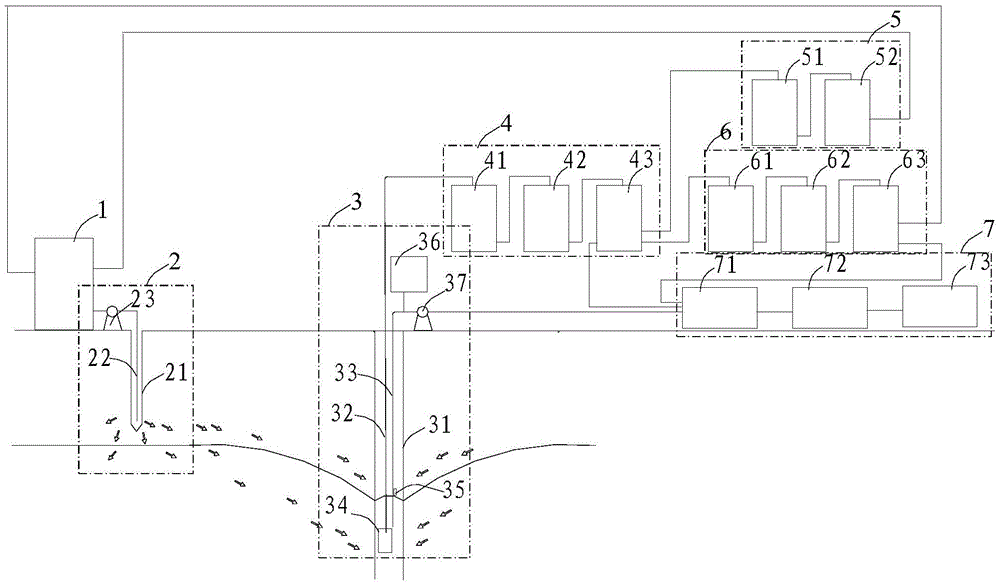

In-situ remediation system and remediation method for organic pollution site of light non-aqueous phase liquids (LNAPLs)

An in-situ repair and repair system technology, applied in the restoration of contaminated soil, etc., can solve the problems of large power consumption, large power consumption, and long repair period, so as to reduce consumption and modification costs, reduce separation difficulty, and reduce pollutants. The effect of high removal rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] A gas station in Jinhua City, Zhejiang Province was affected by oil pipeline leakage, and the soil was polluted by LNAPLs pollutants such as gasoline and diesel, with a soil pollution area of 310m 2 , the pollution depth is 13m.

[0052] The specific implementation is as follows:

[0053] (1) Set up an extraction well and a drug injection well in the polluted site, set up 8 monitoring wells within the contaminated site, and set up 6 monitoring wells around the polluted site. Among them, the diameter of the extraction well and the drug injection well is 15cm, the depth of the injection well is 11.5m, and the depth of the extraction well is 13.5m; the diameter of the monitoring well is 5cm, and the depth of the setting is 5m.

[0054] (2) Install a soil leaching repair system, and select SDBS as the enhanced leaching agent for pollutants.

[0055] (3) According to the power consumption of each equipment, the total power of the soil washing repair system is determined ...

Embodiment 2

[0058] A petrochemical plant in Nantong City, Jiangsu Province was relocated, and the soil and groundwater at the original site were polluted by oily substances (LNAPLs), namely "light oil". The detection rate of petroleum pollutants in groundwater reaches about 50%, the concentration of petroleum pollutants reaches 2.5-4.0mg / l, the pollution depth is about 7.5m, and the pollution area reaches 920m 2 .

Embodiment approach

[0059] The repair implementation plan is as follows:

[0060] (1) Carry out sampling survey on the polluted site to determine the scope and depth of site pollution and the core polluted area. The groundwater flow direction of the polluted site is from northwest to southeast. Four extraction wells and injection wells are respectively set up in the polluted site, and extraction wells are built downstream of the polluted area where groundwater flows, and injection wells are built upstream of the polluted area.

[0061] (2) Set up 15 monitoring wells within the scope of the polluted site, and set up 10 monitoring wells around the polluted site. Among them, the diameter of the extraction well and the injection well is 15cm, the depth of the injection well is 6.5m, and the depth of the extraction well is 8m; the diameter of the monitoring well is 5cm, and the depth of the installation is 7.5m.

[0062] (3) Install a soil leaching repair system, and select SDBS as the enhanced leach...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com