Detonating tool explosive casting automatic production technology and equipment

A production process and technology of detonators, applied in the direction of offensive equipment, blasting barrels, weapon accessories, etc., can solve the problems of poor product quality and product stability of detonators, many production organization personnel, and high labor intensity of workers, etc., to achieve safety Improvement, production capacity improvement, and high production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

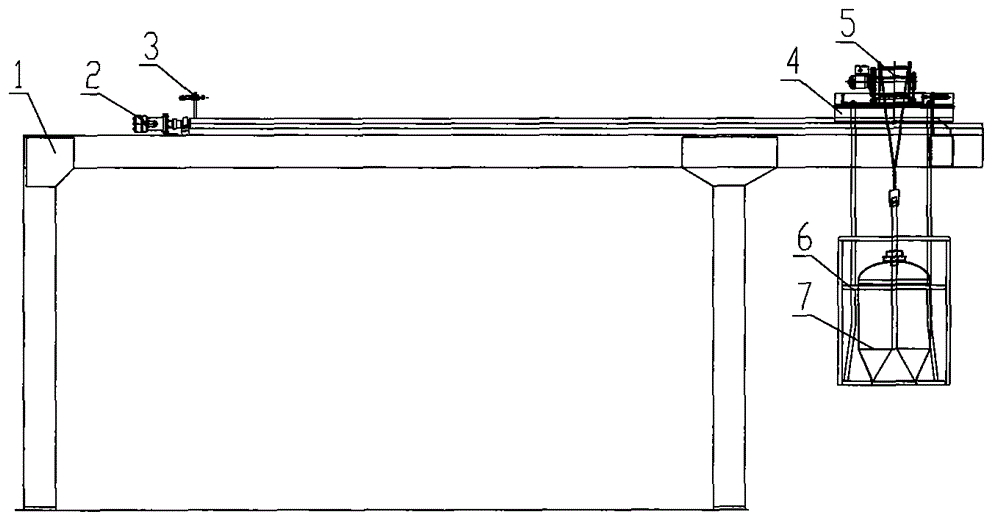

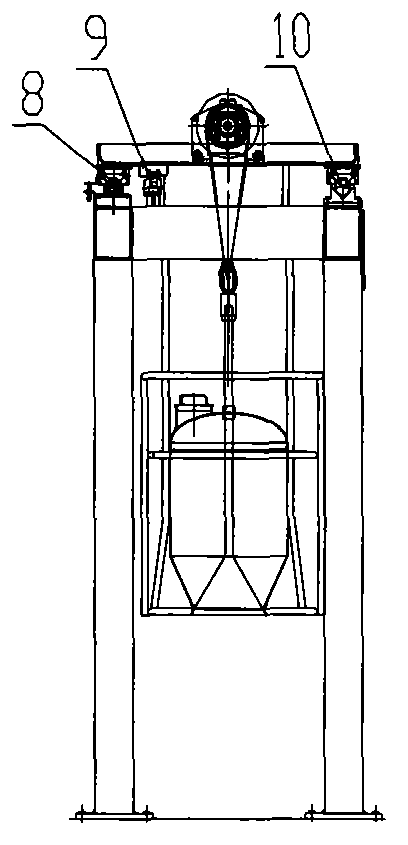

[0049] The best embodiment of the present invention will be further described below in conjunction with the accompanying drawings.

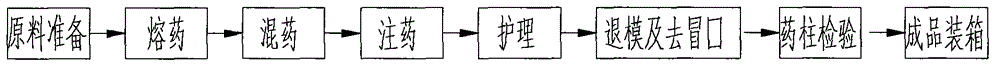

[0050] Such as figure 1 Shown, a detonator casting charge automatic production pouring process.

[0051] First, the raw materials are removed and weighed. The lifting and conveying device puts the materials into the melting device for melting. The melted materials are put into the mixing tank, and solid particles are added for mixing. At the same time, the riser 43 and other components are mixed. Riser assembly, after the materials are evenly mixed, perform a multi-mold quantitative injection in the injection process. After the completion of the charge, the drug column is transported by the conveyor to the nursing process for gradient cooling care, and transported by the conveyor to the ejection process Carry out the overall demoulding, and then go to the riser 43 to separate the riser medicine, clean the riser 43 and reuse it, inspect the medicine co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com