3D printer spray head with adjustable nozzle caliber

A 3D printer and nozzle technology, applied in coating devices, additive processing, etc., can solve the problem of printing speed and display of model details, but can only compromise with each other and cannot be mutually satisfied, and fixed-caliber nozzles cannot be adjusted adaptively and other problems to achieve the effect of reducing heat load, reducing volume, and increasing printing speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Specific examples of the present invention are given below. The specific embodiments are only used to further describe the present invention in detail, and do not limit the protection scope of the claims of the present application.

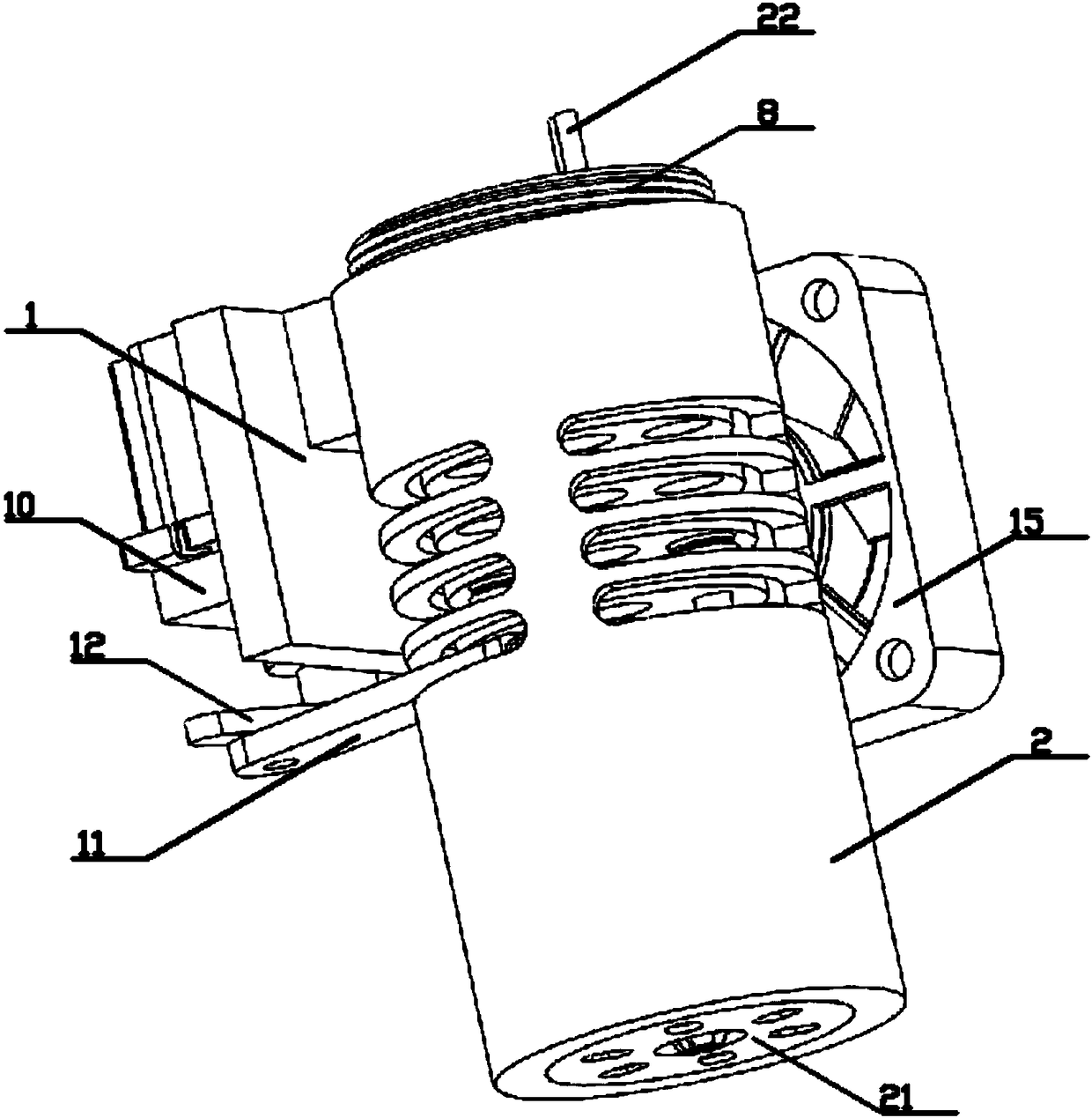

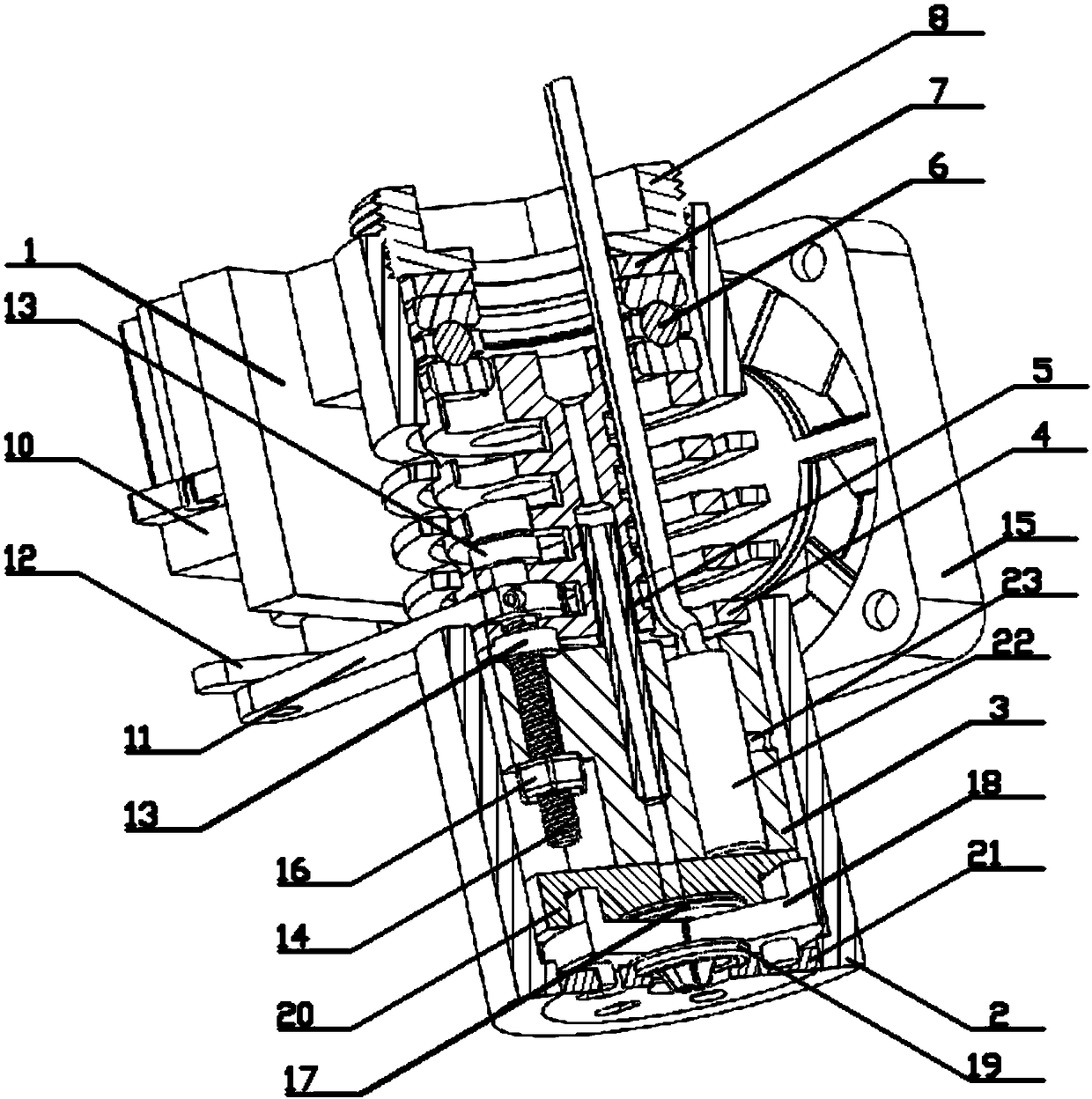

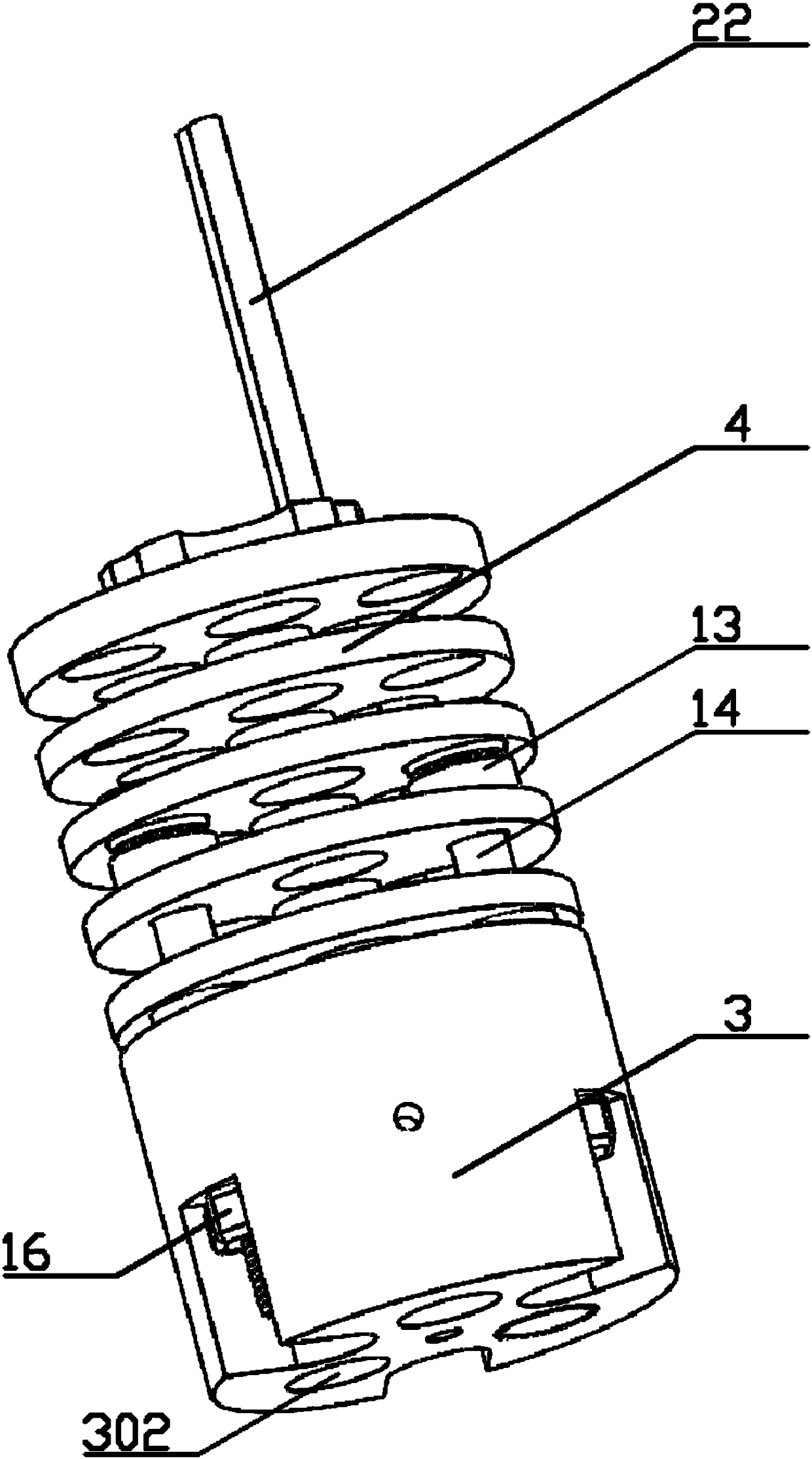

[0028] The invention provides a 3D printer nozzle with adjustable nozzle diameter (see Figure 1-10 , referred to as nozzle), including machine base 1, shell 2, thrust bearing 6, pressure gasket 7, head 8, servo steering gear 10, control connecting rod 11, steering gear rocker arm 12, cooling fan 15 and electric heating tube 22 ; The base 1 is used to install the nozzle on the main engine; the shell 2, the servo steering gear 10 and the cooling fan 15 are fixed on the base 1; the shell 2 is a tubular part with a ventilation hole in the middle; the shell 2. The connection position with the base 1 is located on the side away from the nozzle assembly; the steering gear rocker arm 12 is installed on the rotating shaft of the servo steering gea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com