Electroslag remelting slag for smelting plastic mould steel and preparation method thereof

A plastic mold steel and electroslag remelting technology, which is applied in the field of smelting slag and its preparation, can solve the problems of high viscosity and low gas permeability, and achieve the effects of reducing pollution, high purity, and improving thermal efficiency and electrical efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below:

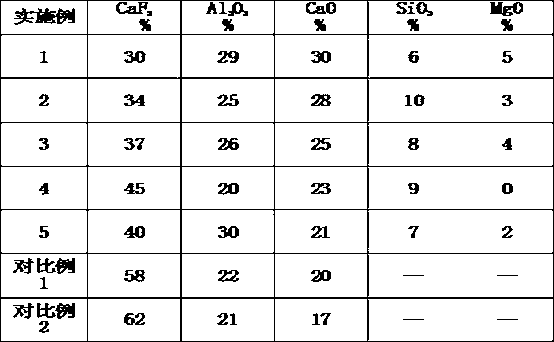

[0025] Table 1 is the value list of each embodiment of the present invention and comparative examples;

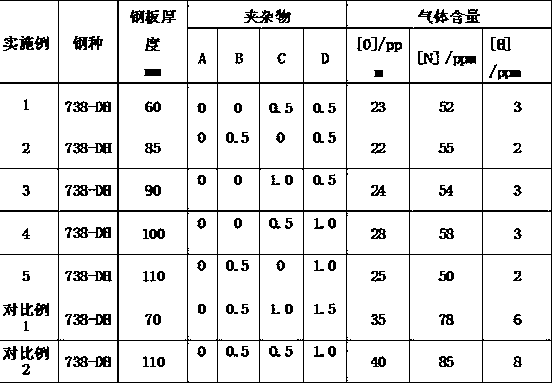

[0026] Table 2 is the main process parameter list of each embodiment of the present invention and comparative example;

[0027] Table 3 is the list of the purity situation of the plastic mold steel that implements each embodiment of the present invention and comparative example;

[0028] Table 4 is a list of the mechanical properties of plastic mold steels smelted in various embodiments of the present invention and comparative examples.

[0029] Each embodiment of the present invention is produced according to the following steps:

[0030] 1) Combine the above raw materials: CaF 2 : 30~45%, Al 2 o 3 : 20~30%, CaO: 20~30%, SiO 2 : 5 ~ 10%, including the added MgO ≤ 5%, mixed evenly;

[0031] 2) Bake the mixed material at a temperature of 1650-1750°C for 180-240 minutes;

[0032] 3) Carry out slag melting, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com