Filter for granulator

A granulator and filter technology, applied in the coating and other directions, can solve the problems of low filtration efficiency, affecting the extrusion uniformity of molten materials, and high requirements for material melting degree and uniformity, and achieve the effect of effective separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

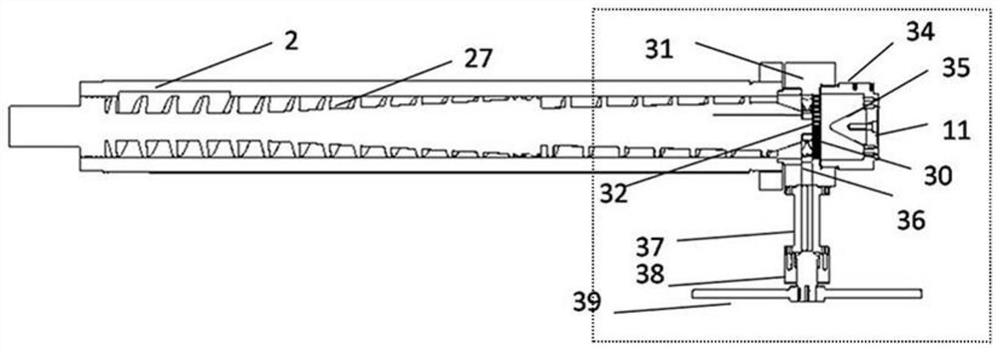

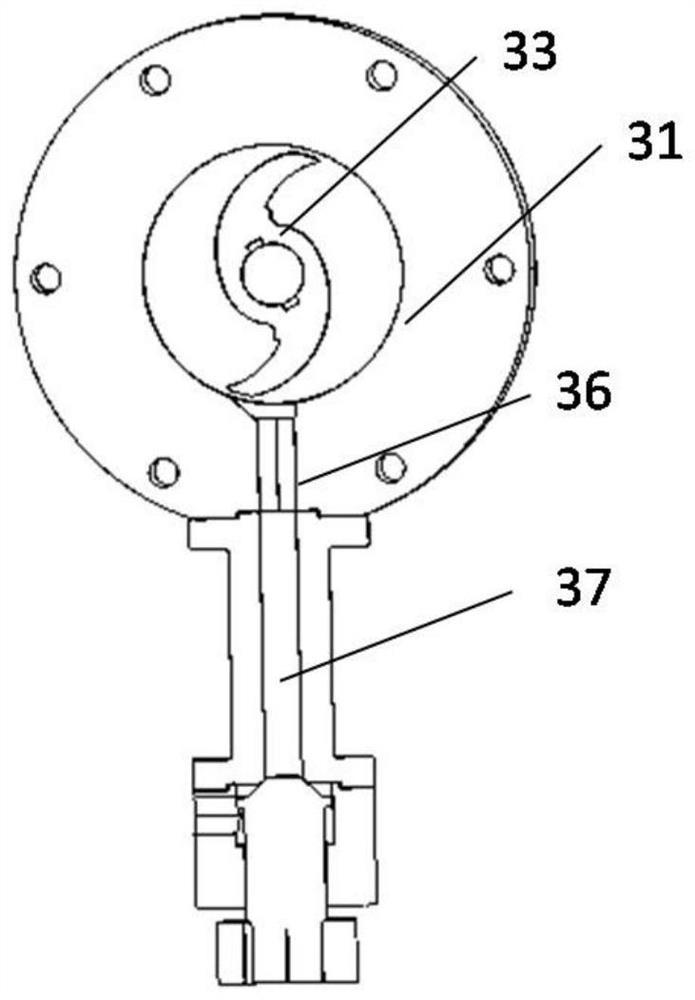

[0029] A filter for a granulator, comprising a net plate 32, a horn scraper 33, a porous flange 31 and a discharge part, the porous flange 31 is located at an end far away from the feed inlet of the sleeve, and one end of the porous flange 31 is connected to the The sleeve is fixedly connected; the outer side of the other end of the porous flange 31 is fixedly connected with a pelletizing flange 34; the inside of the porous flange 31 is hollow and uniform holes are arranged axially through, and the mesh plate 32 is located between the horn scraper 33 and the porous method. Between the uniform holes of the flange 32, the molten material can be filtered; the horn scraper 33 is coaxial with the screw rod 12, and the rotation is controlled by the same motor; the hollow inner cylindrical inner ring of the porous flange 31 has a gap 36 for removing impurities. The impurity removal notch 36 is arranged on the lower edge of the horn scraper 33; further, the lower end of the porous flan...

Embodiment 2

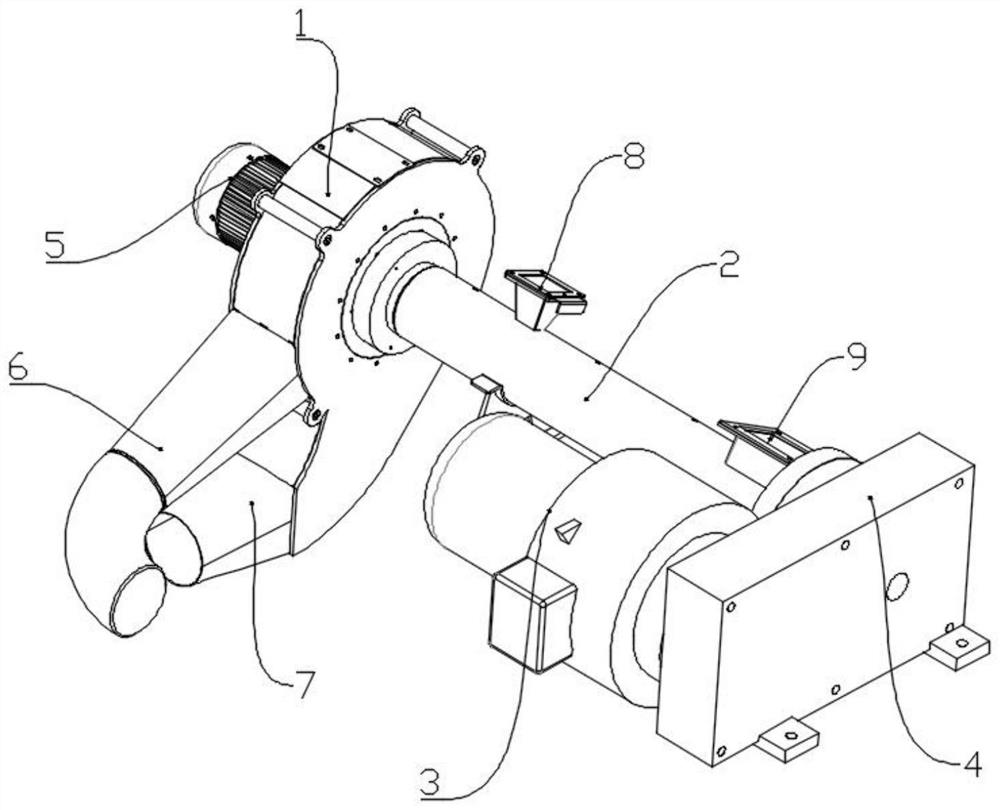

[0032]A kind of granulator, comprises the filter in embodiment 1, also comprises cyclone cover 1, sleeve 2, drive motor 3, reduction box 4, cutter motor 5, granulation plate 11, and winnowing mechanism 25, filter The transmission motor 3 is connected with the reduction box 4, the particle output plate 11 is fixed on the cyclone cover 1, the two ends of the sleeve 2 are respectively fixed on the particle output plate 11 and the reduction box 4, and the screw 12 is set Inside the sleeve 2, bearings are provided at the joints between the two ends of the screw rod 12 and the reduction box 4 and the pellet plate 11; the cutter motor 5 is installed on one side of the cyclone cover 1, and the cutter motor 5 is equipped with a Shaft 20, one end of the motor shaft 20 extends to the inner side of the cyclone cover 1, the motor shaft 20 is provided with a through hole 26 along the axial direction, and one end of the motor shaft 20 is provided with an air outlet 17 connected with the throu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com