Tetrapod-shaped zinc oxide whisker reinforced aluminum alloy hub and preparing method thereof

A four-needle-shaped zinc oxide and aluminum alloy wheel hub technology, applied in the field of aluminum alloy accessories, can solve the problems of limited deterioration treatment effect, unstable casting quality, poor processing performance, etc., and achieve easy implementation, high production efficiency, casting and forging good performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

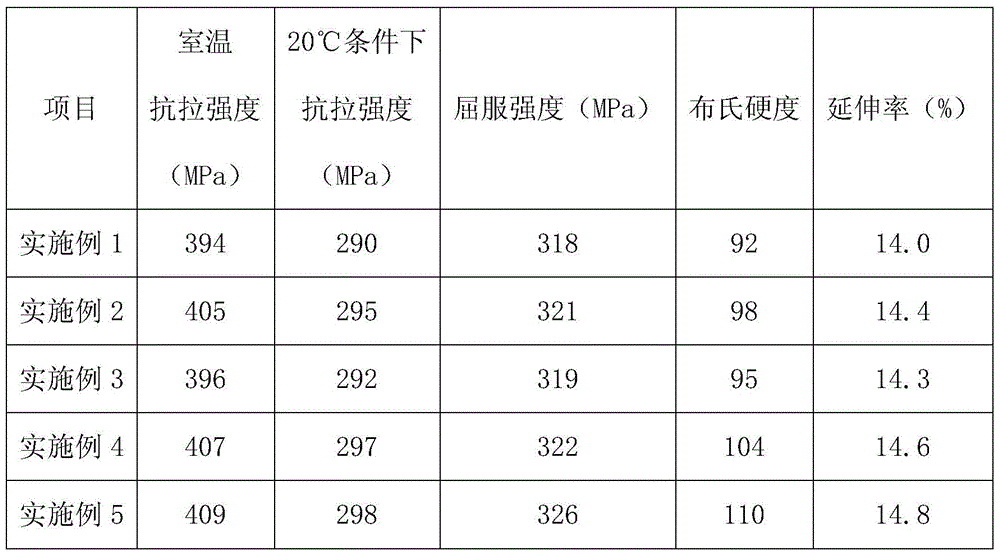

Examples

Embodiment 1

[0025] In the embodiment of the present invention, a four-acicular zinc oxide whisker-reinforced aluminum alloy wheel hub is made of the following components in terms of weight percentage: tetraacicular zinc oxide whisker 8%, silicon 16%, strontium 1.0%, strontium 1.0%, 0.18% of tantalum, 2.0% of magnesium, 2.4% of manganese, 0.40% of chromium and the balance of aluminum.

[0026] The preparation method of the four-acicular zinc oxide whisker reinforced aluminum alloy wheel hub comprises the following steps:

[0027] (1) Take each component raw material according to the above weight percentage, and each component raw material is pure ingot or alloy material;

[0028] (2) Put the aluminum ingot into a melting furnace at 6890°C for melting, remove impurities, deoxidize, and refine once with a refining agent, then raise the temperature of the melting furnace to 760°C, put each alloy material into the melting furnace for melting, and add refining After secondary refining of the a...

Embodiment 2

[0037] In an embodiment of the present invention, a four-needle zinc oxide whisker reinforced aluminum alloy wheel hub is made of the following components in terms of weight percentage: 14% four-needle zinc oxide whisker, 12% silicon, 1.5% strontium, 0.12% of tantalum, 2.8% of magnesium, 1.8% of manganese, 0.56% of chromium and the balance of aluminum.

[0038] The preparation method of the four-needle zinc oxide whisker-reinforced aluminum alloy wheel hub is the same as that in Example 1.

Embodiment 3

[0040] In an embodiment of the present invention, a four-needle zinc oxide whisker-reinforced aluminum alloy wheel hub is made of the following components in terms of weight percentage: 10% four-needle zinc oxide whisker, 15% silicon, 1.2% strontium, 0.17% of tantalum, 2.4% of magnesium, 2.2% of manganese, 0.42% of chromium and the balance of aluminum.

[0041] The preparation method of the four-needle zinc oxide whisker-reinforced aluminum alloy wheel hub is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com