High-strength transparent glass ceramic

A technology of glass-ceramics and crystal phase, applied in the field of high-strength transparent glass-ceramics, can solve the problems of low O content, glass transmittance and strength reduction, difficult high surface strength glass-ceramics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-8

[0036] 1. Test sample preparation

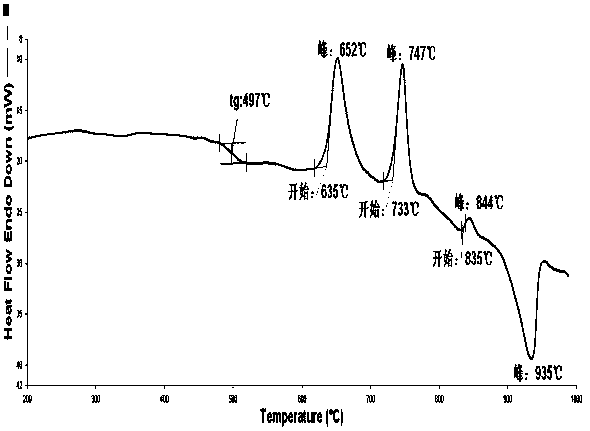

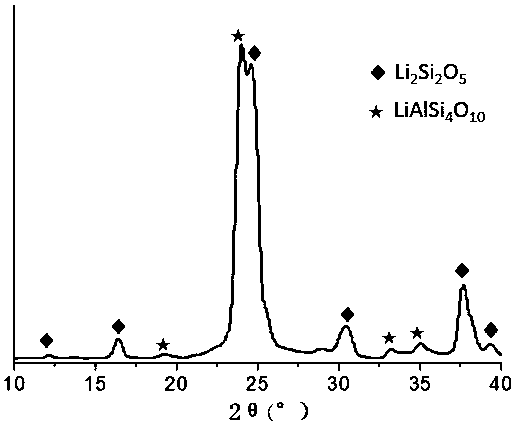

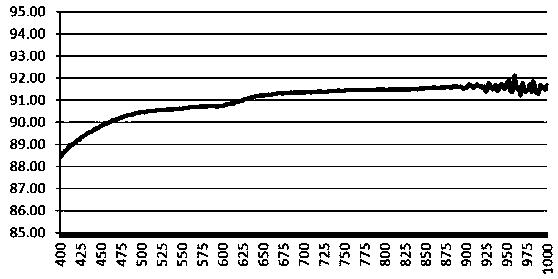

[0037] Example 1-8 Sample preparation: Weigh according to the purity and moisture content of raw materials such as quartz sand, alumina, sodium carbonate, phosphate, lithium carbonate, zirconia, etc., and uniformly mix to obtain uniform ingredients; then mix the ingredients from the plastic Transfer the bottle to about 800ml platinum crucible, put the platinum crucible into the silicon-molybdenum rod high-temperature furnace, gradually raise the temperature to 1500℃~1560℃, keep the temperature for 2~6 hours, accelerate the discharge of glass bubbles and homogenize the glass by stirring eliminate. After melting, pour the molten liquid into a heat-resistant stainless steel mold for molding, then take out the glass block and move it into a box-type annealing furnace for heat treatment at 500°C for 2 hours, and then lower it to 440°C at a rate of less than 1°C / min. Afterwards, it was naturally cooled to room temperature to obtain the base glass...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com