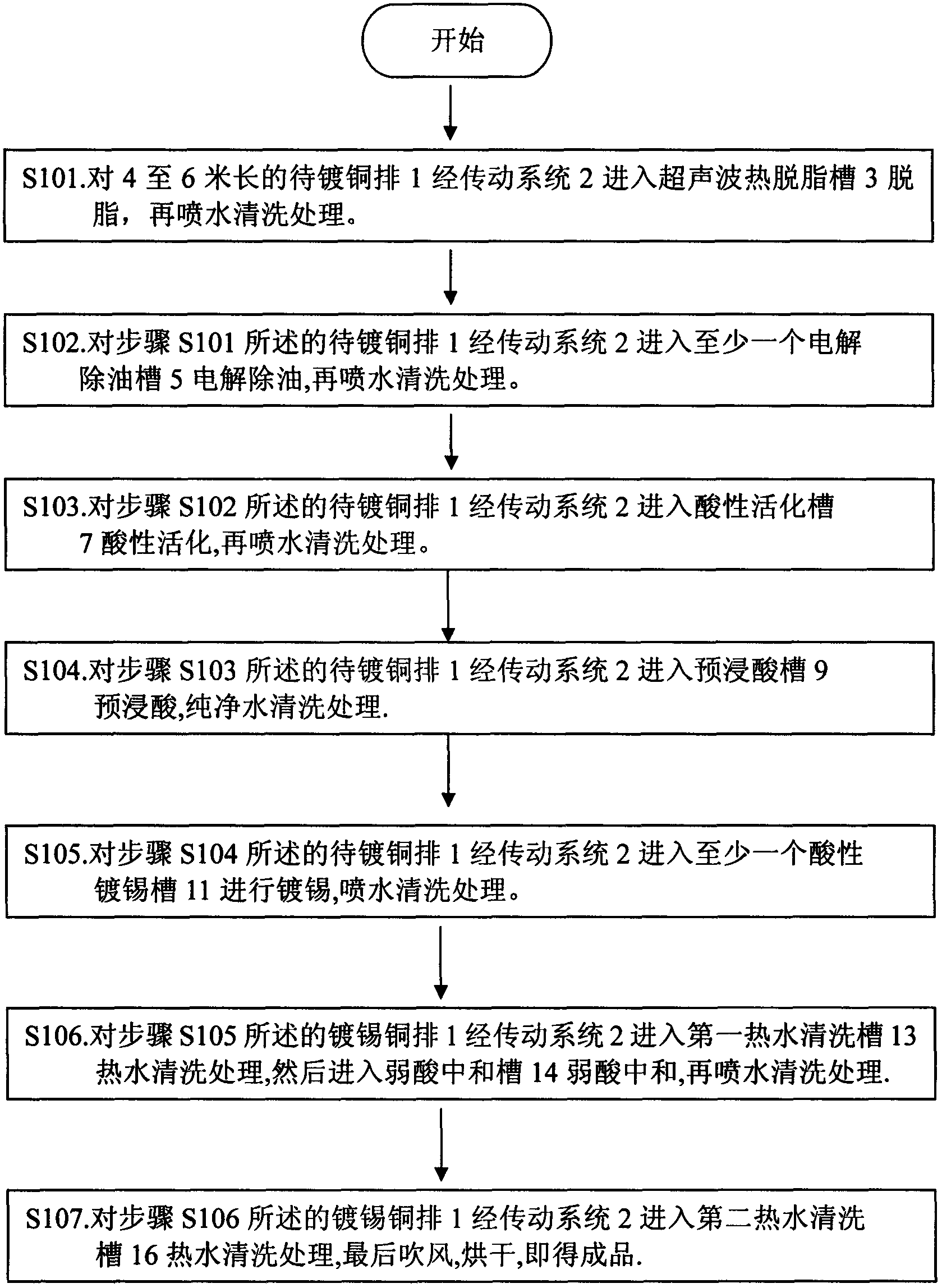

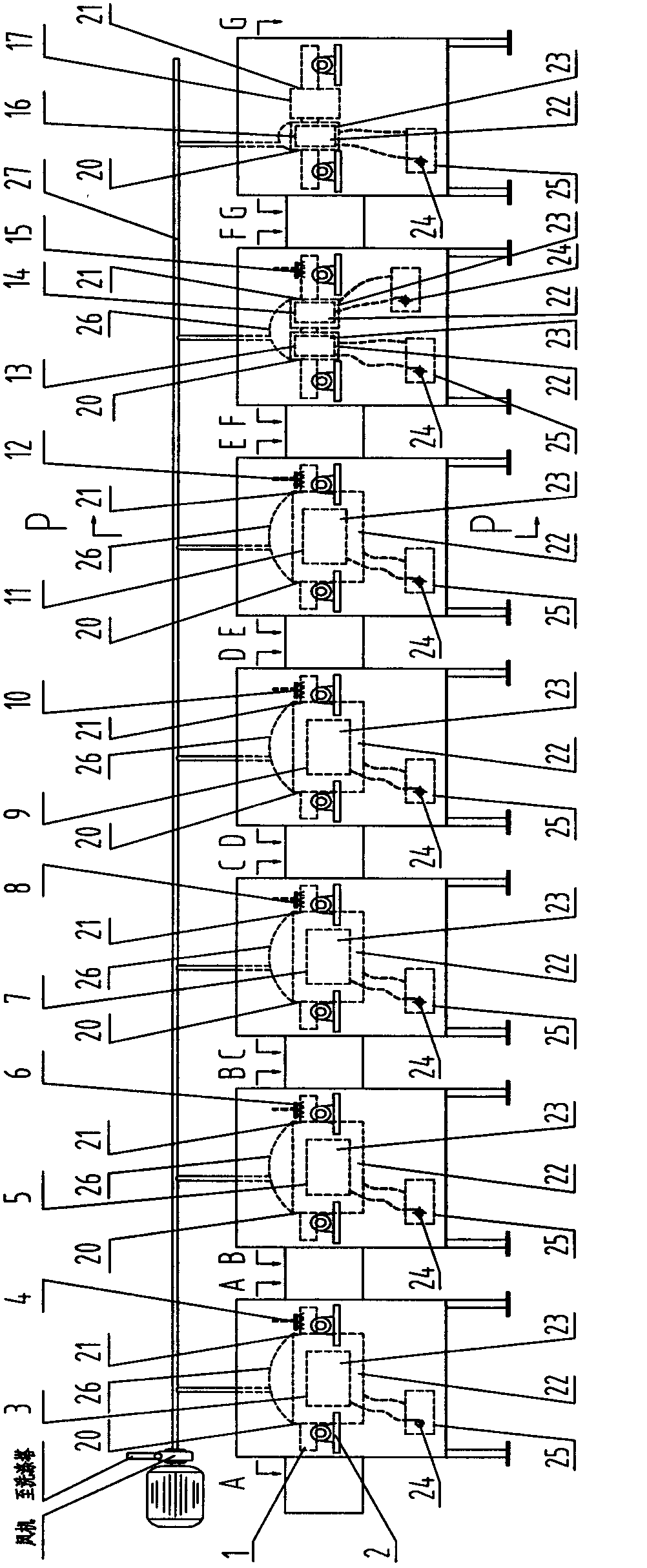

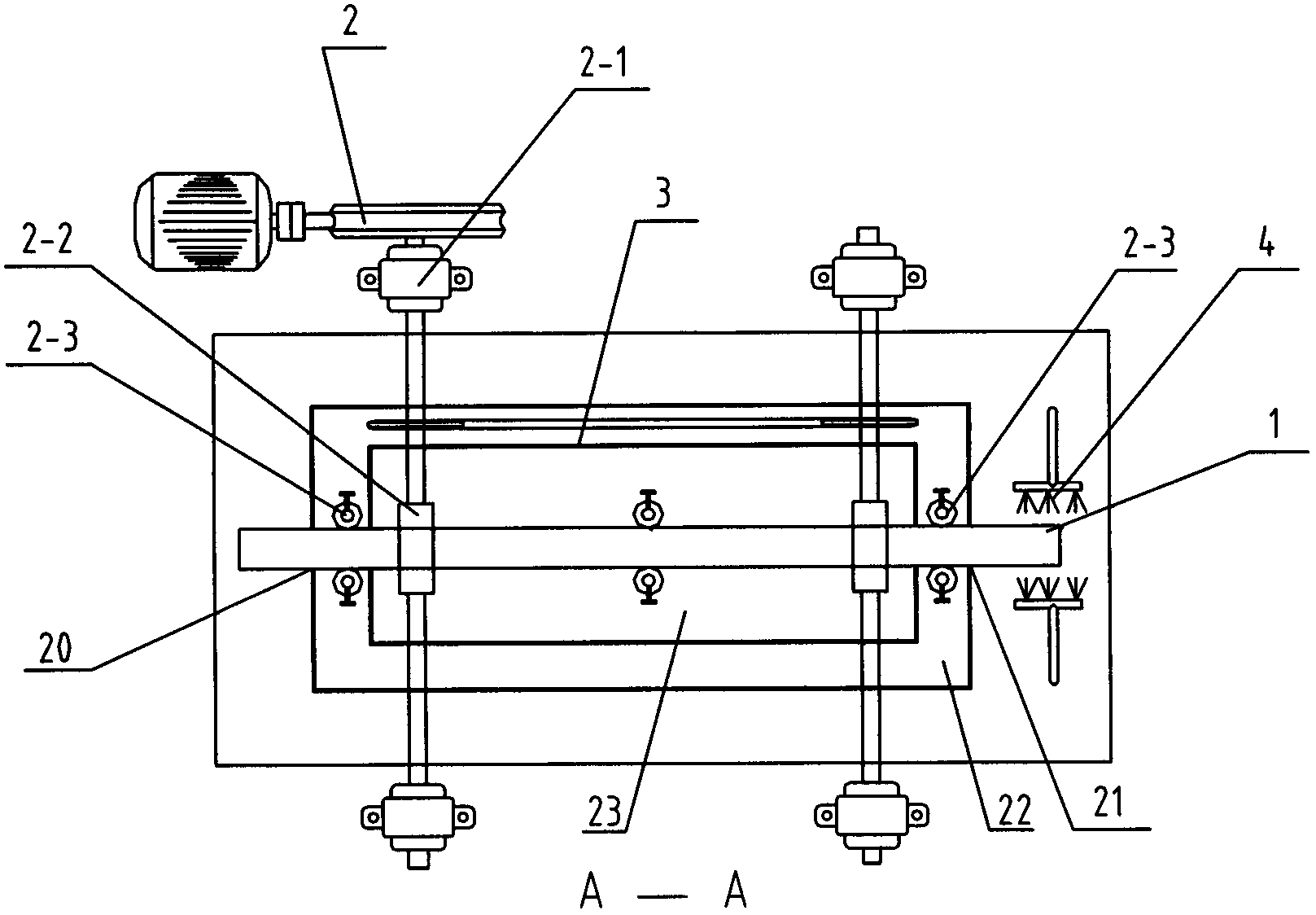

Copper bar continuous travelling tinning method and equipment

ActiveCN102703959ABright surfaceUniform crystallizationElectrolysis componentsTinningHigh current density

The invention discloses a copper bar continuous travelling tinning method and equipment, which includes the follows steps: step S101 is that a to-be-tinned copper bar of 4 to 6 meters in length undergoes ultrasonic thermal bebinding and water-spray washing through a transmission system; step S102 is that the to-be-tinned copper bar undergoes electrolytic degreasing and water-spray washing; step S103 is that to-be-tinned copper bar undergoes acid activating and water-spray washing; step S104 is that the to-be-tinned copper bar undergoes pre-pickling and purified water washing; step S105 is that the to-be-tinned copper bar undergoes tinning and connected with a conducting wheel in a sliding way, and the flowing cooling water pipe on the upper side of the conducting wheel performs water-spray washing after the tinning; step S106 is that the tinned copper bar undergoes hot water washing, weak acid neutralization and water-spray washing; and step S107 is that the tinned copper bar undergoes hot water washing and drying through blowing, so as to obtain the finished product. The method and equipment enable the to-be-tinned copper bar to continuously travel at a uniform speed in the electroplating baths through the transmission system, can electroplate under high current density, and improve the tinning efficiency; the surface of the tinned surface is uniform, smooth and is highly anti-corrosive, the harmful waste gases as alkali and acid mist produced during the tinning process can be purified by the equipment, and the equipment doesn't pollute the environment.

Owner:周建元

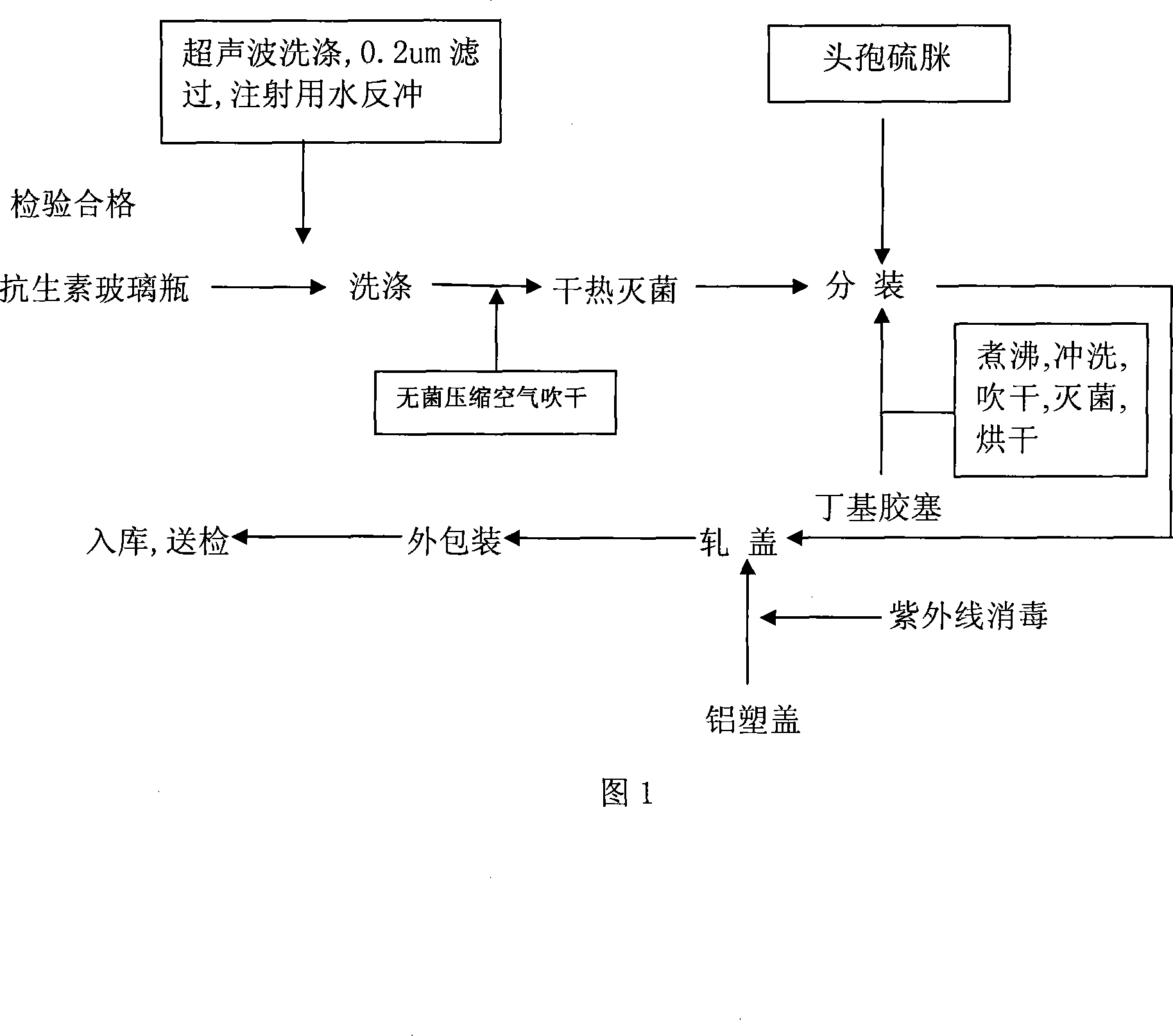

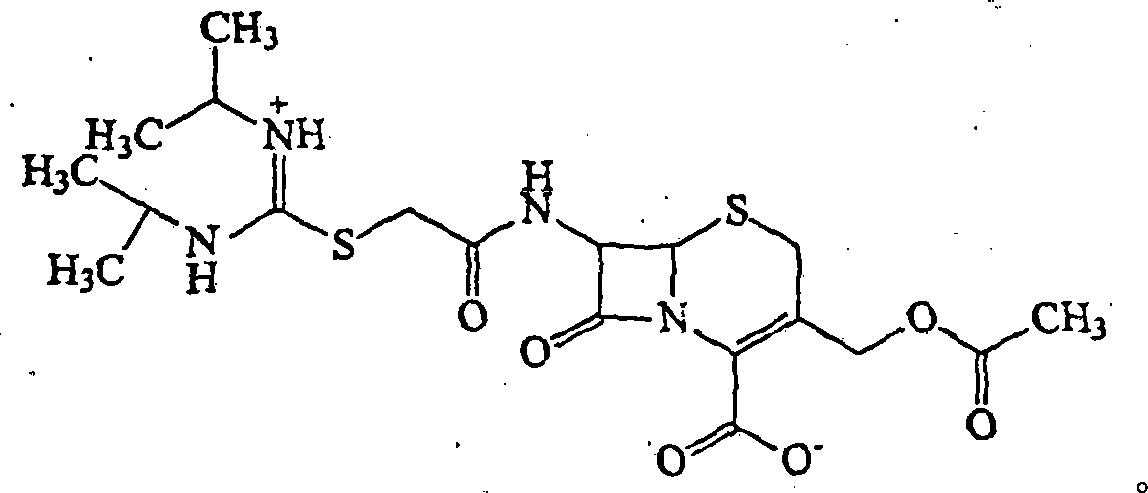

Cefathiamidine freeze-dried powder injection and preparing method thereof

ActiveCN101229139AUniform crystallizationConsistent colorAntibacterial agentsPowder deliveryWater contentChemistry

The invention which discloses a preparation method of cephathiamidine freeze-dried powder injection is characterized in that the cephathiamidine is dissolved in the temperature of 40 to 60 DEG C and after the color removal through activated carbon and filtration, the hot solution is rapidly cooled to minus 41 to minus 30 DEG C in a freeze drier; the temperature is reduced to minus 60 to minus 50 DEG C and the vacuum is pumped and the temperature rises to 20 to 30 DEG C gradually; the obtained cephathiamidine freeze-dried powder injection has the average yield of more than 98 percent, water content of less than 0.4 percent, stable quality of drugs, uniform crystallization and color and plump appearances.

Owner:SHANDONG LUOXIN PARMACEUTICAL GROUP STOCK CO LTD +2

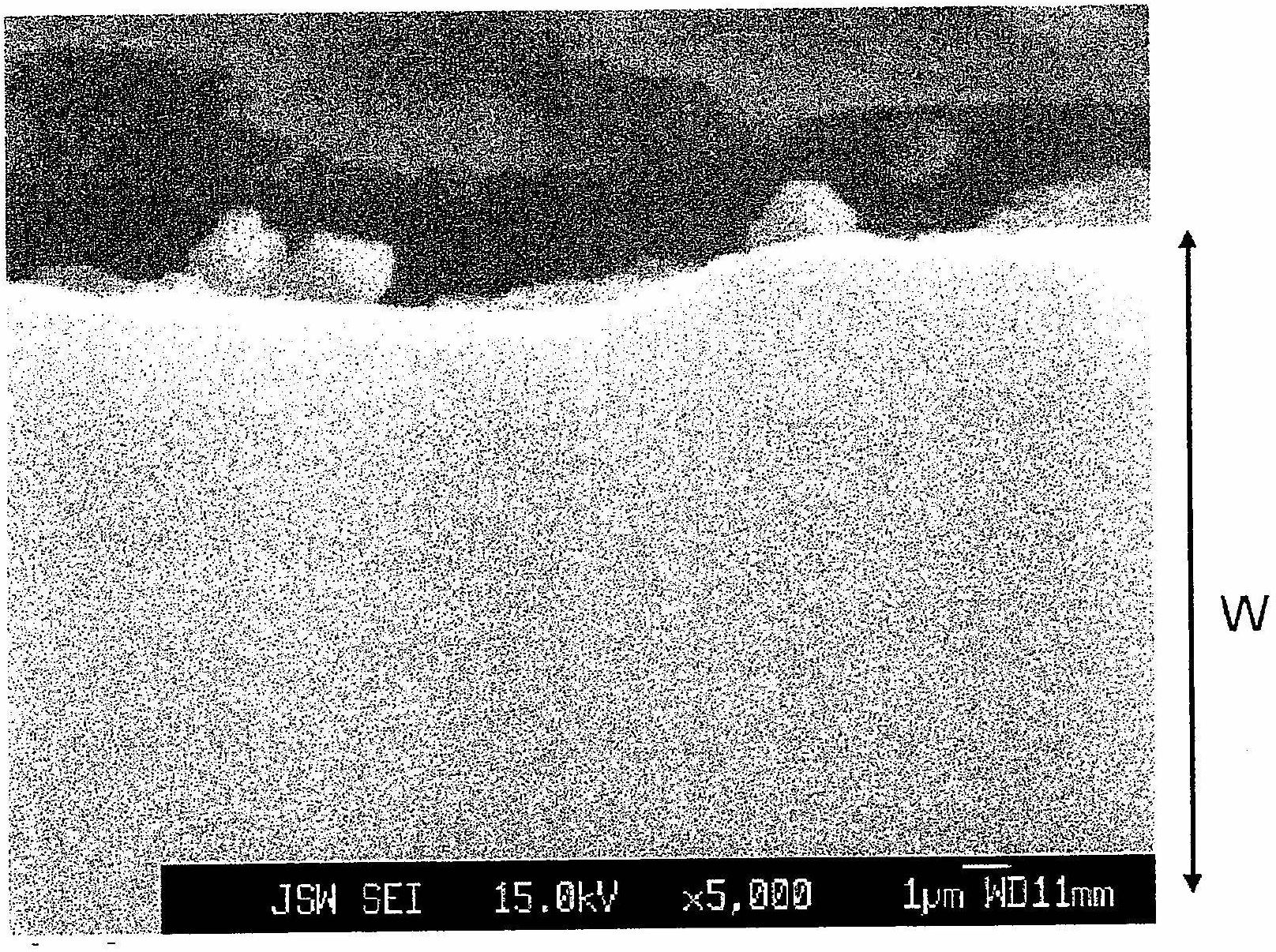

Laser irradiation apparatus, laser irradiation method, and method for manufacturing crystalline semiconductor film

InactiveCN1638039AReduce characteristic unevennessUniform laser irradiation intensityTransistorElectroluminescent light sourcesLight speedRefractive index

An object of the present invention is to provide a compact laser irradiation device and a laser irradiation method using an optical system including an electric mirror and an fθ lens, which can suppress interference caused by secondary beams on the back side of a substrate Therefore, uniform laser annealing can be performed on the irradiated object, and the throughput can be improved. In the present invention, when it is assumed that the thickness of the substrate on which the object to be irradiated is formed is d, the refractive index is n, and the speed of light in vacuum is defined as c, the pulse width t of the laser beam satisfies the inequality ct<2nd. In the above structure, even if an optical system including an electric mirror and an fθ lens is used, the influence of interference due to the secondary beams on the backside of the substrate can be reduced, so that uniform laser annealing can be performed on the object to be irradiated.

Owner:SEMICON ENERGY LAB CO LTD

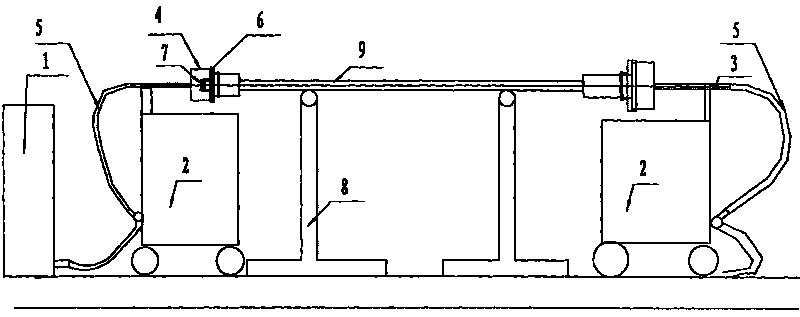

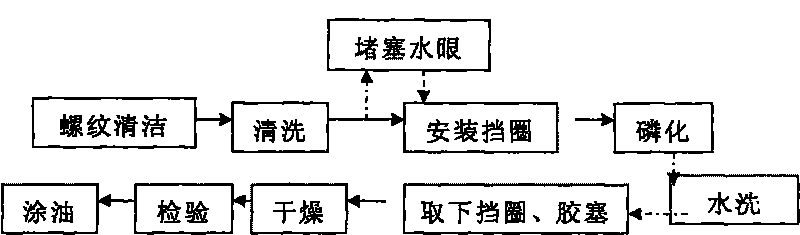

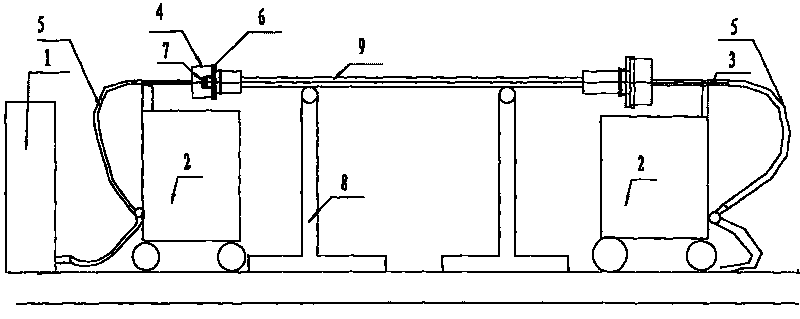

Closed circulating heating thermal phosphorization device and phosphorization method

InactiveCN101696497ASolve temperature problemsSolve the technical problem of uneven spraying of liquid medicineMetallic material coating processesClose contactPetroleum engineering

The invention discloses a closed circulating heating thermal phosphorization device and a phosphorization method, relating to the technical field of drilling tool thread phosphorization. The device comprises a fluid heater, a phosphorization pool, a heating controller, a spray head, a circulation pipeline, a rubber check ring and a rubber stopper, wherein the fluid heater and the phosphorization pool are connected through the circulation pipeline; the spray head is fixed above the phosphorization pool; a water outlet of the circulation pipeline is connected with the spray head; a drilling rod is supported by a pipe rack and arranged above the phosphorization pool; the rubber stopper is arranged in a water hole of the drilling rod; the rubber check ring is sleeved on a drilling rod joint, and the inner wall of the rubber check ring is in close contact with the outer wall of the spray head; threads extend into a cavity formed by the spray head and the rubber check ring; and the heating controller is connected with the fluid heater. The invention can control the temperature, the pressure and the flow to carry out semi-soaking type phosphorization on the threads so as to solve the technical problems of difficult temperature constancy and non-uniform medicine liquid spraying in thermal phosphorization.

Owner:CHINA NAT PETROLEUM CORP CHUANQING DRILLING ENG CO LTD

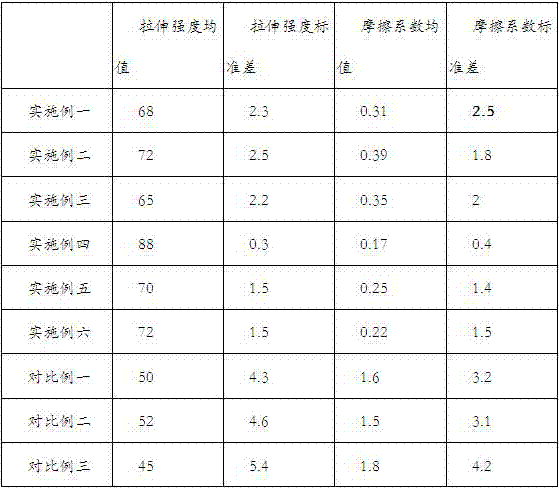

Modified PEEK (polyetheretherketone) material and preparation method of modified PEEK material

The invention discloses a modified PEEK (polyetheretherketone) material, which is prepared from the following ingredients in parts by weight: 70 to 80 parts of PEEK, 5 to 20 parts of polytetrafluoroethylene, 3 to 5 parts of Cu, 5 to 10 parts of MoS2 and 8 to 20 parts of carbon fiber. The prepared PEET modified material has better mechanical strength and friction coefficient, and meanwhile, the property homogeneity is better.

Owner:WENZHOU YUANQIN PETROCHEM MACHINERY CO LTD

Method for producing nitride crystals, and production vessel and members

ActiveCN102695823APrevent precipitationIncrease productivityPolycrystalline material growthFrom normal temperature solutionsSurface roughnessTitanium

Provided is a method for producing nitride crystals with which it is possible to inhibit precipitation of nitride crystals in parts other than on seed crystals and improve the efficiency of producing gallium nitride single crystals grown on seed crystals. When nitride crystals are produced by the ammonothermal method in a vessel holding a solution containing a mineralizer, the portions of the surfaces of the vessel and the members inside the vessel in contact with the solution are at least partially formed from a metal or alloy including one or more atoms selected from the group comprising tantalum (Ta), tungsten (W), and titanium (Ti), and the surface roughness (Ra) is less than 1.80 [mu]m.

Owner:MITSUBISHI RAYON CO LTD +2

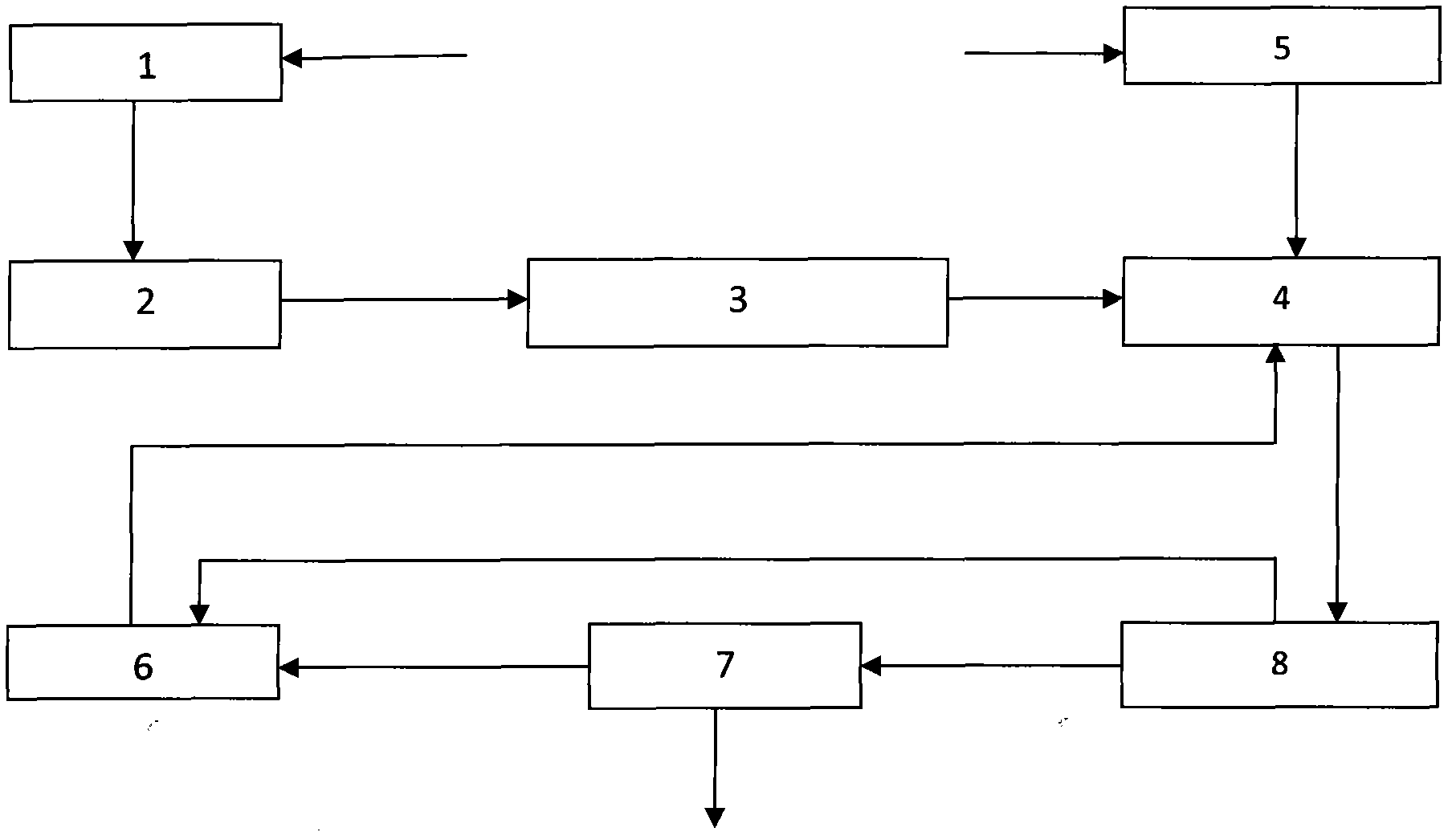

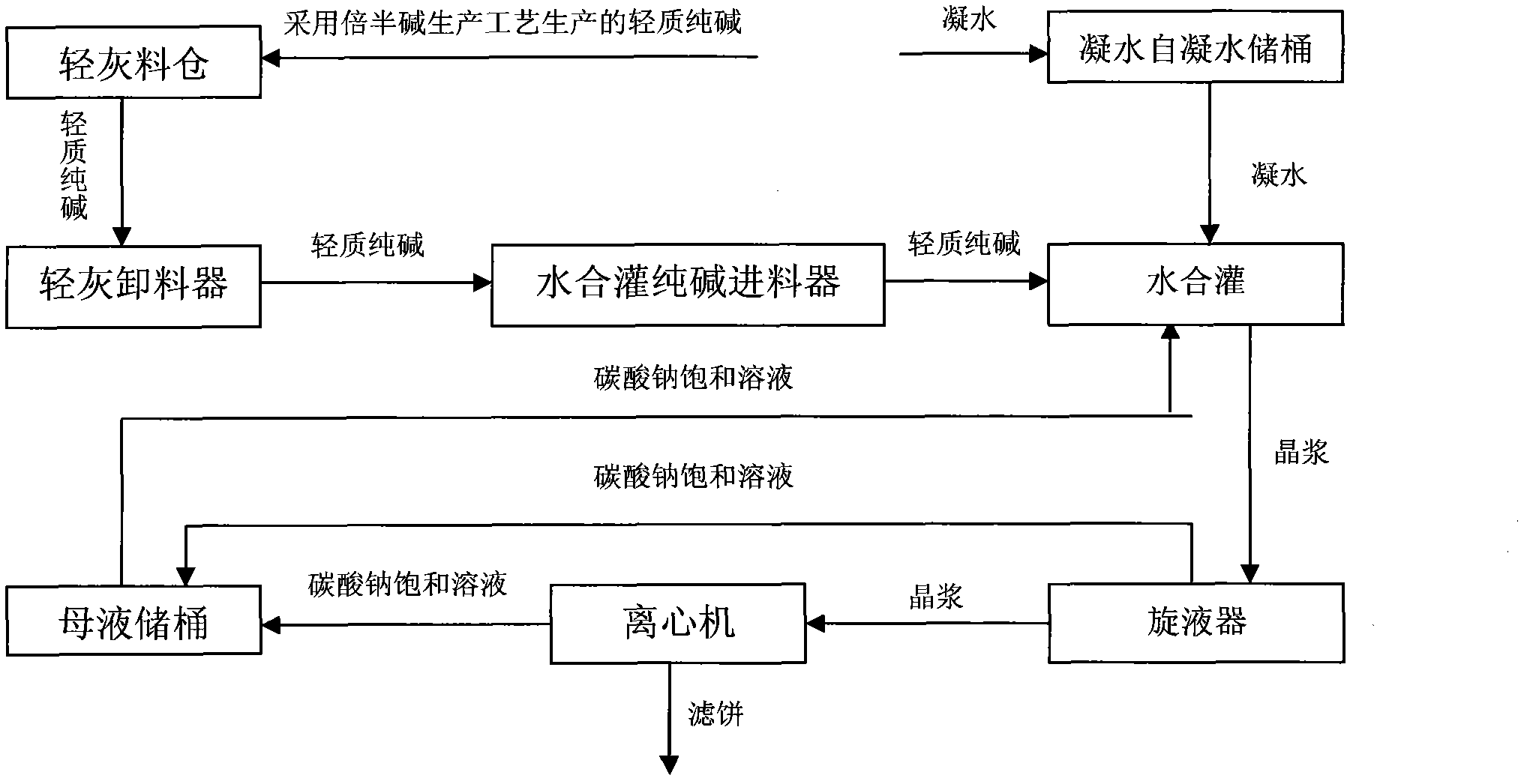

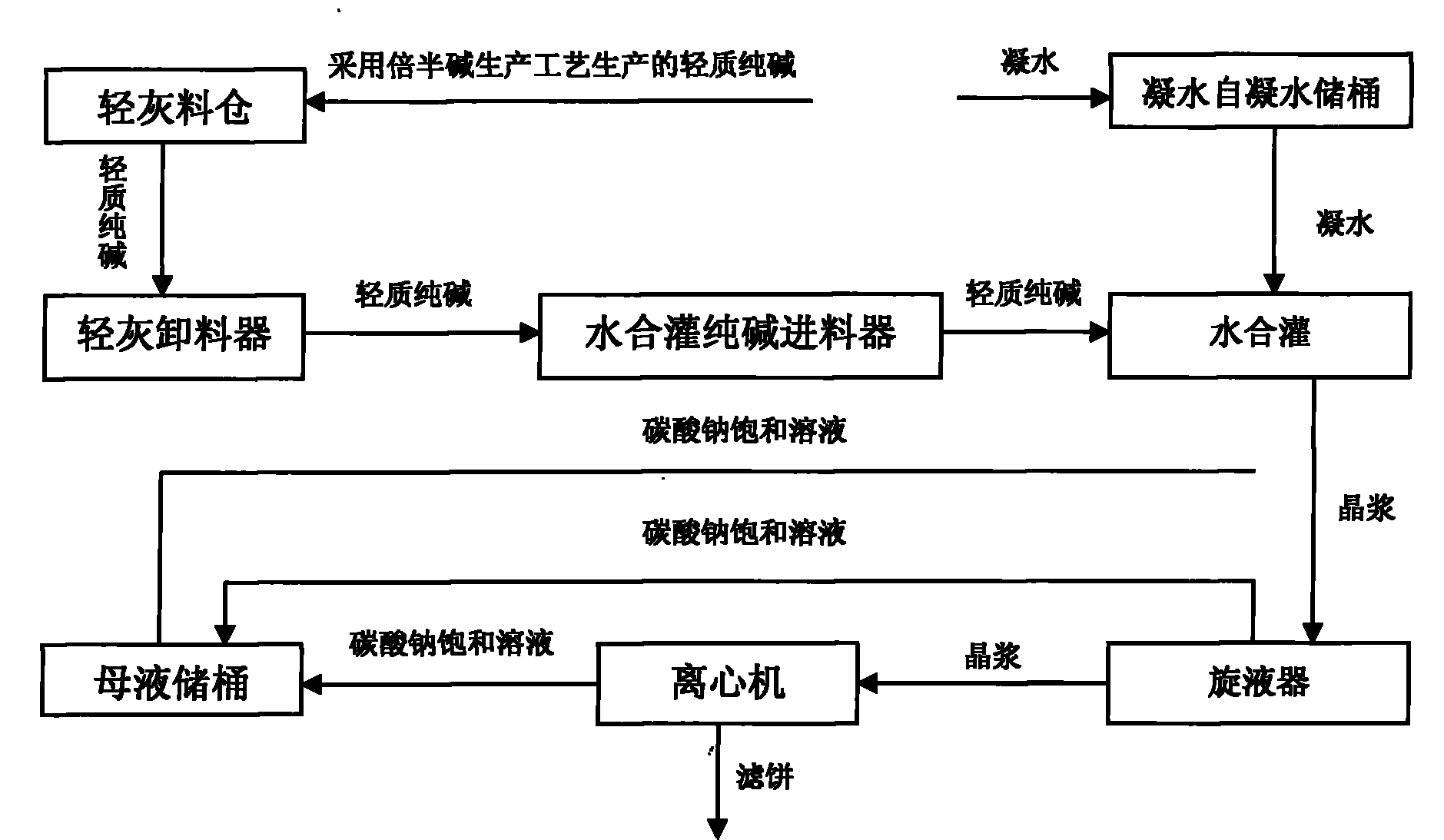

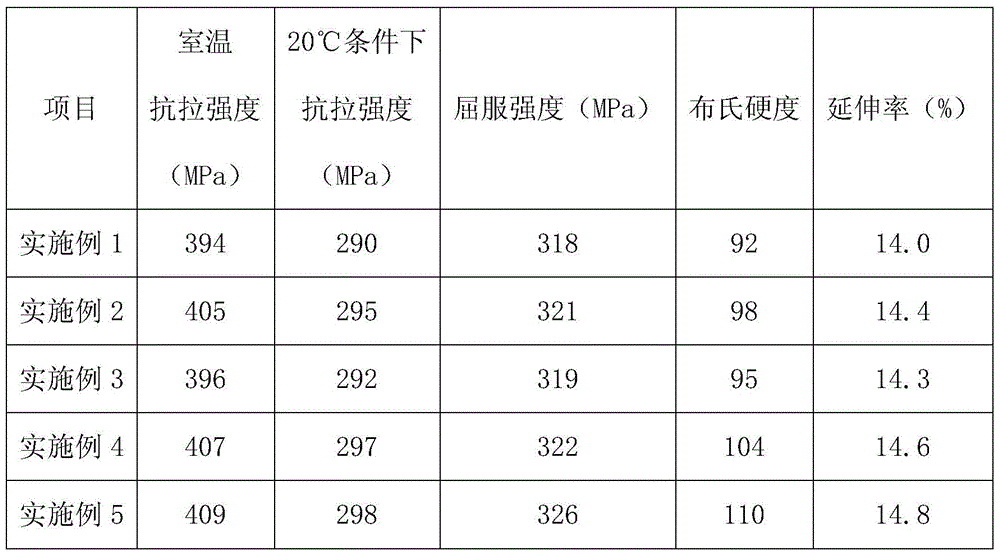

System and process for preparing low-salt dense soda ash by liquid-phase hydration

InactiveCN101928021AConstant material levelFine granularityVarying alkali metal carbonate water contentReaction temperatureSlurry

The invention discloses a system and a process for preparing low-salt dense soda ash by liquid-phase hydration. The method comprises the following steps of: adding light soda ash with the temperature of more than 93 DEG C, condensate water and saturated solution of sodium carbonate according to a mass ratio of 1:0.22:1.4-1:0.22:2.0 into a hydration tank for hydration, wherein the reaction temperature is controlled to be between 100 and 104 DEG C and the reaction time is 20 to 25 minutes, and crystallizing the soda ash in a form of a monohydrate soda, namely Na2CO3.H2O after the reaction; after separating the monohydrate soda crystal slurry with a hydrocyclone separator, feeding the top liquid into a mother liquor storing barrel and feeding the bottom liquid into a centrifuge; after dehydrating the bottom liquid with the centrifuge to obtain a monohydrate soda filter cake; and drying, cooling and screening the monohydrate soda filter cake to obtain the finished product, namely the low-salt dense soda ash, wherein when the centrifuge is used for dehydrating, water is added to wash off a part of salts. The system can guarantee the constant material level of a material bin so that the feeding of the soda ash is stable. The obtained soda ash product has the advantages of large crystallization granule size, high first-rate product rate and high added value, wherein the product with crystallization granule size of more than 180 mu m is up to over 75 percent; the qualification rate is up to 100 percent; and the first-rate product rate is up to 95 percent.

Owner:内蒙古博源工程有限责任公司

Tetrapod-shaped zinc oxide whisker reinforced aluminum alloy hub and preparing method thereof

InactiveCN105671463AUniform crystallizationHigh strengthTurbinesOther manufacturing equipments/toolsManganeseBall mill

The invention discloses a tetrapod-shaped zinc oxide whisker reinforced aluminum alloy hub and preparing method thereof. The aluminum alloy hub is made of compositions including, by weight percent, 8% to 14% of tetrapod-shaped zinc oxide whiskers, 12% to 16% of silicon, 1.0% to 1.5% of strontium, 0.12% to 0.18% of tantalum, 2.0% to 2.8% of magnesium, 1.8% to 2.4% of manganese, 0.40% to 0.56% of chromium and the balance aluminum. The preparing method comprises the steps of burdening, smelting, atomizing and obtaining aluminum alloy powder; performing ball mill mixing, performing cold isostatic pressing, demolding, performing sleeving coating treatment, performing warming pressure maintaining treatment and obtaining a blank; heating, rolling, forging, and spinning forming to obtain a hub workblank; and performing heat treatment, machining and surface treatment, and obtaining a hub finished product. After-casting treatment temperature is reasonably controlled, and the alloy is uniform in crystallization, high in strength, resistant in corrosion and impact, good in heat resistance, free of bubbles and good in casing and forging performance.

Owner:DONGGUAN PINPAI IND INVESTMENT

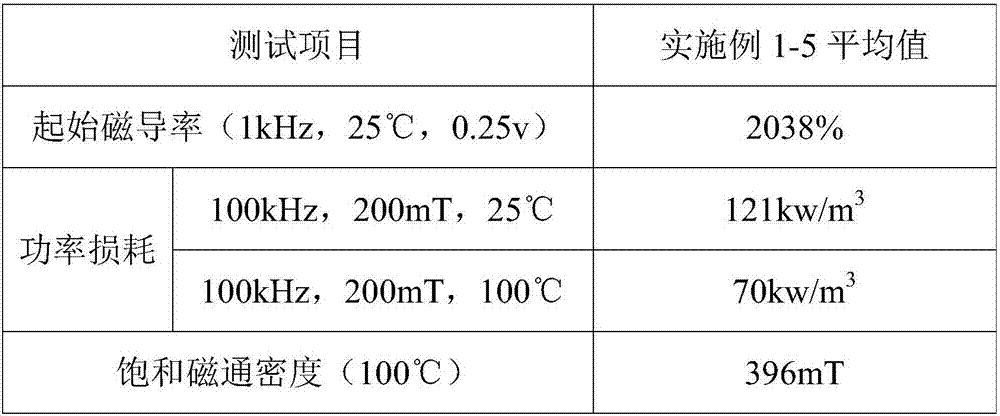

Low-consumption soft magnet ferrite material

ActiveCN107200574ALow melting pointHigh resistivityInorganic material magnetismInductances/transformers/magnets manufactureHigh frequencySoft magnet

The invention discloses a low-consumption soft magnet ferrite material which comprises the following raw materials in parts by weight: 100 parts of a main material, 0.8-0.9 part of an auxiliary material and 6-8 parts of aids, wherein the main material comprises the following raw materials in parts by mole: 56-58 parts of Fe2O3, 30-33 parts of MnO, 8-9 parts of ZnO and 3-4 parts of NiO; the auxiliary material comprises the following raw materials in parts by weight: 2.5-3.5 parts of CaO, 0.8-1.2 parts of V2O5, 0.9-1.1 parts of SnO2, 0.25-0.35 part of TiO2, 0.5-1 part of Co2O3, 0.15-0.25 part of Nb2O5, 0.9-1.1 parts of MoO3, 0.2-0.4 part of Bi2O3 and 0.3-0.5 part of Ta2O5. The low-consumption soft magnet ferrite material has properties of high frequency, high initial magnetic conductivity and low consumption.

Owner:ZHONGDE ELECTRONICS

Crystallization method of ammonium paratungstate

InactiveCN101182039AUniform crystallizationCoarse particlesTungsten compoundsAmmonia compoundsIsothermal crystallizationChemistry

The invention discloses a crystallization method of ammonium paratungstate and relates to a production method of ammonium tungstate by adopting hydrometallurgy. The method is characterized in that the invention has a crystallization process that ammonium paratungstate crystal seeds are added into ammonium tungstate solution when the solution is evaporated and concentrated to appear microcrystalline particles for isothermal crystallization under the solution temperature of 90-95 DEG C for 20-40mins; the solution is then heated up to boil and added with weak aqua ammonia to adjust the pH value of the ammonium tungstate solution to 8.0-8.5 and then treated with feeding and filtering when the density of mother liquor reaches 10.8 to 1.10 g / cm <3>; the solution is again washed with the weak aqua ammonia and deionized water and dried to obtain the ammonium paratungstate crystals with large particle size and uniform distribution. The method of the invention effectively controls the crystallization of the ammonium paratungstate through the measures of removing fine crystals through the weak aqua ammonia, adding the crystal seeds, controlling the evaporation speed, etc.; in addition, the produced ammonium paratungstate crystals with large and controllable particle size are uniform and smooth; and the technology is simple and easy to be operated.

Owner:JINDUICHENG MOLYBDENUM CO LTD

Super-thick aluminum alloy cast-rolled plate production method

The invention relates to the technical field of nonferrous metallurgy, in particular to a super-thick aluminum alloy cast-rolled plate production method for producing aluminum alloy cast-rolled plates through a horizontal cast-rolling machine. The super-thick aluminum alloy cast-rolled plate production method includes the steps of furnace charging, batching, melting through temperature rise, stir for slagging-off, sampling, furnace discharging, refinement through a holding furnace, slagging-off, online refinement, online degassing, filtration, cast rolling and reeling-up. The super-thick aluminum alloy cast-rolled plate production method has the advantages that distribution uniformity of a cast lip is improved, and temperature distribution is uniform; Al-5Ti-1B grain refinement filament adding technological parameters are reasonably determined; all rolling technological parameters are reasonably determined; fourth, qualified 11.5 mm thick and 1550 mm wide plates are successfully cast-rolled; the optimal ratio of cold material to liquid material for batching is reasonably determined; sixth, quality defects causing instable and unqualified thick plates are overcome; seventh, the limit of rolling thickness of the original design of a cast-rolling device is broken through.

Owner:QINGHAI QIAOTOU ALUMINUM & POWER CO LTD

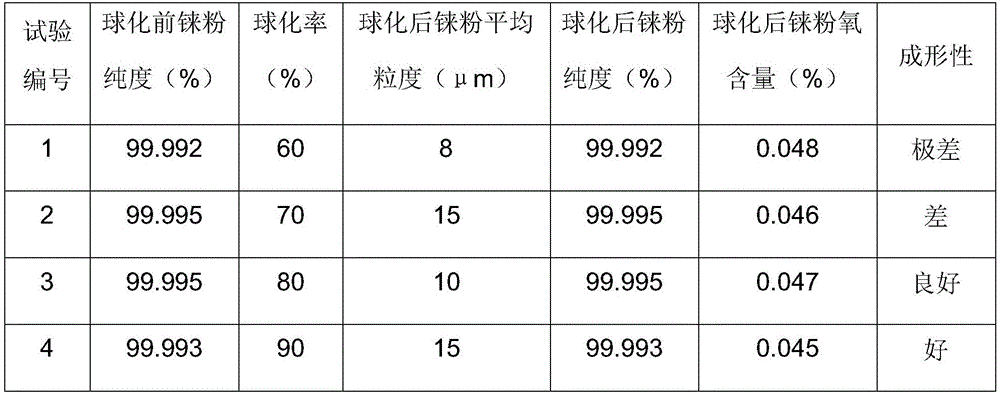

Manufacturing method of ultrathin high-purity rhenium foil

ActiveCN106077617AShorten production timeGuaranteed surface quality of rhenium foilTransportation and packagingMetal-working apparatusRheniumAdhesive

The invention discloses a manufacturing method of a ultrathin high-purity rhenium foil. The manufacturing method comprises the following steps: 1) raw material preparation: firstly, high-purity rhenium powder performs the radio-frequency plasma spheroidizing treatment to obtain high-purity spherical rhenium powder or similarly spherical rhenium powder easy to mold by rolling; 2) pure rhenium pressing blank preparation: adhesive is added in the high-purity rhenium powder after the spheroidizing treatment; and a pure rhenium pressing blank is rolled by using a powder rolling mill; 3) sintering: the pure rhenium pressing blank is sintered at high temperature by a vacuum furnace or other forms to prepare a crystal-uniform pure rhenium plate blank; and 4) continuous rolling and annealing: the pure rhenium plate blank adopts multi-roller rolling mill and annealing linked continuous rolling; and a lubricating agent is coated on the surface of the pure rhenium plate blank for continuous rolling and annealing to obtain a finished rhenium foil with a needed size. The manufacturing method has such advantages as short rolling flow, high annealing efficiency and good surface quality.

Owner:中铼新材料有限公司

Operation technology of glucose crystal

The invention is a glucose crystallization operating process, and its character: it adopts step crystal growth, step by step, pours the syrup made by liquefying, saccharifying, refining and concentrating in a crystallizing kettle with a stirrer and corresponding adds in crystal seeds, preserves the heat and grows the crystals in each step, and controls to lower the temperature according to the crystallization curve to crystallize. It can make uniform crystallization, uneasy to form broken crystals and false crystals, thus enhancing the crystallizing effect, largely saving the crystal seeds, reducing the production cost and providing a feasible way for producing alpha-glucose monohydrate.

Owner:MAOMING COLLEGE

High-magnesium aluminum alloy material for wheel hubs and preparation method thereof

InactiveCN103774007AQuality improvementHigh magnesium aluminum alloy has light weightPorosityManganese

The invention relates to a high-magnesium aluminum alloy material for wheel hubs, which contains the following chemical components in percentage by mass: 12-15% of magnesium, 3.2-3.5% of silicon, 0.2-0.5% of calcium, 0.12-0.17% of molybdenum, 0.1-0.15% of copper, 0.04-0.06% of manganese, 0.2-0.25% of titanium, 0.04-0.06% of nickel, 0.12-0.15% of strontium, 0.12-0.16% of Ta and the balance of aluminum. The high-magnesium aluminum alloy has the characteristics of light weight and corrosion resistance; and the titanium, strontium, nickel and other elements are added to refine the crystal grain and enhance the strength and wear resistance of the alloy, so that the alloy quality is more stable and uniform. When being used for manufacturing wheel hubs, the aluminum alloy has the advantages of favorable casting and forging property, favorable thermal conductivity, light weight and fuel cost saving. When the refining agent is used for casting production, the porosity in the casting can be lowered by 1-2 degrees, the oxide inclusion content is Grade 2 or so, and the yield is high.

Owner:MAANSHAN HENGYI MACHINERY MFG

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com