Bursting device

A bursting and test bench technology, applied in the textile field, can solve problems such as inapplicability, and achieve the effects of improving clamping fastness, improving accuracy and reliability, and ensuring accuracy and effectiveness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

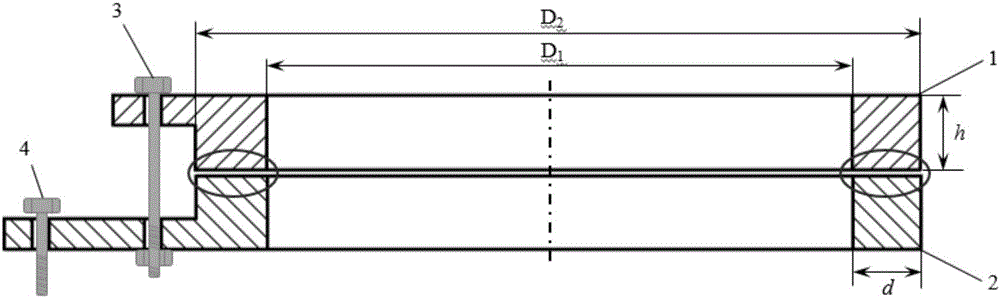

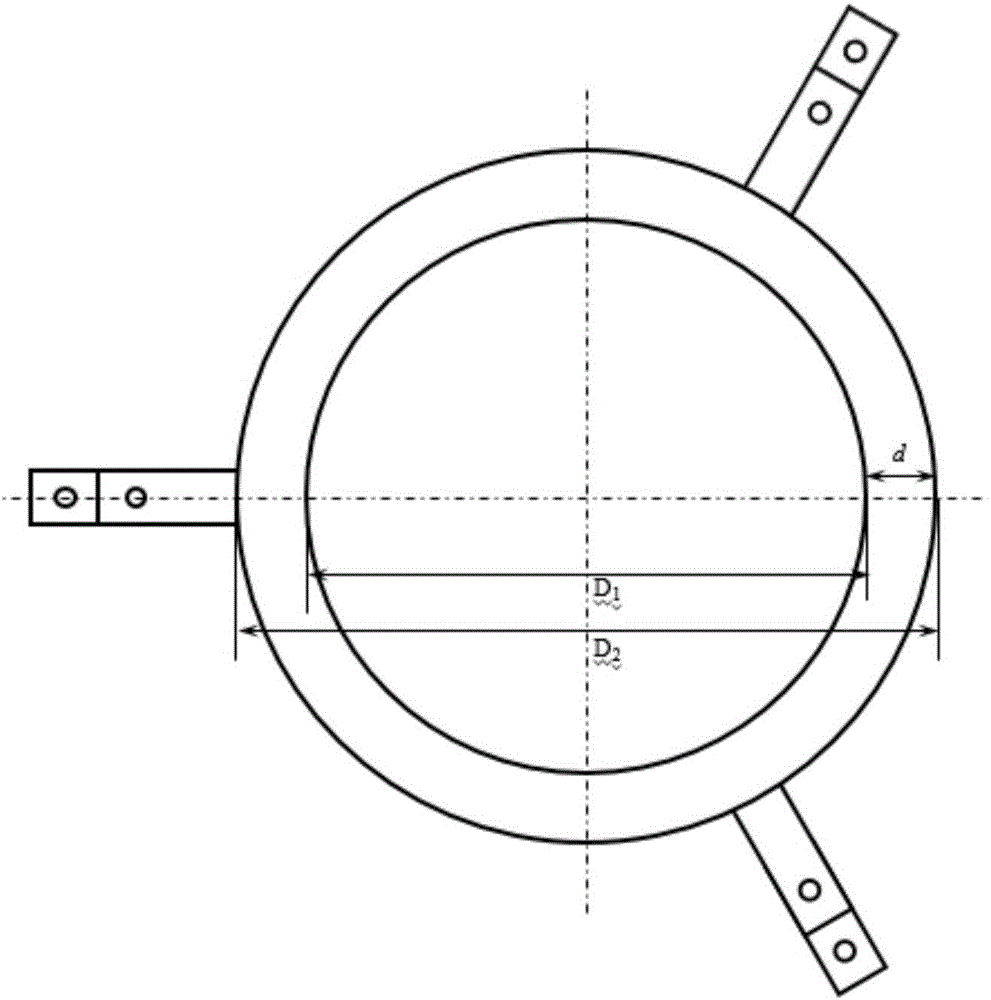

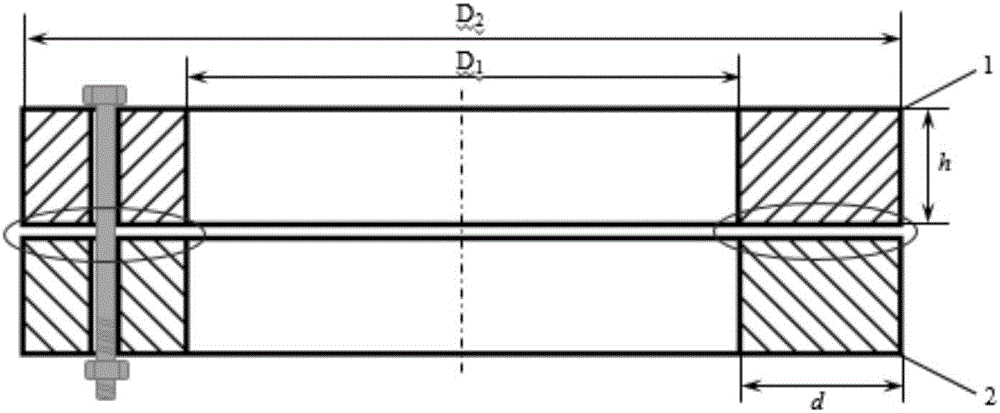

[0031] The invention discloses a bursting device for testing the bursting performance of textile / textile structure reinforced flexible composite materials. Set bolts and nuts for further reinforcement, this design significantly improves the clamping fastness of the textile / textile structure reinforced flexible composite material to be tested, and reduces the relative slip between the sample to be tested and the fixture during the burst test and the textile structure The middle yarn is pulled out to improve the accuracy and reliability of the burst test; in addition, the fixture can also be designed as a positioning pin connected with the lower end test equipment to further increase the stability during the burst test.

[0032] The technical solutions in the embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some of the embo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com