Disperse dyestuff composition with high color fastness to sunlight as well as preparation method and application thereof

A disperse dye and color fastness technology, applied in the field of dyes, can solve the problems of high price, undisclosed ingredients, and low economy, and achieve the effect of small difference, low price, and uniform dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1-6

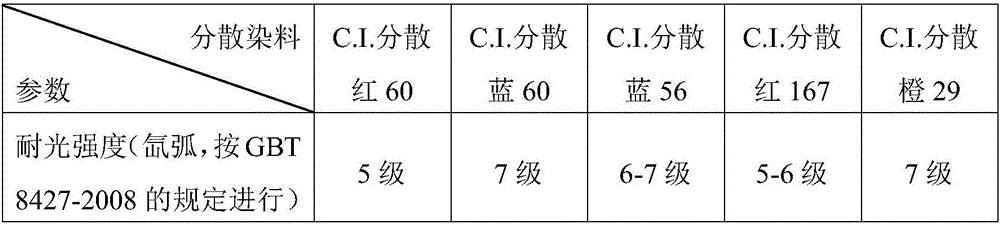

[0043] Take 1-20 parts of C.I. Disperse Red 60, 2-50 parts of C.I. Disperse Blue 60, 1-40 parts of C.I. Disperse Blue 56, 1-20 parts of C.I. Disperse Red 167 and 2-50 parts of C.I. Disperse Orange 29, and mix them; Add 2-20 parts of additives, 10-100 parts of water and 1-10 parts of ethanol, fully disperse by sanding; spray dry the sanded mixture, and evenly spray 5-30 parts of dust-proof oil and 0.5-5 part of light fastness improving agent to obtain the disperse dye composition described in the application, and its particle size was detected to be 0.1 μm to 2 μm.

[0044] See Table 2 for each component and its usage amount in Examples 1-6.

[0045] Each component and usage amount thereof (unit: part) in table 2 embodiment 1-6

[0046]

Embodiment 7-12

[0048] Step 1, the disperse dye composition prepared by embodiment 1-6 is prepared into the disperse dye suspension that concentration is 1.0-2.0g / 500mL with deionized water respectively (note: the disperse dye consumption here is listed in Table 3 Indicated by m);

[0049] Step 2, take 20mL of uniformly dispersed disperse dye suspension, add 80-130mL deionized water to mix (Note: In Table 3, the amount of deionized water added here is represented by N, and the amount of disperse dye in this system is represented by C Express), adjust its pH to 4.5-5.0 with acetic acid;

[0050] Step 3, put 2-3g of pre-treated polyester fiber for high-temperature and high-pressure dyeing: heat up to 130°C within 30-60 minutes, keep warm for 30-60 minutes, cool to 55-60°C for sampling, and obtain colored polyester Ester fiber.

[0051] See Table 3 for each component and its consumption in Examples 7-12.

[0052] Components and consumption thereof of table 3 embodiment 7-12

[0053]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com