Low-consumption soft magnet ferrite material

A soft magnetic ferrite, low loss technology, applied in the direction of inorganic material magnetism, inductance/transformer/magnet manufacturing, electrical components, etc., can solve the problems of reduced service life and high power loss, and achieve reduced loss and high frequency power loss , the effect of increasing the grain boundary resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

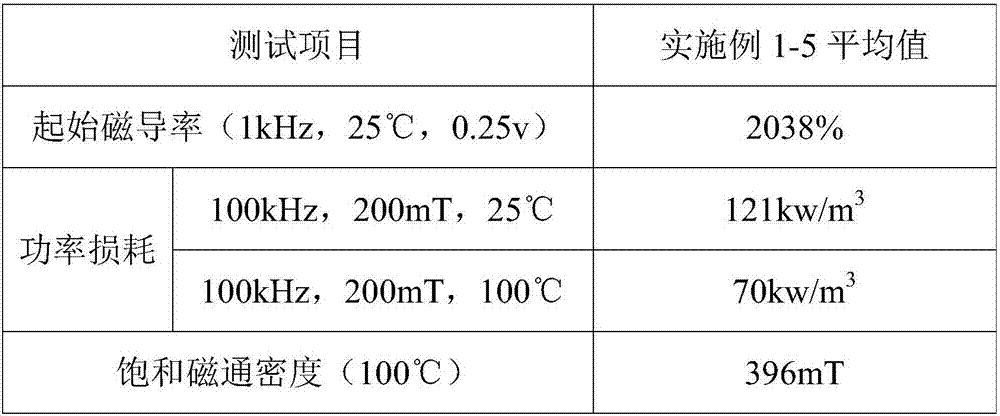

Examples

Embodiment 1

[0017] A low-loss soft ferrite material, the raw materials of which comprise 100 parts by weight of main materials, 0.85 parts of auxiliary materials, and 7 parts of auxiliary materials;

[0018] The ingredients of the main ingredients include: Fe 2 O 3 57 parts, MnO 31 parts, ZnO 8.5 parts, NiO 3.5 parts;

[0019] The raw materials of the auxiliary materials in parts by weight include: 3 parts of CaO, V 2 O 5 1 part, SnO 2 1 part, TiO 2 0.3 parts, Co 2 O 3 0.7 parts, Nb 2 O 5 0.2 parts, MoO 3 1 part, Bi 2 O 3 0.3 part, Ta 2 O 5 0.4 copies.

Embodiment 2

[0021] A low-loss soft ferrite material, the raw materials of which comprise 100 parts by weight of main material, 0.8 parts of auxiliary materials, and 8 parts of auxiliary materials;

[0022] The ingredients of the main ingredients include: Fe 2 O 3 56 parts, MnO 33 parts, ZnO 8 parts, NiO 4 parts;

[0023] The raw materials of the auxiliary materials in parts by weight include: 2.5 parts of CaO, V 2 O 5 1.2 copies, SnO 2 0.9 parts, TiO 2 0.35 parts, Co 2 O 3 0.5 part, Nb 2 O 5 0.25 parts, MoO 3 0.9 parts, Bi 2 O 3 0.4 part, Ta 2 O 5 0.3 copies;

[0024] The raw materials of the auxiliary agent include 17 parts by weight of polyvinyl alcohol, 0.5 parts of cetyltrimethylammonium bromide, 0.3 parts of polydimethylsiloxane, 0.6 parts of magnesium stearate, and 85 parts of water.

Embodiment 3

[0026] A low-loss soft ferrite material, the raw materials of which comprise 100 parts by weight of main material, 0.9 parts of auxiliary materials, and 6 parts of auxiliary materials;

[0027] The main ingredients of the ingredients include: Fe 2 O 3 58 parts, MnO 30 parts, ZnO 9 parts, NiO 3 parts;

[0028] The raw materials of the auxiliary materials in parts by weight include: 3.5 parts of CaO, V 2 O 5 0.8 parts, SnO 2 1.1 parts, TiO 2 0.25 parts, Co 2 O 3 1 part, Nb 2 O 5 0.15 parts, MoO 3 1.1 parts, Bi 2 O 3 0.2 part, Ta 2 O 5 0.5 copies;

[0029] The raw materials of the auxiliary agent include: 13 parts by weight of polyvinyl alcohol, 0.7 parts of cetyltrimethylammonium bromide, 0.1 parts of polydimethylsiloxane, 0.8 parts of magnesium stearate, and 75 parts of water;

[0030] In the preparation process of the low-loss soft ferrite material, take the main material and wet-grind once for 2h, then adjust the temperature to 900℃, and calcinate the calcined material for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com