Complex disperse orange dye

A technology for compound dispersing and dispersing orange, applied in the field of dyes, can solve the problems of difficult to control light orange transition, poor comprehensive color fastness, affecting dyeing rate and uniformity, etc. The effect of increased brightness and weak hue shift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

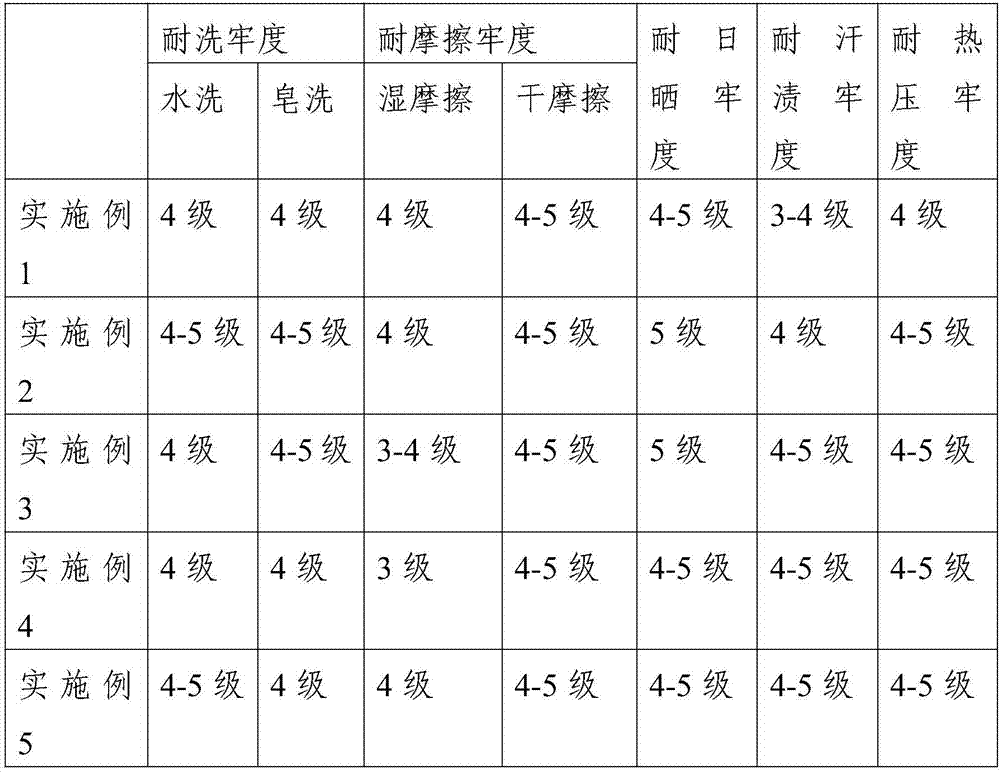

Examples

Embodiment 1

[0019] A composite disperse orange dye is characterized in that it comprises the following percentage raw materials: 7318% disperse orange, 58% disperse orange, 2512% disperse orange, 370% disperse orange, 442% disperse orange, and the balance of additives.

[0020] The auxiliaries include leveling agent, color fixing agent and dispersant, wherein the leveling agent accounts for 8% of the total mass of the auxiliaries, the color fixing agent accounts for 4% of the total mass of the auxiliaries, and the dispersant is the balance.

[0021] Among them, the leveling agent is a mixture of leveling agent BOF and AEO-9, the mass ratio of the two is 1:0.7, the color fixing agent is polyethyleneimine, and the dispersant is dispersant MF with a mass ratio of 2:1:1.5. Composition of dispersant NNO, sodium lignosulfonate.

Embodiment 2

[0023] A composite disperse orange dye is characterized in that it comprises the following percentage raw materials: 7315% disperse orange, 510% disperse orange, 2512% disperse orange, 375% disperse orange, 440% disperse orange, and the balance of additives.

[0024] The auxiliaries include leveling agent, color fixing agent and dispersant, wherein the leveling agent accounts for 4% of the total mass of the auxiliaries, the color fixing agent accounts for 6% of the total mass of the auxiliaries, and the dispersant is the balance.

[0025] Among them, the leveling agent is a mixture of leveling agent BOF and AEO-9, the mass ratio of the two is 1:0.9, the color fixing agent is polyethyleneimine, and the dispersant is dispersant MF with a mass ratio of 2:1:1.5. Composition of dispersant NNO, sodium lignosulfonate.

Embodiment 3

[0027] A composite disperse orange dye is characterized in that it comprises the following raw materials in percent: 7322% disperse orange, 58% disperse orange, 2514% disperse orange, 3711% disperse orange, 446% disperse orange, and the balance of additives.

[0028] Auxiliaries include leveling agent, color fixing agent and dispersant, wherein leveling agent accounts for 7% of the total mass of auxiliaries, color fixing agent accounts for 5% of the total mass of auxiliaries, and dispersant is the balance; The total mass of 8% PEG-1000 and the total mass of 0% polyvinyl acetate.

[0029] Among them, the leveling agent is a mixture of leveling agent BOF and AEO-9, the mass ratio of the two is 1:1, the color fixing agent is polyethyleneimine, and the dispersant is dispersant MF and dispersant with a mass ratio of 1:1. Composition of NNOs.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com