Patents

Literature

102results about How to "Reduce drawing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

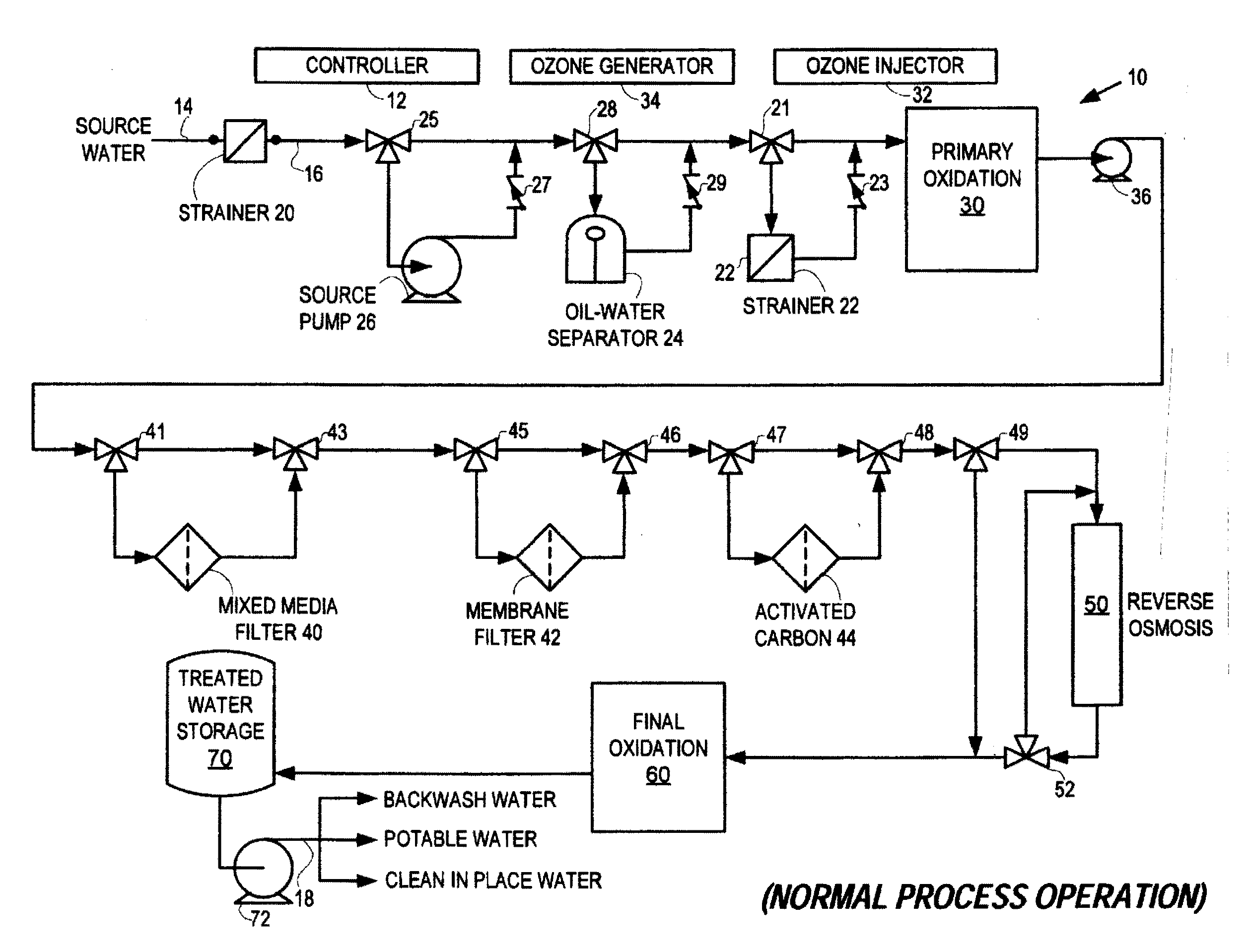

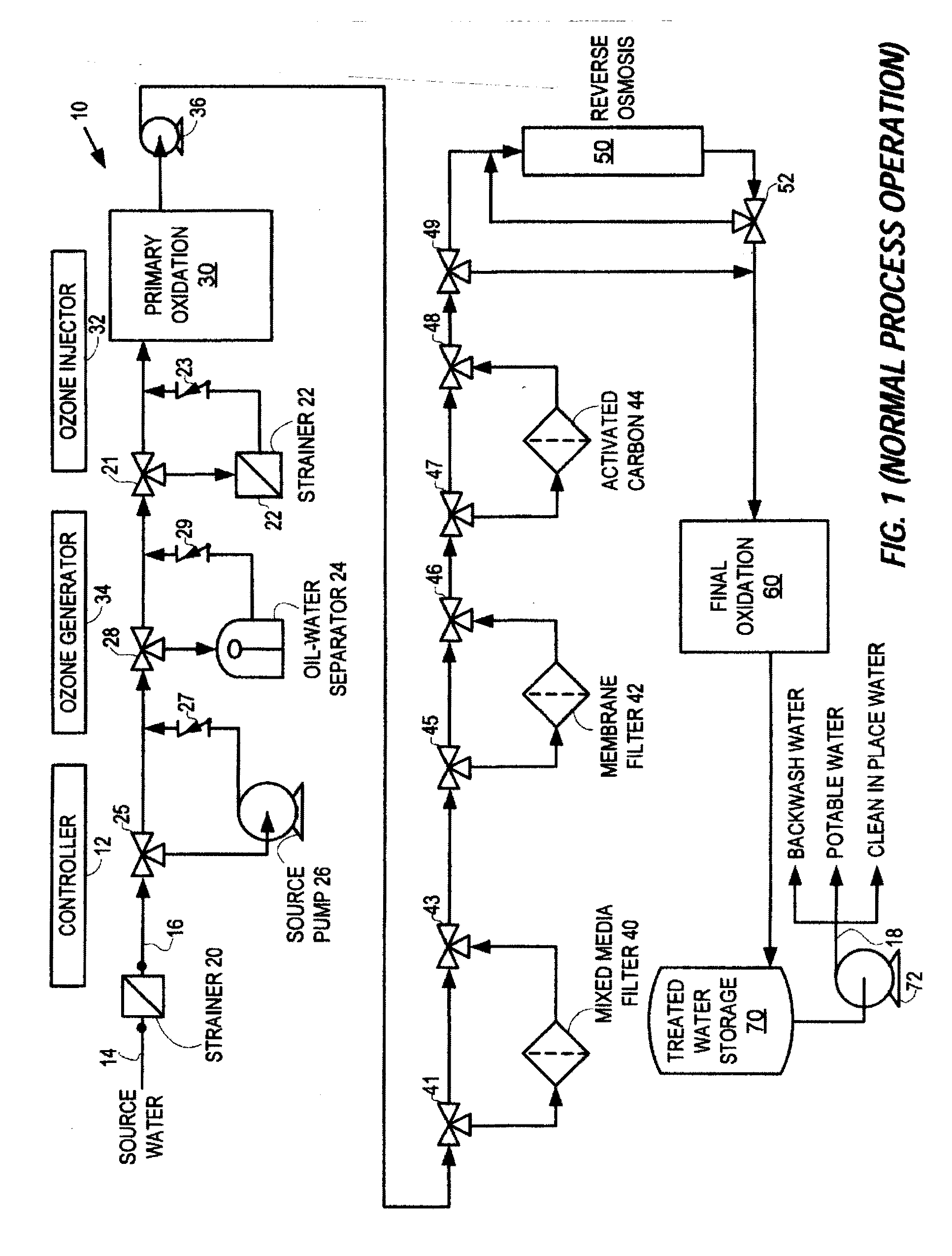

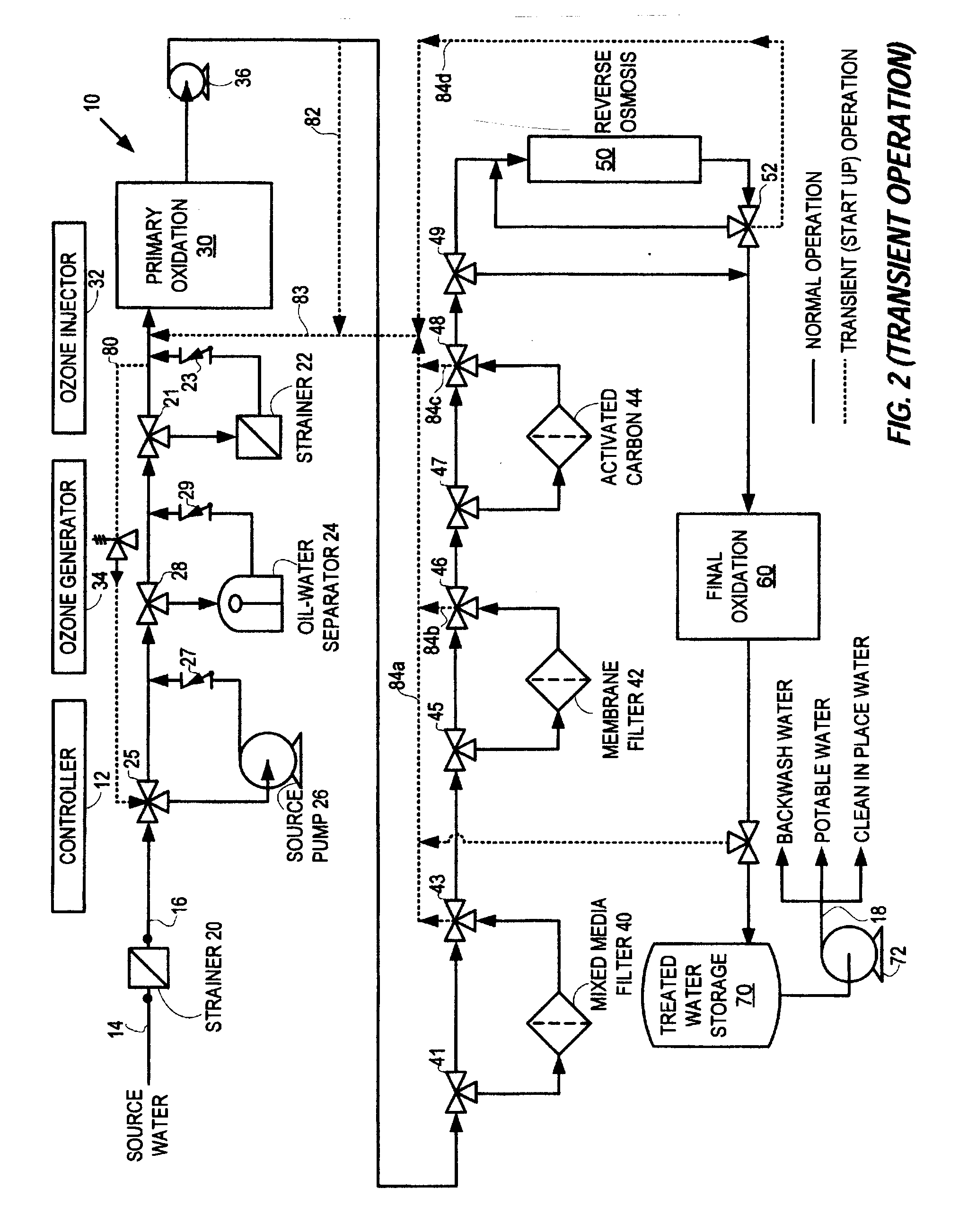

Water treatment systems and methods

InactiveUS20130313191A1Easy to disinfectEnhance advanced oxidationWater treatment parameter controlWater/sewage treatment by irradiationParticulatesActivated carbon

Water treatment systems and methods. Embodiments provide water treatment systems which comprise first oxidation, particulate filtration, and membrane filtration subsystems in that order. Systems also comprise recirculation paths and sensors for these subsystems. A controller determines whether to recirculate water to a previous subsystem in the order. Systems can comprise downstream second oxidation, high pressure membrane, ion exchange, activated carbon subsystems and / or ultraviolet contactors. Systems with high pressure membranes can comprise a pump before the high pressure membranes, a booster pump of the high pressure membrane subsystem, and a damping tank. In such systems the controller maintains a pressure in the damping tank. High pressure membrane subsystems can further comprise nanofiltration membranes and RO membranes. Systems can comprise bypass paths for some / all of the subsystems. For such systems, the controller further determines, whether to bypass these subsystems.

Owner:OMNI WATER SOLUTIONS

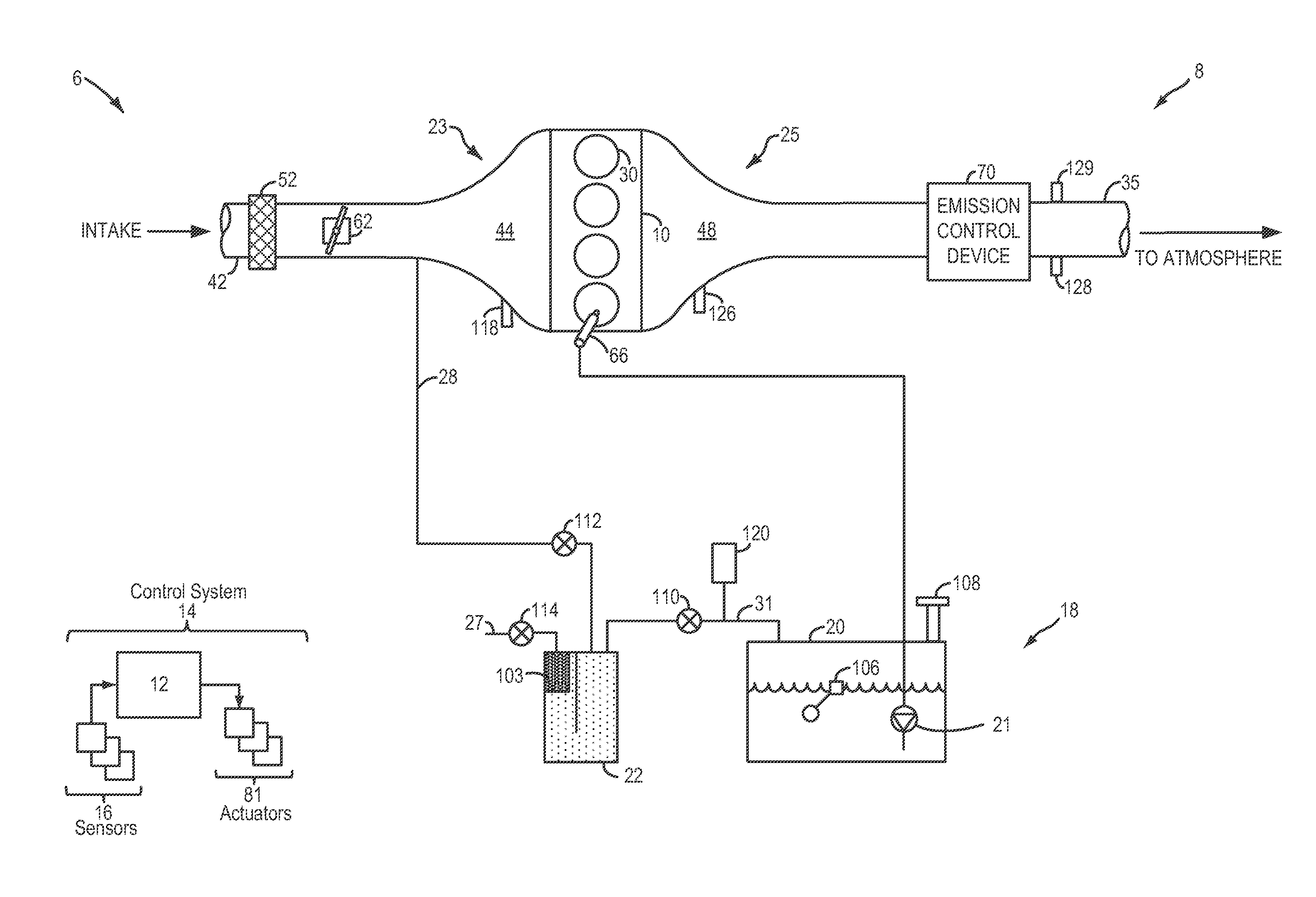

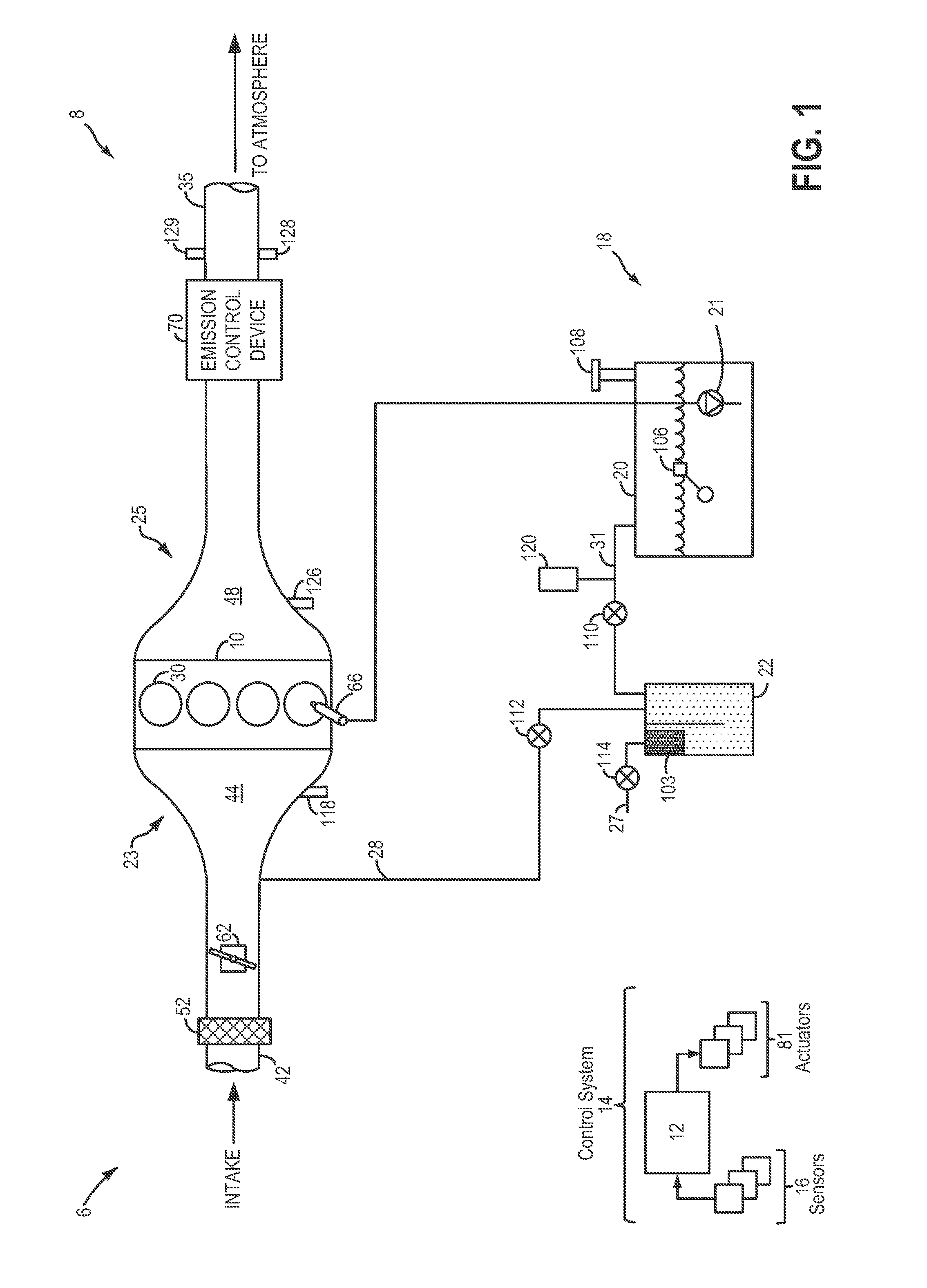

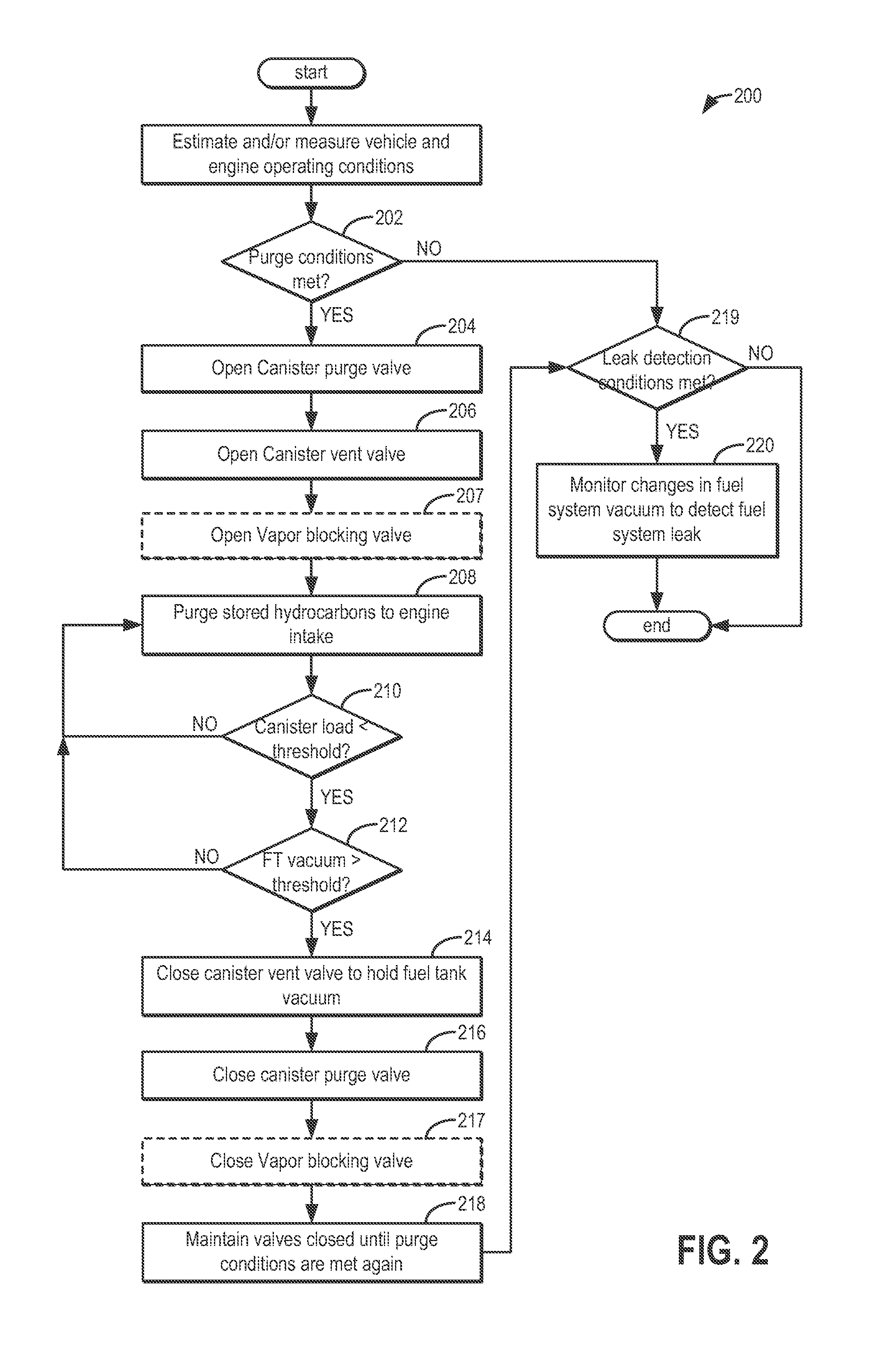

Method and system for fuel system control

ActiveUS20140026866A1Shorten operation timeFuel economyHybrid vehiclesElectrical controlFuel tankEngineering

Methods and systems are provided for controlling a fuel system in a hybrid vehicle. Before canister purging is stopped by closing a purge valve, a canister vent valve is closed to hold fuel tank vacuum. Then, during a subsequent canister purge, the purge valve is opened before opening the vent valve, allowing canister purge to initiate under fuel tank vacuum conditions.

Owner:FORD GLOBAL TECH LLC

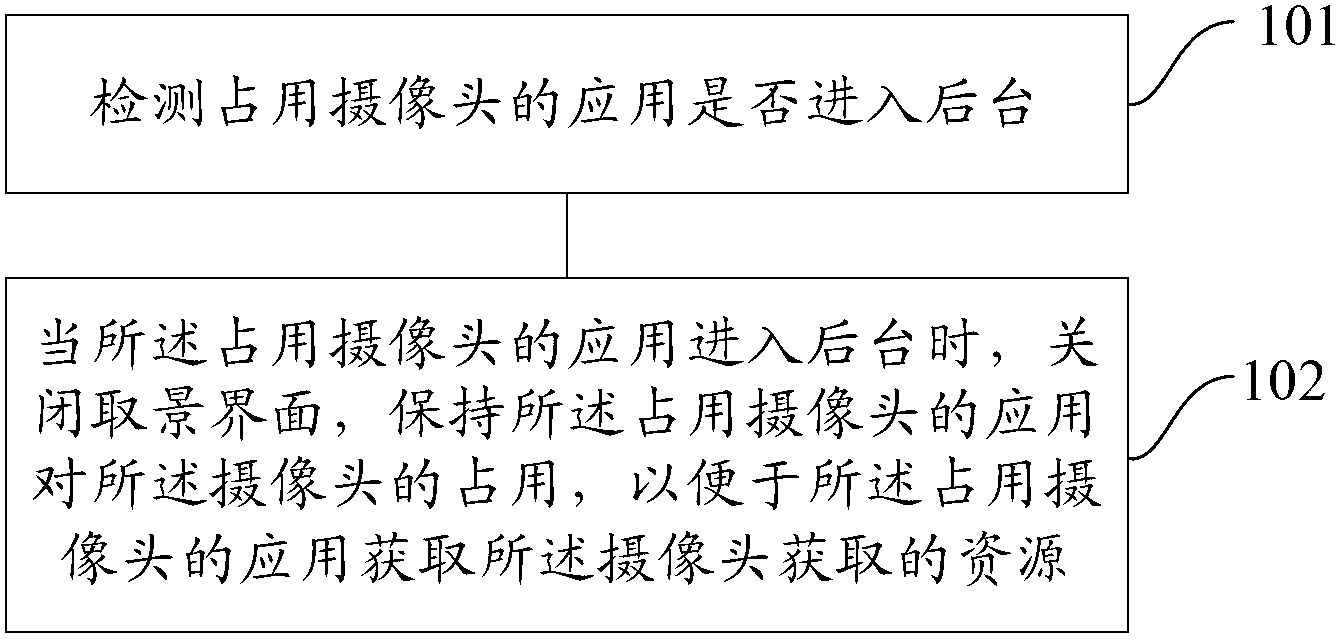

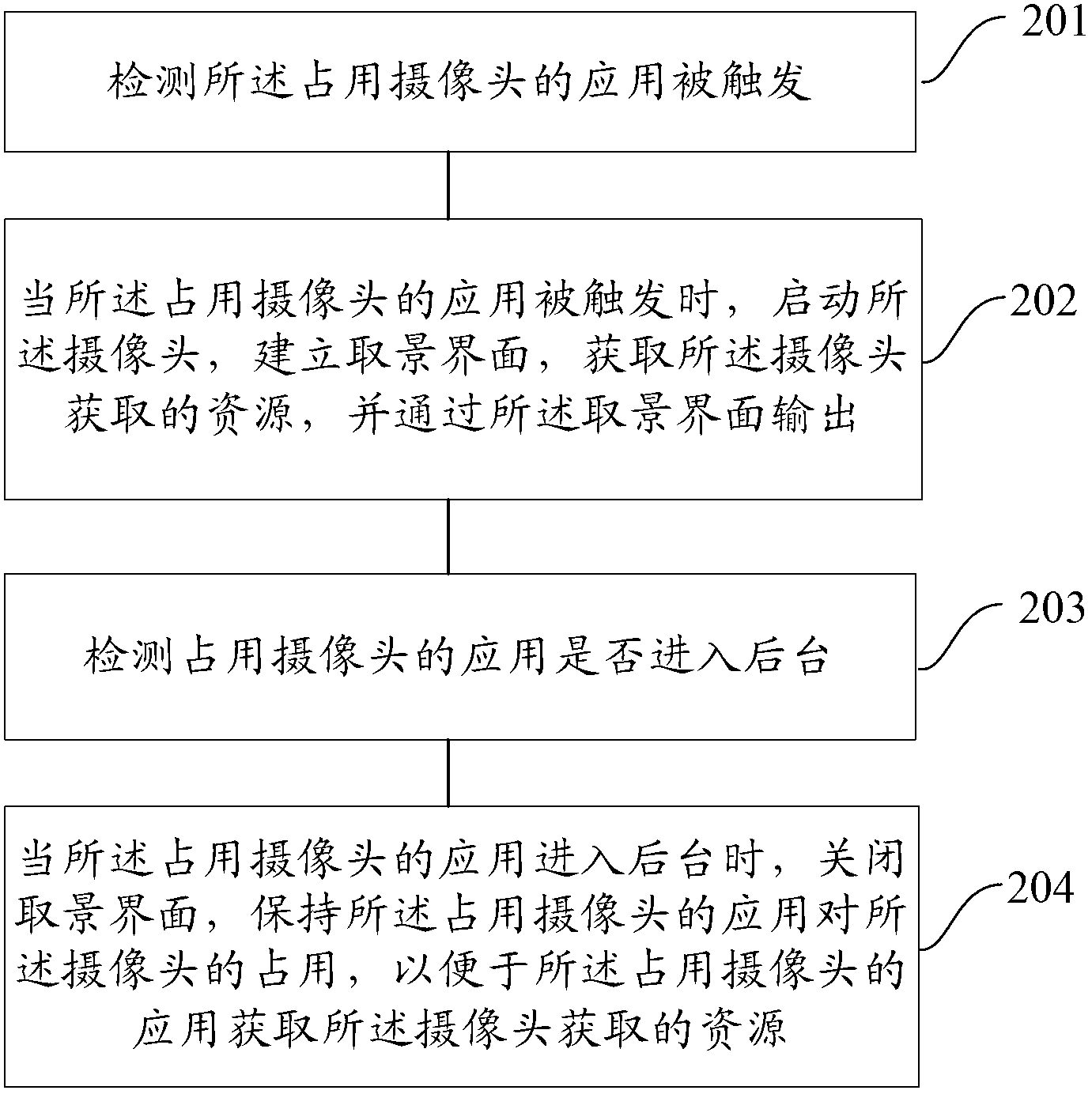

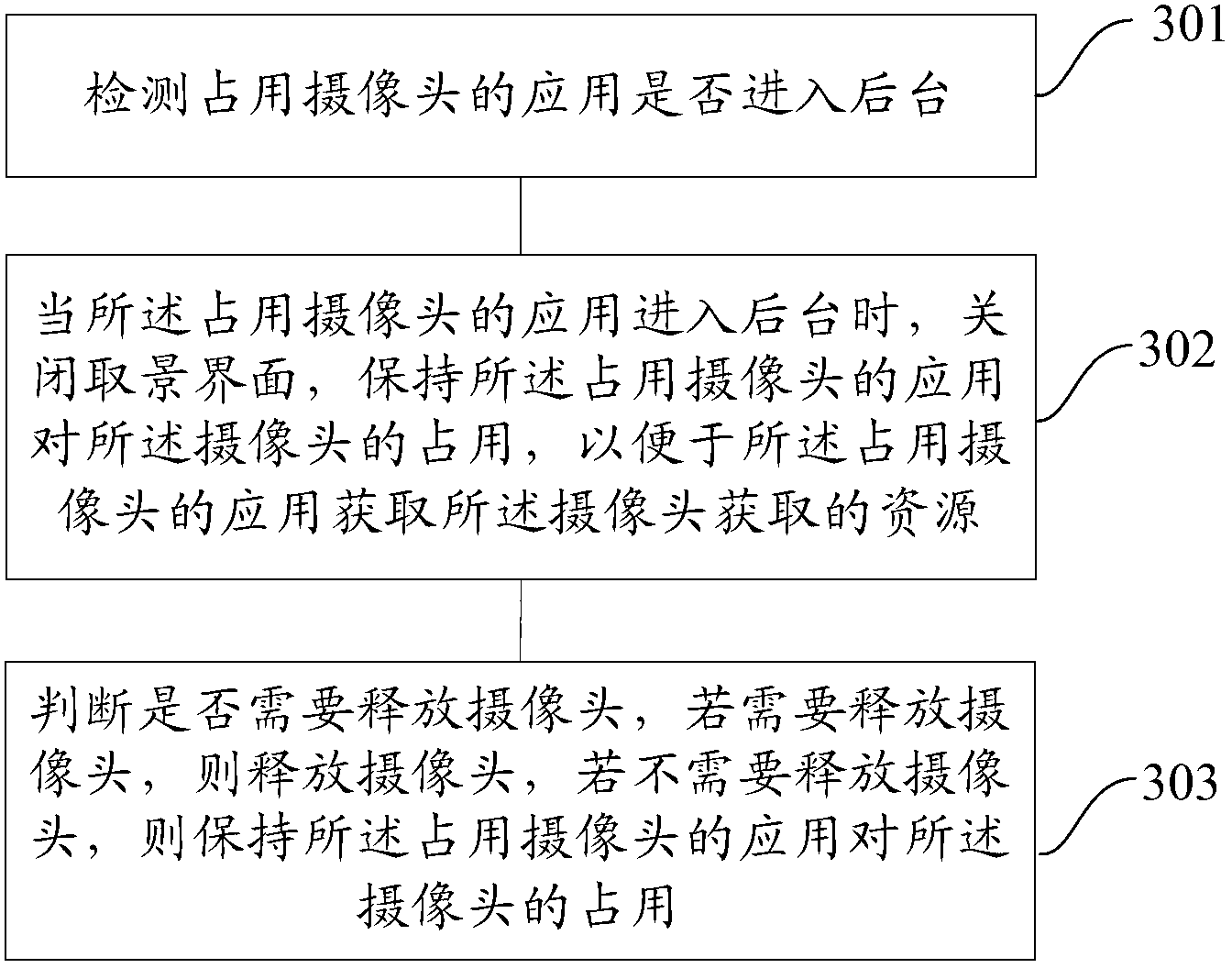

Method, device and equipment for acquiring images

ActiveCN103257939APrivacy protectionIncrease entertainmentEnergy efficient computingElectric digital data processingUser privacyElectric energy

An embodiment of the invention provides a method, a device and equipment for acquiring images. The method includes detecting whether an application occupying a camera enters a background or not; and when the application occupying the camera enters the background, closing a view-finding interface and maintaining occupancy of the application occupying the camera on the camera for the convenience of the application occupying the camera to acquire resources acquired by the camera. By the method, the device and the equipment for acquiring the images, multitask operating capability of intelligent equipment can be guaranteed, electric energy can be saved, system performance can be improved, user privacy can be protected, and entertainment can be increased.

Owner:XIAOMI INC

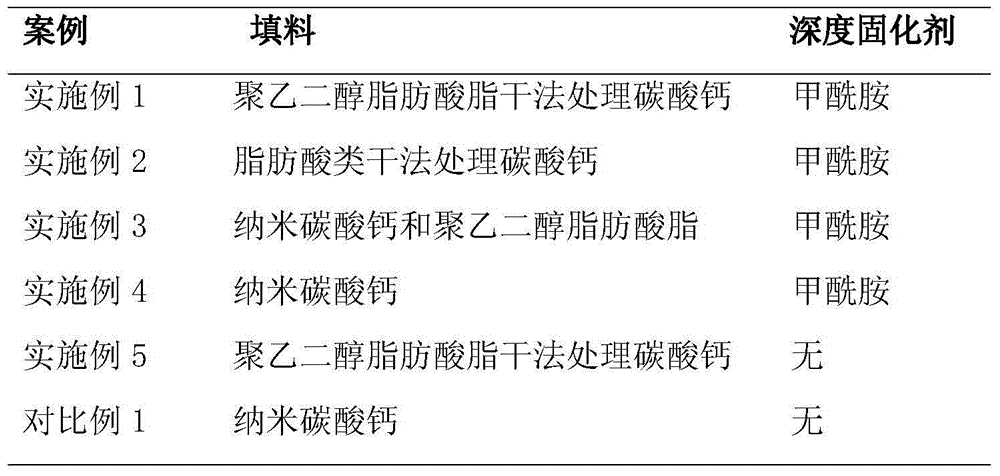

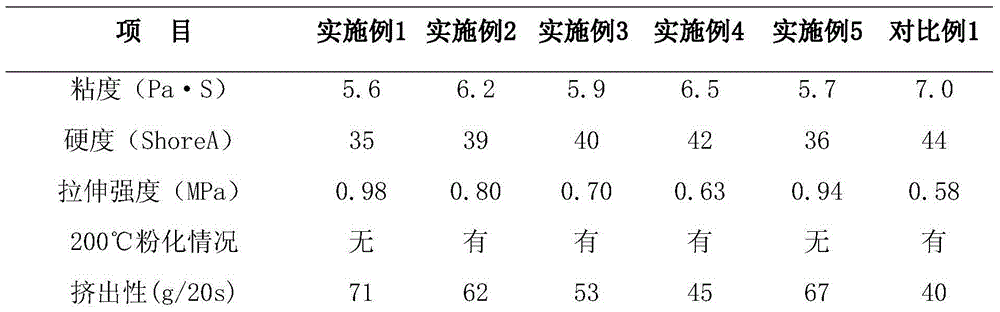

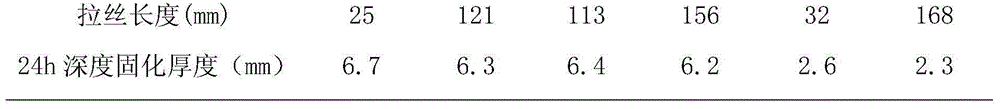

Single-component dealcoholized and room temperature vulcanized organosilicone pouring sealant for leds and preparation method

InactiveCN104449547AImprove liquidityReduce drawingNon-macromolecular adhesive additivesOther chemical processesCross-linkVulcanization

The invention discloses a single-component dealcoholized and room temperature vulcanized organosilicone pouring sealant for LEDs and a preparation method. The pouring sealant is prepared from the following raw materials in parts by weight: 100 parts of alpha, omega-dihydroxy polydimethyl siloxane with a viscosity of 500-15000 mPa.s, 10-50 parts of dry processed nano calcium carbonate, 1-10 parts of calcium chloride, 5-10 parts of white carbon black, 8-20 parts of dimethicone with a viscosity of 100-5000 mPa.s, 3-10 parts of a cross-linking agent, 0.3-5 parts of a coupling agent, 0.5-8 parts of titanium complex, 0.01-0.5 part of organotin and 0.5-10 parts of a deep vulcanization accelerator. The pouring sealant provided by the invention has an excellent flow property with low thread drawing, the capabilities of anti-pulverization at a high temperature and fast and deep curing, and a good mechanical property; the produced gas has good cohesiveness on the base material without corrosive action; the method is simple and feasible in technology, easy to operate and low in production cost, and has preferable economic and social benefits.

Owner:GUANGXI HUANA NEW MATERIALS TECH CO LTD

Building design method based on BIM (building information modeling)

InactiveCN108537519AHigh simulationLearn about service lifeGeometric CADOffice automationInformation processingIntelligent design

The invention discloses a building design method based on BIM (building information modeling). Intelligent design of construction is realized through steps of data acquisition, parametric design, collision check, model optimization, simulated construction, model modification and the like; compared with the traditional building design method, mistaken and omitted drawings are reduced, drawing scalemore approaches reality data, cooperative work is performed, repeated work is reduced, collaboration ability of a team is improved, information transfer and distribution efficiency is increased, anddata sources of economic management and risk management are collected more efficiently; with adoption of a centralized information processing method, an analysis process of management is precise, anddecision making efficiency is increased.

Owner:SHAANXI SCI TECH UNIV

Electroplating-free antique metal surface treatment method

ActiveCN104384088AReduce pollutionReduce grindingPretreated surfacesPolyurea/polyurethane coatingsSolution treatmentAcrylic resin

The invention discloses an electroplating-free antique metal surface treatment method. After a material surface is subjected to deoiling and surface activation, a primer is firstly sprayed and cured and then a finish paint is sprayed, wherein the primer consists of color paste, metal powder, polyurethane resin or acrylic resin and an assistant. According to the method, electroplating, chemical dyeing solution treatment and the like are not required, so that the environment pollution caused by the electroplating and the chemical dyeing solution is greatly reduced, processes such as grinding and wire drawing are also reduced, a production process is simplified, the production cost is reduced, and the technological process is environment-friendly; a texture effect of an antique metal layer is formed on the material surface, so that the product function and quality are improved.

Owner:XIAMEN RUNNER IND CORP

3D printer spray head with adjustable nozzle caliber

ActiveCN108248041AAdjustable sizeQuality improvementIncreasing energy efficiencyApplying layer meansThroat3d printer

The invention discloses a 3D printer spray head with an adjustable nozzle caliber. The 3D printer spray head comprises a rotor and a nozzle assembly; the rotor comprises a heat storage block, a material storage pipe, a throat pipe, a heat insulation gasket, screws and nuts; the nozzle assembly comprises a first gasket, nozzle surrounding sheets, a second gasket, a guide plate and a control plate.The nozzle surrounding sheets are matched with one another to form a polygonal nozzle flow channel, and a guide groove for guiding the movement of the nozzle surrounding sheets is arranged on the guide plate to guide the movement direction of the nozzle surrounding sheets. The control panel is matched with the guide plate, and the relative rotation between the control panel and the guide plate canchange the size of the side length of the polygon enclosed by the nozzle surrounding sheets, thus realizing an adjustable size of the printing nozzle circulation area. The heat storage block is connected with the material storage pipe through screws and nuts, so that the heat transfer resistance between the heat storage block and the material storage pipe can be effectively improved.

Owner:HEBEI UNIV OF TECH

Versatile low power driver for gigabit ethernet systems

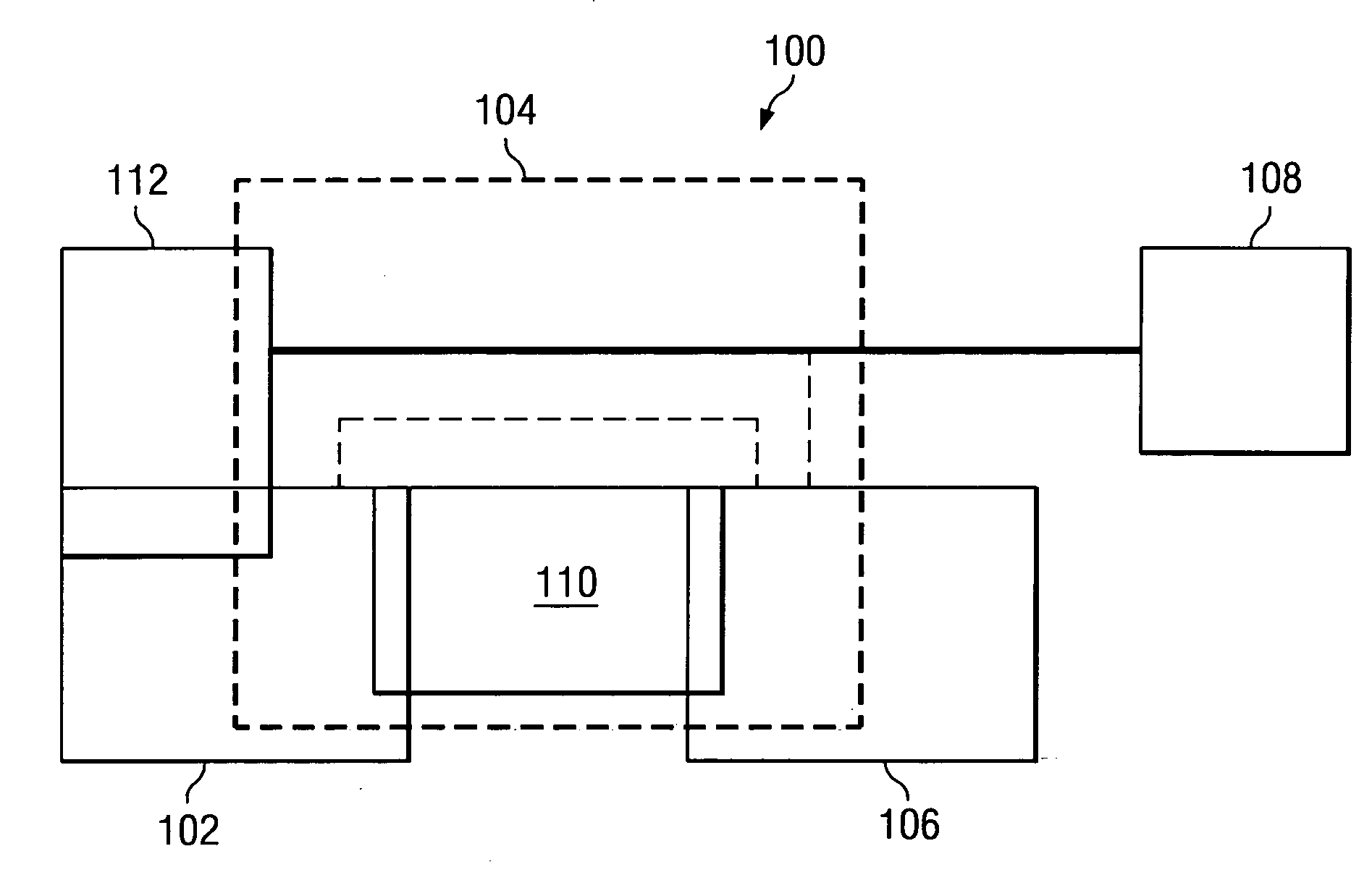

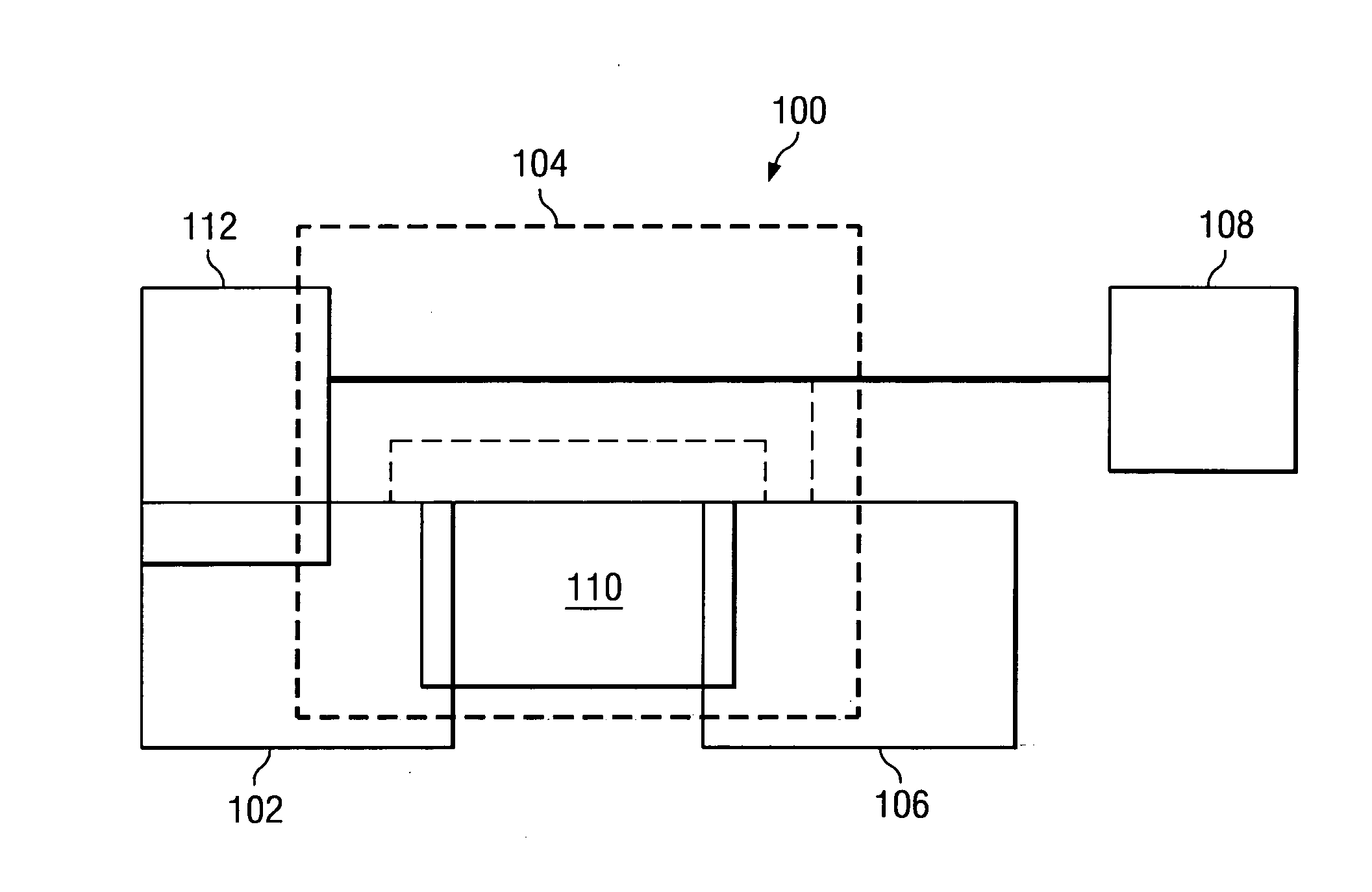

InactiveUS20060023735A1Reduce inefficient transmit power consumptionReduces PHY power consumptionData switching current supplyNetwork connectionsCommunications systemEmbedded system

The present invention provides a system for optimizing transmission output power for a Gigabit Ethernet communications system (100). A PHY operational layer (104) is provided, with a backoff construct (102) that is at least partially implemented within the PHY operational layer. A second end component (108) is communicatively coupled to the PHY operational layer. An estimating construct (110) is implemented within the PHY operational layer, and is cooperatively associated with the backoff construct. The estimating construct determines whether the second end component is at a short or a long distance and, responsive to that determination, the backoff construct adjusts transmit output voltage swing.

Owner:TEXAS INSTR INC

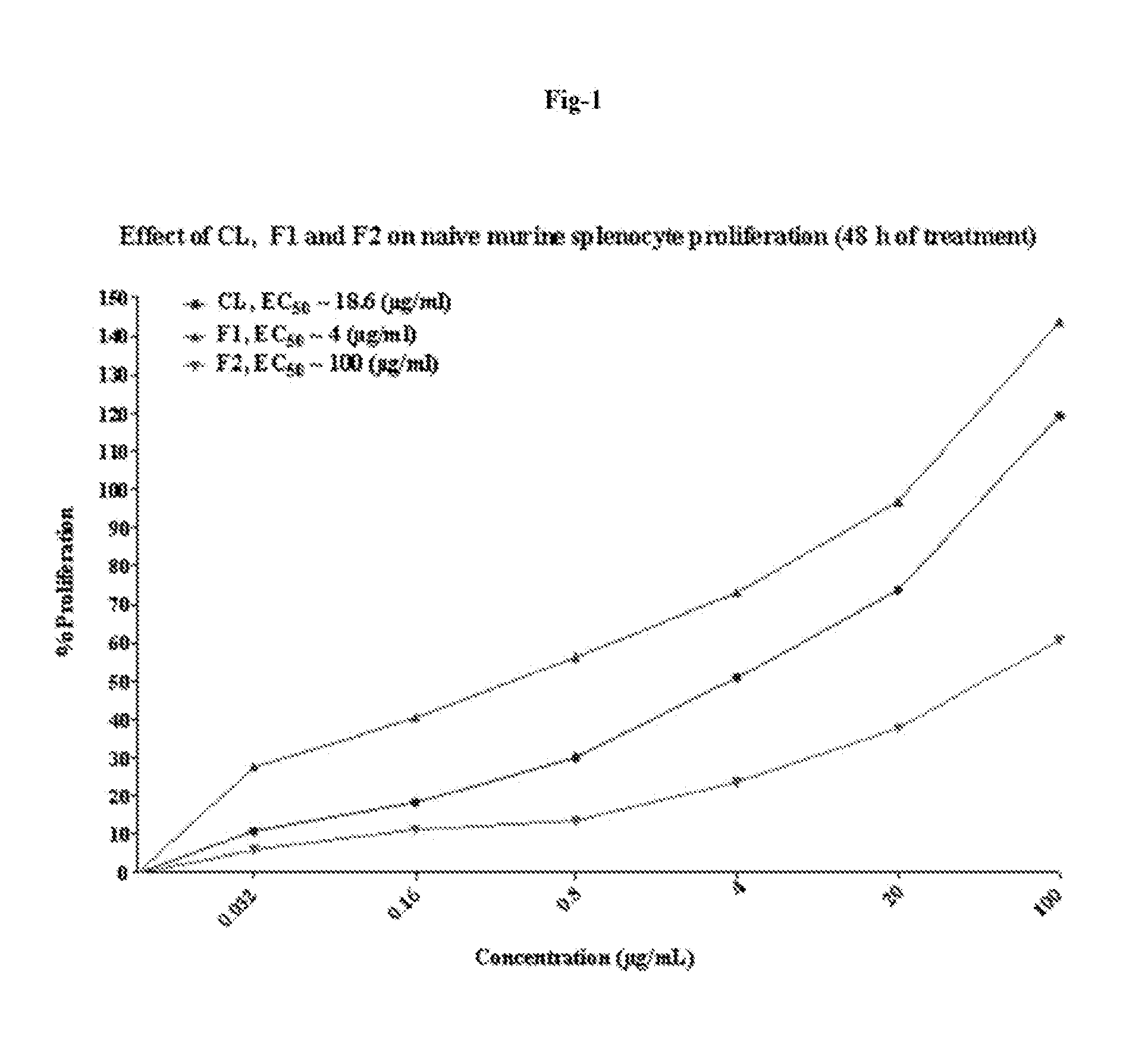

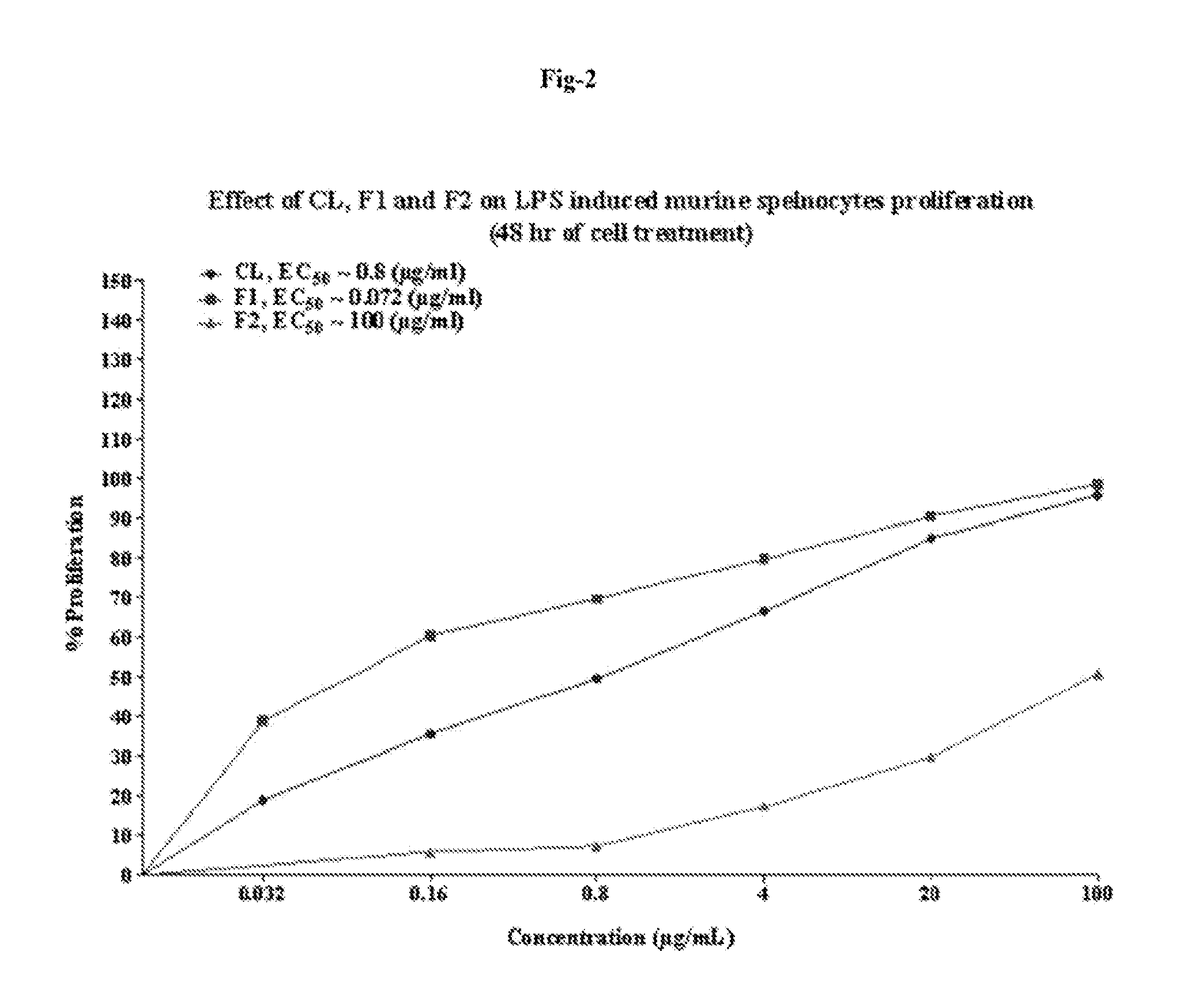

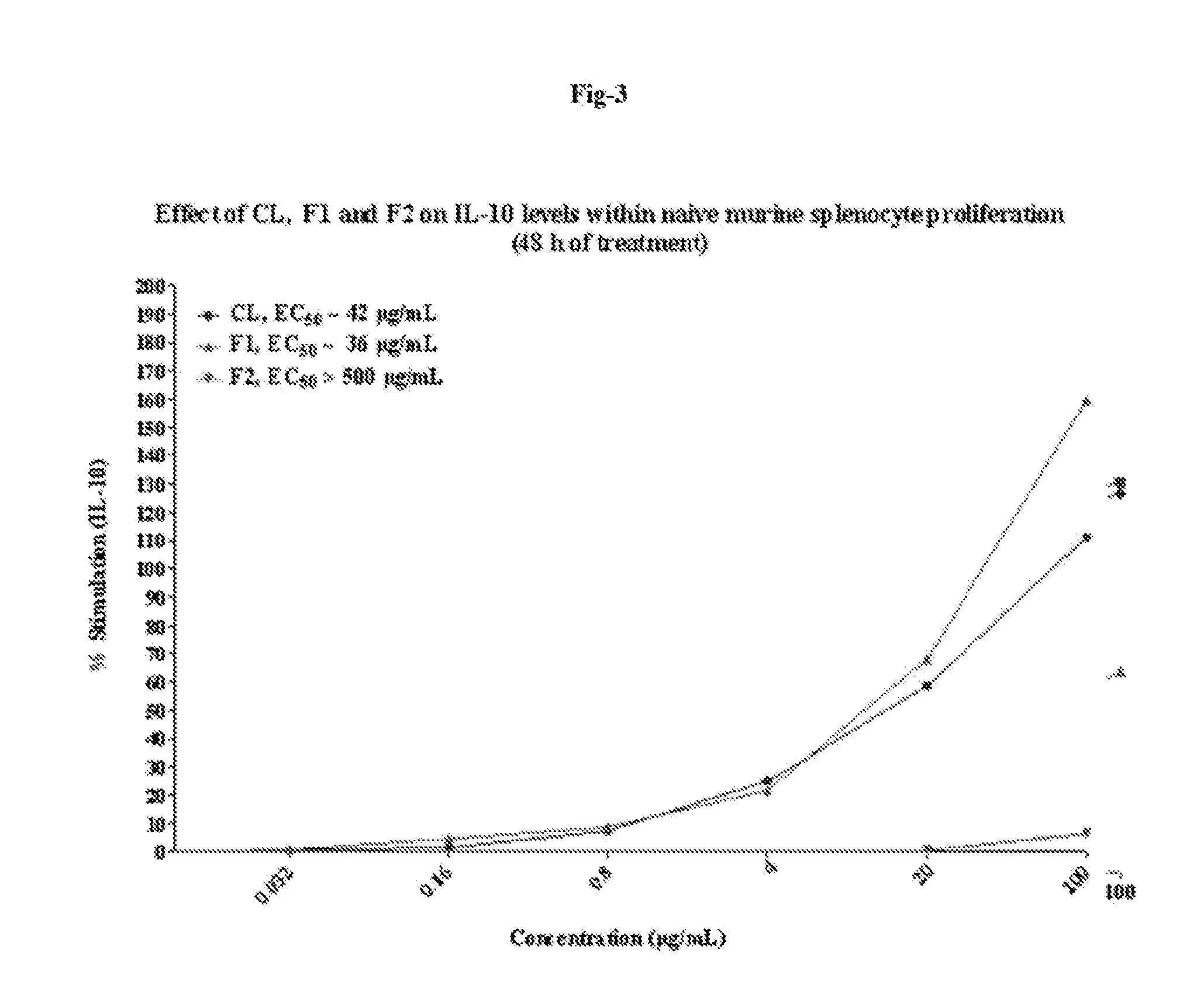

Synergistic phytochemical composition and a process for preparation thereof

ActiveUS20130053339A1Cause constipationIncreased riskBiocideOrganic active ingredientsChronic painExcipient

The present invention provides a synergistic phytochemical composition from Curcuma longa possessing analgesic and anti inflammatory activity used for management of chronic pain and treatment of osteoarthritis. The composition comprises Curcuma longa oil and Curcuma longa water extract. The relative amounts of these materials may be 0.5-5% by weight and 95-99.5% by weight respectively; and optionally pharmaceutically acceptable excipients.The present invention also provides a process for preparing the composition.

Owner:NATURAL REMEDIES PVT LTD

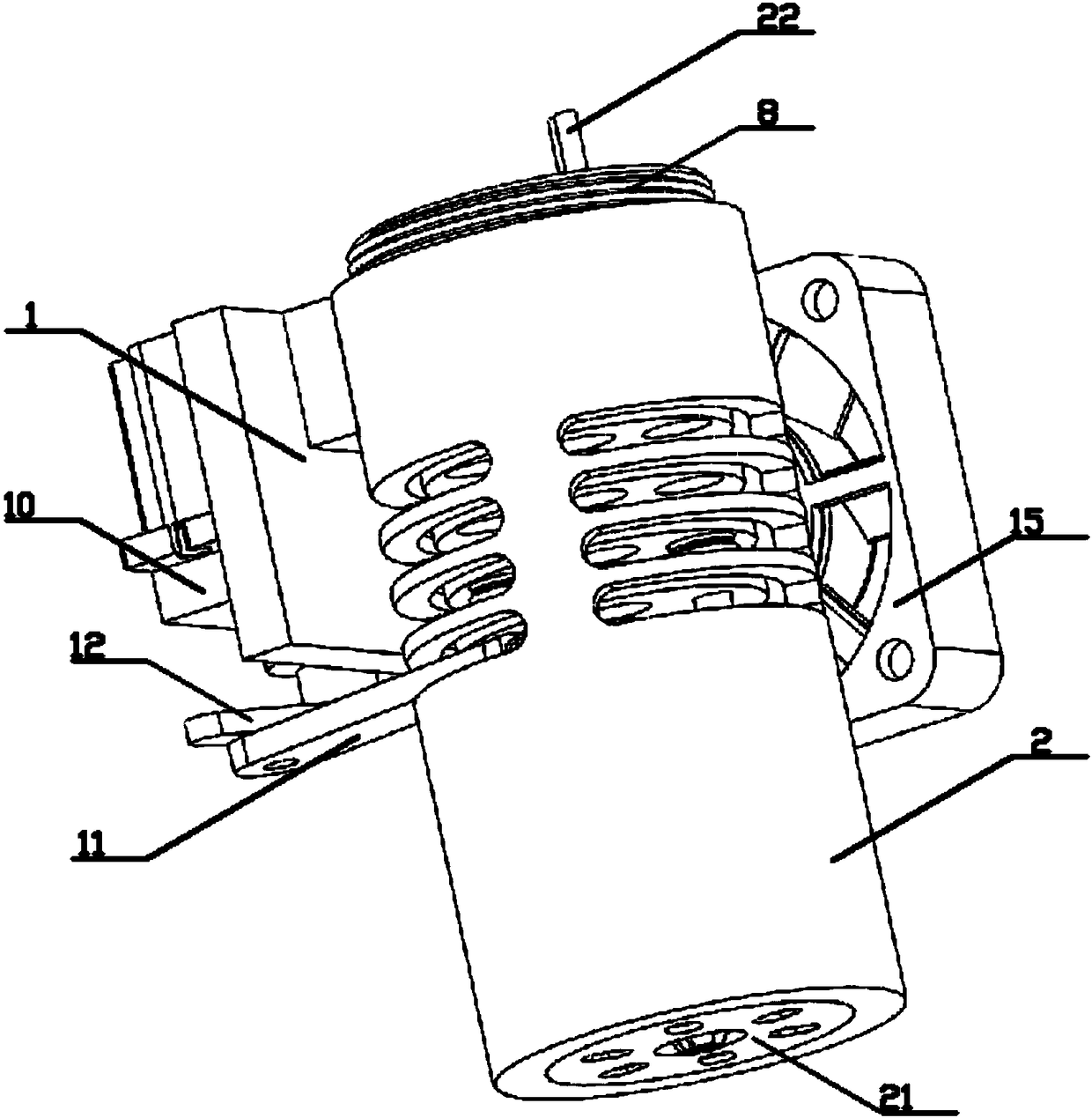

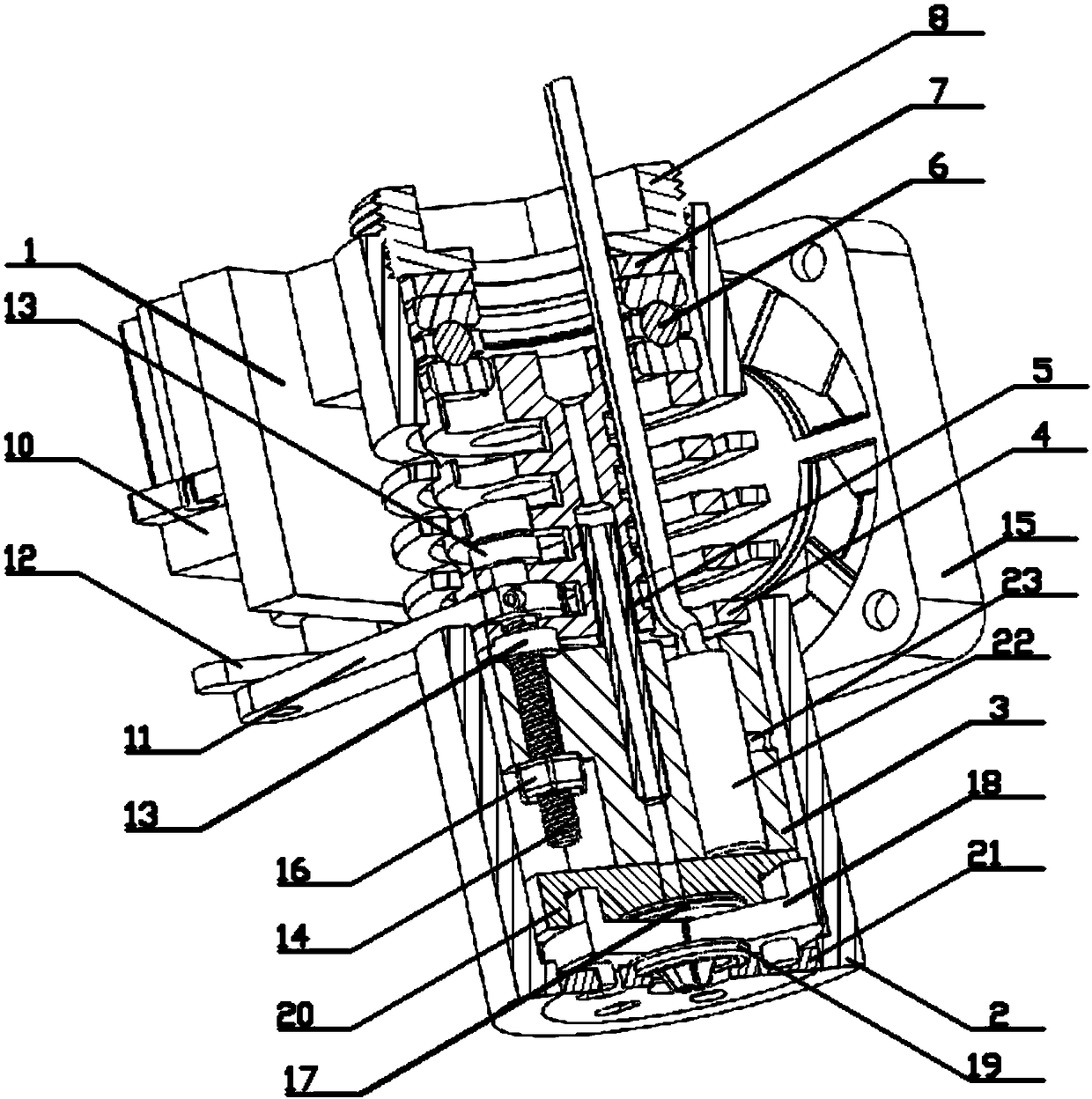

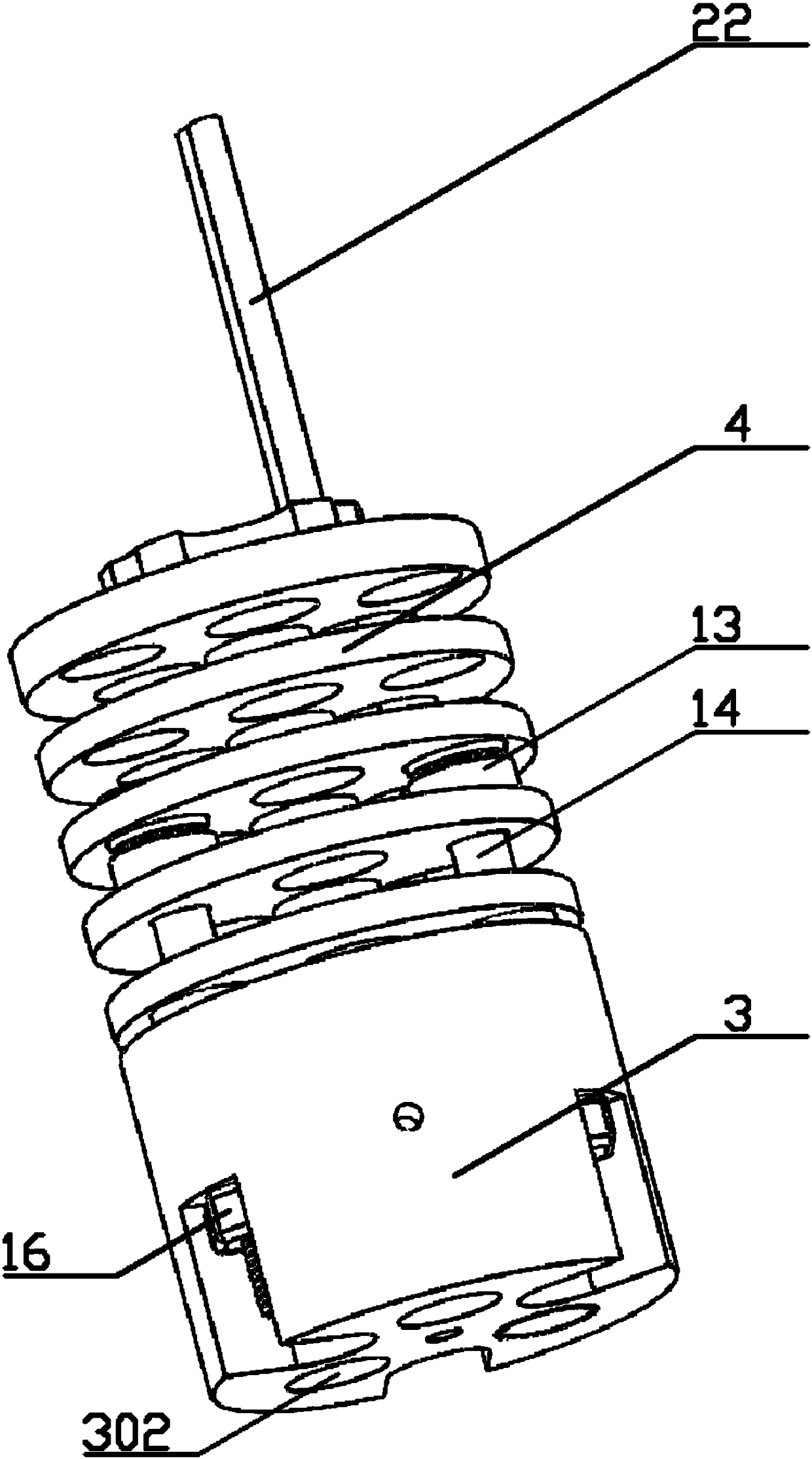

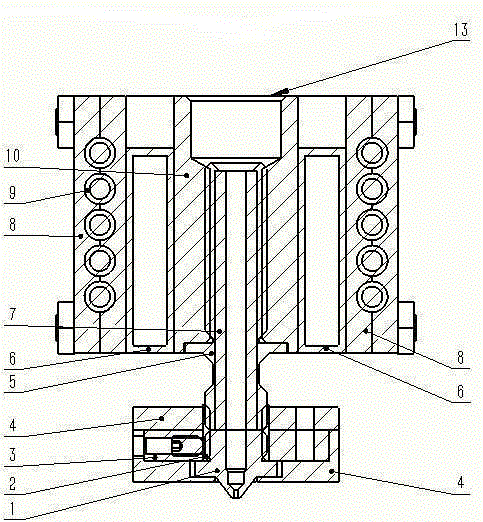

Hot end device of desktop-level FDM (frequency-division multiplexing) 3D printer

ActiveCN105252773AStable printing performanceImprove printing effectAdditive manufacturing apparatusThermal insulationEngineering

The invention discloses a hot end device of a desktop-level FDM (frequency-division multiplexing) 3D printer. The hot end device comprises an extrusion head, wherein the extrusion head comprises an extrusion spray nozzle (1) with a hexagonal flange in middle, an extrusion head heat conduction block (3) with a mounting hole position, an extrusion head thermal insulation housing (4), a stainless steel throat tube (5), a polytetrafluoroethylene lining tube (7) arranged in the stainless steel throat tube (5) and an MCH ceramic heating plate (12), and further comprises a throat tube radiator arranged on the upper part of the stainless steel throat tube (5), wherein the throat tube radiator comprises two semiconductor refrigeration plates (6), a water-cooling heat conduction block (8), a water-cooling bent tube (9), a throat tube heat conduction block (10) and two tetrafluoro fixing parts (11); and the outer upper part of the extrusion spray nozzle (1) is further provided with an inner threaded copper sleeve (2) in a sleeved mode, and is in threaded connection with the lower part of the stainless steel throat tube (5) through the upper part of the inner threaded copper sleeve (2). The hot end device of the desktop-level FDM 3D printer has the advantages of being stable in printing performance, free of wire drawing and adhesion, good in printing effect, high in quality of a printed product, and the like.

Owner:湖州南浔港廊文化旅游发展有限公司

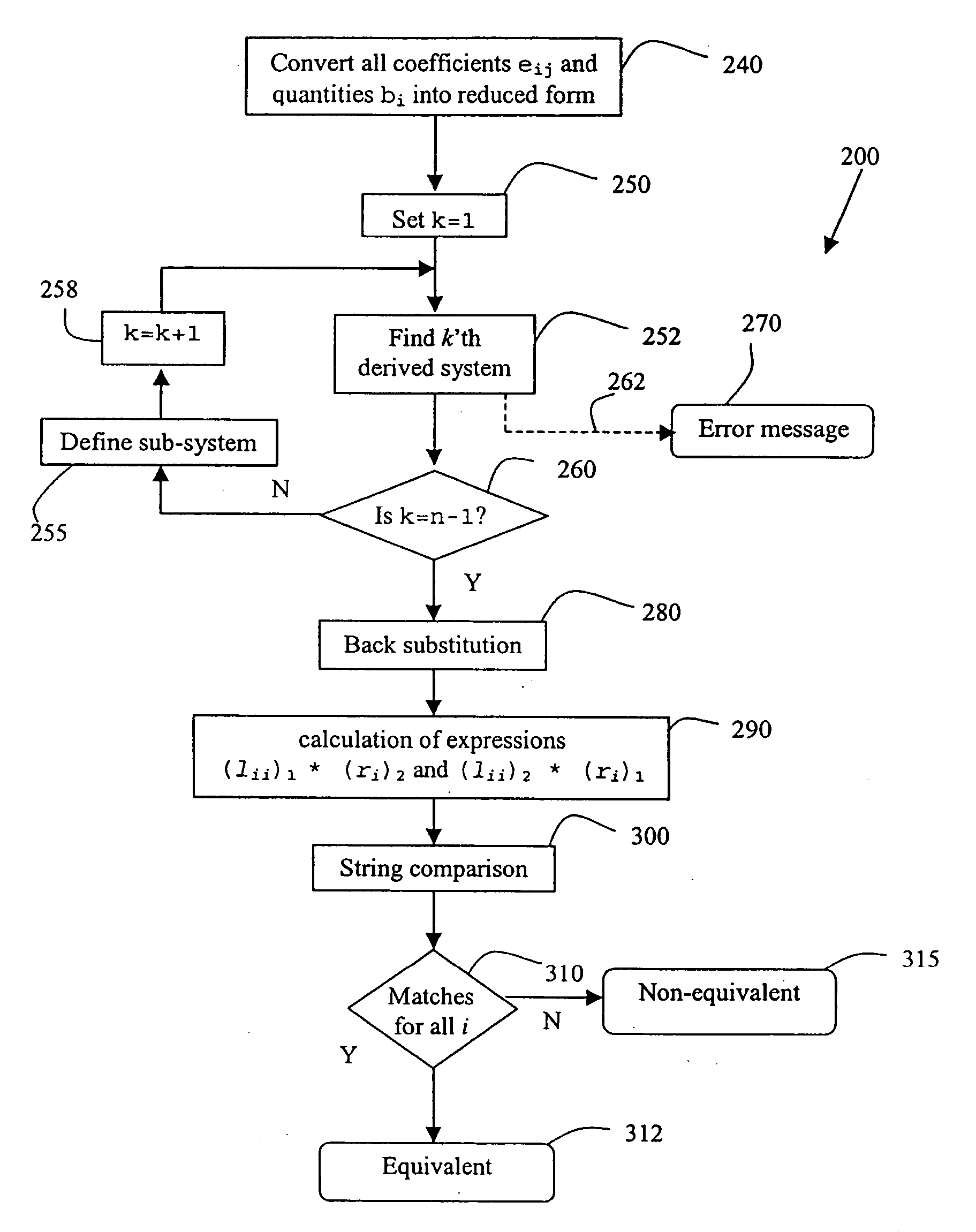

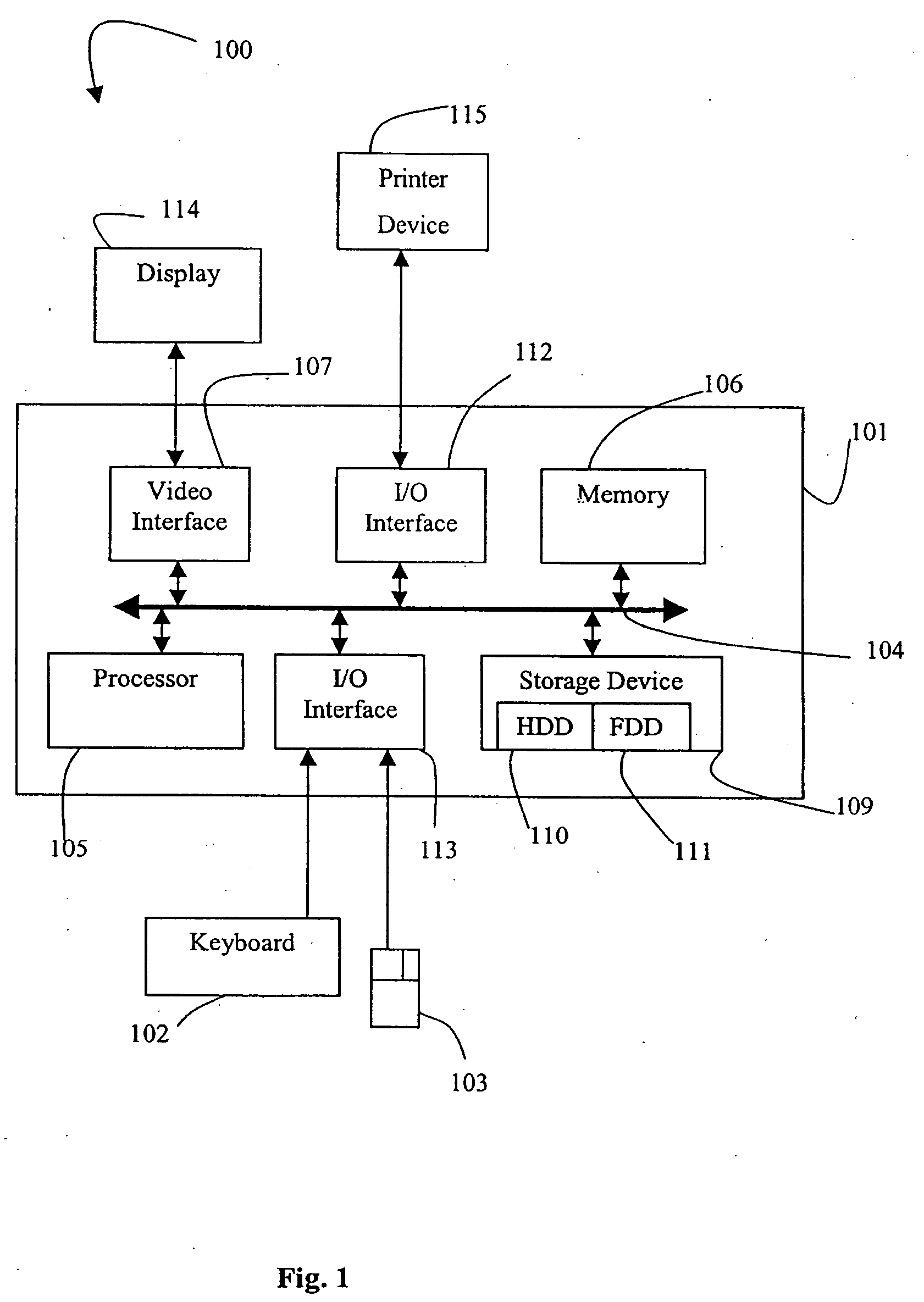

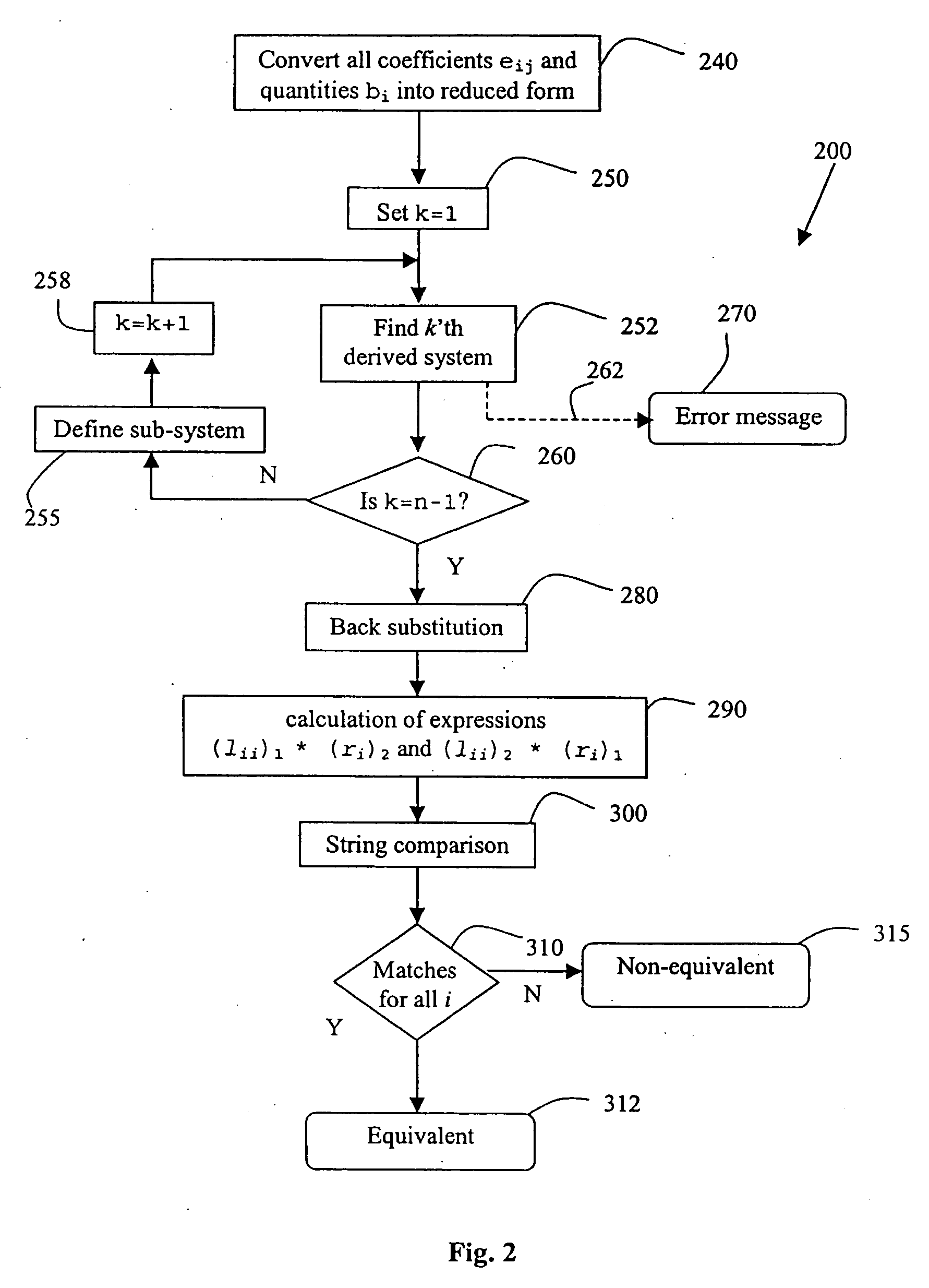

Determining the equivalence of two sets of simultaneous linear algebraic equations

InactiveUS20060015550A1Reduce drawingDigital computer detailsInput/output processes for data processingAlgorithmLinear algebraic equation

Owner:SERVICENOW INC

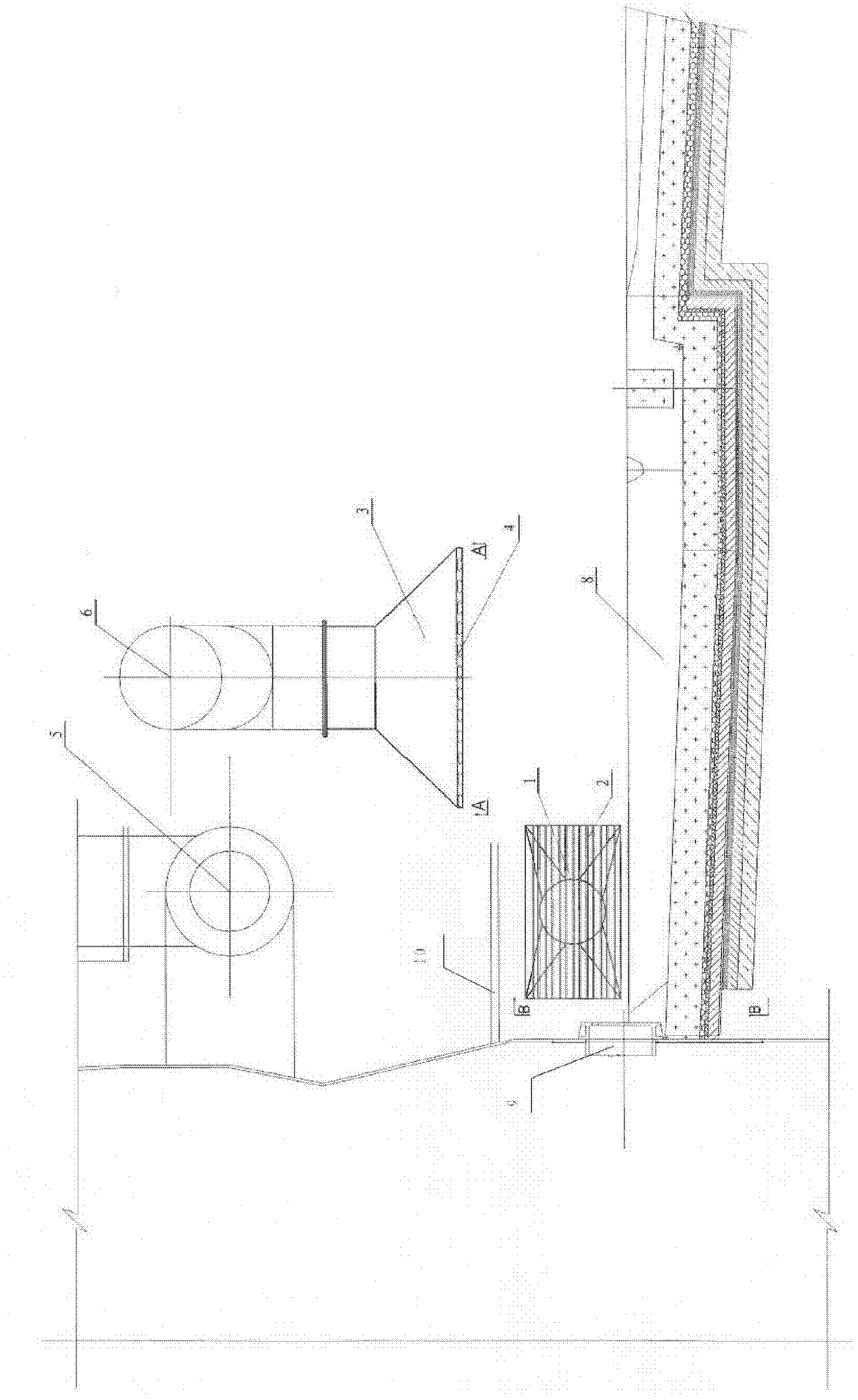

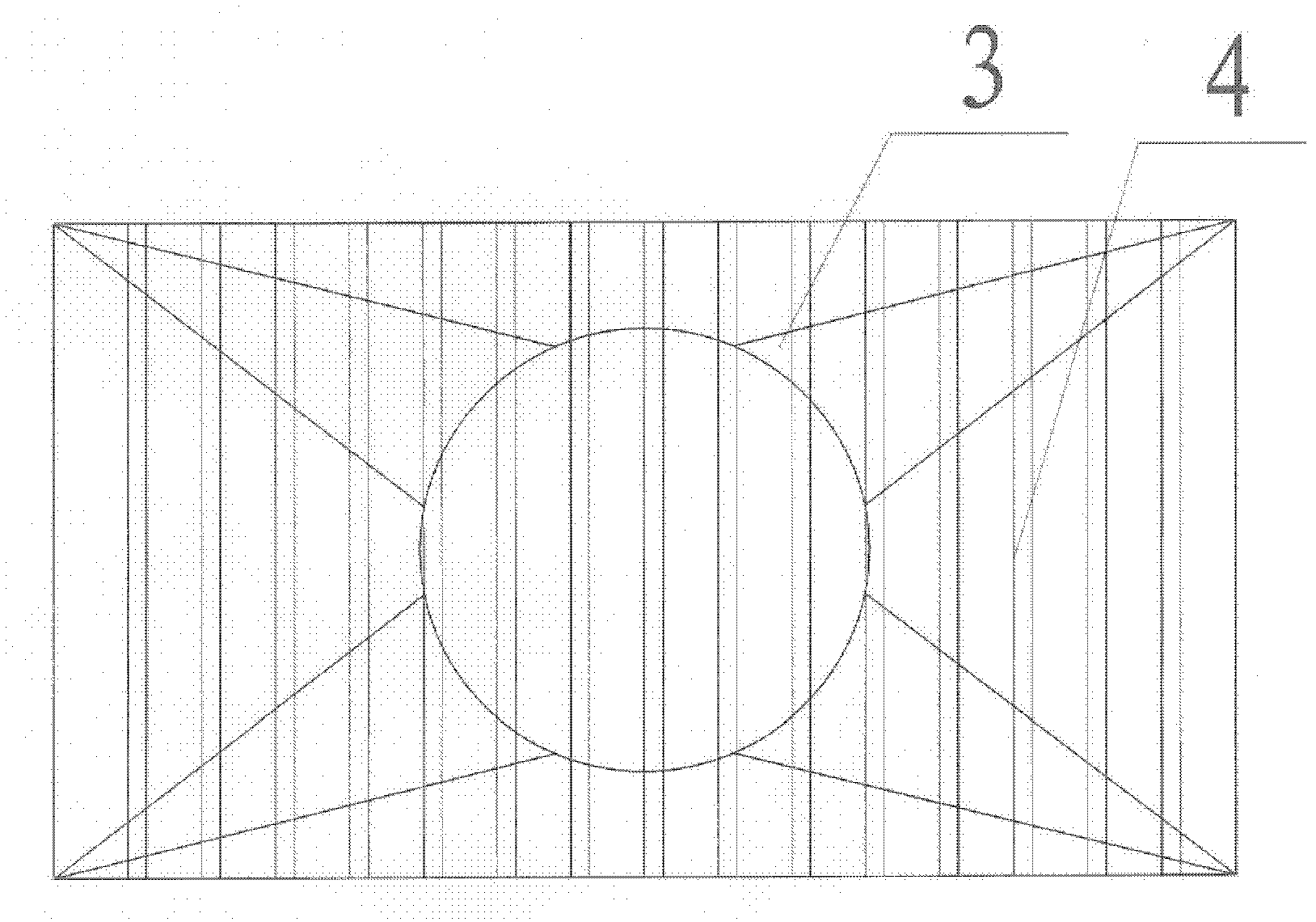

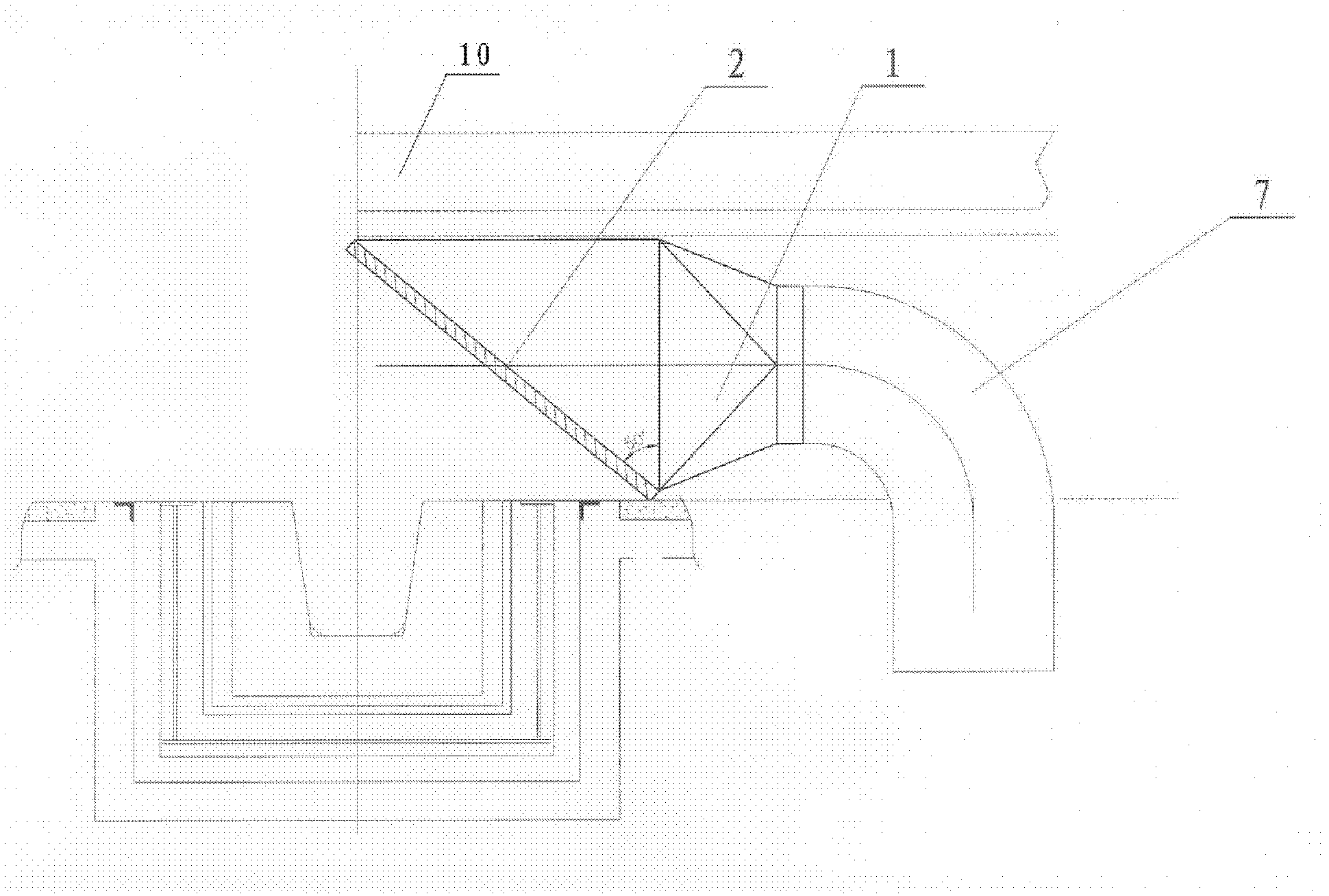

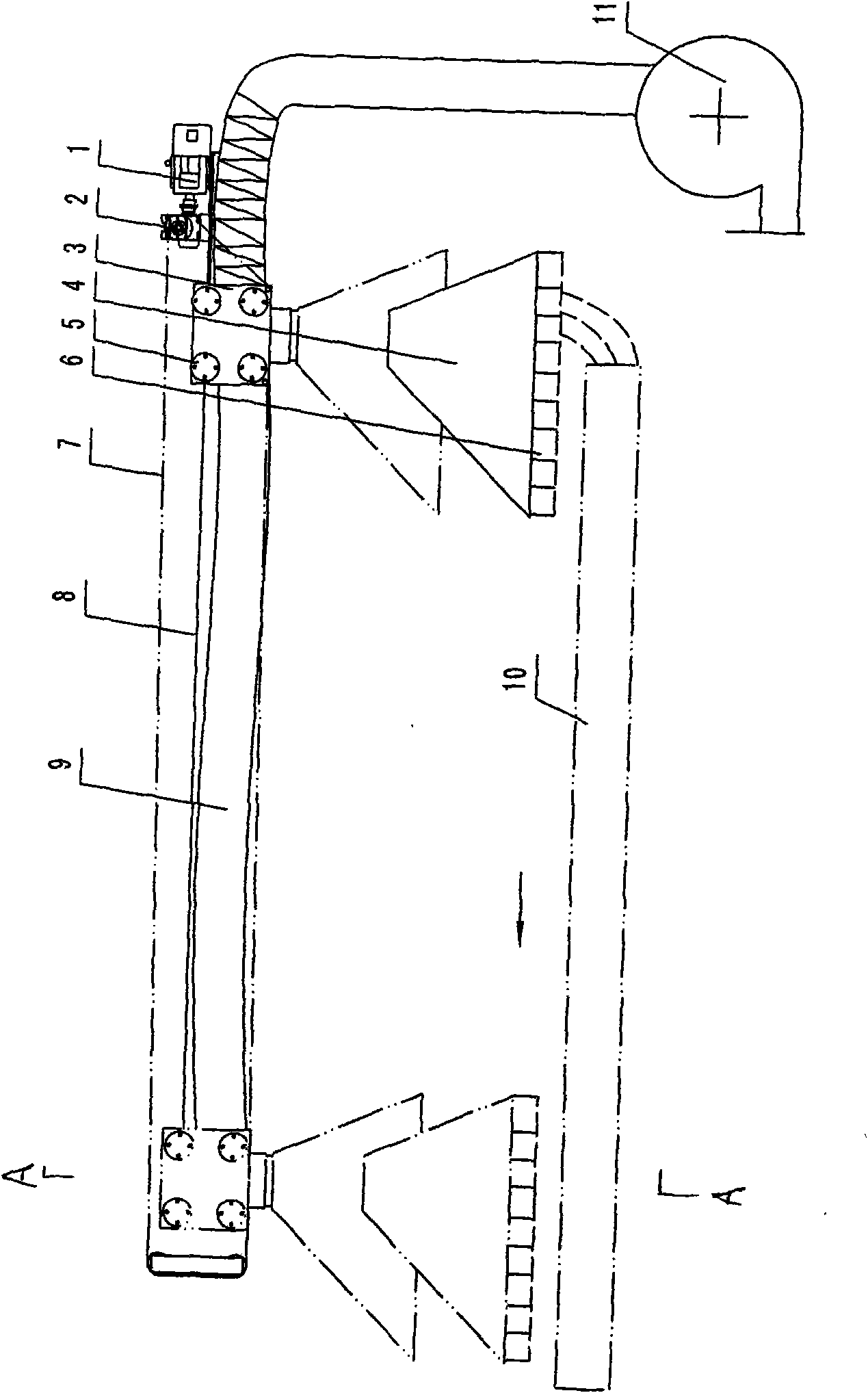

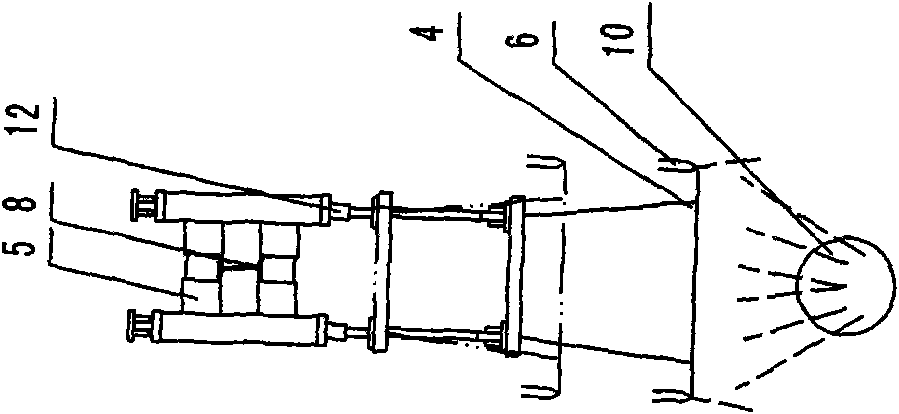

Dust hood for blast furnace tap hole

InactiveCN102586522AImprove capture efficiencyImprove working environmentDischarge devicesDust arrestersWorking environmentEngineering

The invention discloses a dust hood for a blast furnace tap hole. The dust hood for the blast furnace tap hole comprises a top-suction dust hood and a side-suction dust hood, wherein the top-suction dust hood is arranged above the outer side of the blast furnace tap hole, and the side-suction dust hood is arranged at one side of a molten iron trough, which is connected with the blast furnace tap hole; the top-suction dust hood comprises a first dust removal pipe and a first dust hood connected with the first dust removal pipe; the side-suction dust hood comprises a second dust removal pipe and a second dust hood connected with the second dust removal pipe; and the hood mouth of the side-suction dust hood is inclined. According to the dust hood for the blast furnace tap hole, the energy consumption can be reduced, the working environment of a casting house is improved and the smoke dust collection efficiency can be increased.

Owner:WISDRI ENG & RES INC LTD

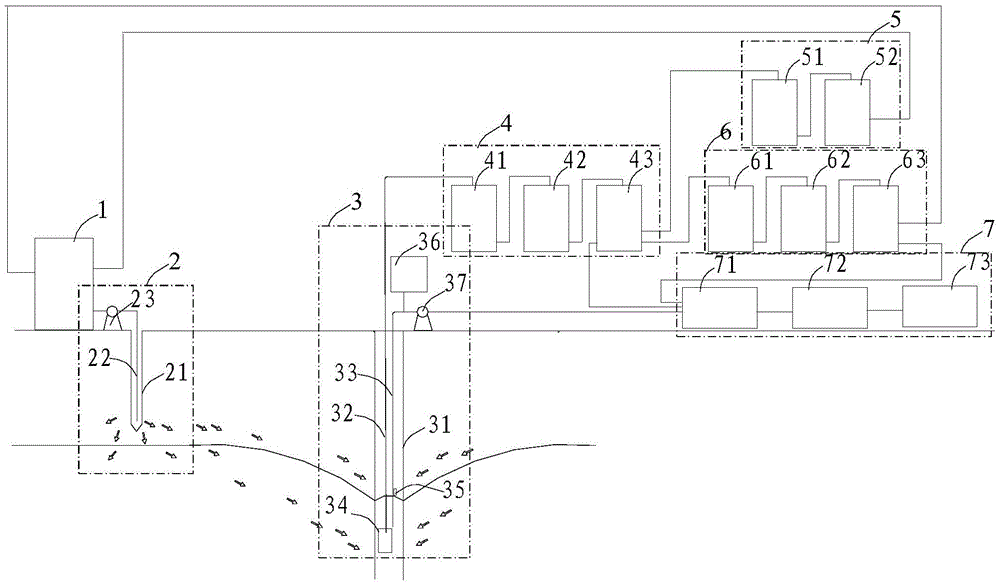

In-situ remediation system and remediation method for organic pollution site of light non-aqueous phase liquids (LNAPLs)

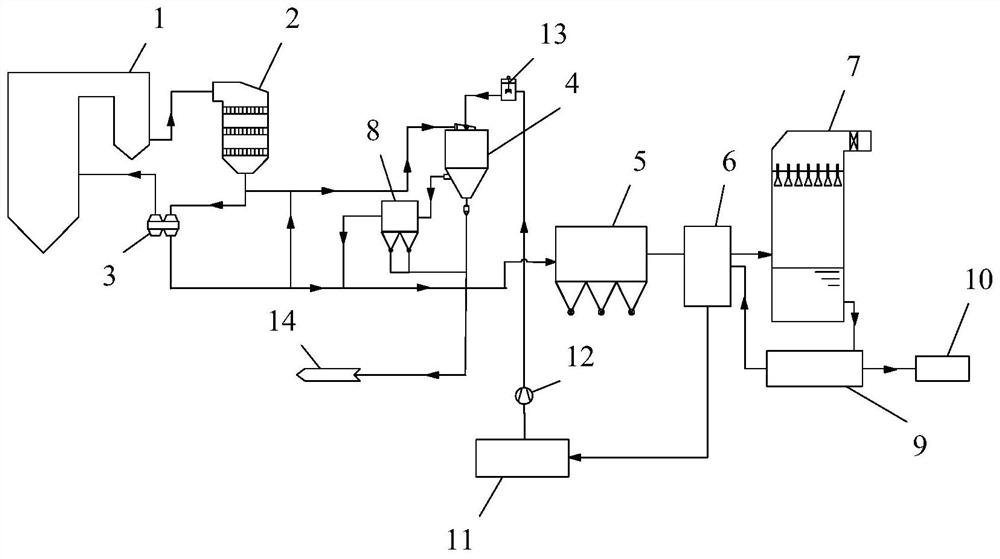

ActiveCN105521990AReduce drawingImprove recycling efficiencyContaminated soil reclamationIn situ remediationEnvironmental engineering

The invention discloses an in-situ remediation system and remediation method for an organic pollution site of light non-aqueous phase liquids (LNAPLs). The in-situ remediation system comprises a soil eluting remediation system and a solar power supply system. The soil eluting remediation system comprises a medicine storage device, a medicine injecting device, an extracting device, an eluant separating device, a groundwater processing device and an eluant recycling device. The medicine storage device is connected with the medicine injecting device, the groundwater processing device and the eluant recycling device. The extracting device is connected with the eluant separating device. The eluant separating device is connected with the groundwater processing device and the eluant recycling device. The solar power supply system comprises a solar power supply battery set, a storage battery set, a solar controller and an inverter. The in-situ remediation system is small in energy consumption, low in cost, high in pollutant removal rate, good in extract separating effect and high in recycling efficiency of groundwater and eluant.

Owner:浙江博世华环保科技有限公司

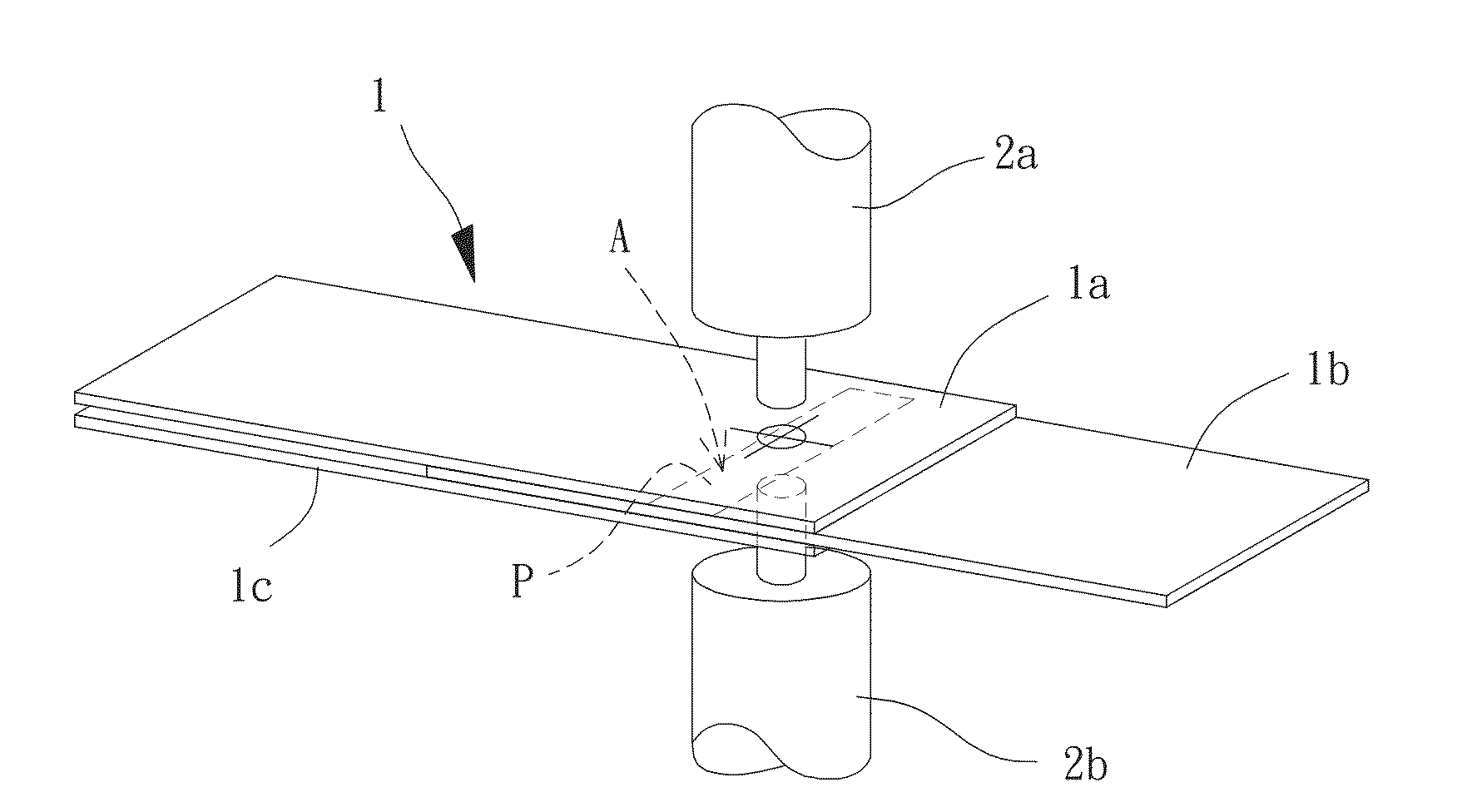

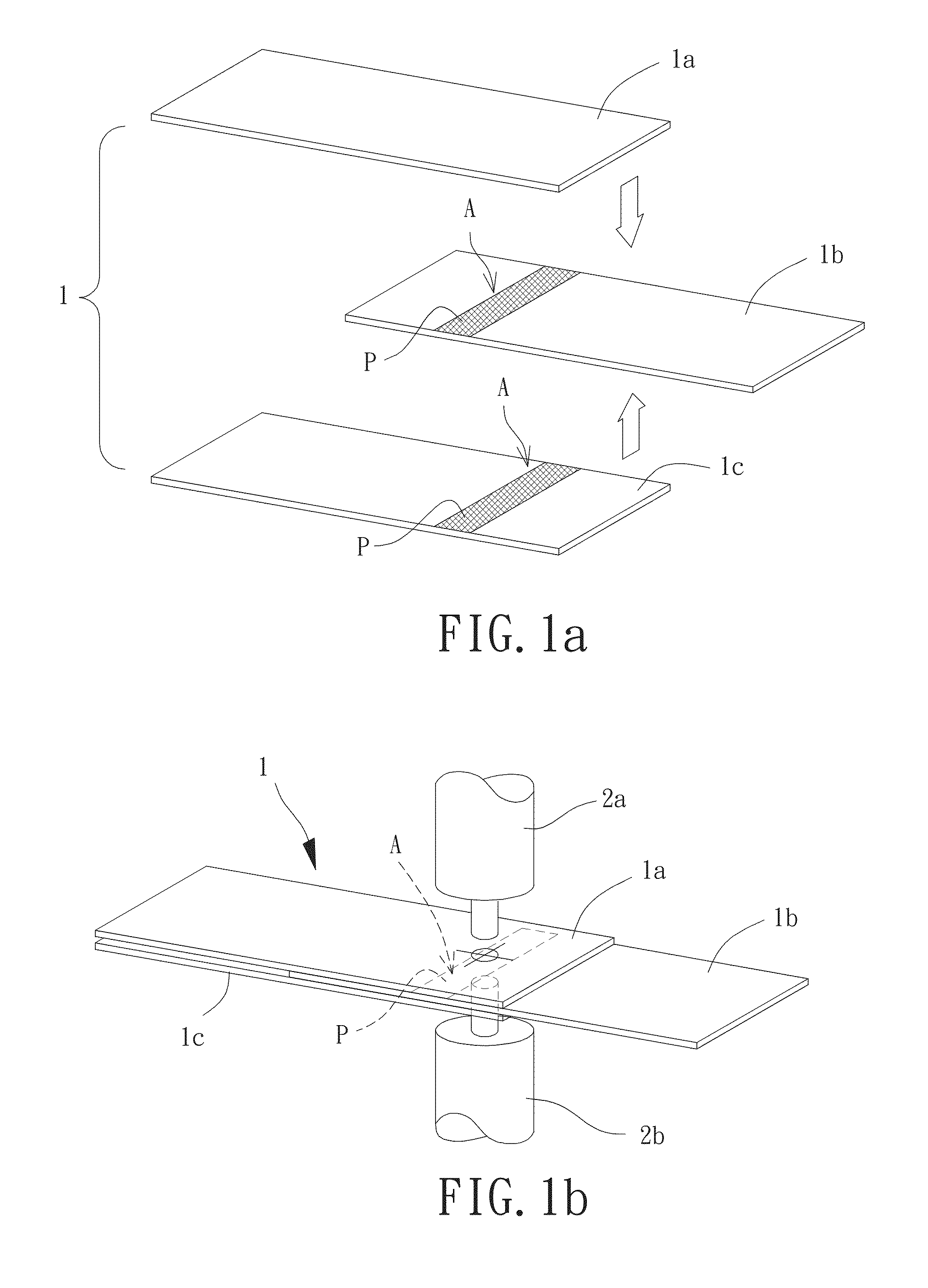

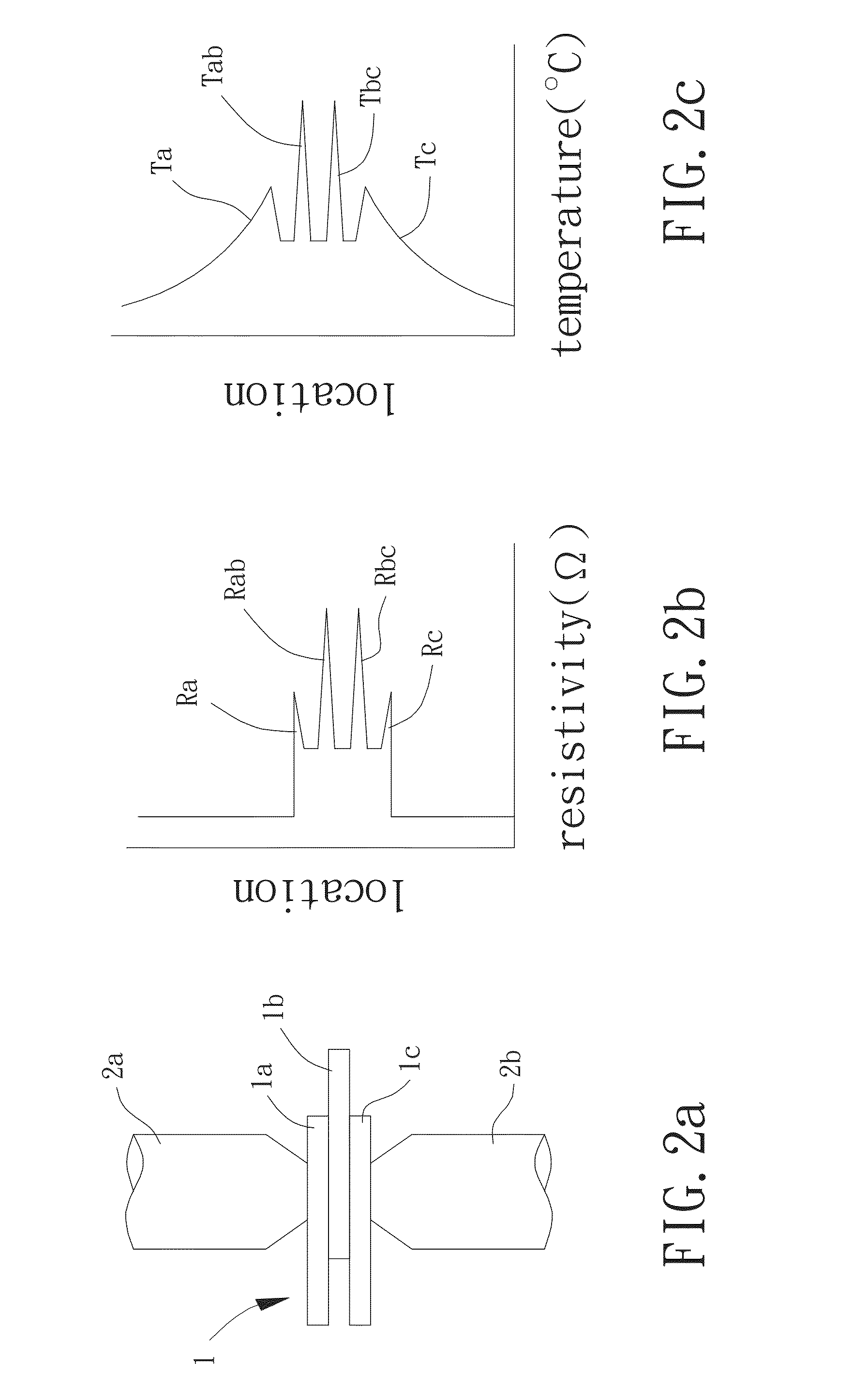

Resistance spot welding method for a lap-joint of multi-metal sheets

InactiveUS20140124485A1Increase the areaIncreasing nugget diameterElectrode featuresElectrical resistance and conductanceOrganic solvent

A resistance spot welding method for a lap joint multi-metal sheets which may improve the welding efficiency and nugget quality comprises: coating a joining zone of one of two mutually facing surfaces of two adjacent metal sheets with an active agent with high resistivity to form a welding region, and clamping the welding region with an upper welding electrode and a lower welding electrode and providing an electric current into the welding region. The active agent with high resistivity generates high heat energy to melt the joining zone and join the two adjacent metal sheets. The active agent with high resistivity has a resistivity much greater than a resistivity of each of the two metal sheets, and the active agent with high resistivity consists of multi-component powders and an organic solvent.

Owner:NAT PINGTUNG UNIV OF SCI & TECH

Bursting device

The invention provides a bursting device. The bursting device comprises a test table, a support arranged on the test table and a base arranged on the test table. The bursting device further comprises a bursting clamping head, a stress and strain sensor connected with the bursting clamping head, a high speed photometer, a hydraulic servo motor, a stabbing cone and a jig. The hydraulic servo motor is connected with the bursting clamping head, and the bursting clamping head is connected with the stabbing cone. Such design significantly improves the fastness of clamping of textile / textile structure reinforced flexible composite material to be tested, reduces the relative slippage between a sample to be tested and the jip, reduces pulling-out of yarn from the textile structure, and improves the accuracy and reliability of a bursting test.

Owner:SUZHOU UNIV

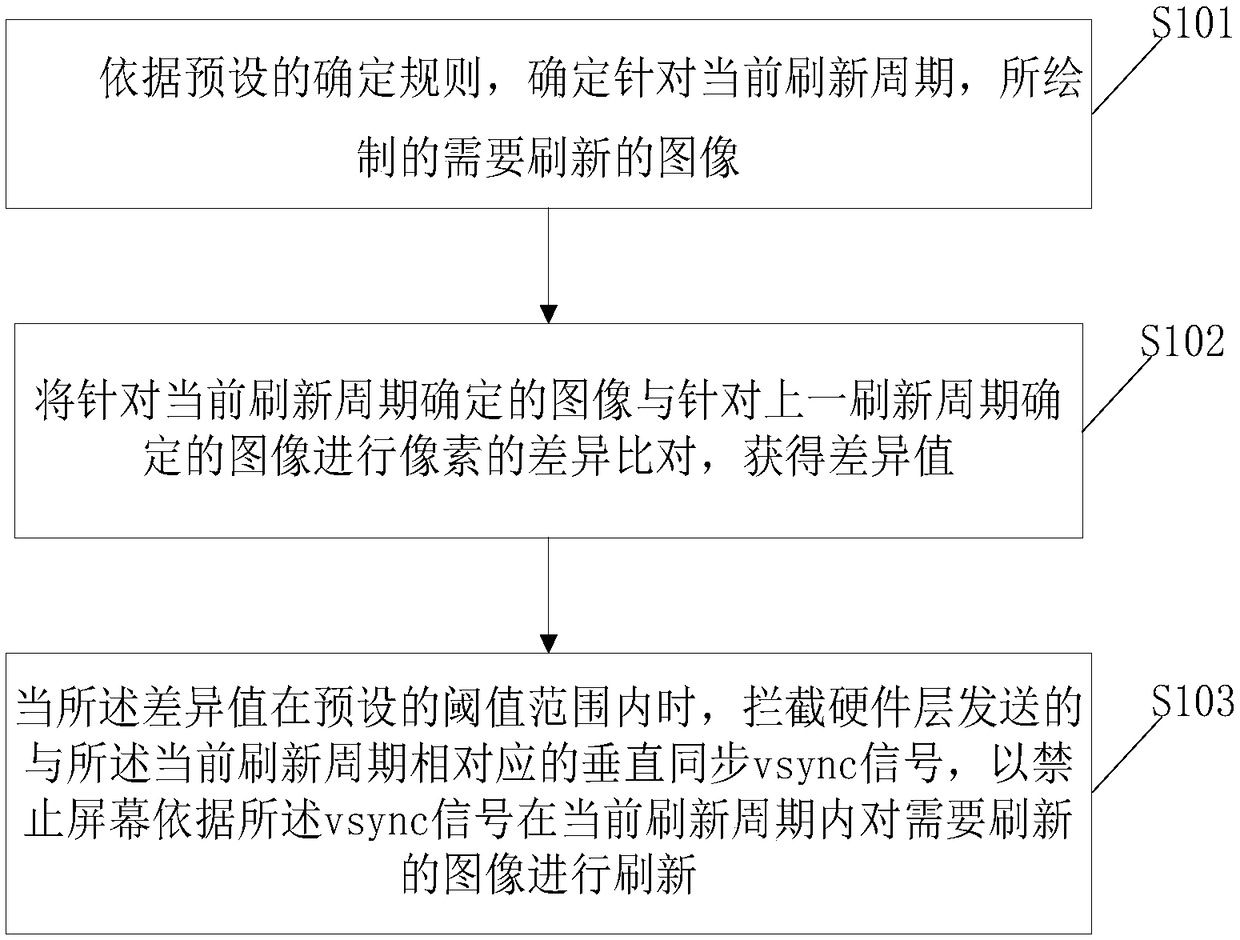

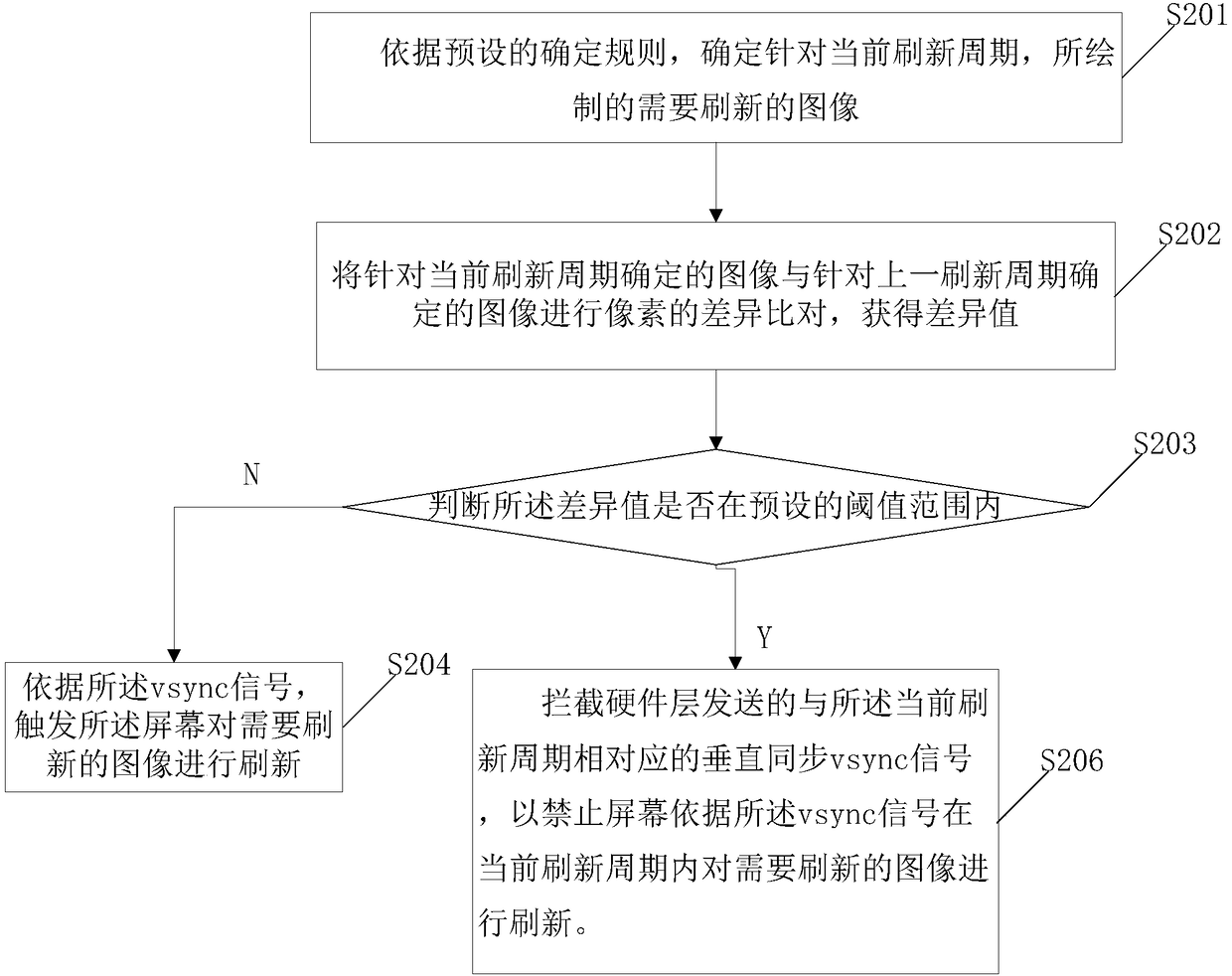

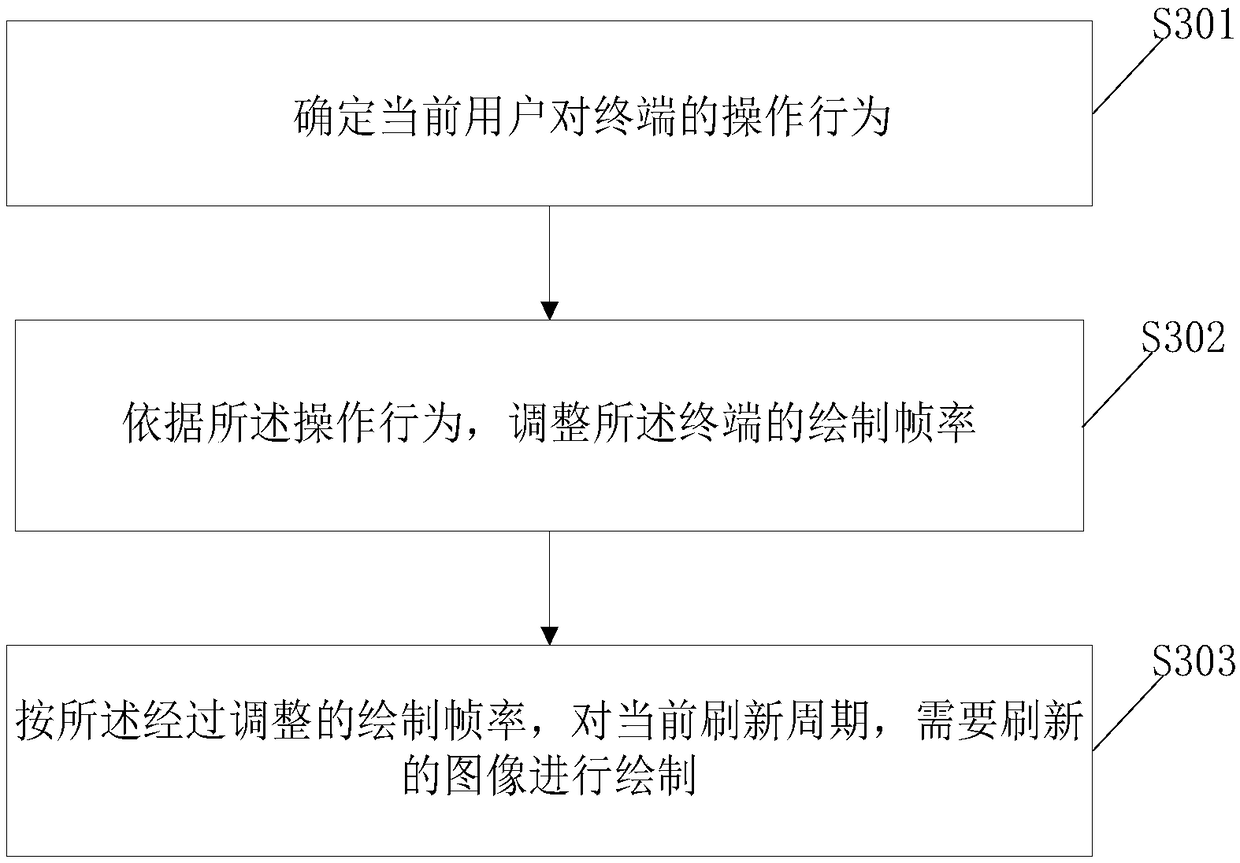

Screen refreshing method and system

InactiveCN108628562AReduce the number of refreshesReduce power consumptionPower supply for data processingDigital output to display deviceComputer hardwareEmbedded system

The invention discloses a screen refreshing method. The method comprises the following steps of: determining a drawn to-be-refreshed image for the current refreshing period according to a preset determination rule; carrying out pixel difference comparison on the image determined for the current refreshing period and an image determined for the last refreshing period so as to obtain a difference value; and when the difference value is in a preset threshold value range, intercepting a vsync signal sent by a hardware layer, so as to prevent a screen from refreshing the to-be-refreshed image in the current refreshing period according to the vsync signal. According to the method, the pixel difference comparison is carried out on the to-be-refreshed image for the current refreshing period and the image determined for the last refreshing period, and when the difference value obtained through the comparison is in the preset threshold value range, the vsync signal for triggering screen refreshing is intercepted so as to prevent the screen from refreshing the to-be-refreshed image in the current refreshing period, so that the screen refreshing frequency is decreased and the terminal power consumption is saved.

Owner:THUNDERSOFT

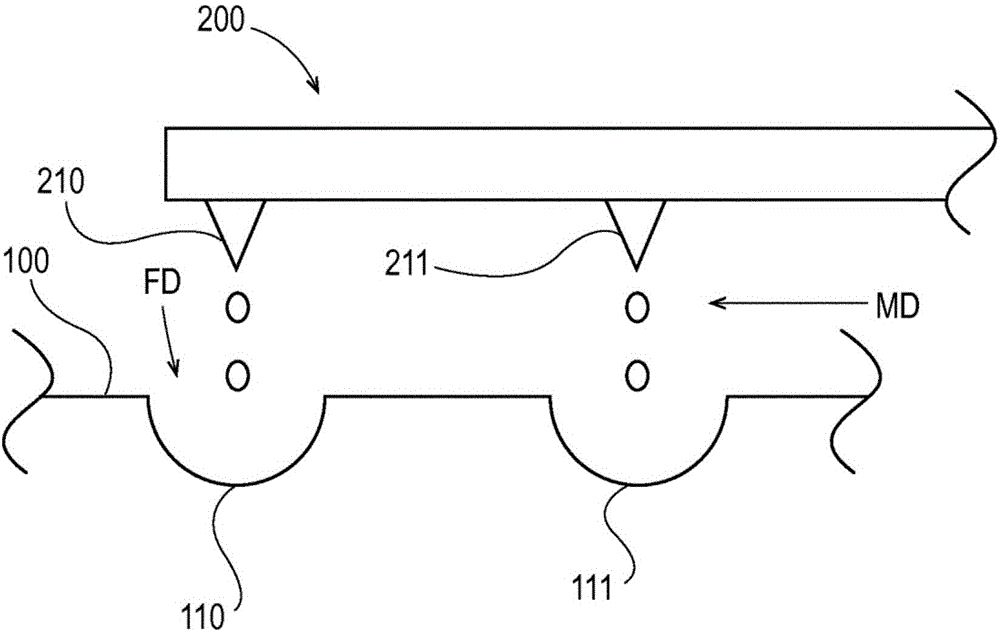

Methods and systems for dispensing composition

InactiveCN106163928ASolve the drawing problemReduce drawingDetergent materialsLiquid materialEngineeringWater soluble

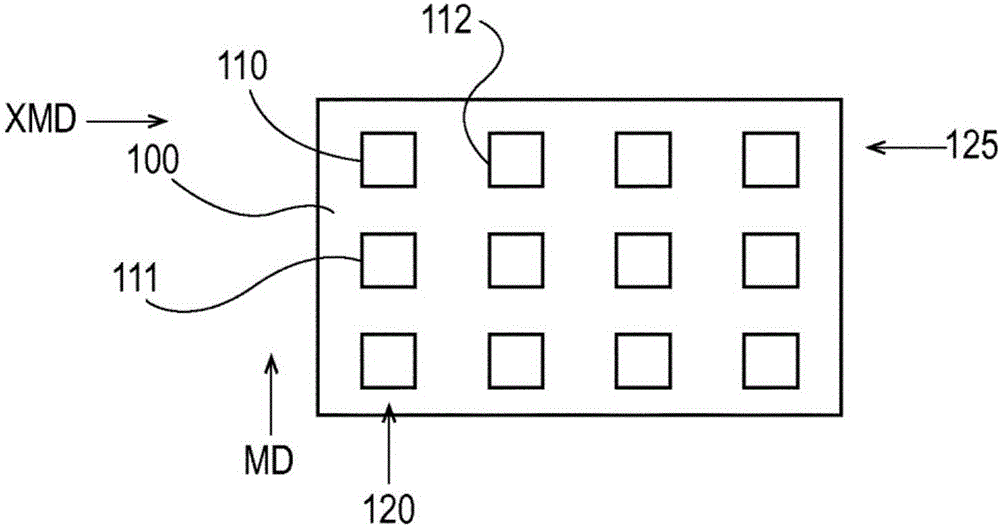

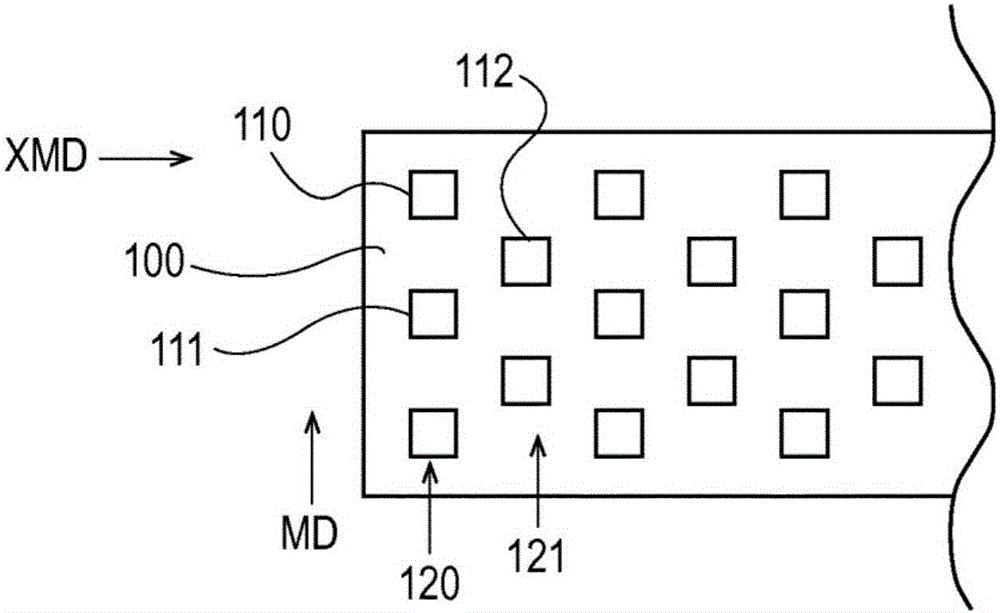

The present disclosure relates to methods, and corresponding systems, for filling cavities (110, 111, 112) with a composition (300) into said cavities (110, 111, 112) of a web (100) that continuously moves in a machine direction (MD), said method comprising the steps of: providing a web (100) comprising a water-soluble film, typically disposed on a continuously moveable surface (116) in a machine direction (MD), said web (100) comprising at least two thermoformable cavities (110, 111, 112) aligned in said machine direction (MD); providing a filling apparatus (200) comprising at least two nozzles (210, 211, 212) aligned in said machine direction (MD), positioned to dispense a household care composition (300), into said cavities (210, 211, 212); dispensing said composition (300) from said at least two nozzles (210, 211, 212) into said at least two cavities (110, 111, 112) while said at least two nozzles (210, 211, 212) move from a first position (FP) to a second position (SP); and returning said at least two nozzles (210, 211, 212) to said first position (FP).

Owner:PROCTER & GAMBLE CO

Process for treating industrial waste water from production of furfural

InactiveCN1654370AAdvanced technologyEasy to operateMultistage water/sewage treatmentWater/sewage treatment by neutralisationActive carbonPollutant

The process of treating industrial waste water from furfural production includes the following steps: 1) neutralizing tower bottom waste water to pH 7-8 via making it flow through one fluidized bed of limestone; 2) concentrating residual liquid through evaporating water inside one double-effect evaporation system; 3) adsorbing the residual liquid heated to boil with powdered active carbon inside one reactor and eccentrically filtering; and 4) stoving filtrate. The said treating process is completed with the production of furfural. The present invention utilizes waste water as useful resource.

Owner:CHANGCHUN JIACHEN ENVIRONMENT PROTECTING EQUIP

Device and method for realizing zero emission of desulfurization wastewater by utilizing flue gas waste heat

PendingCN111792690AReduce hydrationIncrease humidityWater/sewage treatmentWaste water treatment from gaseous effluentsAir preheaterWastewater

The invention discloses a device and a method for realizing zero emission of desulfurization wastewater by utilizing flue gas waste heat. The system comprises a boiler, an SCR denitration reactor, anair preheater, a first dust remover and a wet desulfurization device, which are sequentially connected through a flue. The outlet flue of the SCR denitration reactor and the outlet flue of the air preheater are communicated with the inlet flue of a drying tower through bypass flues; a wastewater evaporation and concentration device is arranged between the first dust remover and the wet desulfurization device, and the wet desulfurization device is connected with a gypsum dehydration device. Medium-temperature flue gas between the first dust remover and the wet desulfurization device is used forcarrying out a concentration and reduction treatment on desulfurization wastewater, the amount of wastewater entering the drying tower is reduced, the extraction amount of hot flue gas can be reduced, and the influence of the system on the boiler efficiency is effectively reduced. Meanwhile, the flue gas behind the SCR denitration reactor and the air preheater is pumped to evaporate the wastewater, and the energy efficiency of the system can be effectively improved.

Owner:DATANG ENVIRONMENT IND GRP +1

Integrated energy storage system

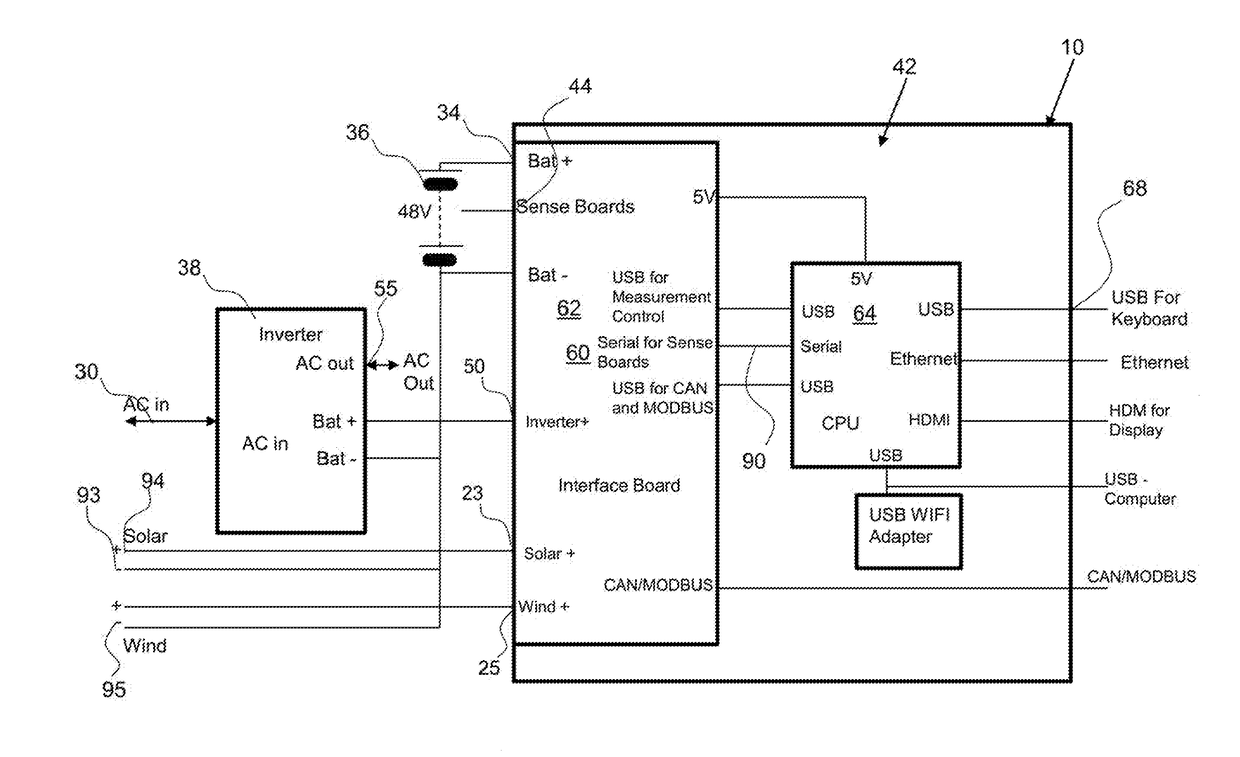

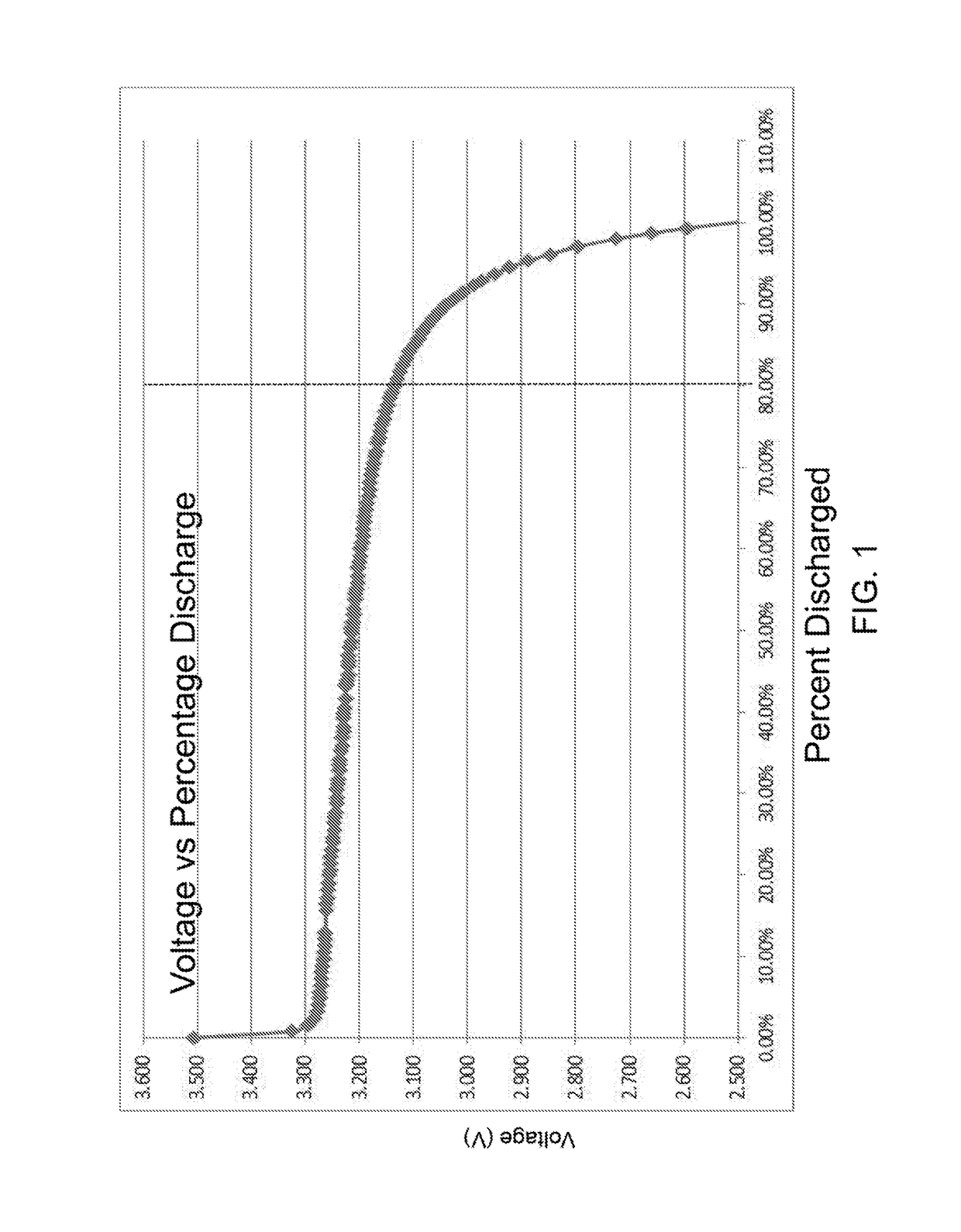

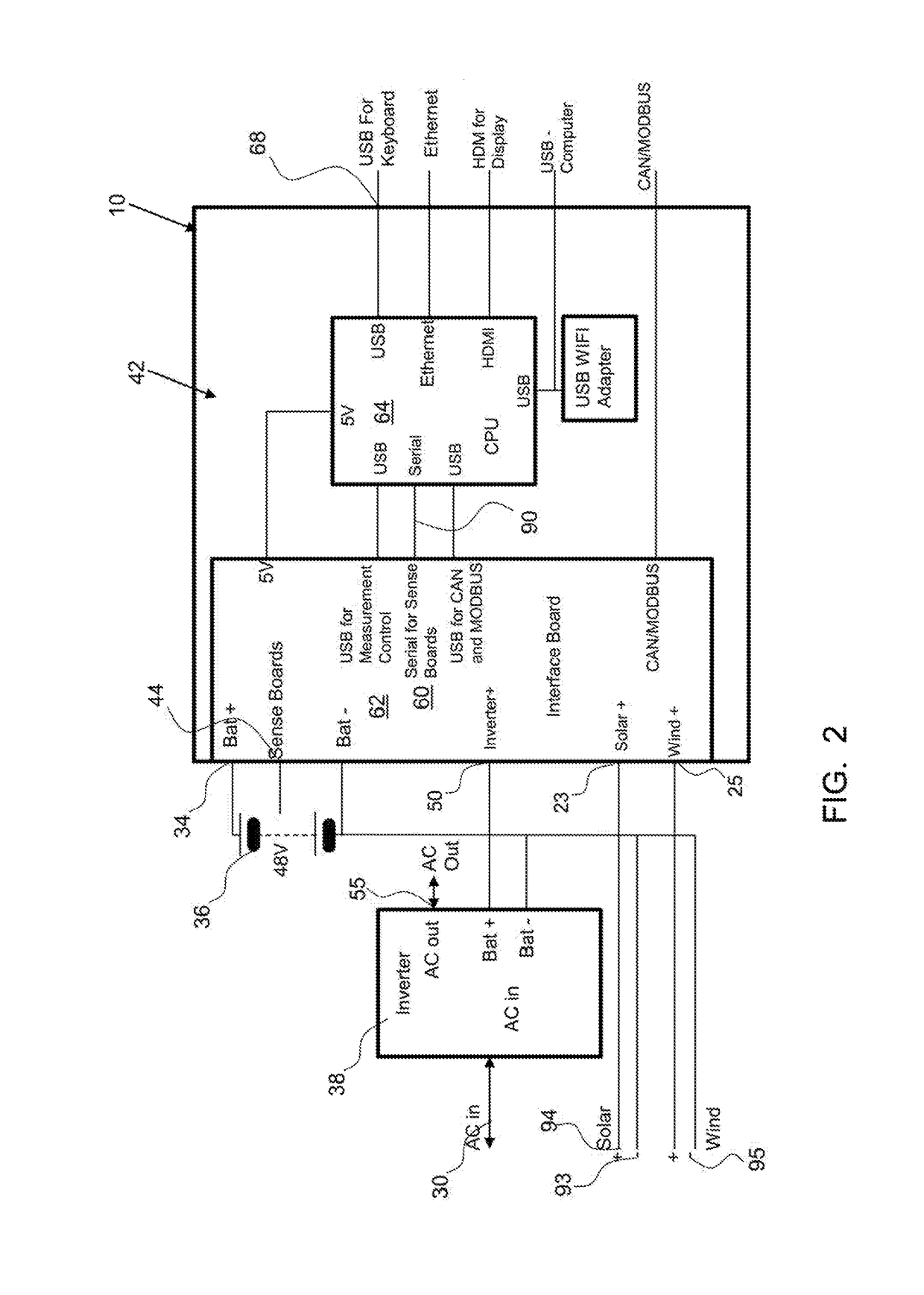

ActiveUS9929571B1High charge densityLimited effective operating temperature rangeClimate change adaptationPhotovoltaicsElectrical batteryPower control system

An integrated battery control system for energy storage incorporates a power control system to reliably provide power to a load and protects lithium ion batteries from over-charging and over-discharging. One or more power sources, such as renewable power sources, such as solar or wind power generators, or a generator, may be coupled with the integrated battery control system to provide power for charging the battery pack and / or for supplying power to said load. A portion of the power from a power source may be used to charge the battery pack and a portion may be provided to a load. A control circuit and one or more microprocessors may control the components of the system to provide power in an efficient manner. Power to and from the battery may run through an inverter and a control system may open and close switches to control flow of power in the system.

Owner:ELITE POWER HLDG LLC

Integrated energy-saving processing process for modified reprocessed plastic

InactiveCN103928726AReduce drawingReduce coolingWaste accumulators reclaimingBattery recyclingEngineeringCrusher

The invention provides an integrated energy-saving processing process for modified reprocessed plastic, relating to the technical field of resource reutilization. The integrated energy-saving processing process comprises the following process steps: (1) cutting waste storage batteries and sequentially separating plastic pieces, grids, lead plaster, lead powder and the like in the waste storage batteries out; (2) putting the separated plastic pieces into washing equipment and washing; after the washing, leaching and conveying the separated plastic pieces into disinfection equipment and disinfecting the separated plastic pieces; (3) putting the disinfected plastic pieces into a crusher, crushing the disinfected plastic pieces into grains and quantitatively adding the plastic grains into an extruder and adding other auxiliary materials according to the requirements on preparation of a product; extruding by the extruder; and (4) directly putting plastic strips extruded by the extruder into a molding mould, and de-molding to directly obtain a finished product; and carrying out surface treatment on the finished product. According to the integrated energy-saving processing process, four links of drawing wires, cooling, granulating and refusing are reduced; compared with a traditional process, the integrated energy-saving processing process has the advantages that energy-saving and environment-friendly effects are achieved; the processing efficiency is improved and the cost is saved.

Owner:JIESHOU SHUANGTE NEW MATERIAL TECH

Preparation method of low-melting-point PBT copolyester fiber

InactiveCN109576813ALow modulusIncrease elasticityMonocomponent copolyesters artificial filamentAdhesiveEsterification reaction

The invention provides a preparation method of a low-melting-point PBT copolyester fiber, which comprises the following steps: butanediol is used as a raw material, a direct esterification method is adopted, dibasic acid and dihydric alcohol monomers with the molar ratio of 1:1.5-1:2.5 are simultaneously added, esterification, prepolymerization and polymerization reaction are carried out under theaction of a catalyst, and the PBT copolyester with the melting point ranging from 140 DEG C to 190 DEG C is prepared, wherein the esterification reaction and the prepolymerization reaction are carried out in two stages. The prepared PBT polyester is subjected to melt spinning after being dried, and is subjected to oiling, balancing, winding and drafting after being cooled. According to the preparation method of the low-melting-point PBT copolyester fiber,, dibasic acid and dihydric alcohol monomers are simultaneously added in the polymerization process of the PBT, and the esterification and prepolymerization reaction processes are carried out in stages, so that the melting point of the PBT is reduced, the fluidity of the PBT melt is improved, the toughness of the PBT is increased, the impact strength is improved, the prepared low-melting-point PBT polyester fiber has the advantages of low modulus, high elasticity and good hand feeling, and can also be used as a substitute adhesive torealize the bonding function.

Owner:SINOPEC YIZHENG CHEM FIBER +1

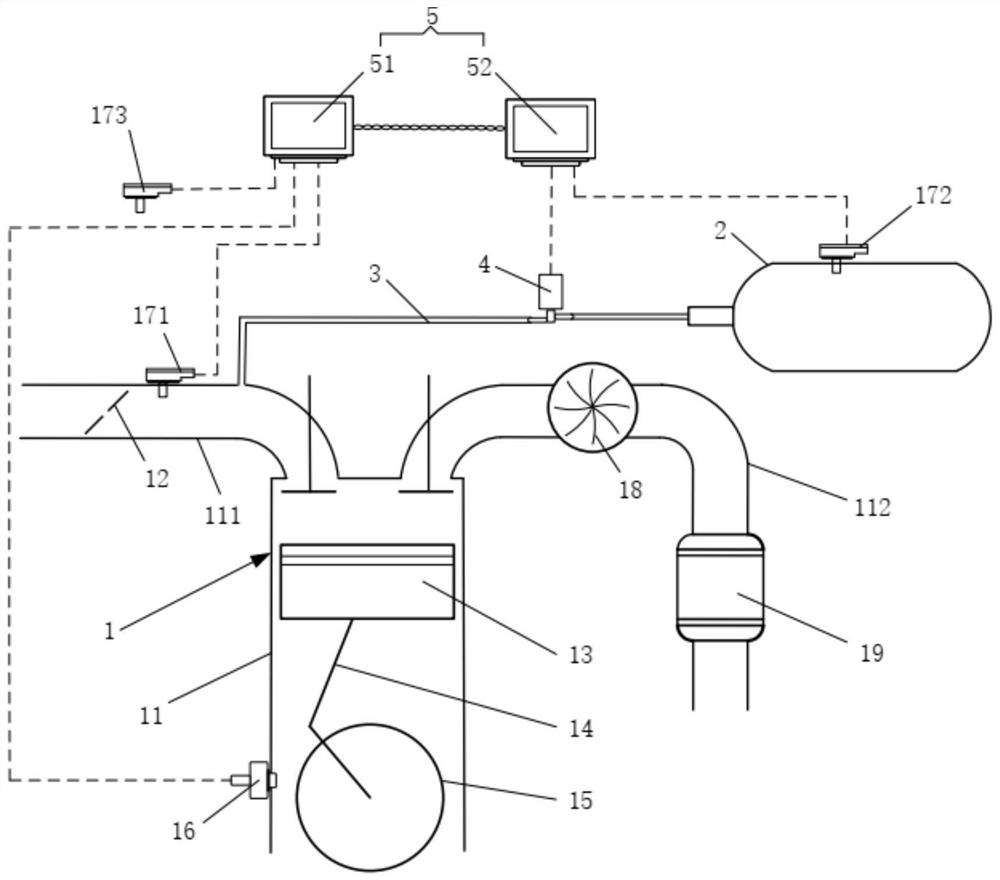

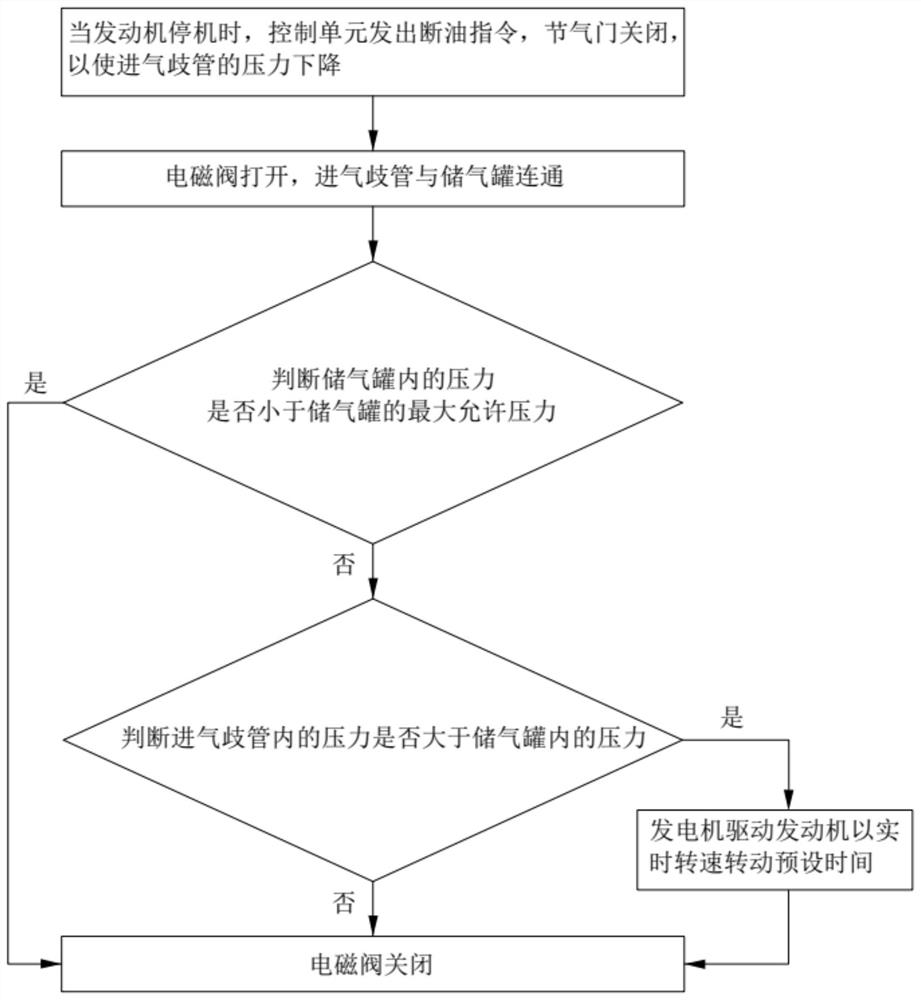

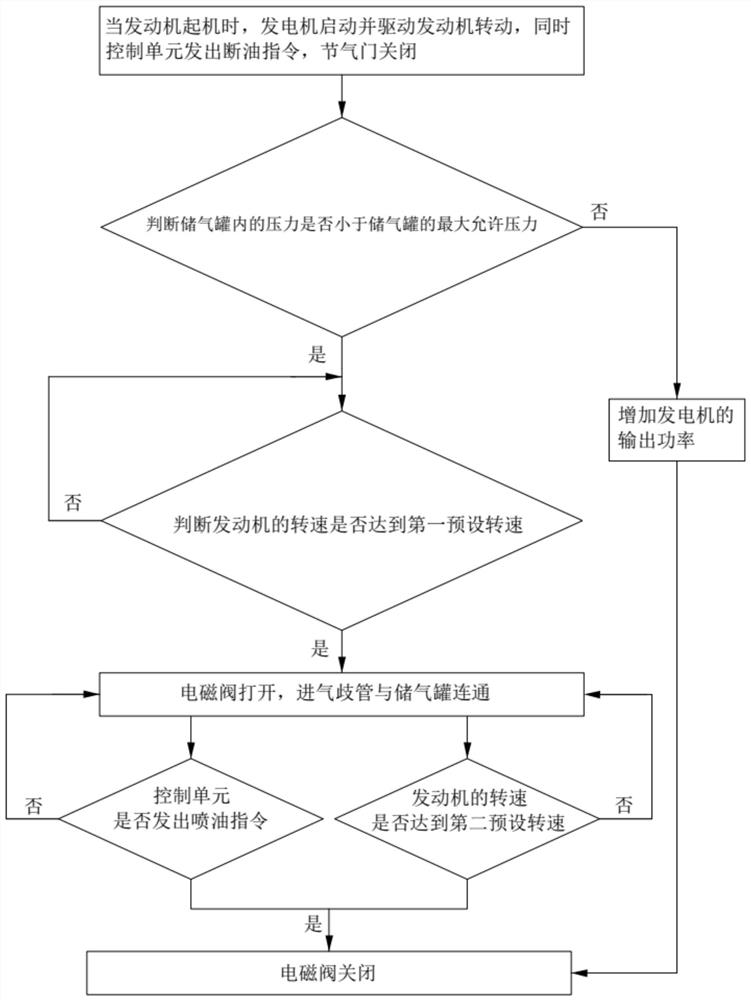

Starting system and control method

ActiveCN113982805AReduced compression reactionReduced drag torqueHybrid vehiclesElectrical controlControl theoryGas holder

The invention relates to the technical field of automobiles, and discloses a starting system and a control method. The starting system comprises an engine, a generator, a control unit, a gas storage tank, a suction pipeline and an electromagnetic valve. The generator can drive the engine to rotate. The engine comprises a cylinder, a piston and a throttle valve, the cylinder is provided with a gas intake manifold, and the throttle valve is arranged on the gas intake manifold. The two ends of the suction pipeline can communicate with the gas storage tank and the gas inlet manifold correspondingly, and the throttle valve and the suction pipeline are sequentially arranged in the flowing direction of gas in the gas inlet manifold. And the electromagnetic valve is arranged on the suction pipeline. In the shutdown process, the throttle valve is closed, the electromagnetic valve is opened, the piston sucks air in the gas storage tank through the gas inlet manifold, and the pressure of the gas storage tank is reduced. In the starting process, the pressure of the gas storage tank is smaller than the maximum allowable pressure of the gas storage tank, the throttle valve is closed, the electromagnetic valve is opened, and the gas storage tank extracts air of the gas inlet manifold, so that the compression reaction force of the piston is reduced, the starting efficiency is improved, and the NVH performance of the engine is improved.

Owner:CHINA FIRST AUTOMOBILE

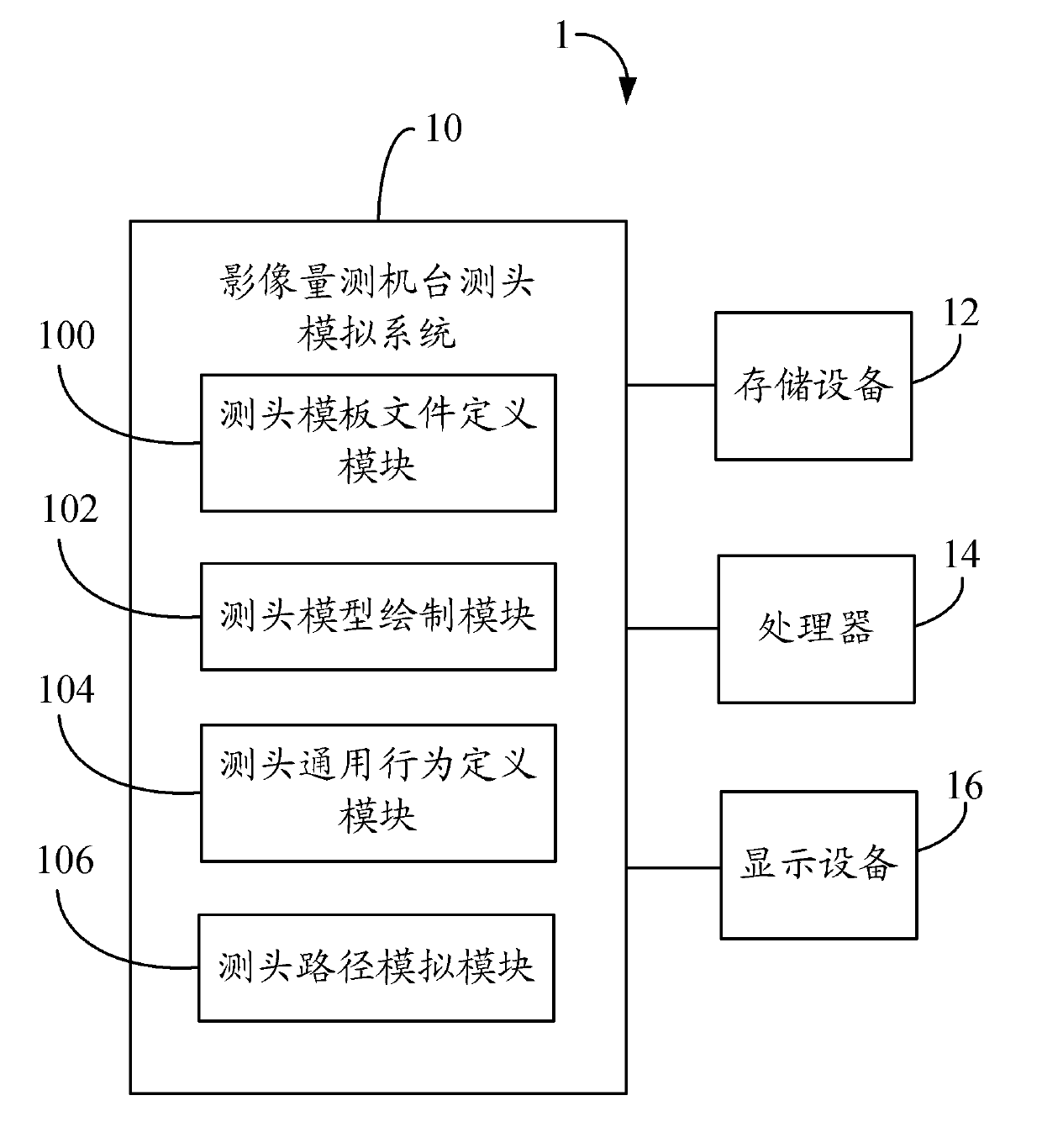

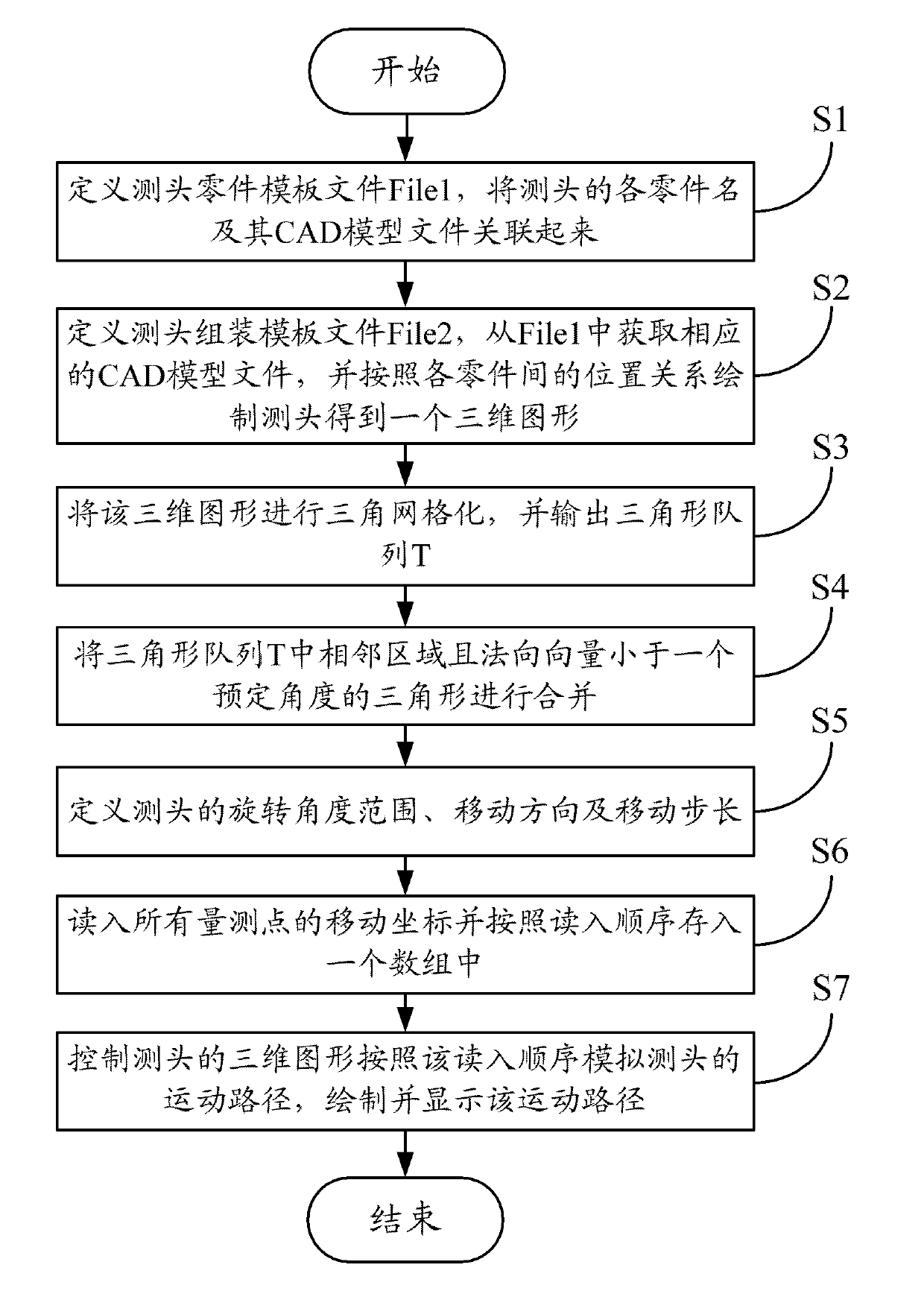

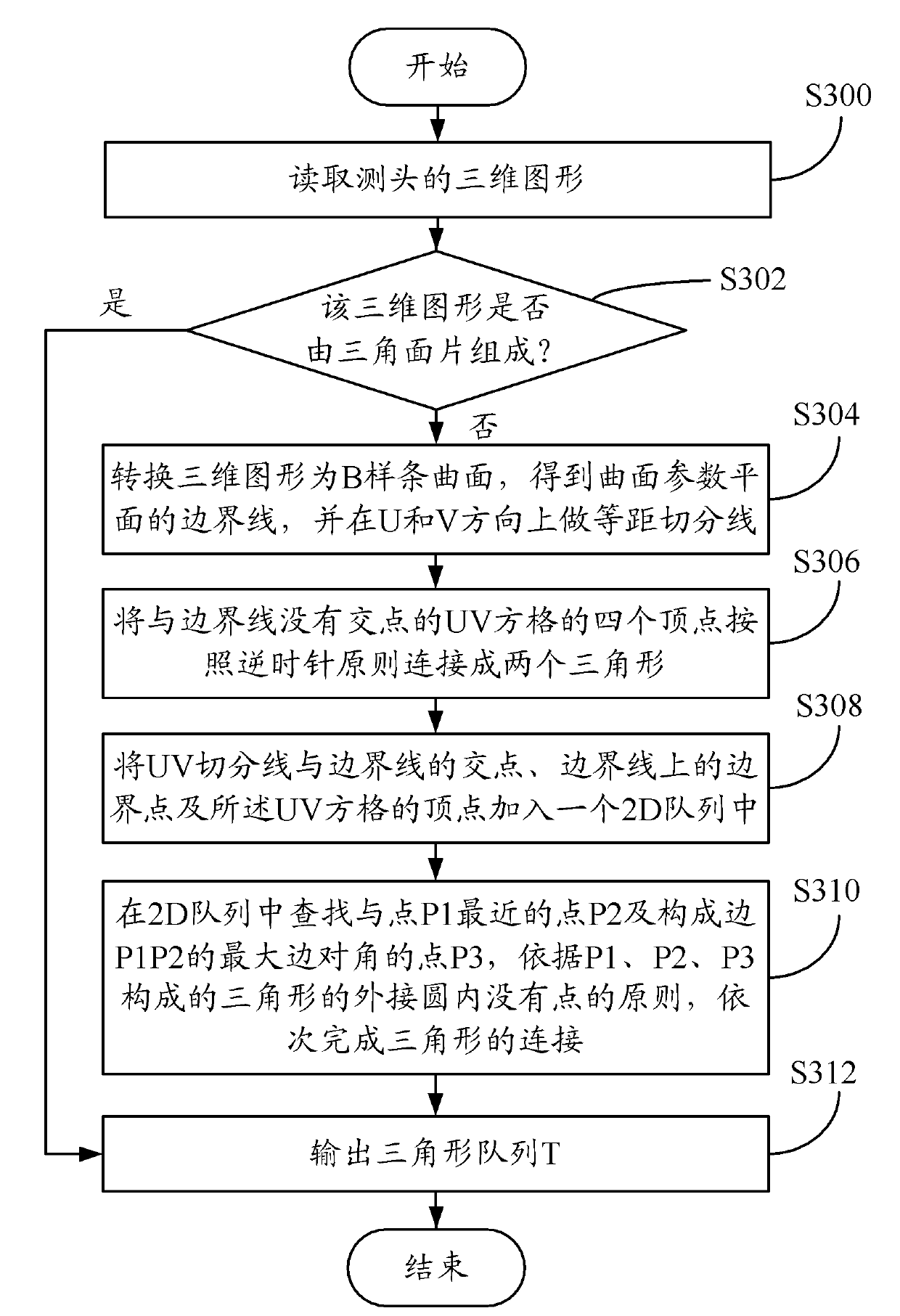

Measuring head simulation system and method of image measurement machine

InactiveCN102445147AReduce drawingUsing optical meansImage data processingGraphicsComputer Aided Design

The invention relates to a measuring head simulation method of an image measurement machine, which is operated in a host machine. The method comprises the steps of storing all part names, CAD (computer aided design) model file names corresponding to all parts and position relation among all parts into a measuring head part template file File1, and associating all part names and CAD model files corresponding to all the part names; storing the part names into a measuring head assembling template file according to the drawing sequence, obtaining the corresponding CAD model file from the File1 and drawing a measuring head according to the position relation among all the parts to obtain a three-dimensional figure; defining the rotating angle range, the moving direction and the moving step size of the measuring head; reading moving coordinates of all measuring points and storing the moving coordinates of the measuring points into an array according to the reading sequence; simulating the motion path of the measuring head according to the reading sequence, and drawing and displaying the motion path. The invention also provides a measuring head simulation system of an image measurement machine. By utilizing the invention, the moving simulation to the measuring head can be rapidly realized.

Owner:HONG FU JIN PRECISION IND (SHENZHEN) CO LTD +1

Liquid laundry detergent composition

ActiveUS10066195B2Reduce drawingImproved dissolution profileNon-ionic surface-active compoundsOrganic detergent compounding agentsLiquid laundry detergentWater soluble

A liquid laundry detergent composition suitable for formulation into a water-soluble unit dose article, wherein the liquid laundry detergent composition includes a. an anionic surfactant, b. 1,2-propanediol; c. dipropylene glycoland a water-soluble unit dose article including said liquid laundry detergent composition.

Owner:PROCTER & GAMBLE CO

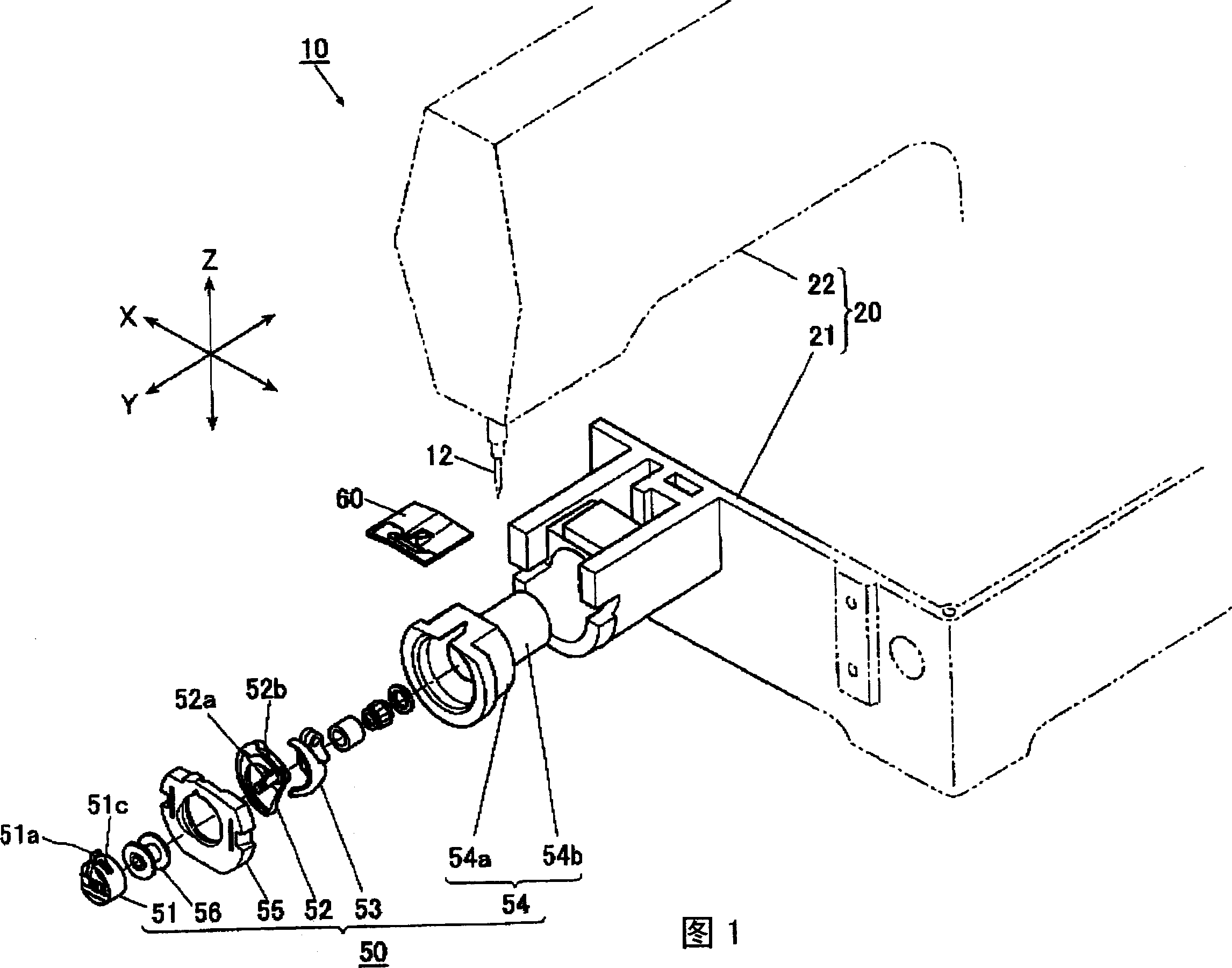

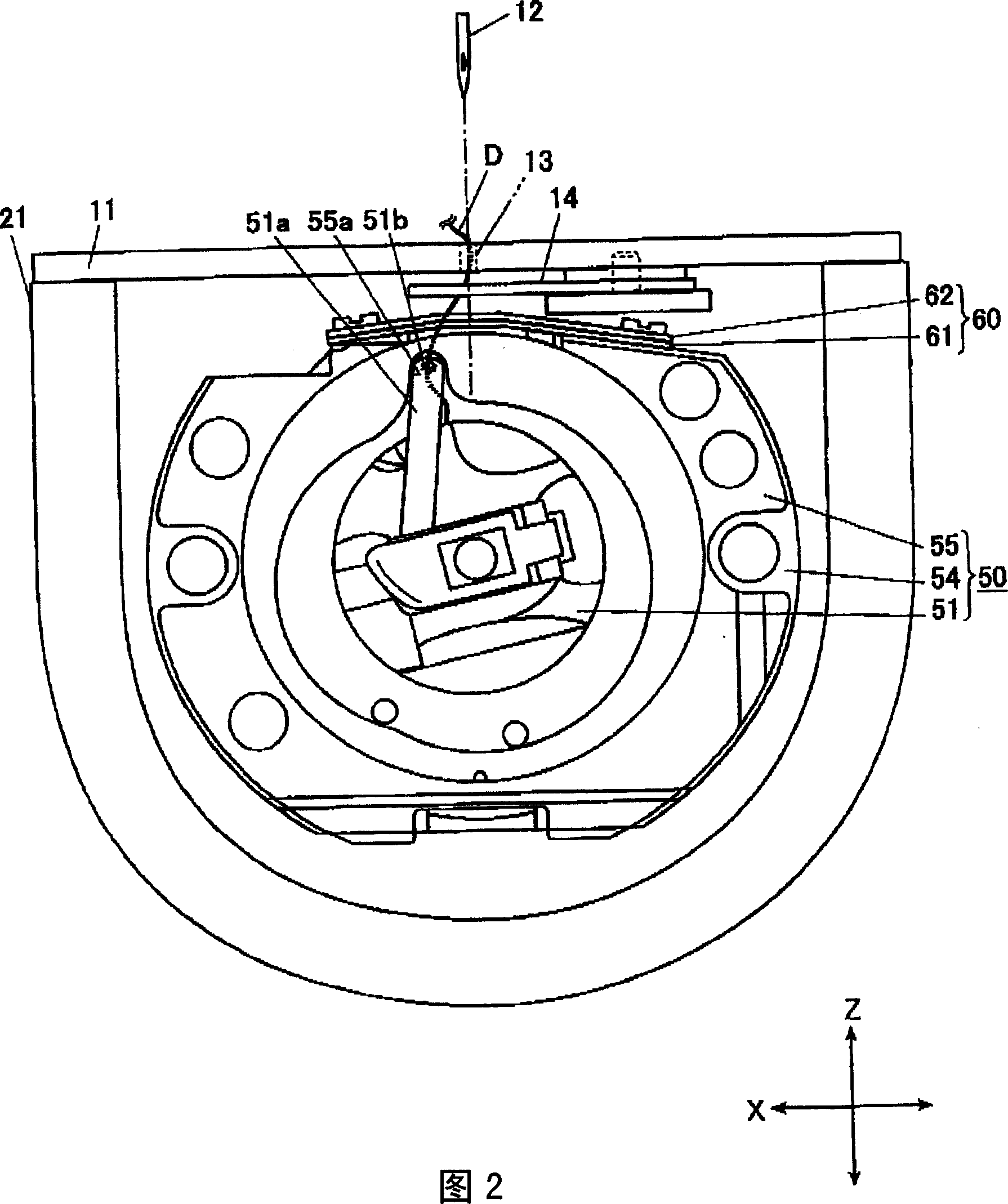

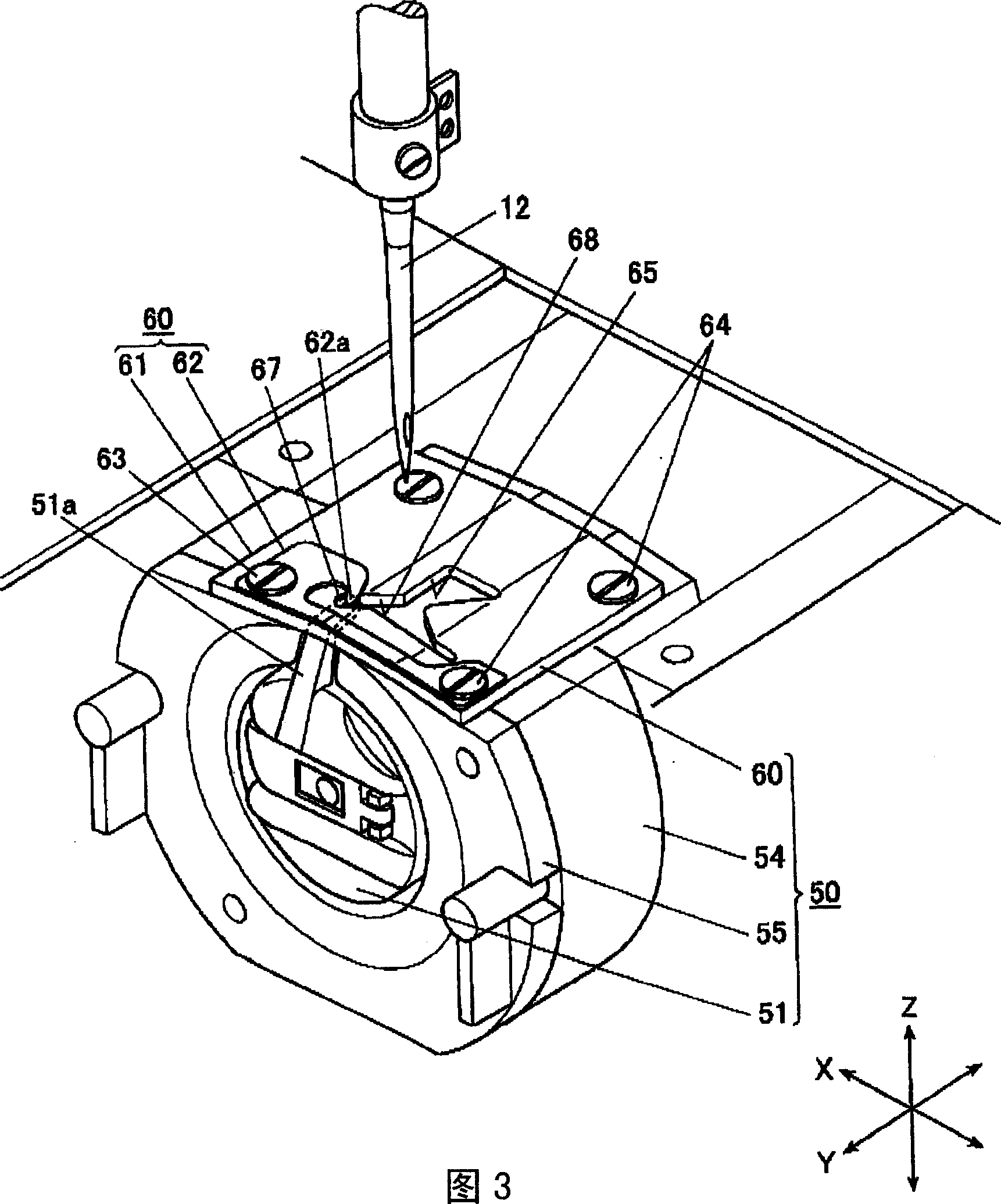

Bobbin thread holding device for seamer

ActiveCN1904182AReduce drawingImprove sewing qualityWorkpiece carriersNeedle severing devicesBobbinEngineering

The invention satisfactorily carrys out nex sewing after cutting off a looper. A shuttle mechanism 50 for a sewing machine is provided with: a bobbin case 51 for housing a bobbin 56 of a looper D; an inner shuttle 52 which is turned reciprocatively around the bobbin case; a large shuttle 54 which holds the inner shuttle inside in a reciprocatively rotatable state; and a thread guide plate 60 arranged at the upper part of the large shuttle. The shuttle mechanism 50 is arranged under a thread cutting device within a sewing machine head part 21. The thread guide plate is provided with a bobbin thread holding part 67 for catching the bobbin thread cleared away by a moving knife 14 of a thread cutting device, and the bobbin thread holding part is positioned in the vicinity of the bobbin thread guide-out part of the bobbin case compared with a bobbin thread pass-through position P in the case of sewing to the thread guide plate.

Owner:JUKI CORP

Composition used for fused deposition modeling 3D printing, preparing and application thereof

ActiveCN108297469AGood paving performanceReduce drawingAdditive manufacturing apparatus3D object support structuresDiffusionFused deposition modeling

The invention relates to a preparing method and application of a composition provided with micron order holes and used for fused deposition modeling 3D printing. Macromolecular material particles aremade into wire rods through a screw extruder, supercritical CO2 fluid above the critical pressure and the critical temperature is adopted, the characteristics that the fluid is high in density, low inviscosity and large in diffusion coefficient are used, the fluid can be immersed into the macromolecular substrate, finally, pressure is relived suddenly, the micron order holes are formed in the macromolecular substrate, the holes range from 0.5 um to 100 um, the composition is adopted to prepare a product with multi-scale holes, holes with two kinds of different scales are achieved, the first kind of holes are formed in the fused deposition modeling printing process, the holes range from 0.1 mm to 1 mm, the other kind of holes are formed through the above composition, and the holes range from 0.1 um to 50 um.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI

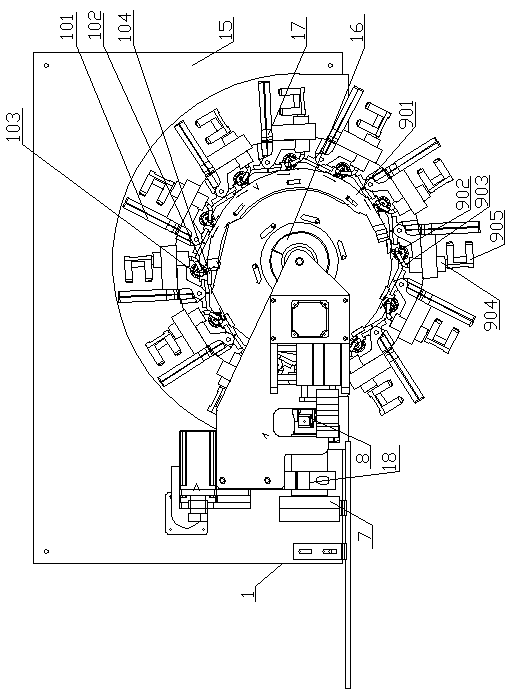

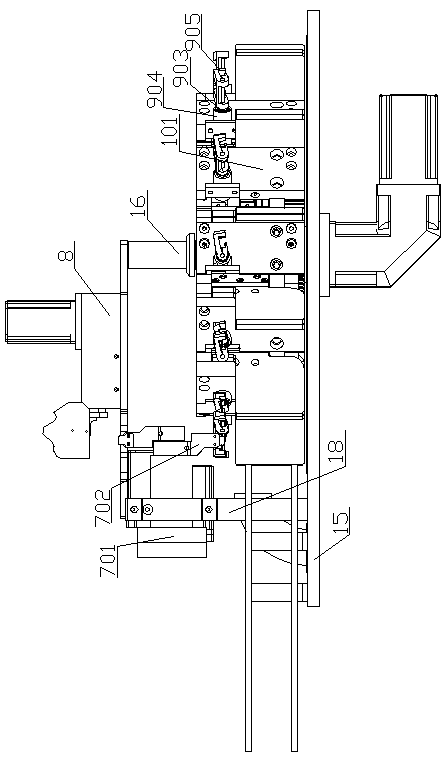

Device for absorbing graphite dust

The invention discloses a device for absorbing graphite dust, comprising a bracket. The bracket is provided with a motor (1), a speed reducer (2) and an I-beam (8). The motor (1) drives the speed reducer (2). The device is characterized in that the I-beam (8) is positioned right above a steel tube (10) made of an expanding pipe, the speed reducer (2) drives a pulley (5) to move along the I-beam (8) through a steel wire (7), the pulley (5) is fixedly connected with a dust absorbing hood (4) arranged below the pulley (5) and the dust absorbing hood (4) is connected with a draught fan (11) through a hose (9). The device ensures that the dust absorbing hood is positioned above the tail of the steel tube at any time by adopting a moving mode and effectively absorbs graphite diffused from a steel tube cavity to the outdoor at any time.

Owner:烟台鲁宝钢管有限责任公司

Cover pasting device and method for liquid packing box

The invention relates to a cover pasting device and method for a liquid packing box. The device comprises a rotating frame (1) used for driving the liquid packing box to move, a gluing device (8) arranged on the rotating frame (1) and used for applying adhesive glue on the liquid packing box or a cover, and a cover pressing device (7) arranged on the rotating frame (1) and used for connecting thecover to the liquid packing box; and through the rotating frame (1), the liquid packing boxes are sorted and pass through the gluing device (8) and the cover pressing device (7), through the gluing device (8), the adhesive glue is applied on the liquid packing box or the cover, and through the cover pressing device (7), mounting of the cover and the liquid packing box is realized, so that the cover pasting effect of the liquid packing box is improved.

Owner:YANTAI KAIFU FOOD

Liquid laundry detergent composition

ActiveUS20170226449A1Reduce drawingImproved dissolution profileNon-ionic surface-active compoundsOrganic detergent compounding agentsPropylene glycolWater soluble

A liquid laundry detergent composition suitable for formulation into a water-soluble unit dose article, wherein the liquid laundry detergent composition includes a. an anionic surfactant, b. 1,2-propanediol; c. dipropylene glycoland a water-soluble unit dose article including said liquid laundry detergent composition.

Owner:THE PROCTER & GAMBLE COMPANY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com