Three-dimensional adjustable assembled light-weight batten outer wall system and construction method thereof

A prefabricated, slatted technology, applied to walls, building components, insulation, etc., can solve problems such as the difficulty of nailing heavy objects, small shear stiffness, and small panel thickness, so as to improve connection safety and bond strength , to meet the effect of aesthetic requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

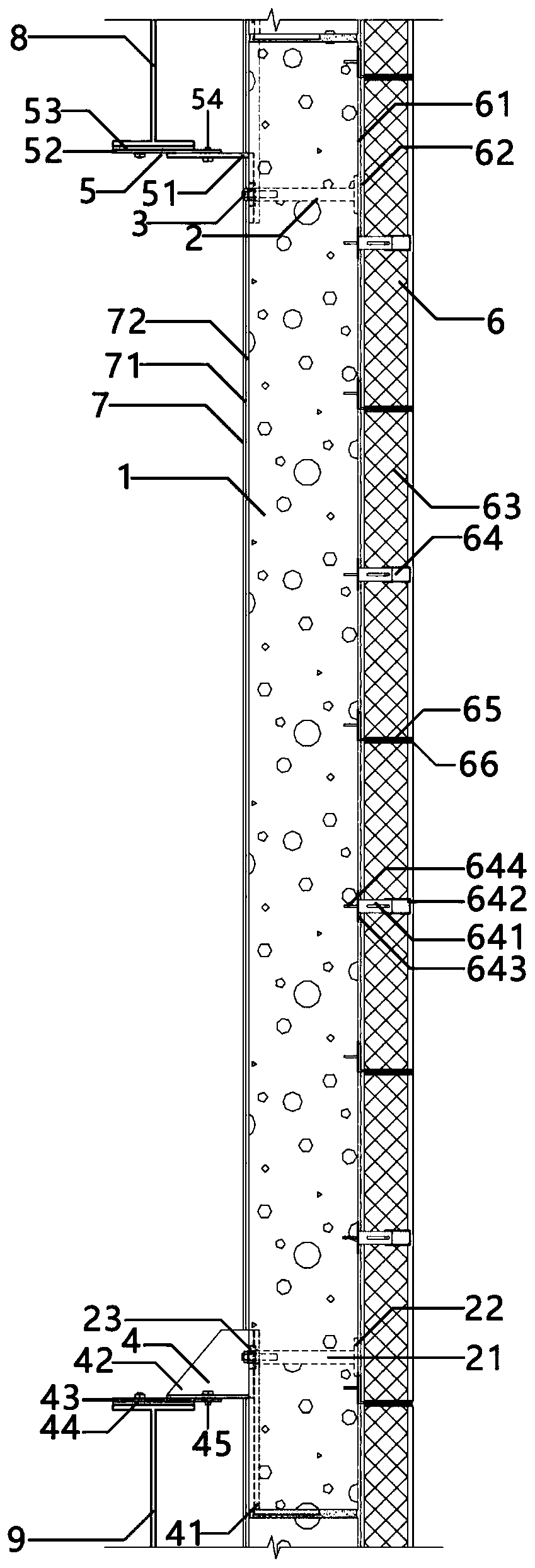

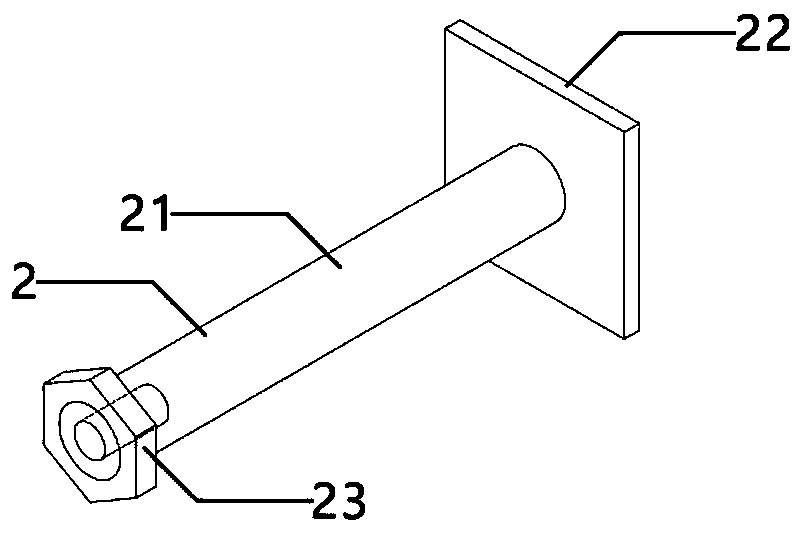

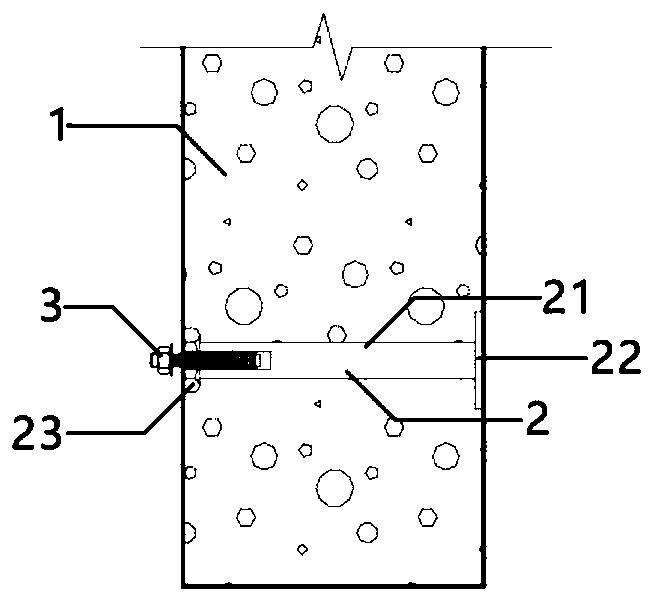

[0033] Such as figure 1 As shown, the three-dimensional adjustable assembled light-weight batten exterior wall system is used for fabricated steel structure buildings, including: light-weight battens 1, sleeves 2, connecting bolts 3, supporting parts 4, tie parts 5, and outer Insulation decorative board system 6, inner side facing system 7, wherein: the upper and lower ends of the lightweight strip 1 are respectively provided with a sleeve 2 close to the end of the board, and the lower end of the lightweight strip 1 passes through the sleeve 2, the connecting bolt 3, The supporting part 4 is connected with the steel beam 9 of the lower frame to realize the three-dimensional adjustment of the connection of the lower end of the lightweight strip 1 along the thickness, width and height of the wall panel; the upper end of the lightweight strip 1 passes through the sleeve 2, the connecting bolt 3, and the The joints 5 are connected to the upper frame steel beams 8 to realize the th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com