Dust hood for blast furnace tap hole

A blast furnace iron tapping and dust removal hood technology, applied in dust collectors, discharge devices, etc., can solve problems such as difficult collection, excessive air, and increased energy consumption, and achieve the effects of improving collection efficiency, uniform suction, and eliminating disturbances

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

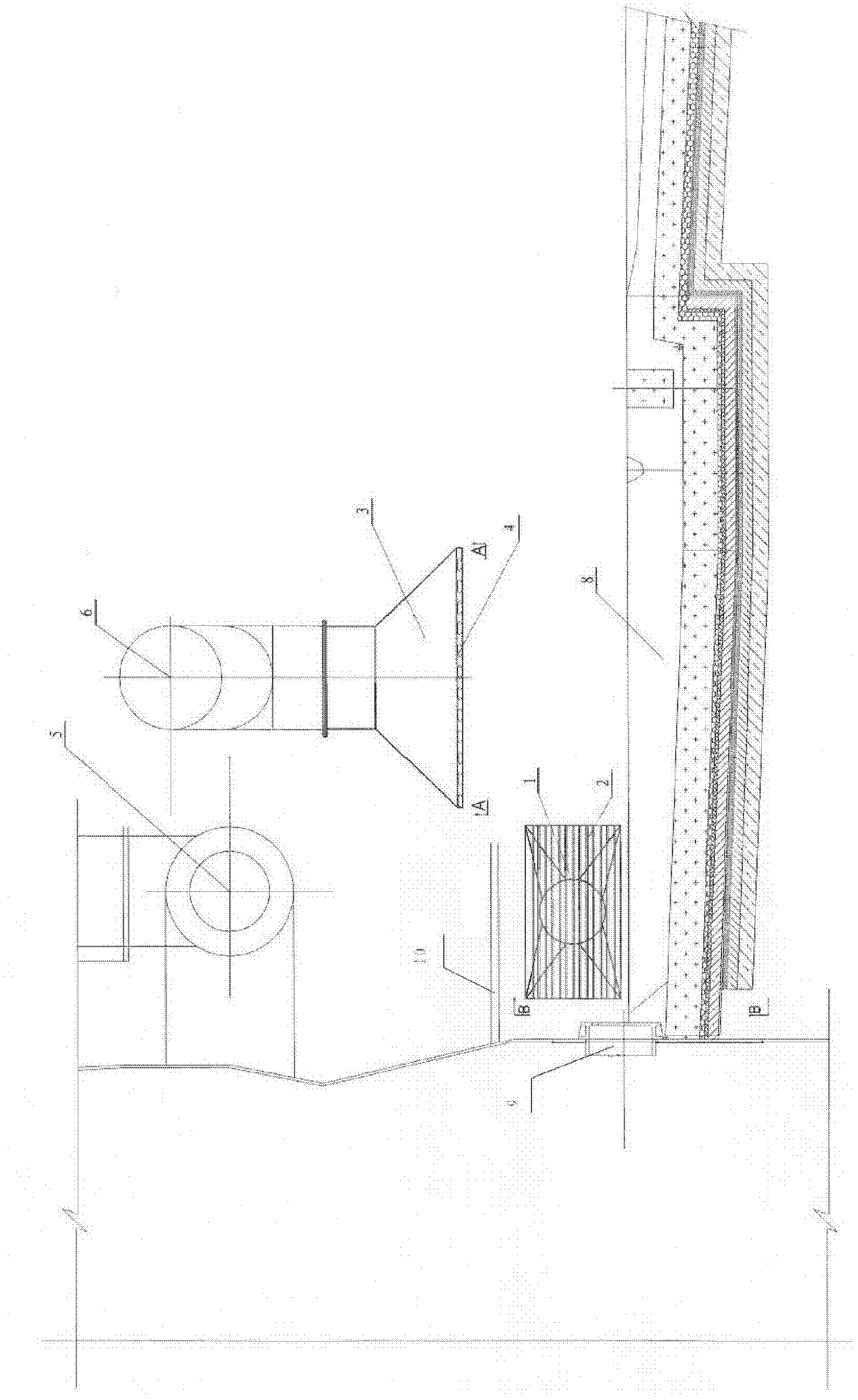

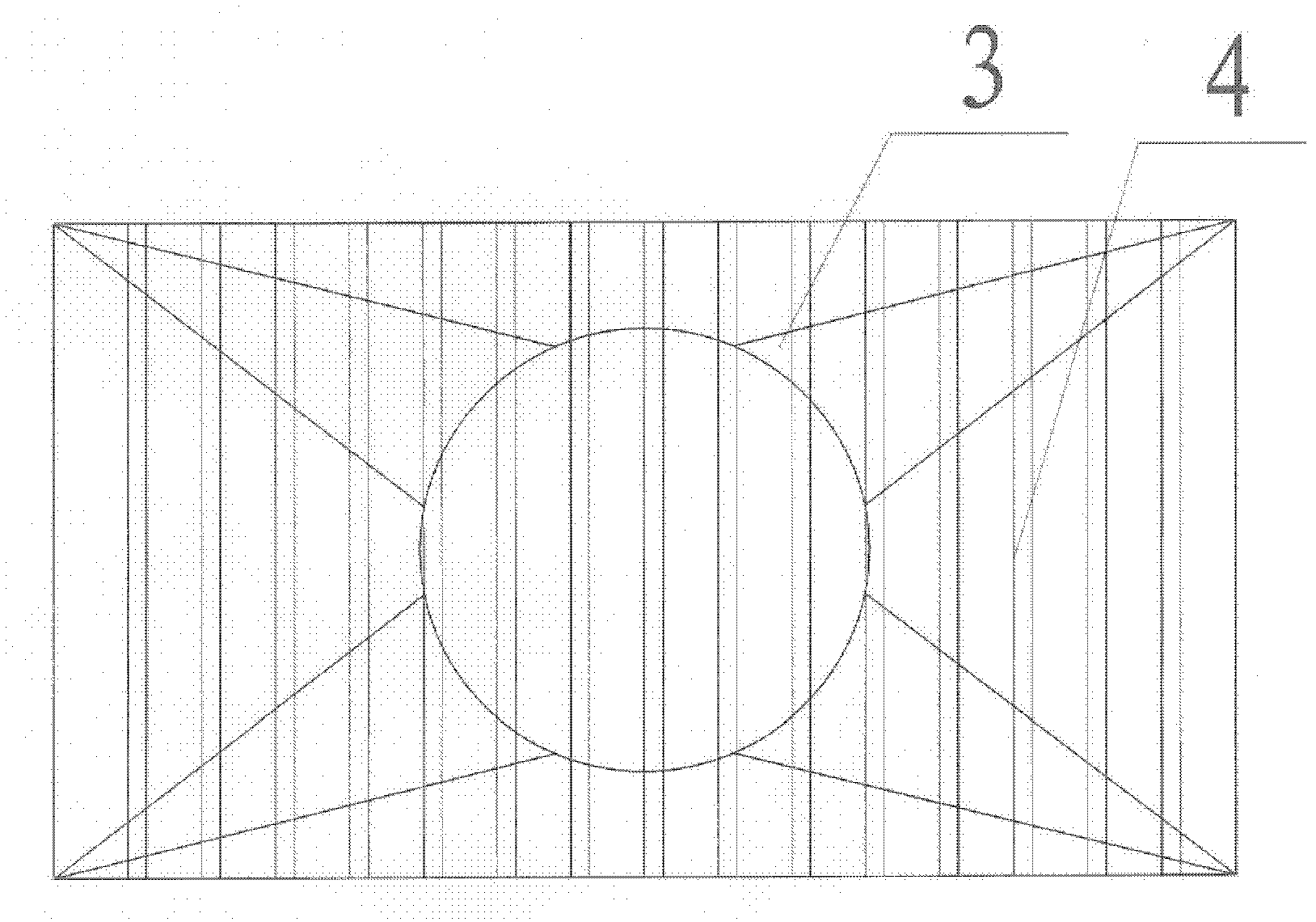

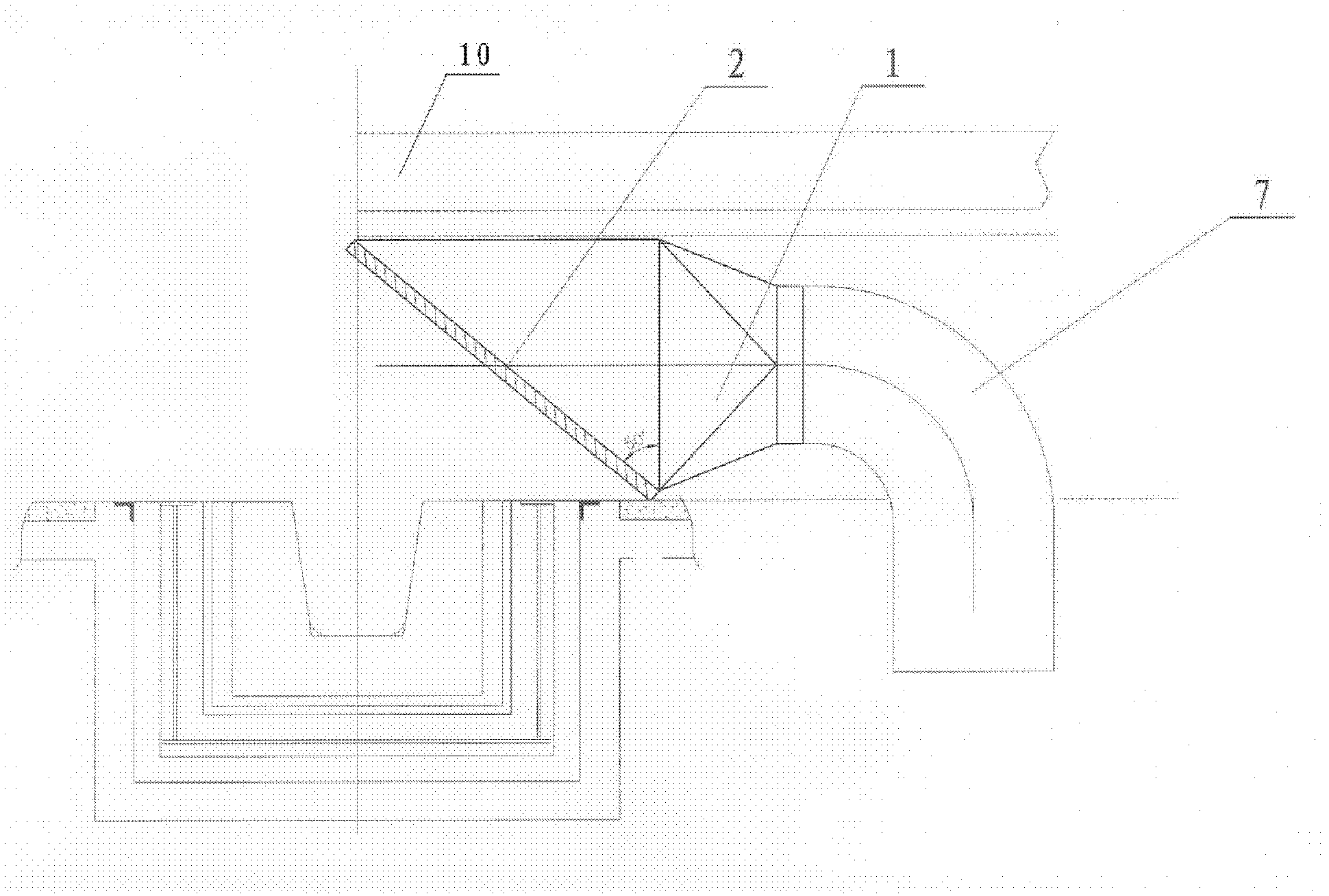

[0017] refer to figure 1 , a dust removal cover for a blast furnace taphole, which includes a top suction dust removal cover and a side suction dust removal cover, wherein the top suction dust removal cover is installed above the outer side of the blast furnace taphole 9, and the side suction dust removal cover is installed on the outside of the blast furnace taphole One side of the iron ditch 8 connected to the mouth, and located below the tuyere platform 10, wherein the tuyere platform 10 is located below the hot air tail pipe 5; the top suction dust removal cover includes the first dust removal pipe 6 and the first dust removal pipe connected Dust removal cover 3; the side suction dust removal cover includes the second dust removal pipe 7 and the second dust removal cover 1 connected with the second dust removal pipe, the mouth of the side suction dust removal cover is inclined, and its inclination angle is 50°; The cover opening of the dust removal cover is provided with t...

Embodiment 2

[0020] It is basically the same as Embodiment 1, except that the mouth of the side suction dust removal hood is inclined, and the inclination angle is 45°.

Embodiment 3

[0022] It is basically the same as Embodiment 1, except that the mouth of the side suction dust removal hood is inclined, and the inclination angle is 30°.

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com