Modified PEEK (polyetheretherketone) material and preparation method of modified PEEK material

A technology of modification and modifier, which is applied in the field of polymers and can solve problems affecting the overall strength, irregular shape, and internal stress accumulation, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

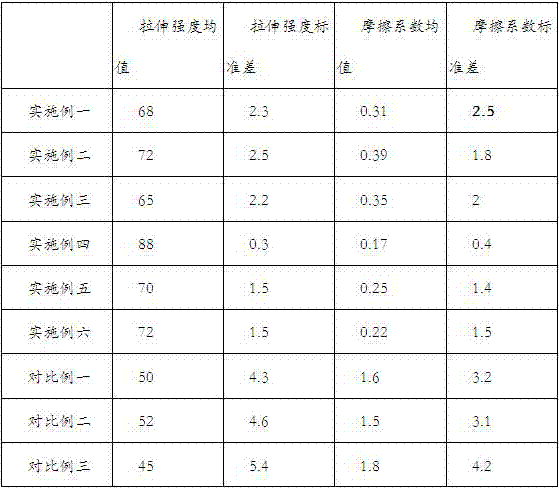

Examples

Embodiment 1

[0034] PEEK: 70 parts;

[0035] Polytetrafluoroethylene: 10 parts;

[0036] Cu: 5 parts;

[0037] MoS 2 : 10 copies;

[0038] Carbon fiber: 15 parts.

[0039] Step 1: Stir the raw materials evenly according to the proportion;

[0040] Step 2: put the uniformly mixed raw materials into a molding machine and mold them to obtain molded tablets;

[0041] Step 3: Sintering the molded sheet;

[0042] Step 4: Tempering the sintered molded sheet;

[0043] Step 5: Finishing the tempered product to obtain the product.

[0044] In the third step, the sintering temperature is 400° C., and the sintering time is 8 hours.

[0045] The tempering temperature in the step 4 is 200° C., and the tempering time is 4 hours.

Embodiment 2

[0047] PEEK: 80 parts;

[0048] Polytetrafluoroethylene: 5 parts;

[0049] Cu: 5 parts;

[0050] MoS 2 : 7 copies;

[0051] Carbon fiber: 20 parts.

[0052] Step 1: Stir the raw materials evenly according to the proportion;

[0053] Step 2: put the uniformly mixed raw materials into a molding machine and mold them to obtain molded tablets;

[0054] Step 3: Sintering the molded sheet;

[0055] Step 4: Tempering the sintered molded sheet;

[0056] Step 5: Finishing the tempered product to obtain the product.

[0057] In the third step, the sintering temperature is 400° C., and the sintering time is 8 hours.

[0058] The tempering temperature in the step 4 is 200° C., and the tempering time is 4 hours.

Embodiment 3

[0060] PEEK: 80 parts;

[0061] Polytetrafluoroethylene: 20 parts;

[0062] Cu: 3 parts;

[0063] MoS 2 : 5 copies;

[0064] Carbon fiber: 8 parts.

[0065] Step 1: Stir the raw materials evenly according to the proportion;

[0066] Step 2: put the uniformly mixed raw materials into a molding machine and mold them to obtain molded tablets;

[0067] Step 3: Sintering the molded sheet;

[0068] Step 4: Tempering the sintered molded sheet;

[0069] Step 5: Finishing the tempered product to obtain the product.

[0070] In the third step, the sintering temperature is 400° C., and the sintering time is 8 hours.

[0071] The tempering temperature in the step 4 is 200° C., and the tempering time is 4 hours.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com