Measuring head simulation system and method of image measurement machine

A technology of image measurement and simulation method, which is applied in measurement devices, image data processing, instruments, etc., can solve problems such as unintuitiveness, difficulty in selecting probes, and inability to determine the movement path of probes, so as to reduce drawing and display quickly. and the effect of motion simulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

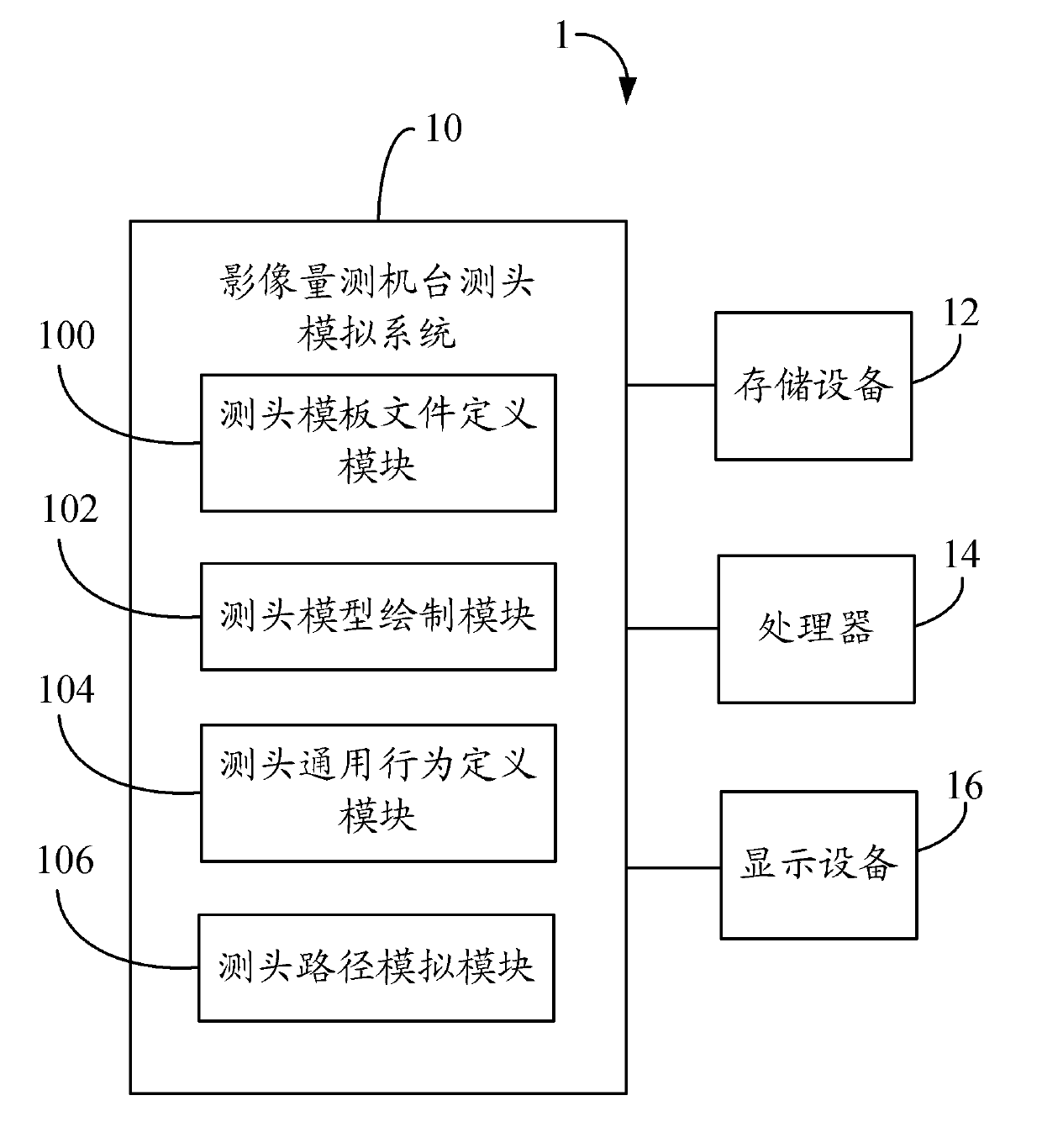

[0016] Such as figure 1 As shown, it is a schematic diagram of the operating environment of a preferred embodiment of the probe simulation system of the image measuring machine of the present invention. The probe simulation system 10 of an image measuring machine (hereinafter referred to as “system 10 ”) runs on a host 1 , and the host 1 includes a storage device 12 , a processor 14 and a display device 16 .

[0017] In this embodiment, the system 10 is installed in the storage device 12 in the form of software programs or instructions. In other embodiments, the storage device 12 may be an external storage of the host 1 .

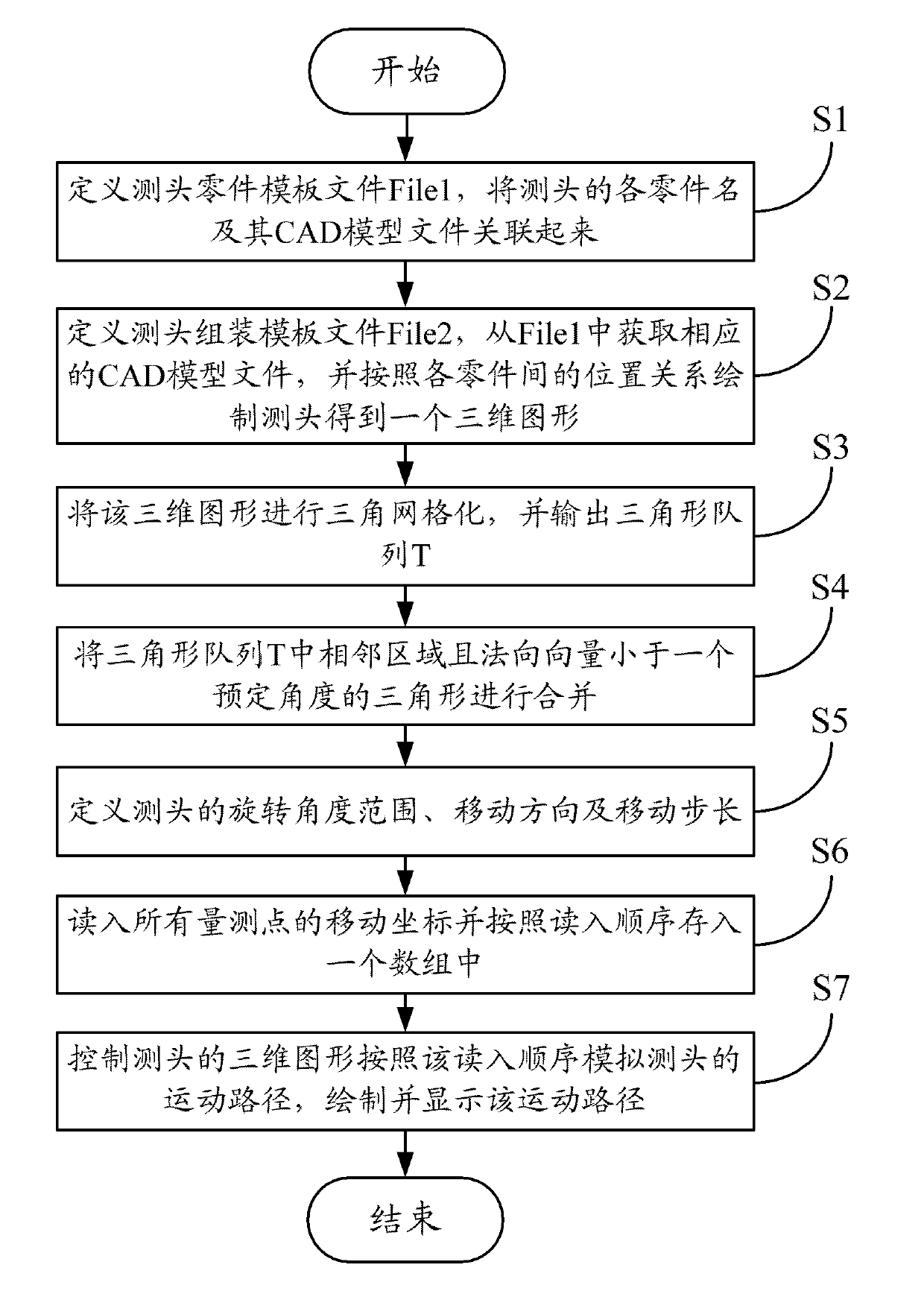

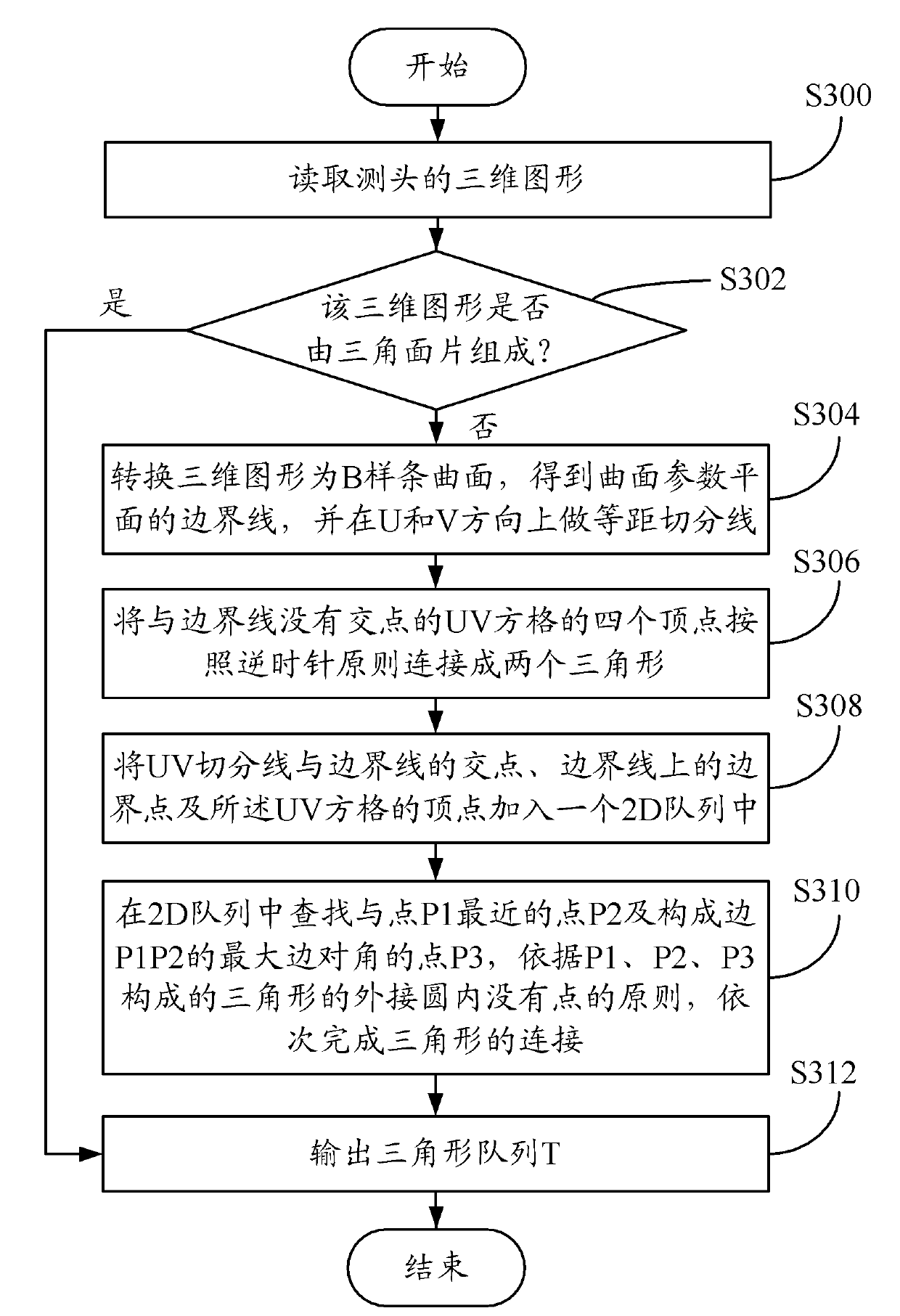

[0018] The processor 14 executes the program code of the system 10 to simulate the movement path of the probe, that is, associate the part names of the components of the probe and their corresponding CAD drawings and merge the graphics to reduce the detail of the three-dimensional graphics. Drawing, by reading in the moving coordinates and sequence of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com