Air conditioner device with module heat exchange component and control method thereof

A technology of an air-conditioning device and a control method, which is applied to heating methods, air-conditioning systems, refrigerators, etc., can solve the problems of high cost, small adjustable range, large flow rate, etc., and achieve the effect of increasing refrigerant flow rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

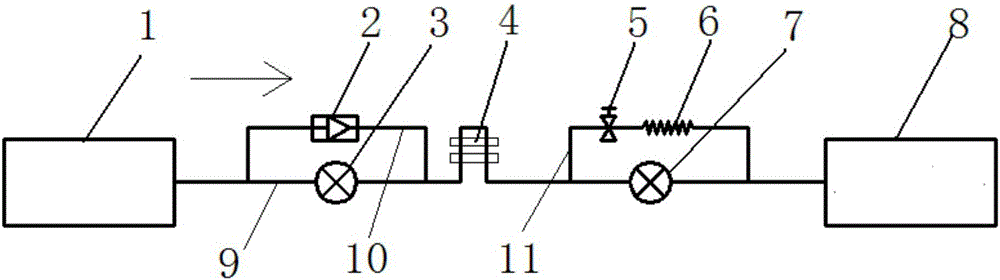

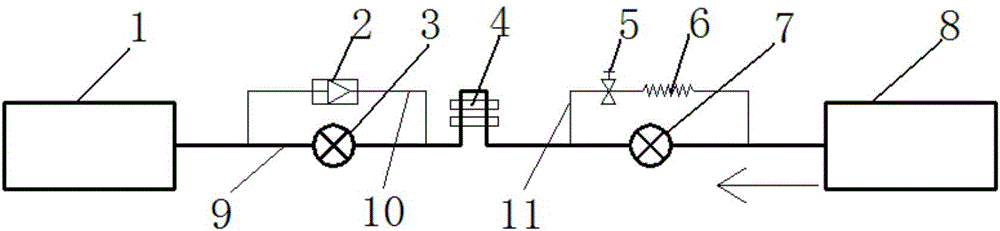

[0044] Such as figure 1 , 2 As shown, the air conditioner of the present invention has a first electronic expansion valve 3, a module heat dissipation component 4, and a second electronic expansion valve 7 arranged sequentially in the main refrigerant pipeline 9. According to different cooling or heating modes, the refrigerant flows in the The flow direction in the main refrigerant pipeline is different, and there is also a control device (not shown in the figure), which controls the first and second electronic expansion valves to play a throttling role according to the obtained signal, so that the refrigerant always exchanges heat from the module Component flow to the electronic expansion valve, which is throttling. exist figure 1 In cooling mode, the opening degree of the second electronic expansion valve 7 is adjusted by the control device according to the system load for throttling, and the first electronic expansion valve 3 is opened to the maximum opening degree withou...

Embodiment 2

[0050] As an improvement of the previous embodiment, as shown in the figure, refrigerant branch pipelines are arranged in parallel at both ends of the first and second electronic expansion valves. Through this parallel branch, the technical bottleneck of using small-flow electronic expansion valves in large cooling units has been successfully solved.

Embodiment 3

[0052] As an improvement of the previous embodiment, as shown in the figure, a one-way valve 2 is connected in series on the branch pipeline connected in parallel with the first electronic expansion valve 3 . The one-way conduction of the one-way valve is used in the parallel branch circuit, which simply and effectively solves the self-regulation of different cooling capacity requirements under the two working modes of the air conditioner.

[0053] Of course, the one-way valve 2 can also be replaced by a solenoid valve, and its on-off is controlled by the control device according to the flow direction of the refrigerant, so that the effect of the one-way valve can also be achieved.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com