Preparation method for producing disperse orange by salt-free diazotization method and high-temperature coupling method

A diazo method and disperse orange technology, applied in chemical instruments and methods, azo dyes, monoazo dyes, etc., can solve problems such as inability to divert waste water, backward dye production technology, and failure to recycle waste water. Achieve the effect of reducing the amount of ice, reducing labor intensity and improving the reaction conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

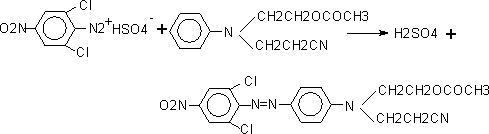

Method used

Image

Examples

Embodiment 1

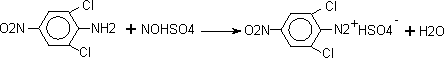

[0027] Embodiment 1, a kind of preparation method of salt-free diazonium method and high temperature coupling method produces disperse orange, and its steps are as follows:

[0028] (1) Diazotization: Put nitrosyl sulfuric acid in the reaction pot, wait until the temperature drops to 20°C, start to add 2,6-dichloro-4-nitroaniline, control the feeding temperature at 25°C, and add naturally Raise the temperature to 30°C, maintain the reaction at this temperature for 5 hours, check whether the diazotization is complete (diazo solution and freezing point test), and wait for coupling after the heat preservation; the nitrosyl sulfuric acid (100%), 2,6 - The weight ratio of dichloro-4-nitroaniline is 0.59:1, and the mass content of nitrosyl sulfuric acid is 25%.

[0029] (2) Coupling: Add 5 tons of mother liquor water, pour in diazonium solution under stirring, 1.0 hour, after finishing, control the temperature at -5°C, add esterification solution (N-cyanoethyl-N-acetoxyethyl) dropwi...

Embodiment 2

[0030] Embodiment 2, a kind of preparation method of salt-free diazonium method and high-temperature coupling method producing disperse orange, its steps are as follows:

[0031] (1) Diazotization: Put nitrosyl sulfuric acid in the reaction pot, wait until the temperature drops to 15°C, start to add 2,6-dichloro-4-nitroaniline, control the feeding temperature at 15°C, and add naturally Raise the temperature to 35°C, maintain the reaction at this temperature for 7 hours, check whether the diazotization is complete (diazo solution and freezing point test), and wait for coupling after the heat preservation is completed. The weight ratio of the nitrosyl sulfuric acid (100%) to 2,6-dichloro-4-nitroaniline is 0.64:1, and the mass content of the nitrosyl sulfuric acid is 40%.

[0032] (2) Coupling: Pour in 15 tons of mother liquor water, pour in diazonium solution under stirring, about 2.5 hours, after finishing, control the temperature at 5°C, add esterification solution (N-cyanoeth...

Embodiment 3

[0033] Embodiment 3, a kind of preparation method of salt-free diazonium method and high-temperature coupling method producing disperse orange, its steps are as follows:

[0034] (1) Diazotization: Put nitrosyl sulfuric acid in the reaction pot, wait until the temperature drops to 30°C, start to add 2,6-dichloro-4-nitroaniline, control the feeding temperature at 30°C, and add naturally Raise the temperature to 35°C, maintain the reaction at this temperature for 6 hours, check whether the diazotization is complete (diazo solution and freezing point test), and wait for coupling after the heat preservation is completed. The weight ratio of the nitrosyl sulfuric acid (100%) to 2,6-dichloro-4-nitroaniline is 0.62:1, and the mass content of the nitrosyl sulfuric acid is 30%;

[0035] (2) Coupling: Pour in 10 tons of mother liquor water, pour in diazonium solution under stirring, about 1.5 hours, after finishing, control the temperature at 0°C, add esterification solution (N-cyanoeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com