Device for absorbing graphite dust

A dust collector and graphite dust technology are applied in the directions of removing smoke and dust, cleaning methods and utensils, chemical instruments and methods, etc., which can solve the problems of graphite dust polluting the working environment and threatening personal safety, saving air volume and ensuring dust collection effect. , the effect of good vacuuming effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

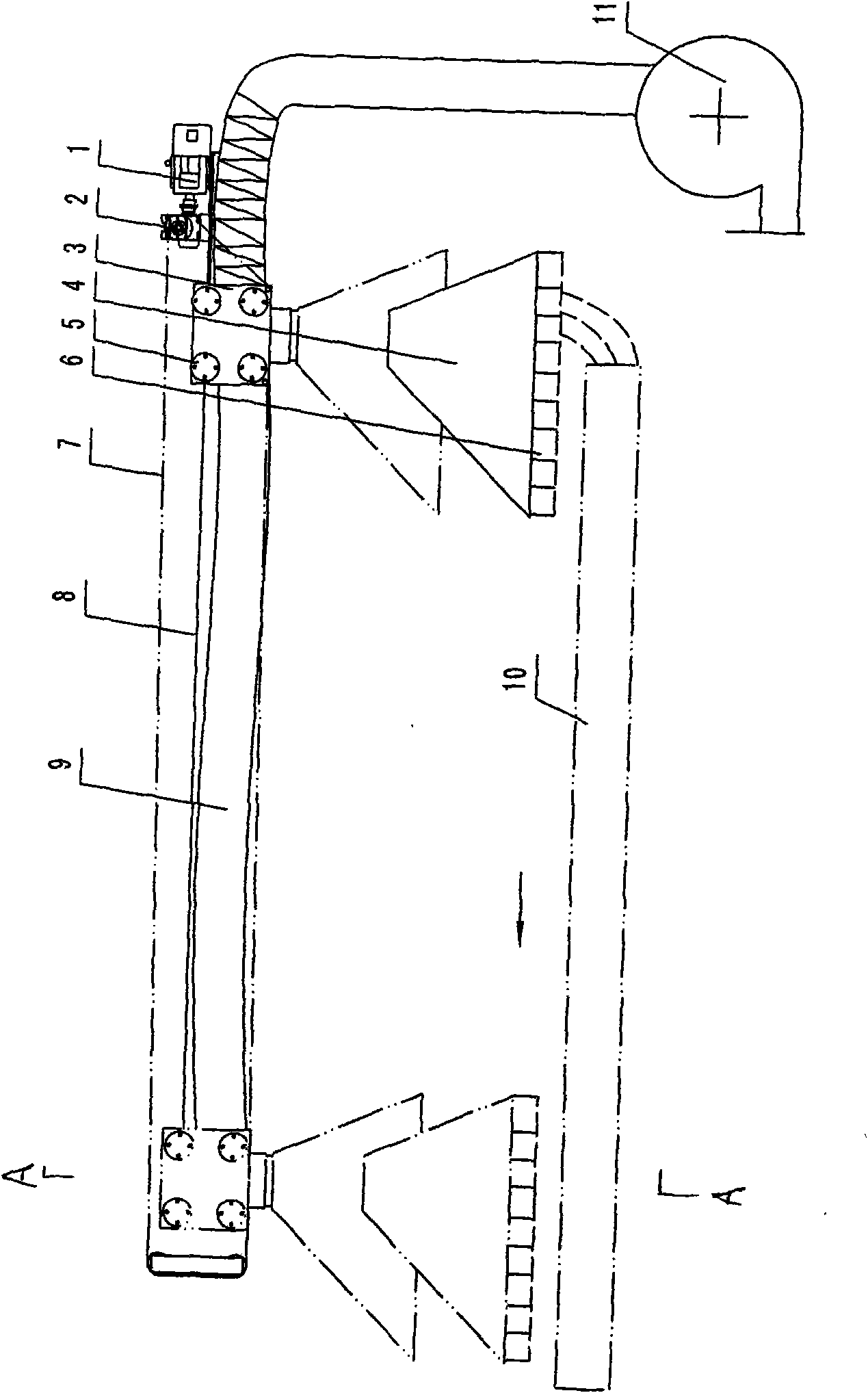

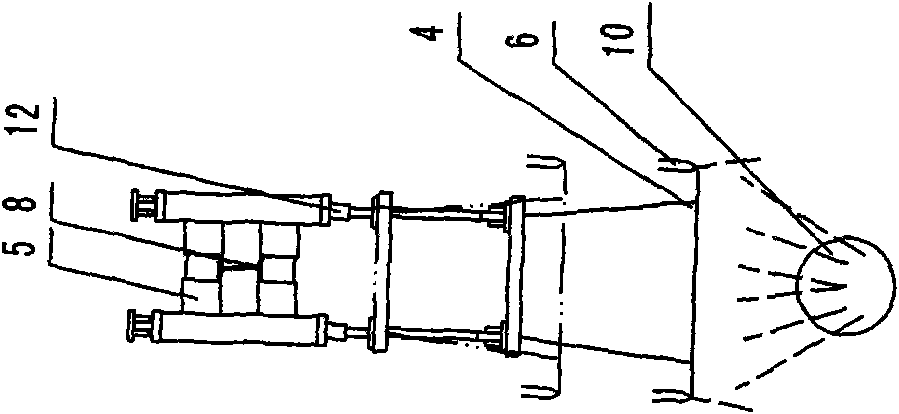

[0011] Example 1, see figure 1 , 2 , install a bracket at the position of the steel pipe produced by expansion, install motor 1, reducer 2 and I-beam 8 on the bracket, I-beam 8 is located directly above the steel pipe 10 produced by expansion, and motor 1 drives reducer 2, through The wire rope 7 drives the pulley 5 to move along the I-beam 8, and the dust collection cover 4 is fixedly connected to the bottom of the pulley 5, and the cylinder 12 is installed on the dust collection cover 4, and the other end of the cylinder 12 is connected with the support 3 of the pulley 5. Side plate is installed on the mouth limit of 4, and air duct device is installed in its both sides, forms wind wall device 6, dust collection cover 4 is connected with induced draft fan 11 by flexible pipe 9.

[0012] The graphite dust suction device of the present invention, when working, the dust collection cover moves with the tail of the steel pipe, the dust collection cover is driven by a cylinder, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com