made of ferrophosphorus in co 2 prepared in atmosphere li x fe y p z o 4 Methods

A ferrophosphorus and atmosphere technology, applied in the field of material manufacturing process, can solve the problems of high cost of atmosphere manufacturing and single variety, and achieve the effects of simple and convenient reaction, short production process and reduced manufacturing cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

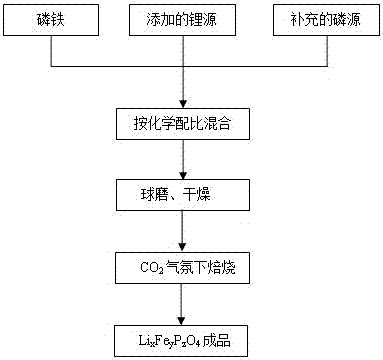

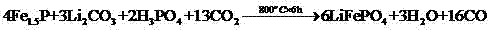

[0020] Ferrophosphorus was prepared by solid-phase synthesis in CO 2 Preparation of Li in atmosphere x Fe y P z o 4 method, first iron phosphorus FeP 1.5 Grinding to 1000-2000 mesh powder, using ferrophosphorus as Li x Fe y P z o 4 Provide all iron elements and some phosphorus elements, and add the required lithium source Li according to the molar ratio of total lithium elements, total iron elements and total phosphorus elements (0.9~1.1): 1: 1 2 CO 3 and supplementary phosphorus source H 3 PO 4 Mixed ingredients with ferrophosphorus to form a precursor, ball milled and dried in CO 2 atmosphere 800 o C roasted for 6 hours, cooled and ground to obtain the product, and the reaction equation is as follows:

[0021]

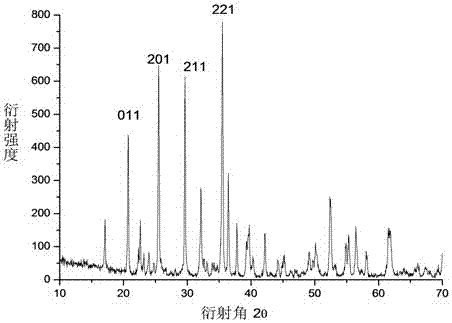

[0022] The XRD pattern of the sample prepared from the reaction ( figure 2 ), the sample has four main crystal plane diffraction peaks (011), (201), (211) and (221) around 2θ=20.7°, 25.5°, 29.7° and 35.6°, which is similar to LiFePO produced by Vale...

Embodiment 2

[0024] On the basis of Example 1, change supplementary phosphorus source, H 3 PO 4 Change to NH 4 h 2 PO 4 Compared with phosphoric acid solution, the price of ammonium dihydrogen phosphate powder is lower, which further reduces the manufacturing cost.

[0025] Ferrophosphorus was prepared by solid-phase synthesis in CO 2 Preparation of Li in atmosphere x Fe y P z o 4 , first crush ferrophosphorus to a certain particle size, then weigh ferrophosphorus, Li 2 CO 3 and NH 4 h 2 PO 4 (Li: Fe: P molar ratio (0.9~1.1): 1:1) mixed, dispersed and ground with alcohol to the rheological phase, dried in CO 2 atmosphere 650 o C firing for 10 hours. The response equation is as follows:

[0026]

[0027] This reaction converts the H in Example 1 3 PO 4 Changed to NH 4 h 2 PO 4 Repeated preparation, it can be seen that LiFePO can still be generated 4 The positive electrode material also has the advantages of Embodiment 1, and further reduces the cost.

Embodiment 3

[0029] The lithium source in the preparation can be replaced by other lithium compounds that do not introduce impurities except lithium carbonate, and LiOH is taken as an example below. Ferrophosphorus was prepared by solid-phase synthesis in CO 2 Preparation of Li in atmosphere x Fe y P z o 4 , first crush ferrophosphorus to a certain particle size, then weigh ferrophosphorus, LiOH and H 3 PO 4 (Li: Fe: P molar ratio (0.9~1.1): 1:1) mixed, dispersed and ground with alcohol to the rheological phase, dried in CO 2 atmosphere 850 o C firing for 4 hours. The reaction equation is as follows:

[0030]

[0031] This reaction will Li in the embodiment 1 2 CO 3 Changed to LiOH for repeated preparation, it can be seen that LiFePO can still be generated 4 The positive electrode material also possesses the characteristics of Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com