Single-component dealcoholized and room temperature vulcanized organosilicone pouring sealant for leds and preparation method

A room temperature vulcanization and dealcoholization technology, applied in chemical instruments and methods, dyed low molecular organic compound treatment, adhesives, etc., can solve the problems of inconvenient operation, easy powdering, insufficient adhesion, etc., and achieve good economic benefits. and social benefits, the process is simple and feasible, and the effect of excellent flow performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

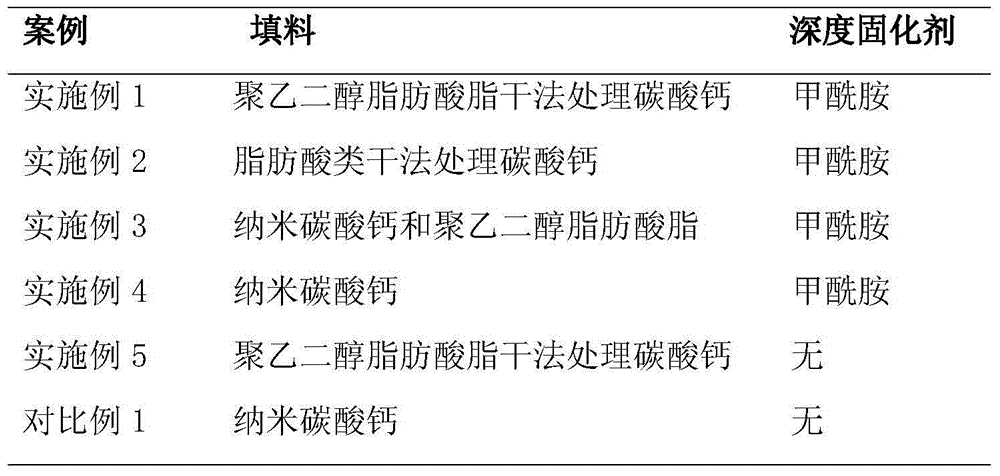

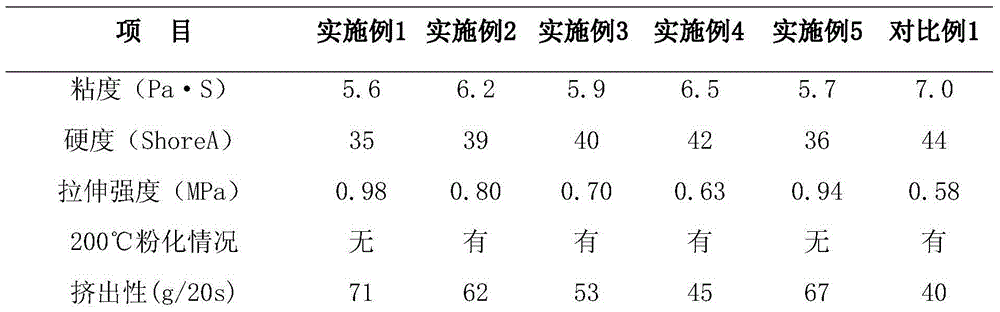

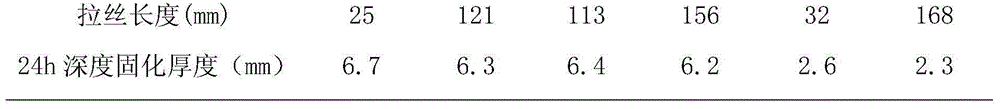

Examples

Embodiment 1

[0031] 1. Use 2.5% polyethylene glycol fatty acid ester (calcium carbonate total amount) to carry out secondary dry process to nano-calcium carbonate by conventional method.

[0032] 2. Mix 100 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 2000mPa·s, 15 parts of dry-processed nano-calcium carbonate, 5 parts of calcium chloride, 5 parts of white carbon black and 8 parts of viscosity Put the 200mPa·s simethicone oil into the high-speed disperser, stir evenly, and at the same time evacuate to -0.09MPa, heat to 90°C, and disperse at a speed of 1000rpm in the high-speed disperser for 100min.

[0033] 3. Cool the high-speed disperser to 35°C with cooling water, release the vacuum with nitrogen, add 4 parts of the mixture of methyltrimethoxysilane and ethyltrimethoxysilane, stir evenly, continue to vacuum, and keep the vacuum at - 0.095MPa, high-speed dispersion for 30min.

[0034] 4. Blow nitrogen to release the vacuum, add 2 parts of the mixture of γ-aminopropylt...

Embodiment 2

[0037]1. Use 2.5% fatty acid treatment agent (calcium carbonate total amount) to carry out secondary dry process to nanometer calcium carbonate by conventional method.

[0038] 2. Mix 100 parts of α, ω-dihydroxypolydimethylsiloxane with a viscosity of 2000mPa·s, 15 parts of dry-processed nano-calcium carbonate, 5 parts of calcium chloride, 5 parts of white carbon black and 8 parts of viscosity Put the 200mPa·s simethicone oil into the high-speed disperser, stir evenly, and at the same time evacuate to -0.09MPa, heat to 90°C, and disperse at a speed of 1000rpm in the high-speed disperser for 100min.

[0039] 3. Cool the high-speed disperser to 35°C with cooling water, release the vacuum with nitrogen, add 4 parts of the mixture of methyltrimethoxysilane and ethyltrimethoxysilane, stir evenly, continue to vacuum, and keep the vacuum at - 0.095MPa, high-speed dispersion for 30min.

[0040] 4. Blow nitrogen to release the vacuum, add 2 parts of the mixture of γ-aminopropyltrietho...

Embodiment 3

[0043] 1. 100 parts of α with a viscosity of 2000mPa·s, ω-dihydroxy polydimethylsiloxane, 15 parts of nano calcium carbonate, 2.5% polyethylene glycol fatty acid ester (calcium carbonate total amount), 5 parts of chlorinated Calcium, 5 parts of white carbon black and 8 parts of simethicone oil with a viscosity of 200mPa·s are placed in a high-speed disperser, stirred evenly, and at the same time, vacuumed to -0.09MPa, heated to 90°C, and dispersed in a high-speed disperser at a speed of 1000rpm 100min.

[0044] 2. Cool the high-speed disperser to 35°C with cooling water, release the vacuum with nitrogen, add 4 parts of the mixture of methyltrimethoxysilane and ethyltrimethoxysilane, stir evenly, continue to vacuum, and keep the vacuum at - 0.095MPa, high-speed dispersion for 30min.

[0045] 3. Blow nitrogen to release the vacuum, add 2 parts of the mixture of γ-aminopropyltriethoxysilane and γ-(2,3-epoxypropane)propyltriethoxysilane, bis(acetylacetone)bis(iso Propoxy) titana...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com