System and process for preparing low-salt dense soda ash by liquid-phase hydration

A heavy soda ash and hydration technology, which is applied in the system and production process of low-salt heavy soda ash, can solve the problems of difficult control of alkali salt content, uneven alkali particle size, system defects, etc., to avoid the generation of fine crystals, The effect of high added value and stable feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

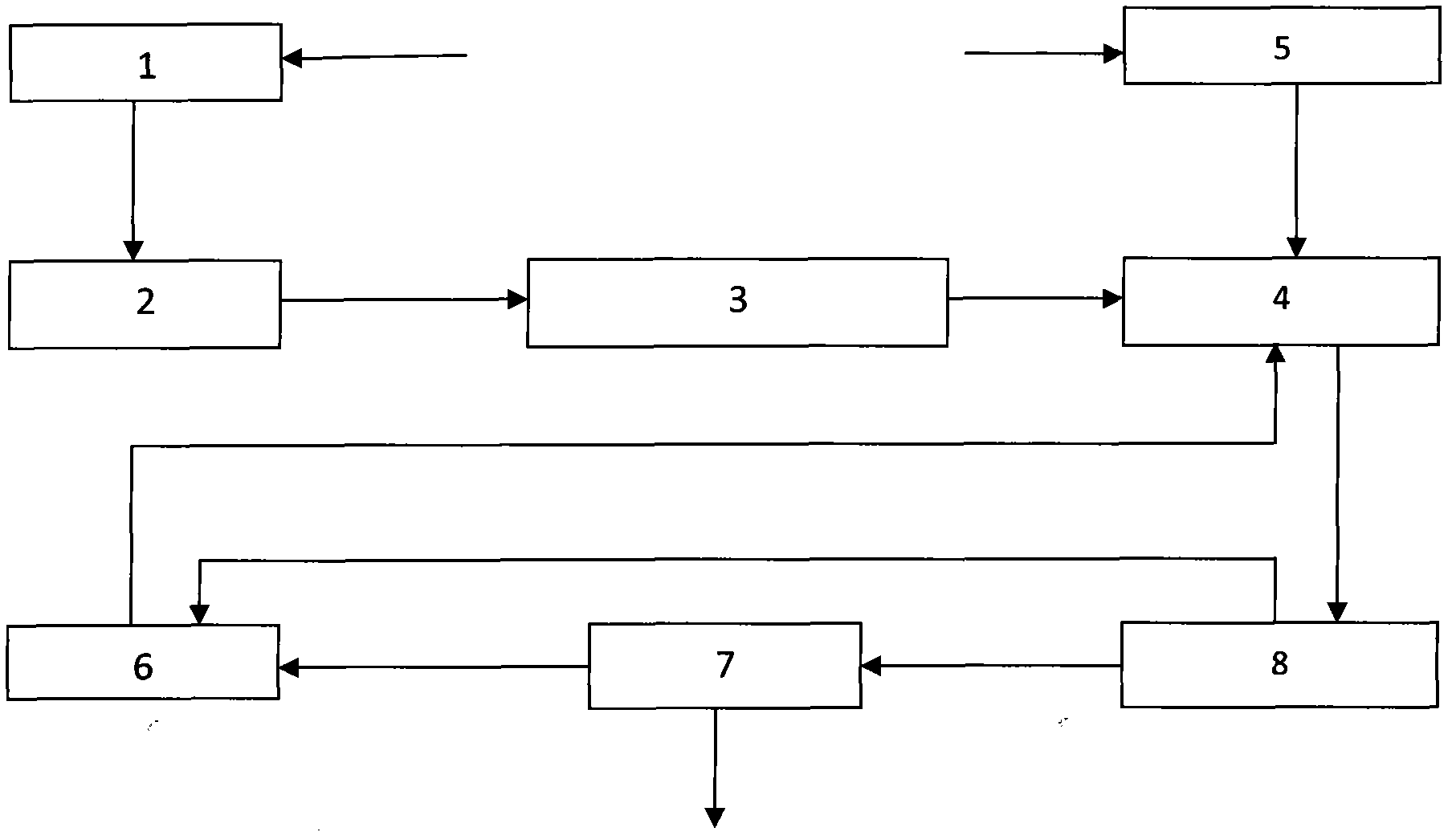

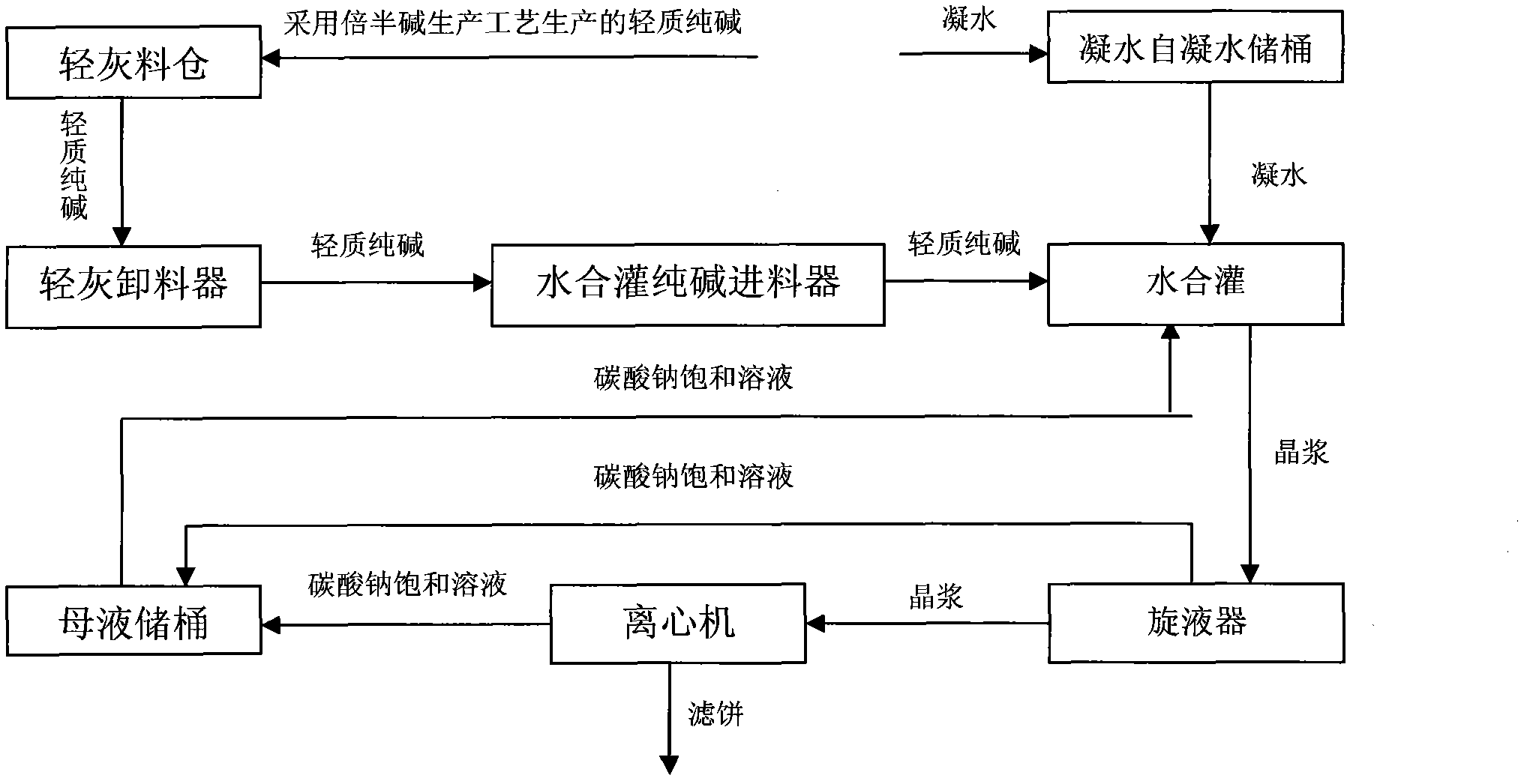

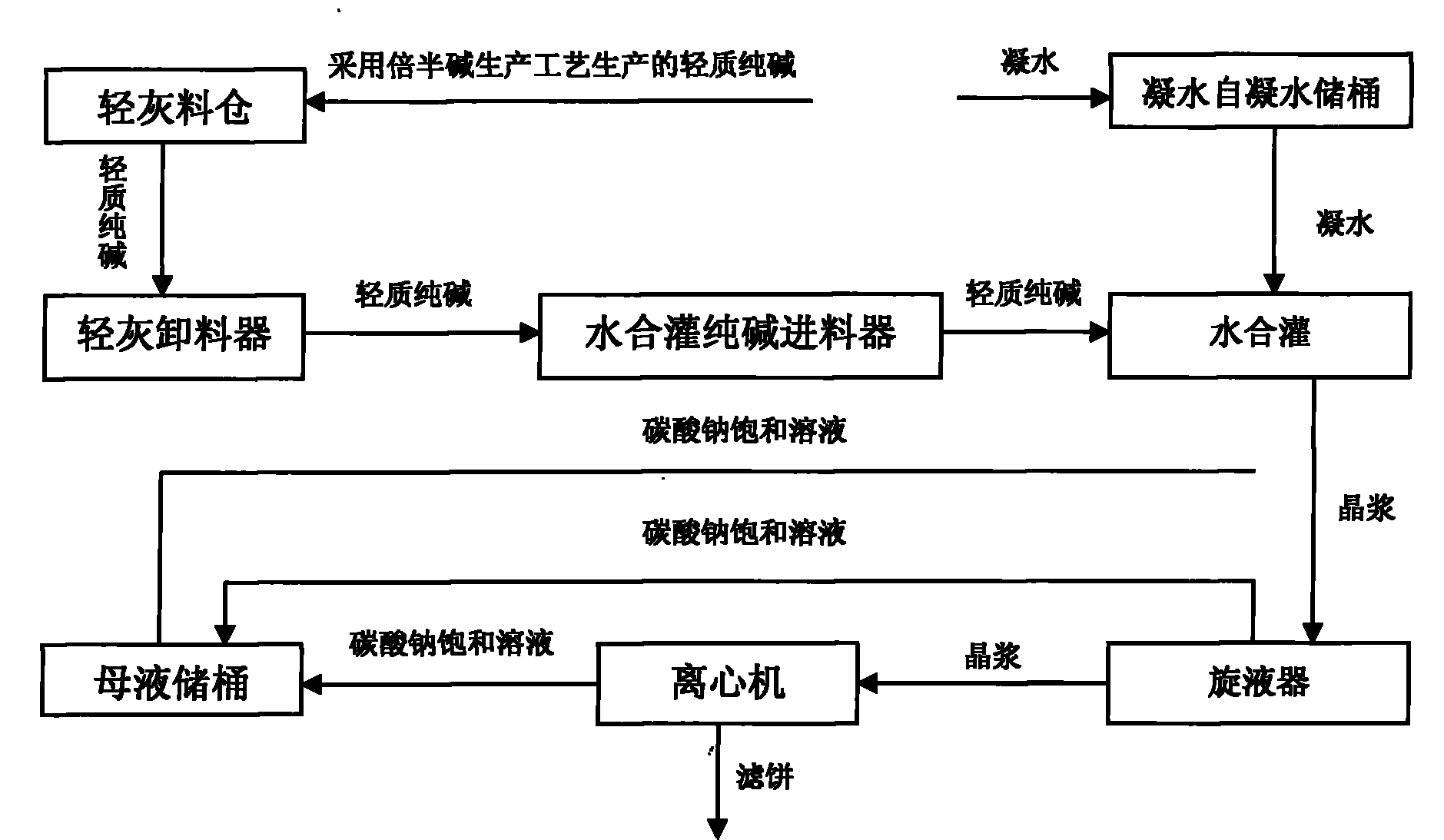

[0018] Embodiment 1: a kind of system of liquid-phase hydration method system of low-salt heavy soda ash, it comprises following device: light ash silo 1, light ash unloader 2, hydration tank soda ash feeder 3, hydration tank 4, condensation Water self-condensing water storage tank 5, mother liquor storage tank 6, centrifuge 7, liquid cyclone 8, wherein the light ash silo 1 is connected with the light ash unloader 2, and the light ash unloader 2 is connected with the soda ash feeder of the hydration tank 3 are connected, the soda ash feeder 3 of the hydration tank is connected with the hydration tank 4, the condensed water self-condensing water storage tank 5 is connected with the hydration tank 4, the mother liquor storage tank 6 is connected with the hydration tank 4, and the hydration tank 4 is connected with the liquid cyclone 8, The liquid cyclone 8 is connected to the centrifuge 7 and the mother liquid storage tank 6 respectively, and the centrifuge 7 is connected to the ...

Embodiment 2

[0020] Example 2: The structure of the system for producing low-salt heavy soda ash by liquid phase hydration is as described in Example 1.

[0021] Adopt the system of above-mentioned liquid-phase hydration method to prepare low-salt heavy soda ash to carry out the production process of liquid-phase hydration method to make low-salt heavy soda ash, it is implemented by the following steps: (1) prepare light soda ash, adopt sesquialkali method to make 170~ The light soda ash at 180°C is delivered to the light ash silo through the conveying equipment and kept full all the time. The light soda ash with a temperature of 160°C in the light ash silo is sent to the hydration tank through the light ash unloader and the soda ash feeder of the hydration tank; (2) Prepare condensed water, the condensed water at 99°C is added to the hydration tank through the condensed water from the condensed water storage tank; (3) Prepare saturated sodium carbonate solution, add the saturated sodium ca...

Embodiment 3

[0022] Example 3: The structure of the system for producing low-salt heavy soda ash by liquid phase hydration is as described in Example 1.

[0023] Adopt the system of above-mentioned liquid-phase hydration method to prepare low-salt heavy soda ash to carry out the production process of liquid-phase hydration method to make low-salt heavy soda ash, it is implemented by the following steps: (1) prepare light soda ash, adopt sesquialkali method to make 170~ The light soda ash at 180°C is delivered to the light ash silo through the conveying equipment and kept full all the time. The light soda ash with a temperature of 170°C in the light ash silo is sent to the hydration tank through the light ash unloader and the soda ash feeder of the hydration tank; (2) Prepare condensed water, the condensed water at 100°C is added to the hydration tank through the condensed water from the condensed water storage tank; (3) Prepare saturated sodium carbonate solution, add the saturated sodium c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com