Electroplating-free antique metal surface treatment method

A metal surface treatment and electroless plating technology, applied in the direction of pretreatment surface, surface coating liquid device, polyurea/polyurethane coating, etc., can solve the problems of potential safety hazards and high requirements, achieve strong three-dimensional effect, reduce Production cost, pollution reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

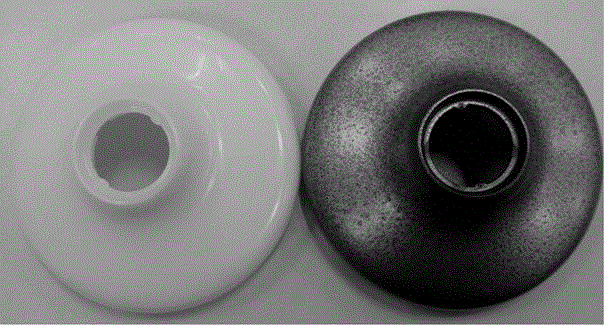

Image

Examples

Embodiment 1

[0023] Weigh 30g of black oily color paste and 10g of 600-mesh non-leafing aluminum powder, add 10g of commonly used PU diluent, 2 drops of silicone oil additives and 7g of polyisocyanate curing agent after mixing, stir well and test for chemical degreasing and activation The board is sprayed, and after the curing is complete, the polyurethane varnish is sprayed.

Embodiment 2

[0025] Weigh 20g of black oily color paste and 2g of 800-mesh non-leafing copper-zinc alloy powder. After mixing, add 4g of commonly used PU diluent, 1 drop of silicone oil additive and 7g of polyisocyanate curing agent. The test panel is sprayed, and after the curing is complete, the polyurethane varnish is sprayed.

Embodiment 3

[0027] Weigh 9g of black oily color paste and 3g of 1000 mesh non-leafing copper-zinc alloy powder, stir well and add 60g of polyurethane resin SY-308, mix well and add 10g of PU diluent, 1 drop of silicone oil additive and polyisocyanate curing agent 14g, after stirring evenly, spray on the test panel that has undergone chemical degreasing and activation, and spray polyurethane varnish after curing is complete.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com