Patents

Literature

50results about How to "Structural environmental protection" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

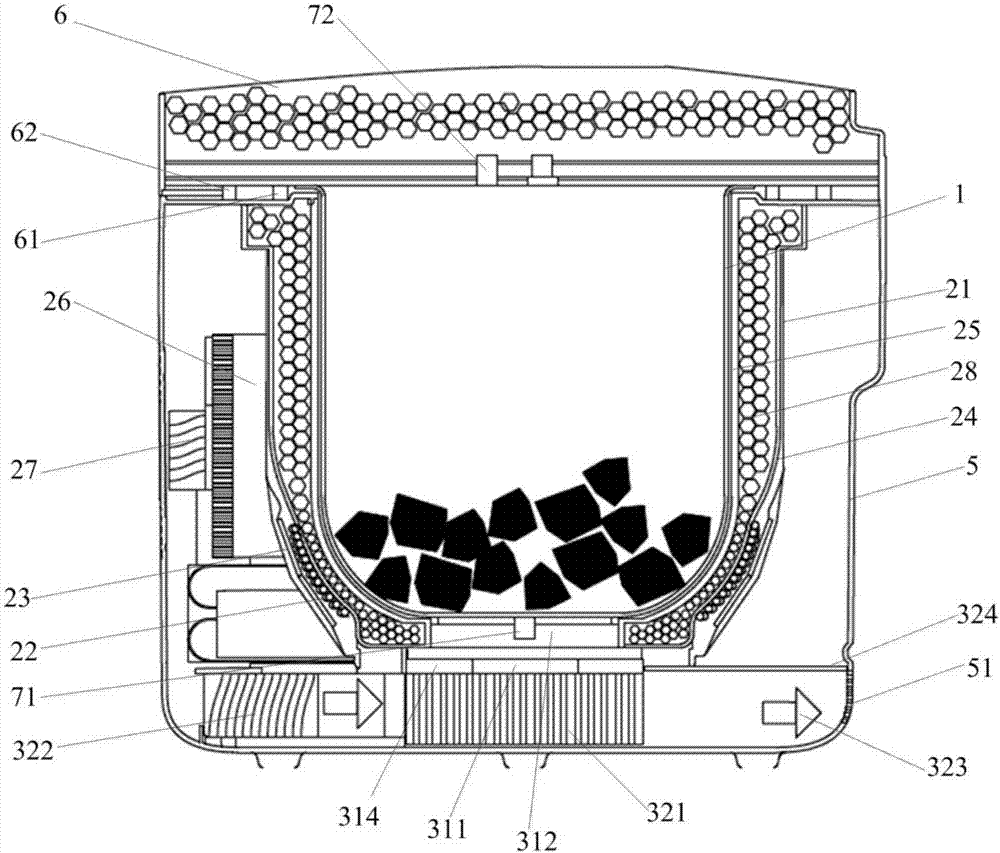

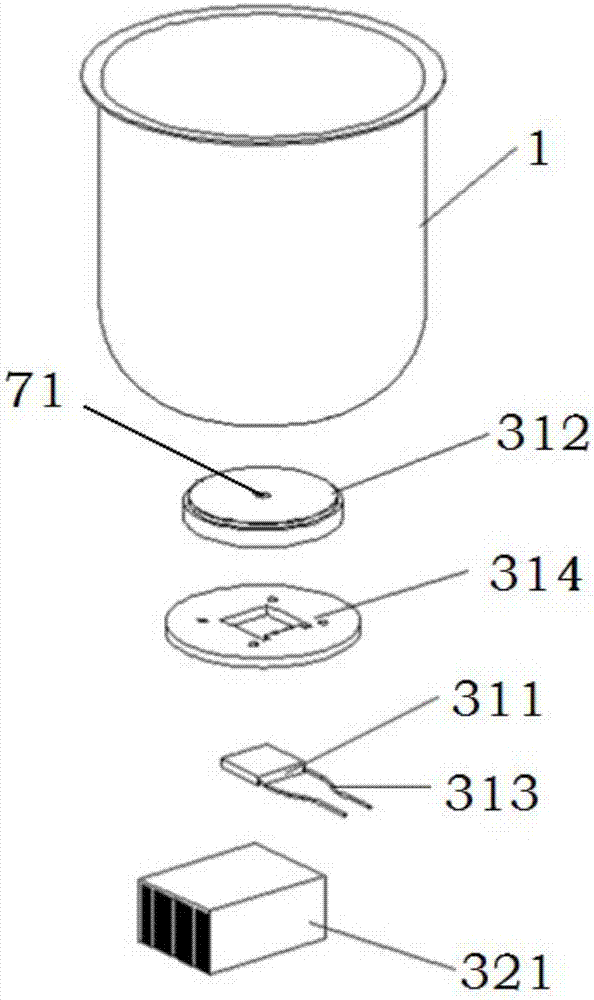

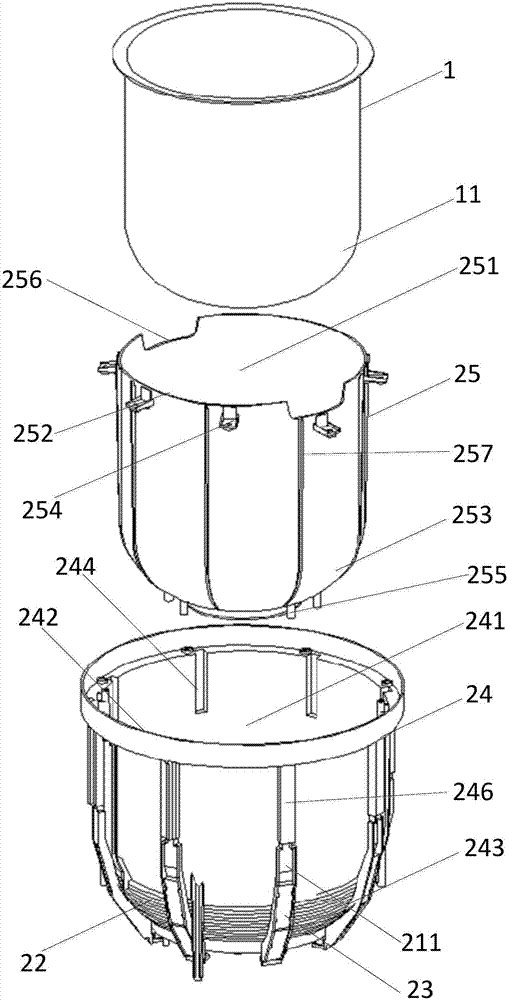

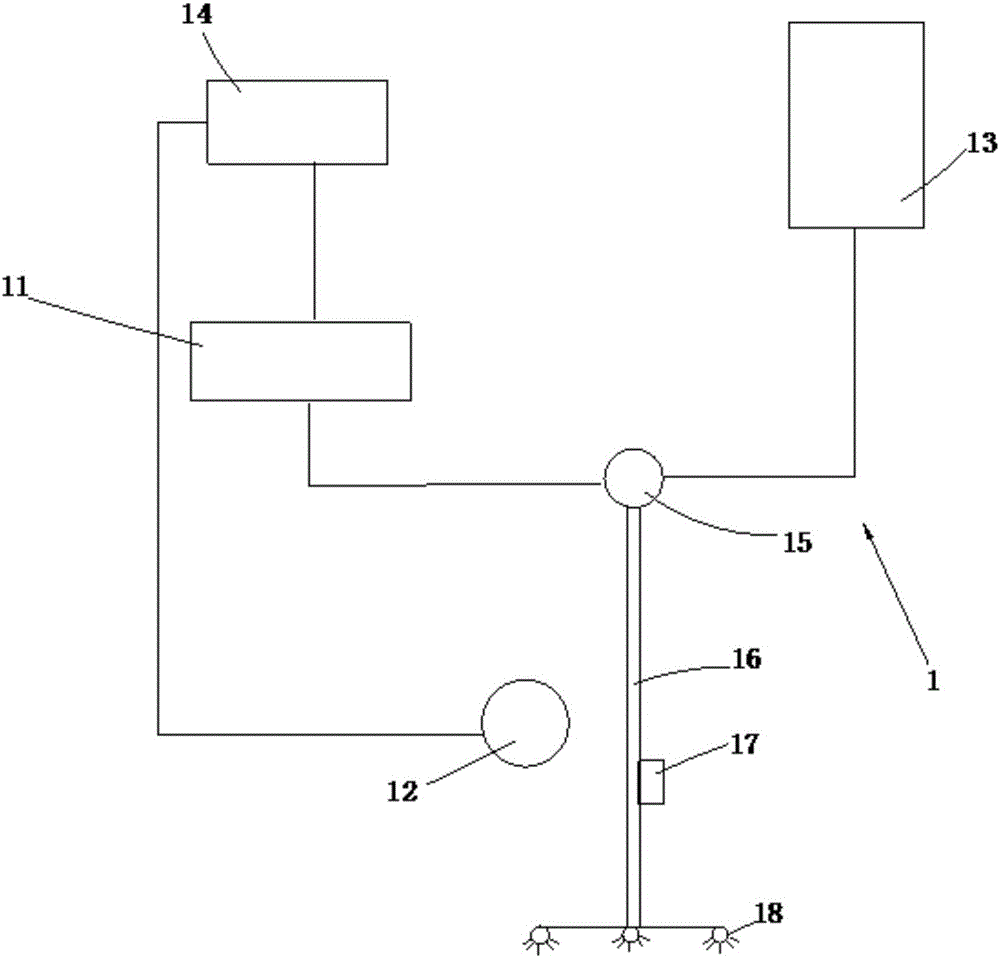

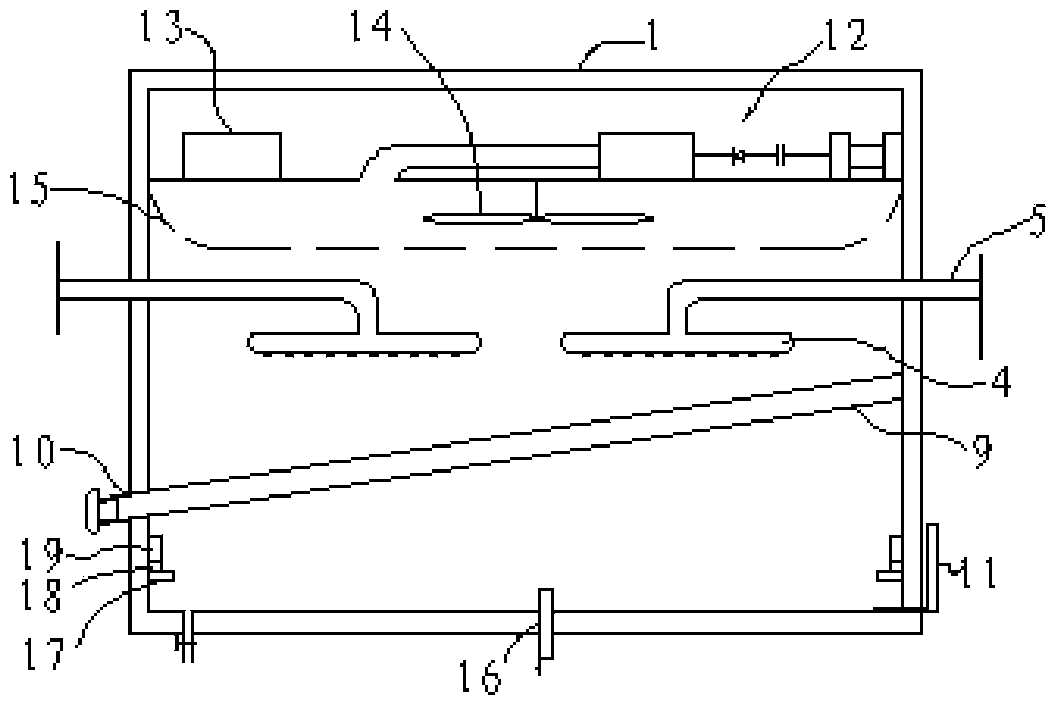

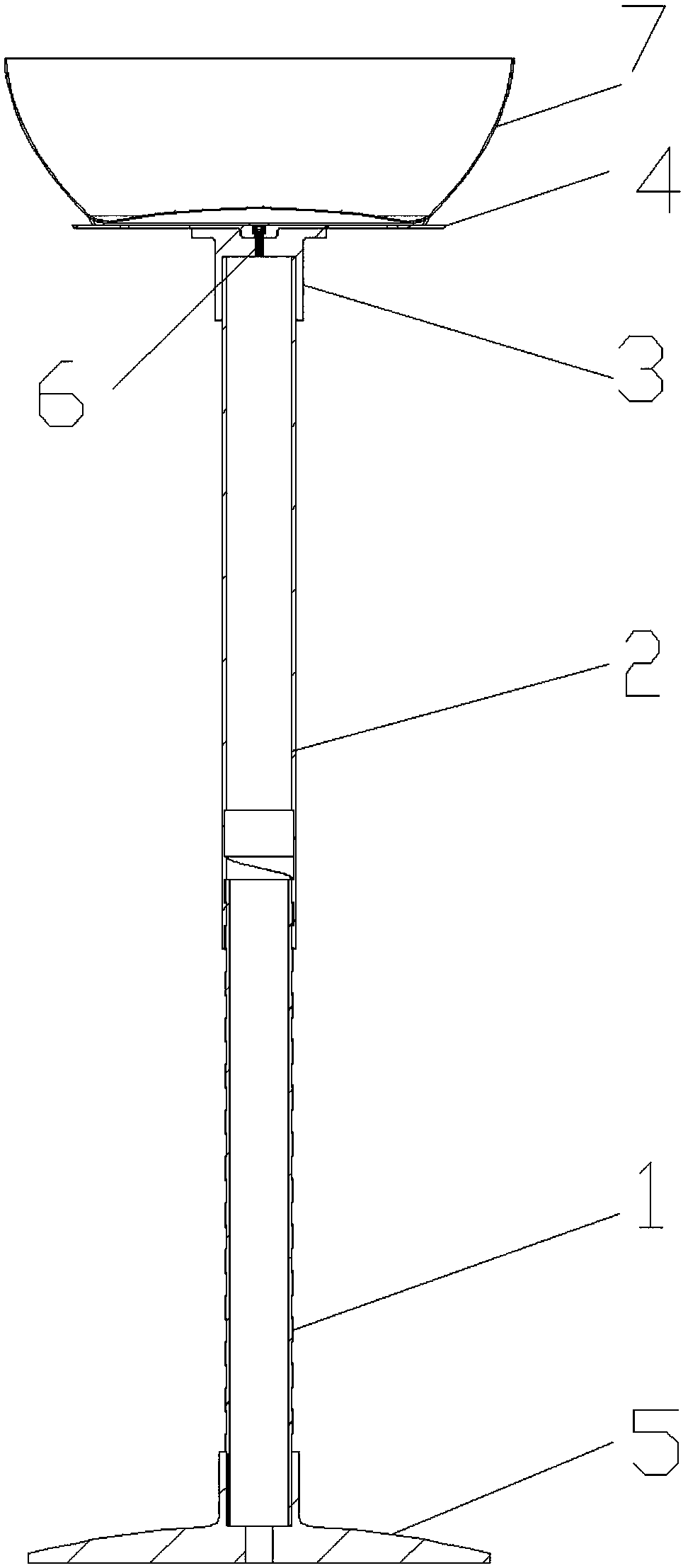

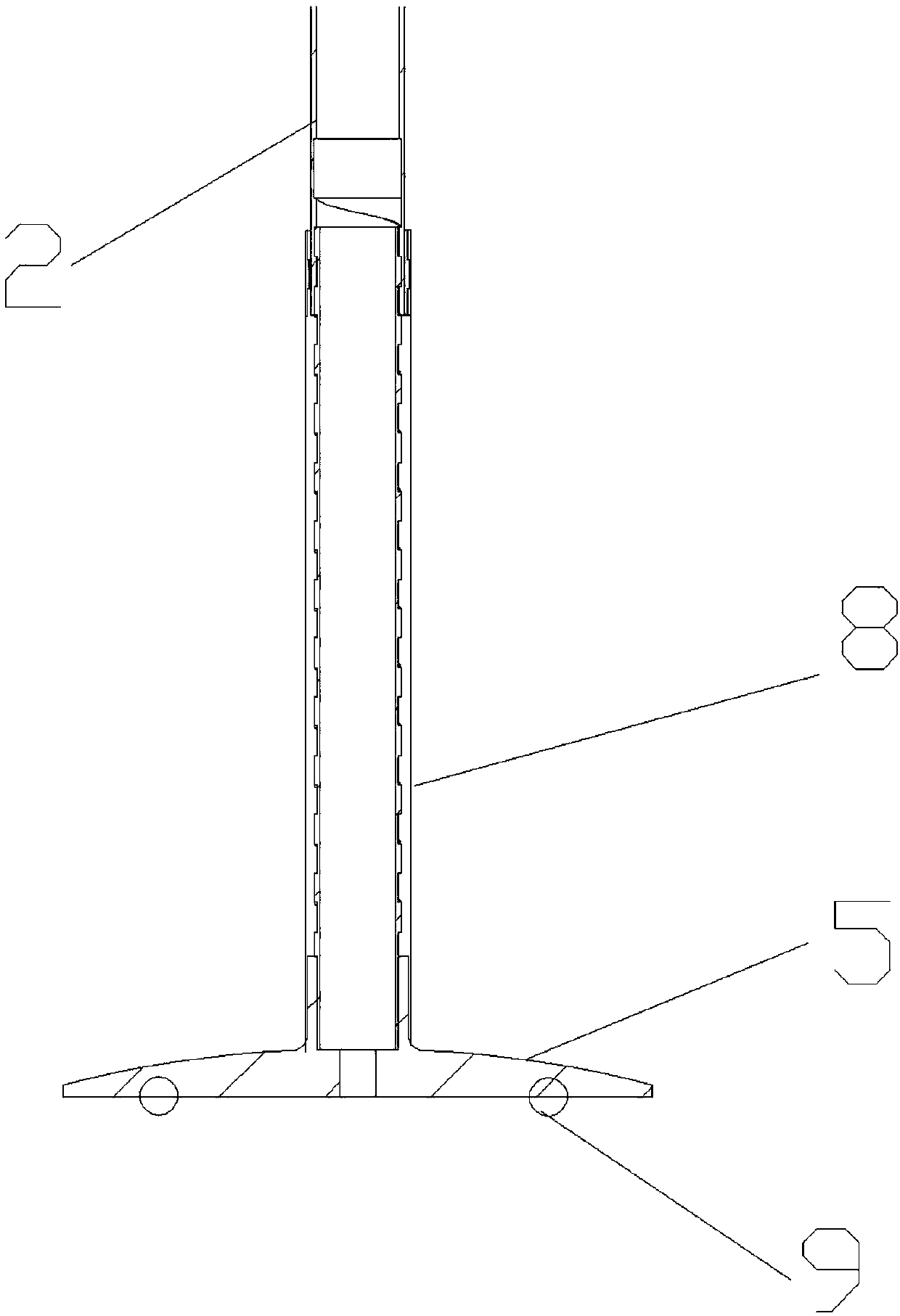

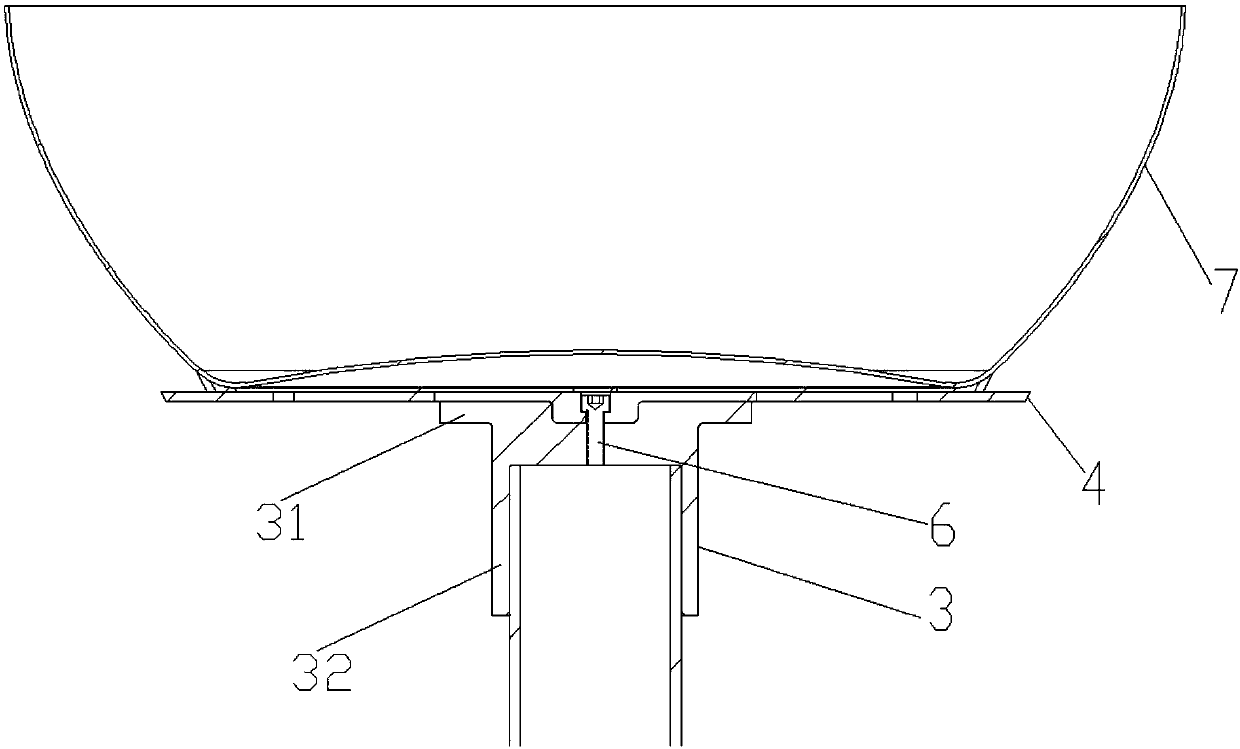

Electric cooker with fresh-keeping and refrigerating functions

InactiveCN107440482AFast cooling and coolingStructural environmental protectionCooking-vessel lids/coversMachines using electric/magnetic effectsEngineeringElectromagnetic heating

The invention discloses an electric cooker with fresh-keeping and refrigerating functions. The electric cooker comprises a cooker body, a cooker cover arranged on the cooker body as well as a pot body, an electromagnetic heating furnace core, a refrigerating and fresh-keeping device and a controller which are arranged in the cooker body, wherein the electromagnetic heating furnace core comprises a furnace core casing and an electromagnetic heating coil, and an electromagnetic coil part is formed after the electromagnetic heating coil wounds around the furnace core casing and corresponds to a circular arc transition part of the pot body; the electromagnetic heating coil is electrically connected with a heating control end of the controller; the refrigerating and fresh-keeping device comprises a semi-conductor refrigerating module and a heat dissipating device, a cold surface of the semi-conductor refrigerating module is attached to the bottom wall of the pot body, the heat dissipation device is arranged on the hot surface of the semi-conductor refrigerating module, and the semi-conductor refrigerating module is electrically connected with a refrigerating control end of the controller. The electric cooker also has fresh-keeping and refrigerating functions except conventional functions and can cool and refrigerate the pot body and food materials in the pot body, so that the food materials in the pot body can be kept fresh and refrigerated.

Owner:SHENZHEN ADVANCED TECH CO LTD

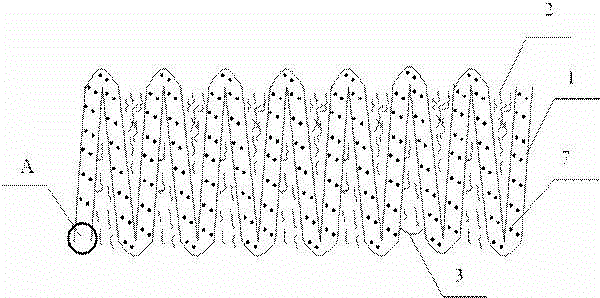

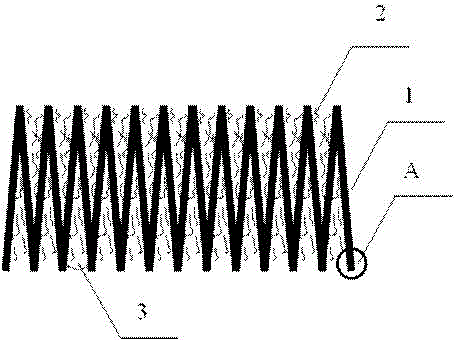

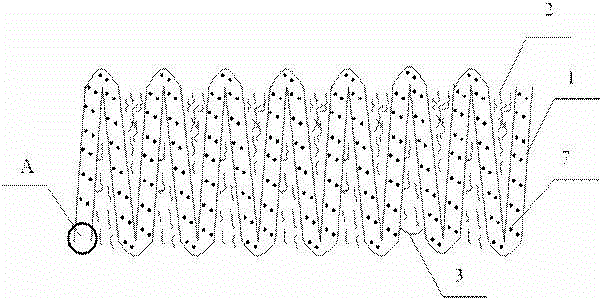

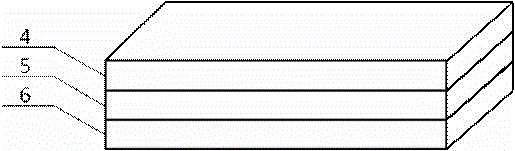

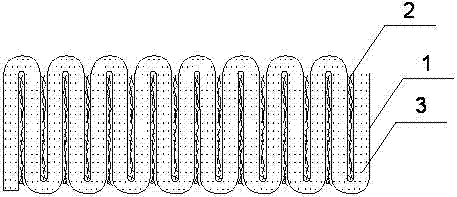

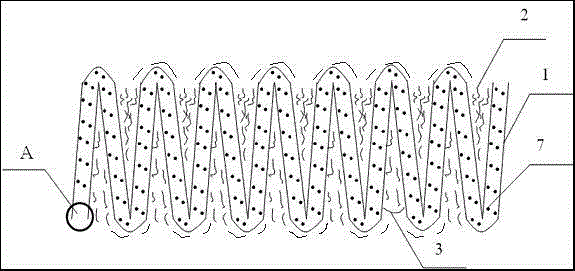

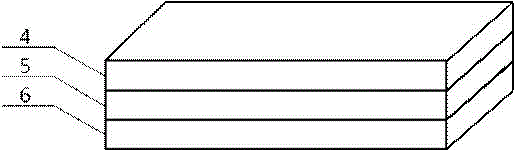

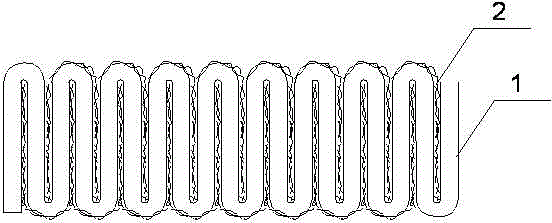

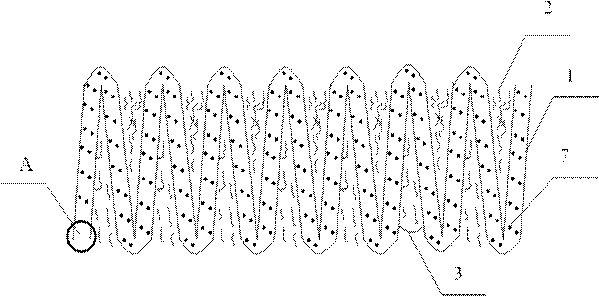

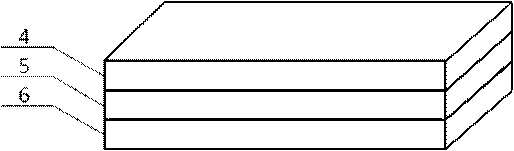

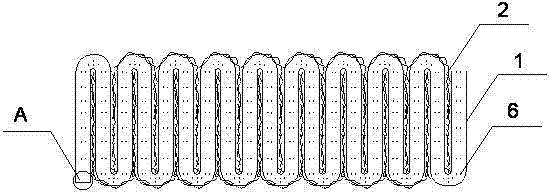

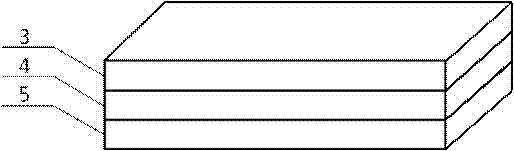

High-elastic flame-retardant non-woven cloth of honeycomb structure and preparation method thereof

The invention relates to a high-elastic flame-retardant non-woven cloth of a honeycomb structure. The high-elastic flame-retardant non-woven cloth of the honeycomb structure comprises a plurality of compound fiber webs which are stacked in a round-trip Z shape. The inner sides of the fiber webs are spread with mixed powders of hot-melting powders and flame-retardant powders. The compound fiber webs are connected from heads to ends in sequence. Hot-melting fibers are clamped between adjacent compound fiber webs. When the high-elastic flame-retardant non-woven cloth of honeycomb structure is manufactured, an upper layer fiber web, an elastic fiber web and a lower layer fiber web are prepared respectively through the processes of reparation before web forming and carding web by a machine. The hot-melting powders and flame-retardant powders are spread on the upper layer fiber web, the elastic fiber web and the lower layer fiber web. The upper layer fiber web, the elastic fiber web and the lower layer fiber web are overlapped into a compound fiber web. The upper layer fiber web and the lower layer fiber web are a mixture of low-melting-point dacron staple fibers and three-dimensional crimped hollow dacron staple fibers. The elastic fiber web is a mixture of low-melting-point dacron staple fibers and elastic polyester staple fiber. Vertical lapping is conducted through the process of vertical lapping, hot-melting fibers are spread between the compound fiber webs, and the high-elastic flame-retardant non-woven cloth of the honeycomb structure is manufactured through the processes of drying, trimming and winding.

Owner:WUHAN TEXTILE UNIV

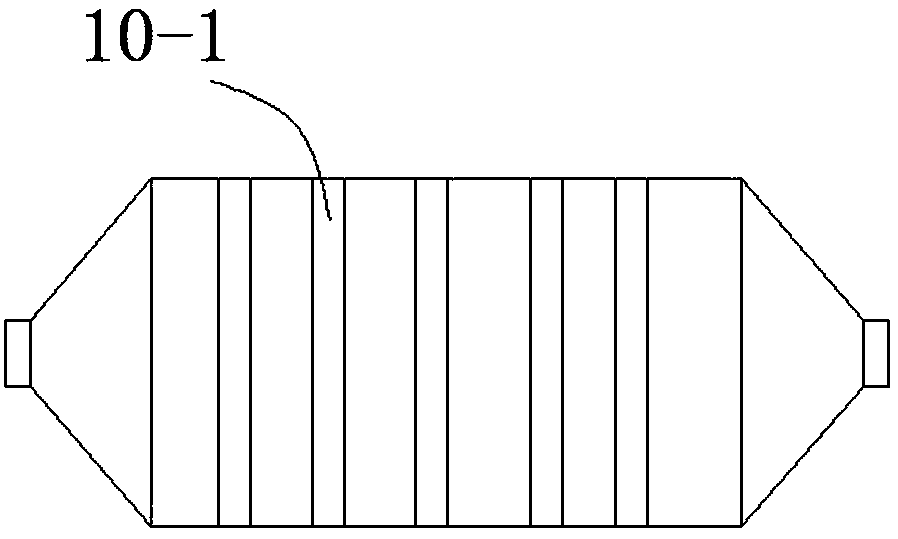

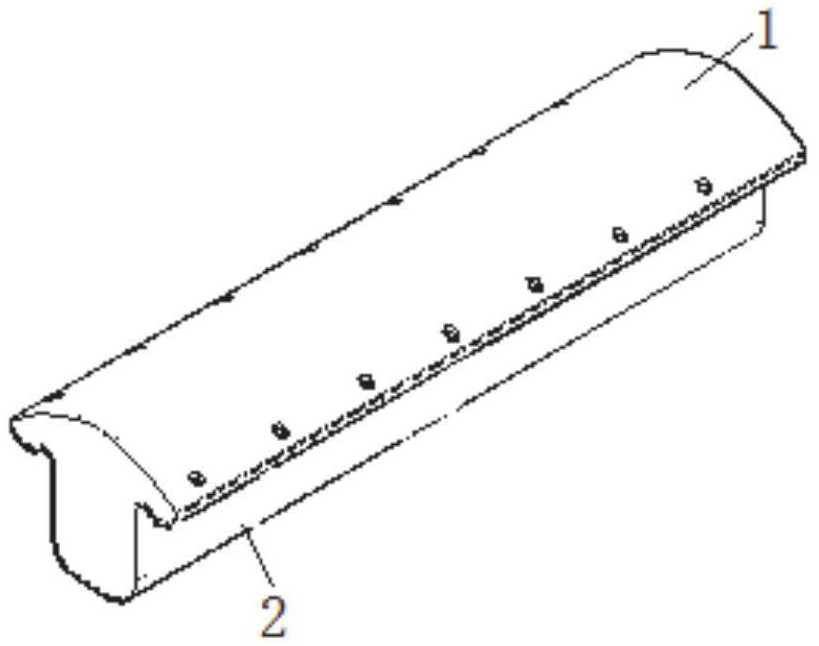

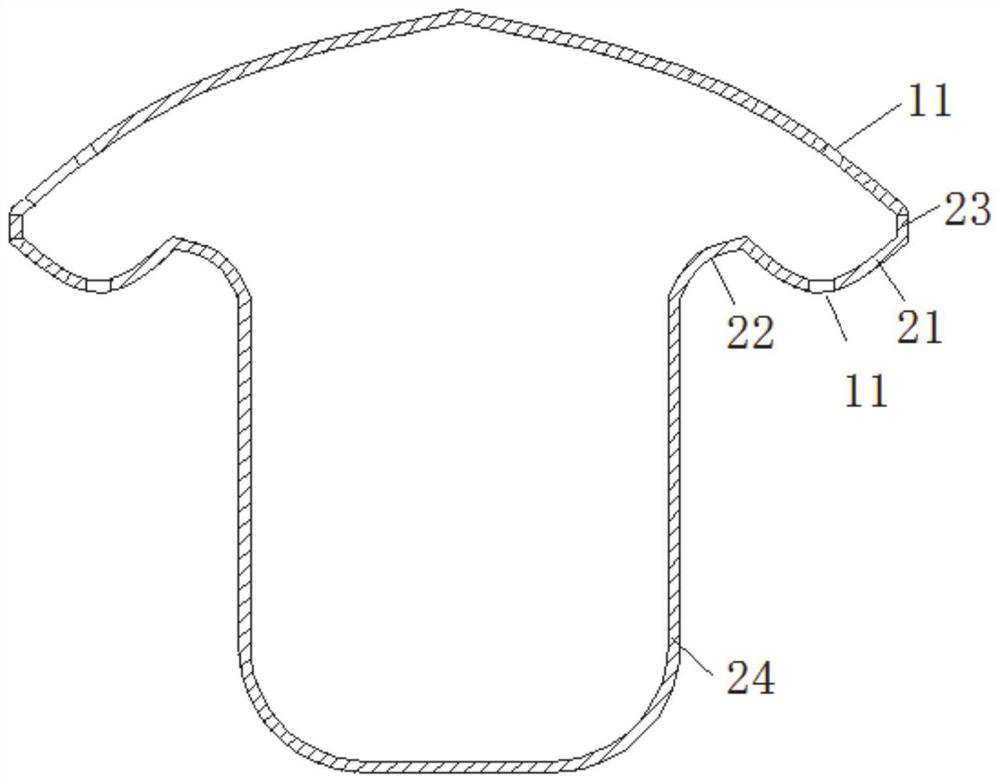

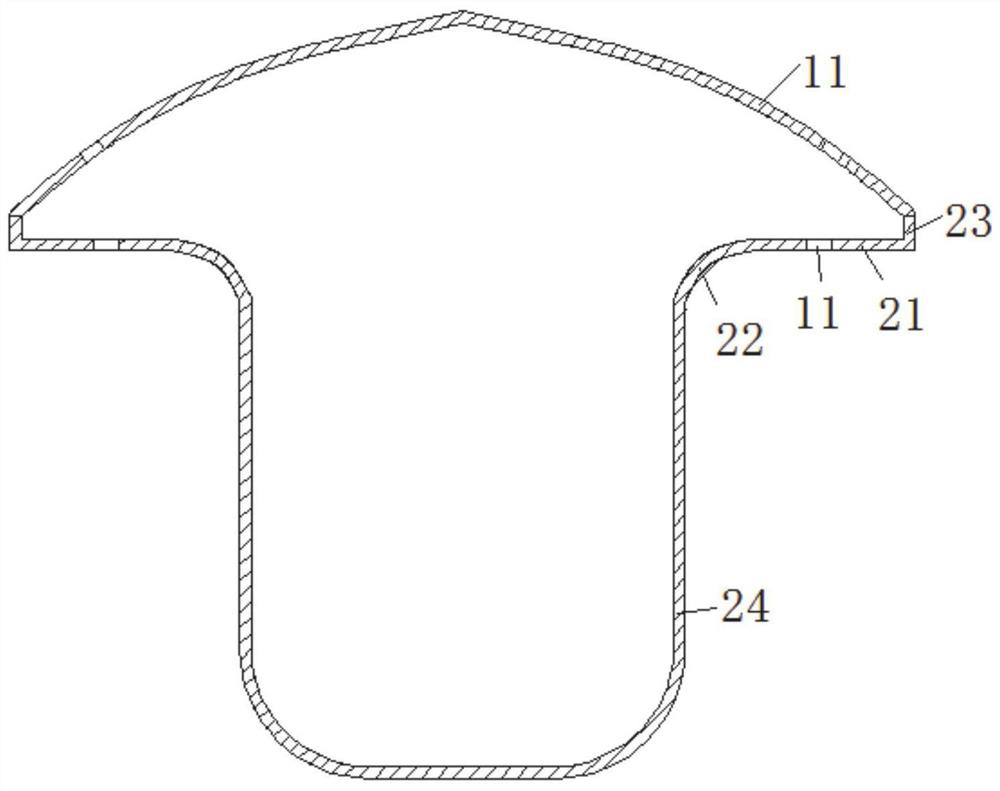

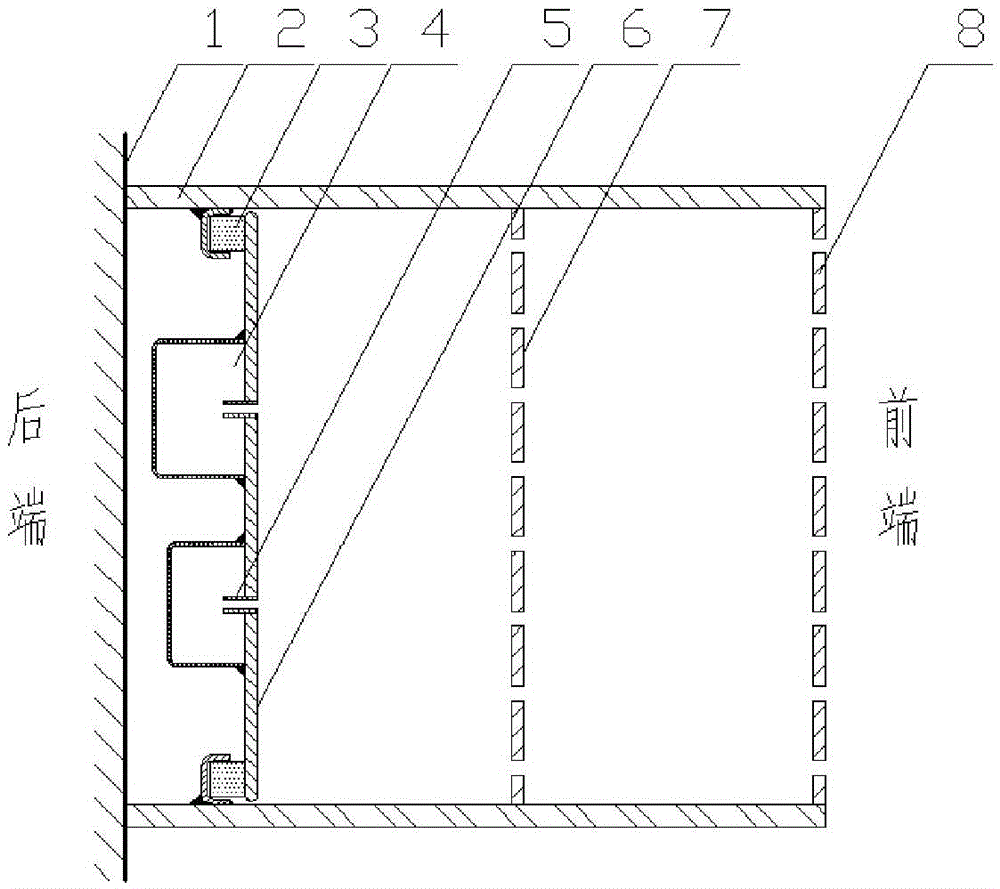

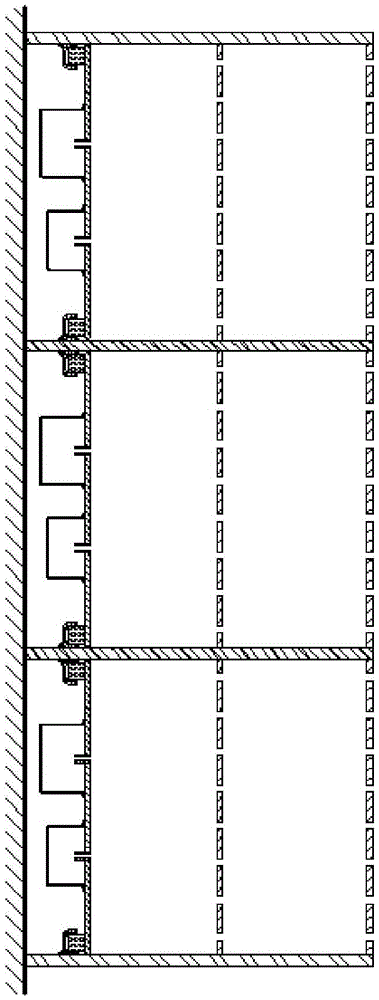

Large-span U-shaped beam prefabricating construction technology capable of realizing pre-tensioned and post-tensioned prestressed combined construction

InactiveCN109747037AReduce investmentSave the amount of prestressed reinforcementCeramic shaping apparatusShaped beamPre stress

The invention relates to the field of concrete U-shaped beam prefabricating construction, in particular to a large-span U-shaped beam prefabricating construction technology capable of realizing pre-tensioned and post-tensioned prestressed combined construction. The technology mainly includes the following steps that bottom molds and side molds of a U-shaped beam are mounted and are bound into a steel reinforcement framework, impurities are cleaned, a support plate is mounted, collapse-proof embedded pieces are mounted, the steel reinforcement framework is hung, the steel reinforcement framework, steel strands and corrugated pipes are adjusted, end formworks are mounted, the prestress is adjusted preliminarily, embedded conduits are mounted, embedded pieces are mounted, overall tensioning is performed with the final tensioning stress, concrete pouring is performed, natural curing is performed, inner molds are dismounted, the side molds are loosened, the single end of a beam body is released synchronously, the steel strands are cut off mechanically, the end formworks are dismounted, the steel strands are bundled with the post-tensioning method, post-tensioned prestressed tensioning is performed, anchor sealing and beam storage are performed, and hole grouting, curing and the like are performed. According to the technology, a pre-tensioned and post-tensioned combined prestressed bridge is adopted, the stress and the deflection of the U-shaped beam and the control on cracks meet requirements, the prestressed steel reinforcement quantity and the equipment and the personnel investment are saved, the construction period is shortened, and the economic benefit is obtained.

Owner:GUANGDONG CONSTR CO LTD OF CHINA RAILWAY NO 3 ENG GRP CO LTD +1

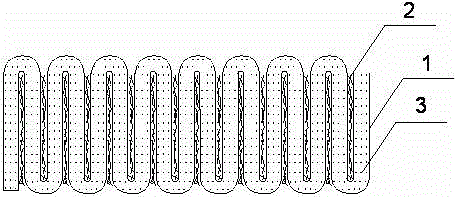

High-elastic non-woven fabric with honeycomb structure and preparation method thereof

A high-elastic non-woven fabric with a honeycomb structure comprises a plurality of compound fiber meshes sequentially stacked in a back-and-forth Z shape. The compound fiber meshes are sequentially in end-to-end connection, and a hot melting fiber is clamped between the adjacent compound fiber meshes. When the high-elastic non-woven fabric is manufactured, through preparation prior to mesh formation and a process of mesh formation through mechanical combing, an upper layer fiber mesh, an elastic fiber mesh and a lower layer fiber mesh are prepared respectively and then are overlaid into the compound fiber mesh through a fiber mesh compounding process; each of the upper layer fiber mesh and the lower layer fiber mesh is the mixture of a low melting point polyester short fiber and a three-dimensional curly hollow polyester short fiber, and the elastic fiber mesh is the mixture of a low melting point polyester short fiber and an elastic polyester short fiber. The prepared compound fiber meshes are vertically laid through a vertical mesh laying process, the hot melting fiber is scattered between the compound fiber meshes, and then the high-elastic non-woven fabric with the honeycomb structure is obtained through a drying, trimming and winding process. The high-elastic non-woven fabric not only is high in elasticity and simple in structure, but also is low in cost and environmentally friendly.

Owner:WUHAN TEXTILE UNIV

High-elastic antibacterial vertical cotton with fiber-bonded honeycomb structure and preparation method of vertical cotton

High-elastic antibacterial vertical cotton with a fiber-bonded honeycomb structure comprises back-and-forth Z-shaped sequentially stacked fiber meshes. Antibacterial agents are sprayed into the fiber meshes, the fiber meshes are sequentially connected end to end, and hot-melting fibers are clamped between the adjacent fiber meshes. During manufacture, the fiber meshes are prepared by mesh forming pre-preparation and mechanical combing mesh forming procedures and are mixtures of low-melting-point polyester staple fibers and elastic polyester staple fibers, the weight percent of the low-melting-point polyester staple fibers is 15%-35%, and the weight percent of the elastic polyester staple fibers is 65%-85%. After the antibacterial agents are sprayed into the fiber meshes, the fiber meshes are vertically laid by a vertical mesh laying procedure, the hot-melting fibers are spread among the fiber meshes, and the high-elastic antibacterial vertical cotton with the fiber-bonded honeycomb structure is prepared by drying, trimming and winding procedures. The high-elastic antibacterial vertical cotton is high in elasticity, fine in antibacterial property, simple in structure, low in cost and environmentally friendly.

Owner:WUHAN TEXTILE UNIV

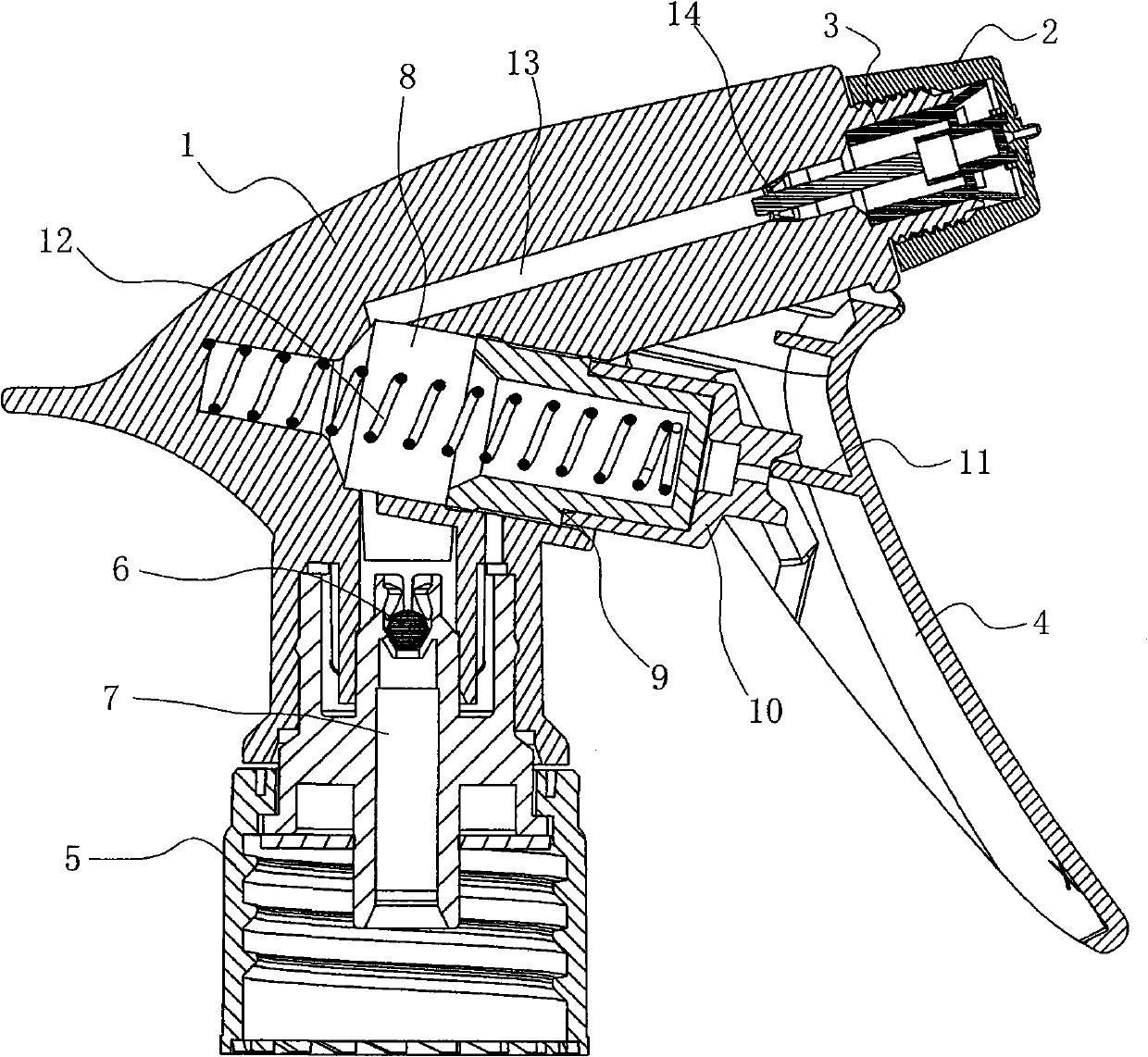

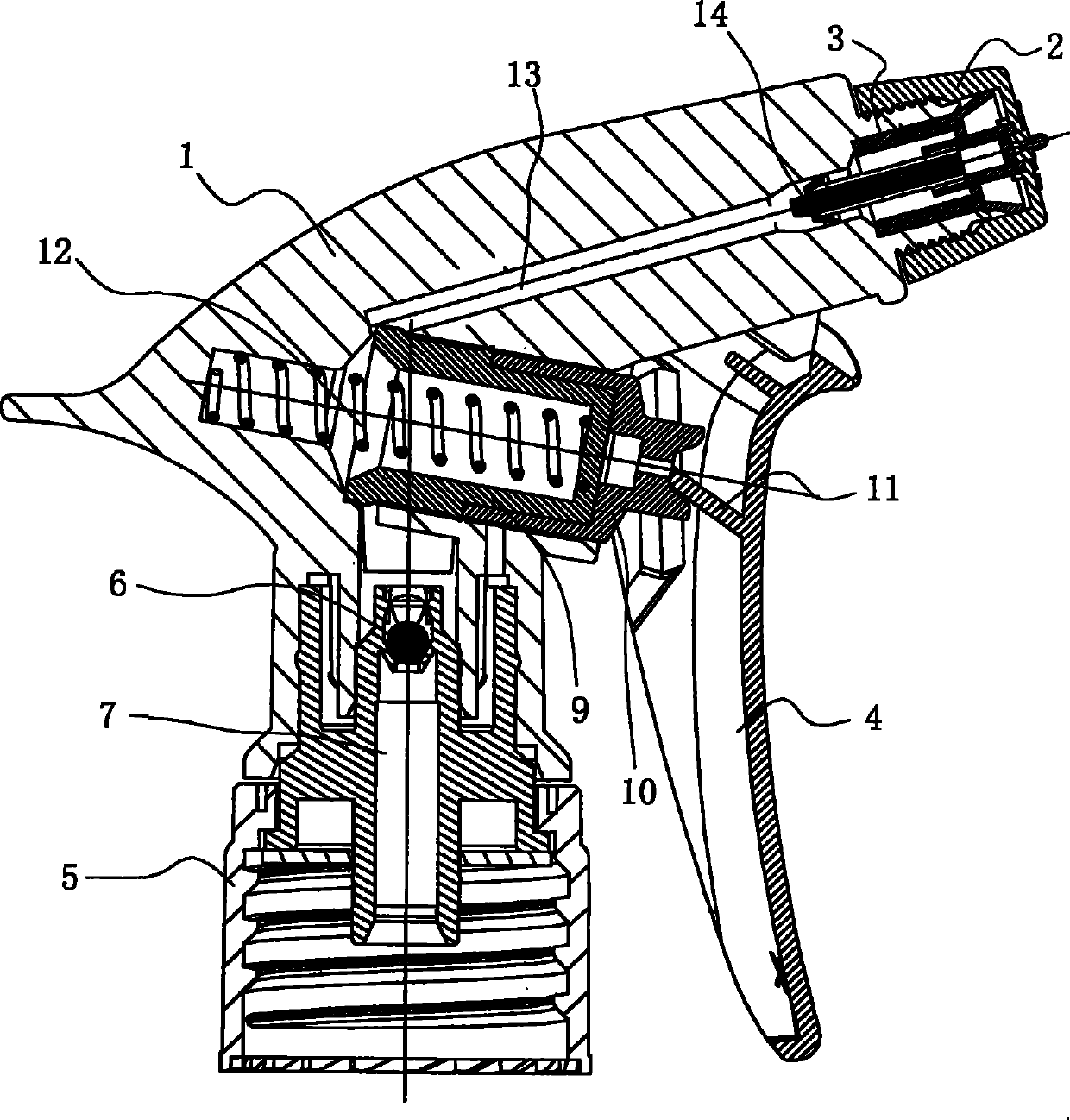

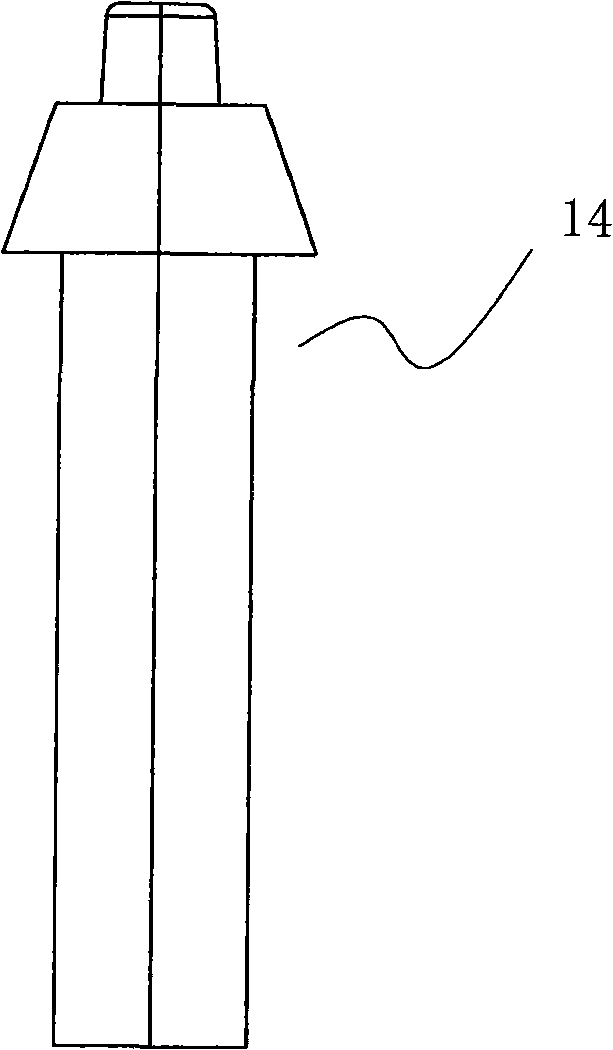

Spray nozzle of sprayer

InactiveCN101767074ASensitive and reliableMeet needsCheck valvesSingle-unit apparatusSprayerSpray nozzle

A spray nozzle of a sprayer comprises a main body of the spray nozzle, a head cap, a water distribution sleeve, a wrench, a big ring and a one-way liquid inlet mechanism, wherein one end of the water distribution sleeve is embedded in the head of the main body, and the other end butts against the head cap; a piston body is arranged in a cylinder body of the main body and inserted at the inner end of a piston body seat; one end of the piston body seat exposed outside the cylinder body is in butting fit with a top plate on the wrench; the wrench is articulated outside the main body; one end of a spring is embedded in the main body and the other end thereof is arranged at the inner end of the piston body; and a check valve is arranged in a liquid channel close to a liquid outlet part. The spray nozzle of the sprayer is characterized in that the check valve is made of soft plastic, one end of the check valve is inserted in the water distribution sleeve, and the other end is arranged in the liquid channel, and the check valve is sealed with the liquid channel in a matching way through a valve on the check valve. As the check valve is made of high soft plastic, the spray nozzle of the sprayer has simple structure, convenient manufacturing and low cost.

Owner:杭建平

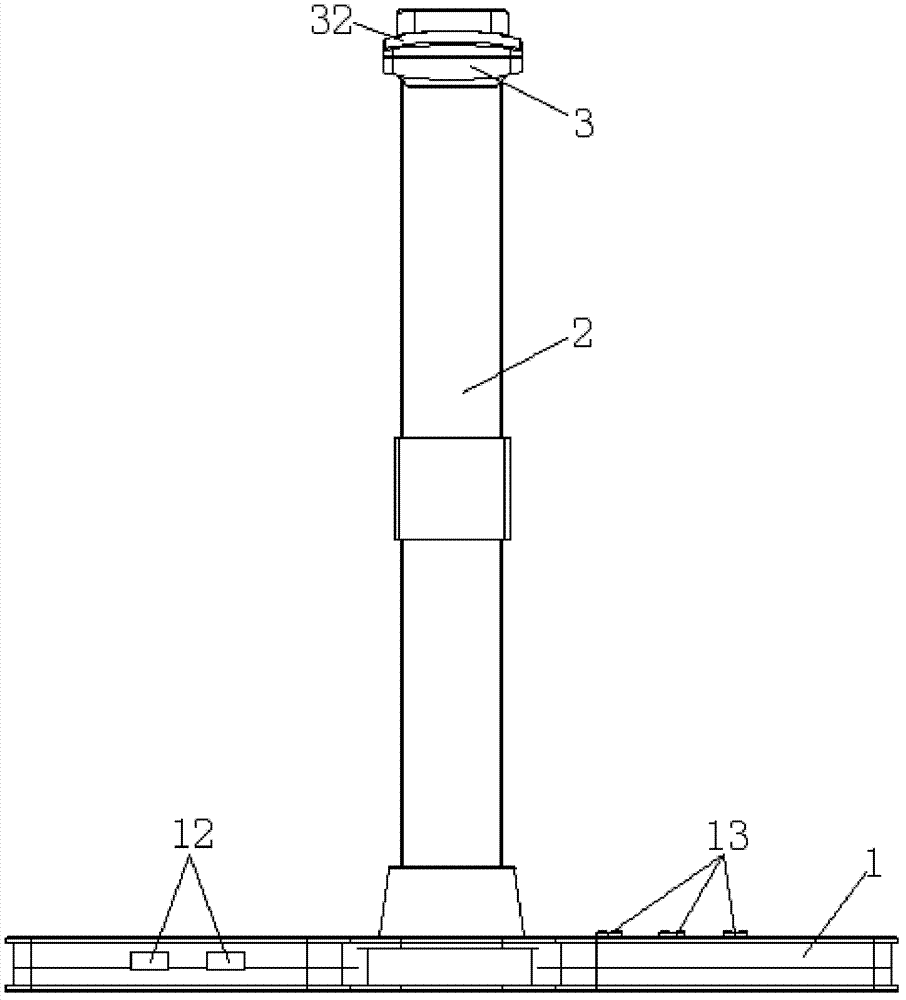

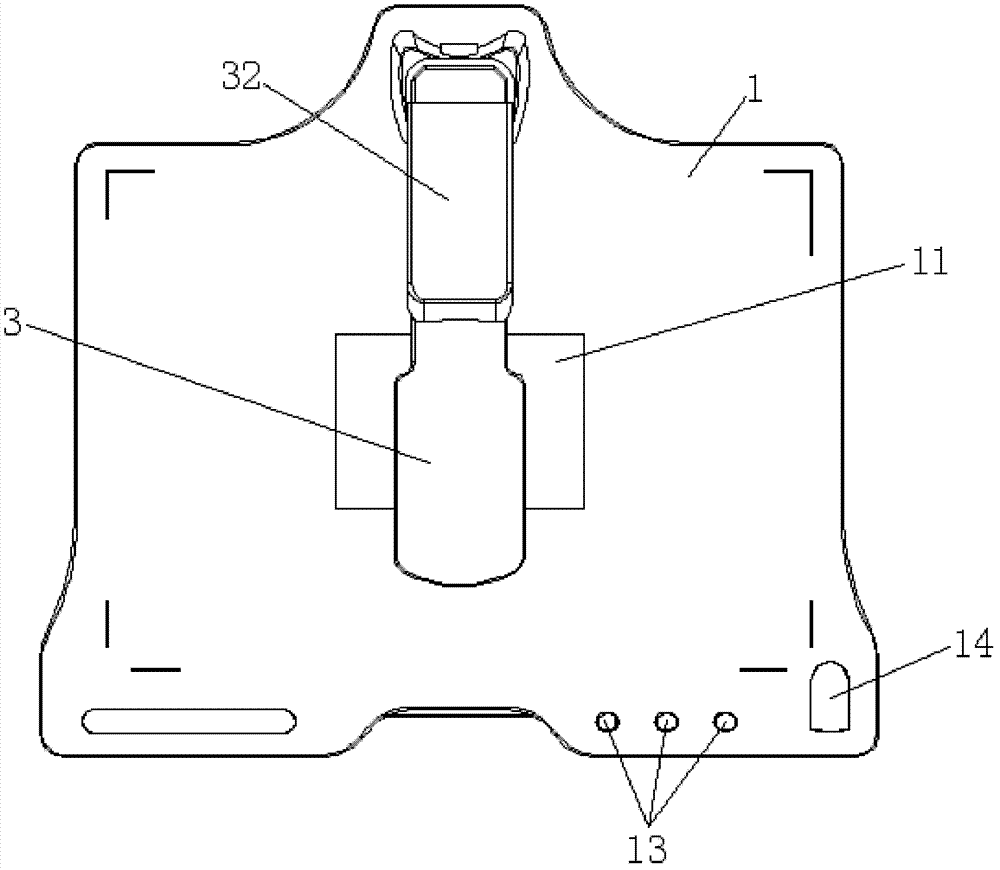

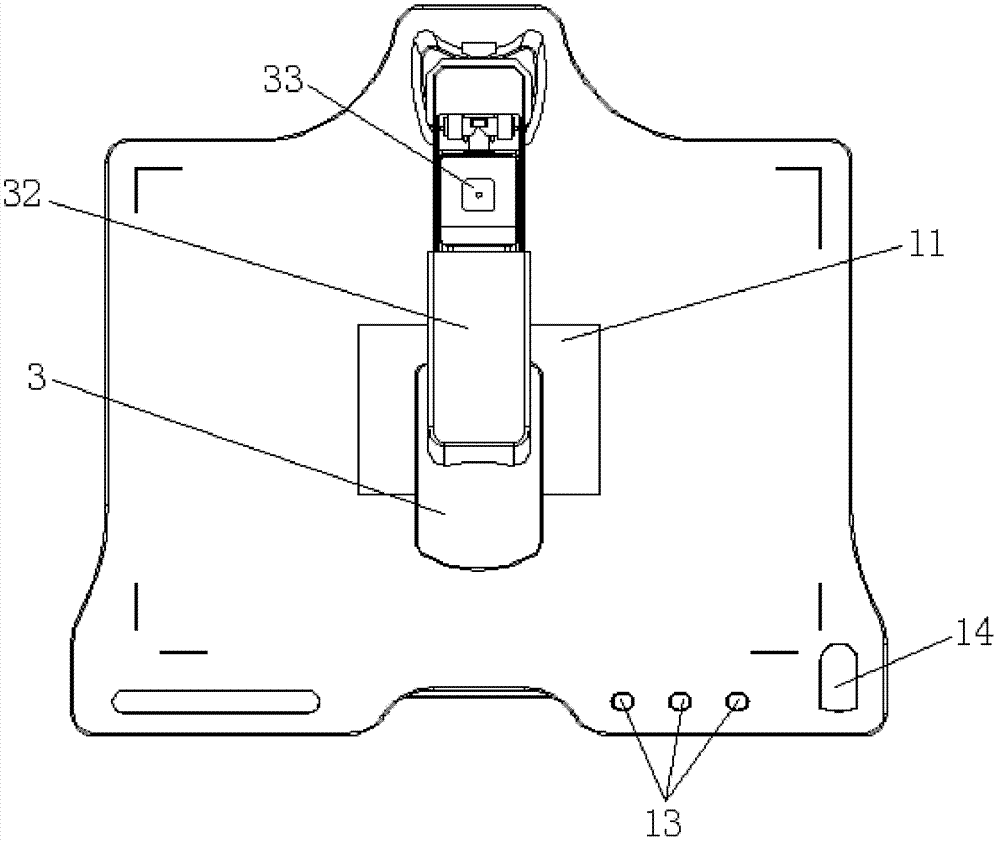

Incase projector

InactiveCN103095970ASimple and elegant appearanceMake sure it's not reflectiveTelevision system detailsColor television detailsElectricityComputer science

The invention discloses an incase projector which comprises a base, a stand column and a support. The stand column is fixed on the base, and the rear portion of the support is fixedly connected with the top of the stand column. A second-generation identification card recognition module and a fast shooting button are arranged in the base. A first camera is arranged on the lower end face of the front portion of the support. The fast shooting button is electrically connected with the first camera. The incase projector integrates multiple functions, recognizes an identification card when shooting, and is concise and taste in appearance, and solid and stable in whole equipment.

Owner:GUOGUANG ELECTRONICS INFORMATION TECH

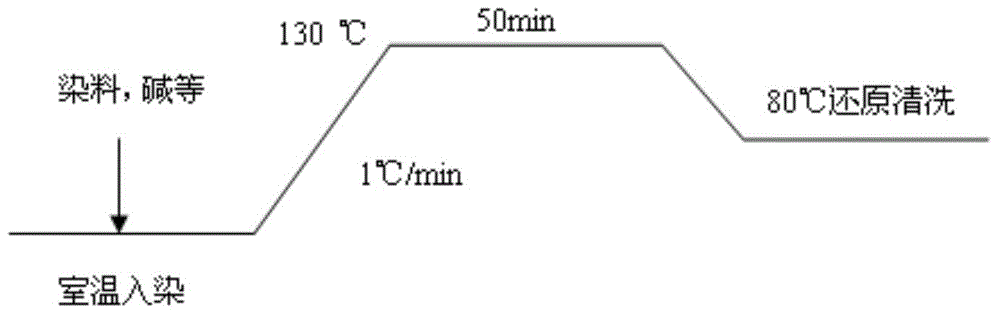

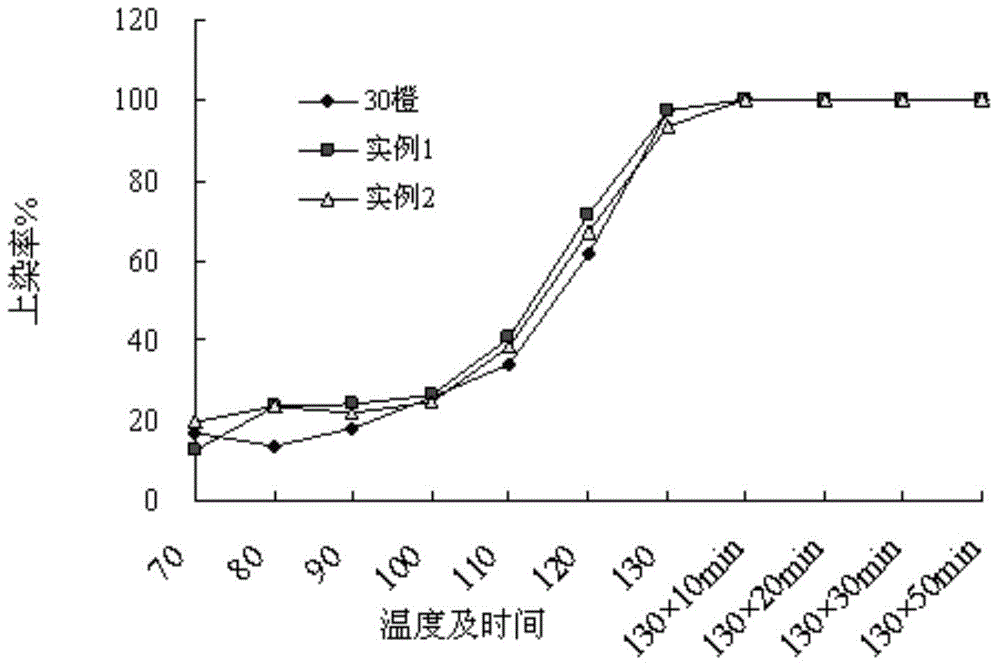

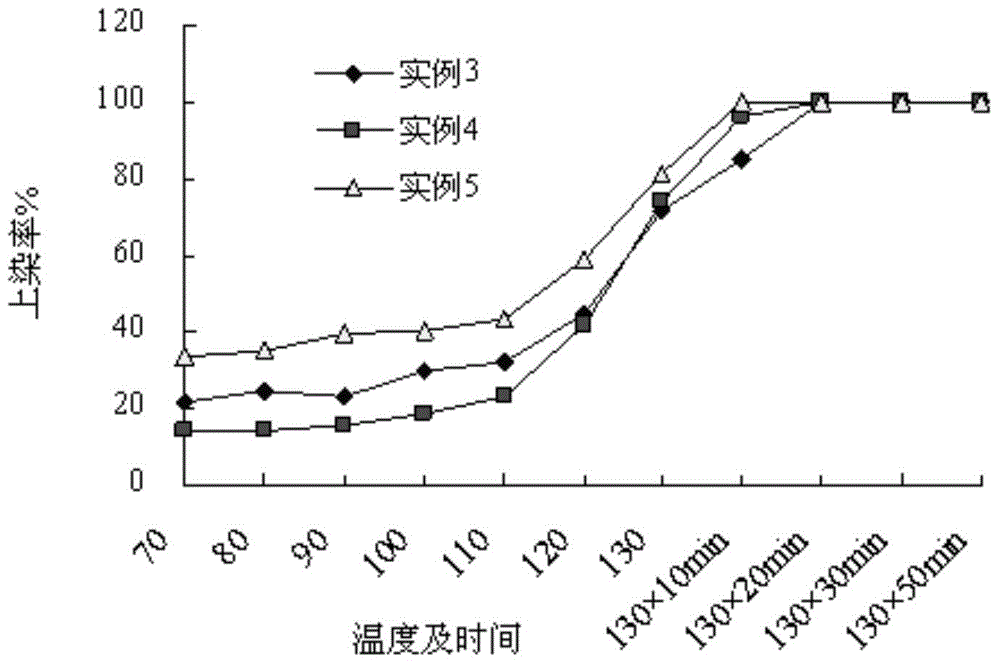

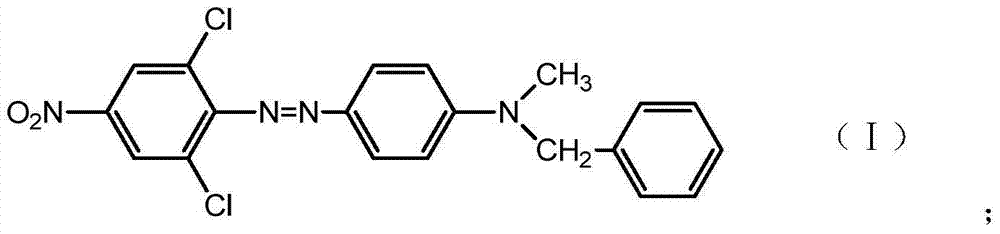

Environment-friendly alkaline-resistant high-washing-dispersity orange dye composition and application thereof

ActiveCN104151865AStructural environmental protectionGood alkali resistanceOrganic dyesDyeing processDispersityStructural formula

The invention relates to an environment-friendly alkaline-resistant high-washing-dispersity orange dye composition and an application thereof. The dye composition comprises dyes and auxiliaries, wherein the dyes include a dye A and a dye B; the structural formula of the dye A is as shown in the specification, while the structural formula of the dye B is as shown in the specification; the environment-friendly alkaline-resistant high-washing-dispersity orange dye composition is applied to textile dyeing. The environment-friendly alkaline-resistant high-washing-dispersity orange dye composition is good in all build-up, fixation rate, levelling property, compatibility and alkali resistance, and especially quite excellent in washing fastness. Specially, the dye composition is similar to the existing C.I. disperse orange 30 dye in chromatic light intensity and dyeing property, overcomes the defects of no resistance to alkali and non-environmental friendliness of the existing dye, and thus can be used for substituting for the existing C.I. disperse orange 30 dye.

Owner:ZHEJIANG WANFENG CHEM

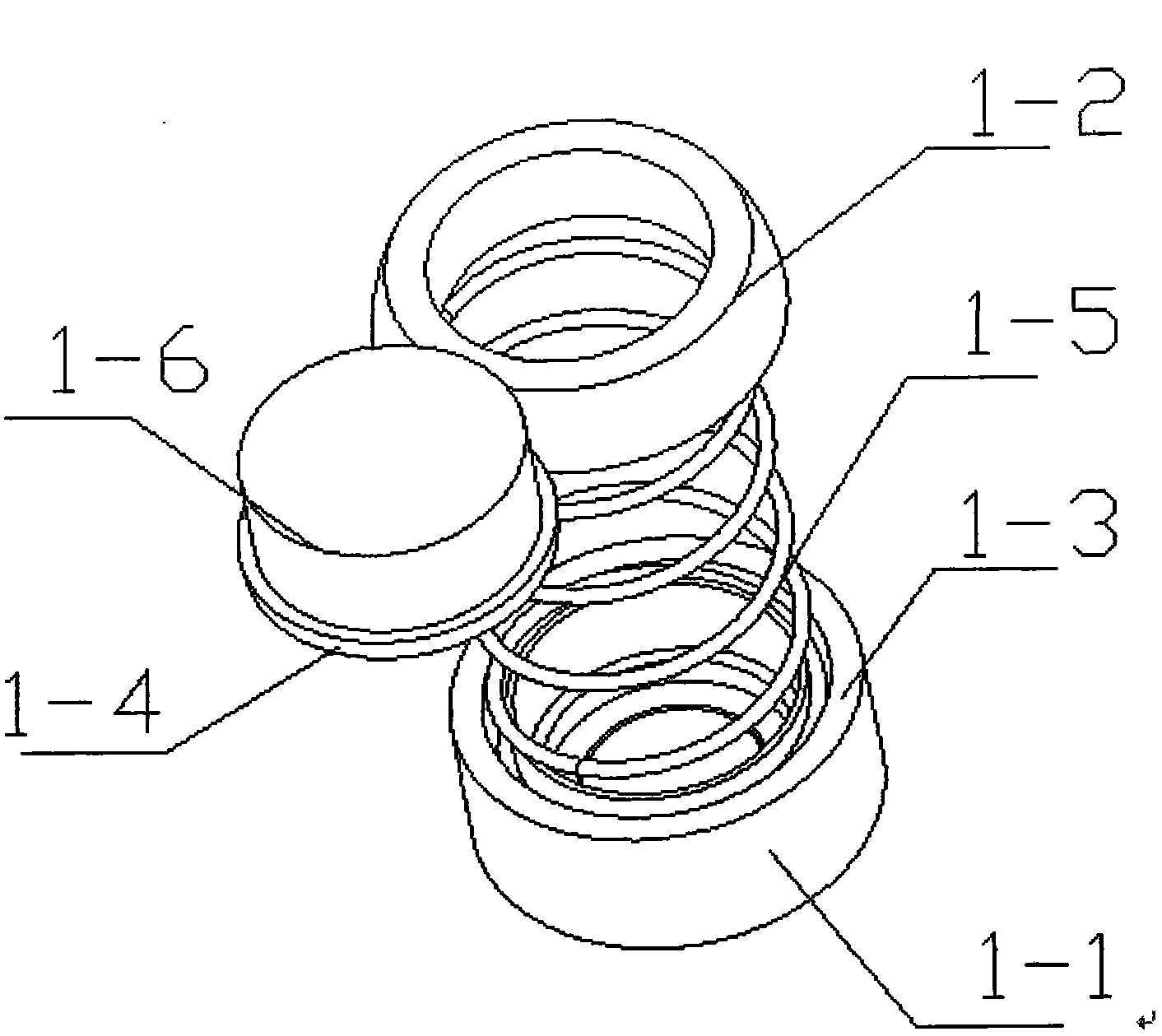

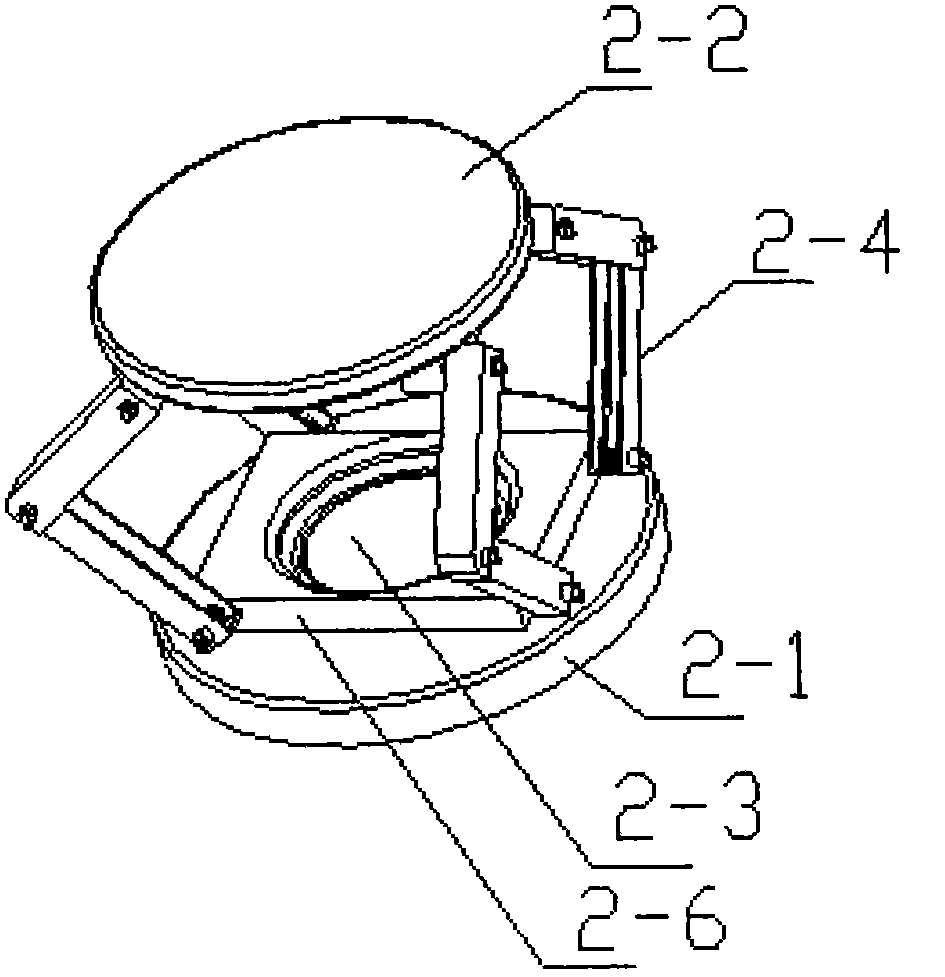

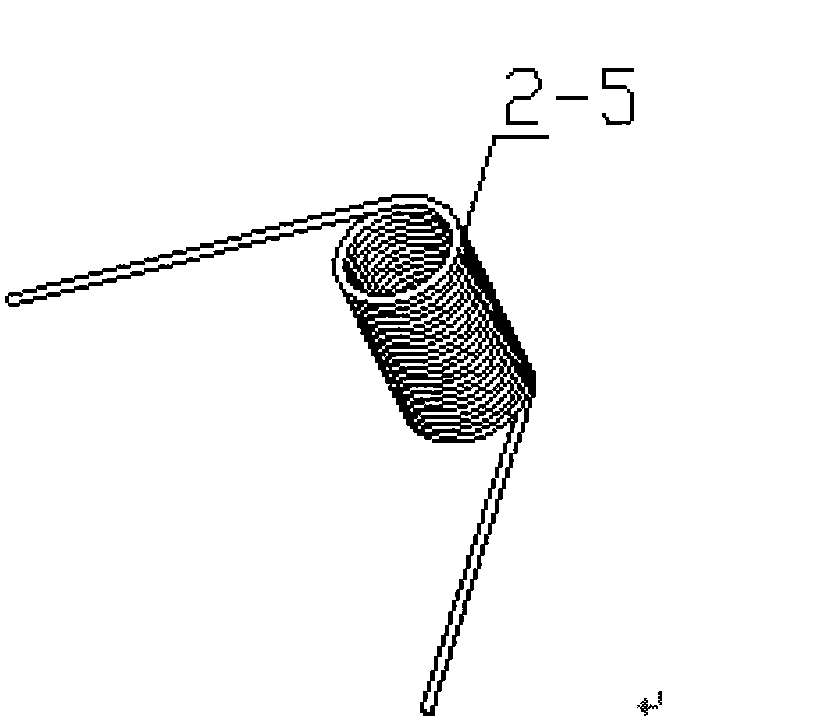

Portable stable type self-resetting can compressor

The invention discloses a portable stable type self-resetting can compressor. The portable can compressor comprises a bottom and a top, wherein the bottom is provided with a circular groove, the diameter of the circular groove is equivalent to that of a can, the top is annular and is provided with a flipping pedal, the bottom is connected with the top through a spring, a columnar bulge is arranged at the inner side of the flipping pedal, and the length of the columnar bulge is greater than that of the top. According to the can compressor provided by the invention, the structure is compact, the power is derived from manpower, the circular groove in a base can stabilize a can body, and the compressor is enabled to reset by the spring between the base and the top after a can is flattened; and the overall structure is simple and environment-friendly and is convenient in operation, the can can be easily flattened, and thus, the residential space is saved.

Owner:HUZHOU TEACHERS COLLEGE

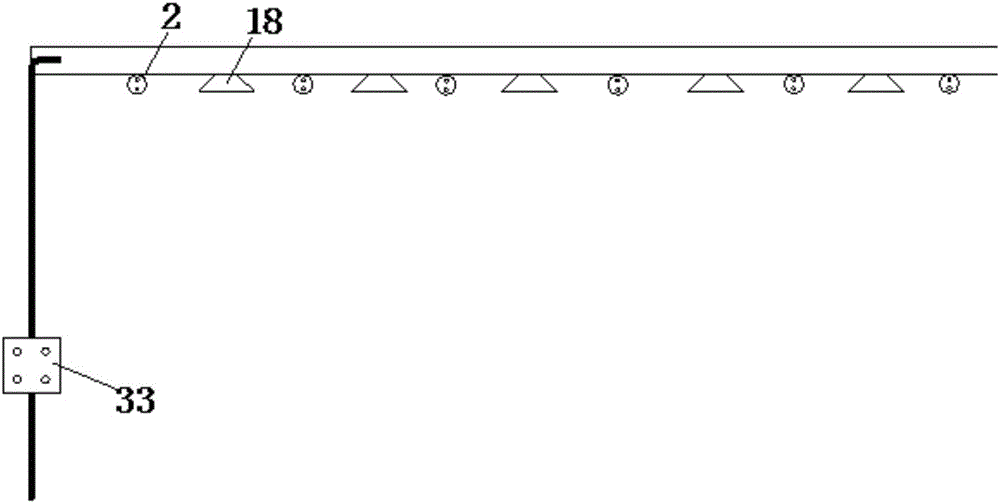

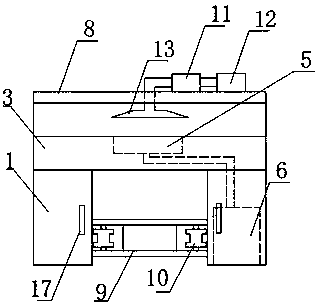

Fully-automatic kitchen whole-disinfection system

InactiveCN105833320AComprehensive disinfectionAll-round disinfectionLavatory sanitoryDeodrantsUltraviolet lightsEngineering

The invention belongs to the technical field of disinfection systems, and particularly relates to a fully-automatic kitchen whole-disinfection system. The fully-automatic kitchen whole-disinfection system comprises an anion generation system and LED disinfection lamps which are arranged on a ceiling of a kitchen and capable of emitting ultraviolet rays. The disinfection system further comprises a controller, and the controller is connected with the LED disinfection lamps and the anion generation system respectively, and comprises a timing chip and a driving chip. Compared with the prior art, the system has the advantages that ultraviolet light can be emitted to realize a sterilization function by the LED disinfection lamps capable of emitting the ultraviolet rays; water containing anions and ozone can be sprayed by the anion generation system, thereby achieving sterilization, disinfection and cleaning effects; the anion generation system is combined with the LED disinfection lamps, so that more complete disinfection and sterilization can be implemented, and in addition, the kitchen can be comprehensively disinfected; moreover, the system can be used for implementing automatic disinfection, and is high in automation degree, simple in structure and environment-friendly.

Owner:王红亮

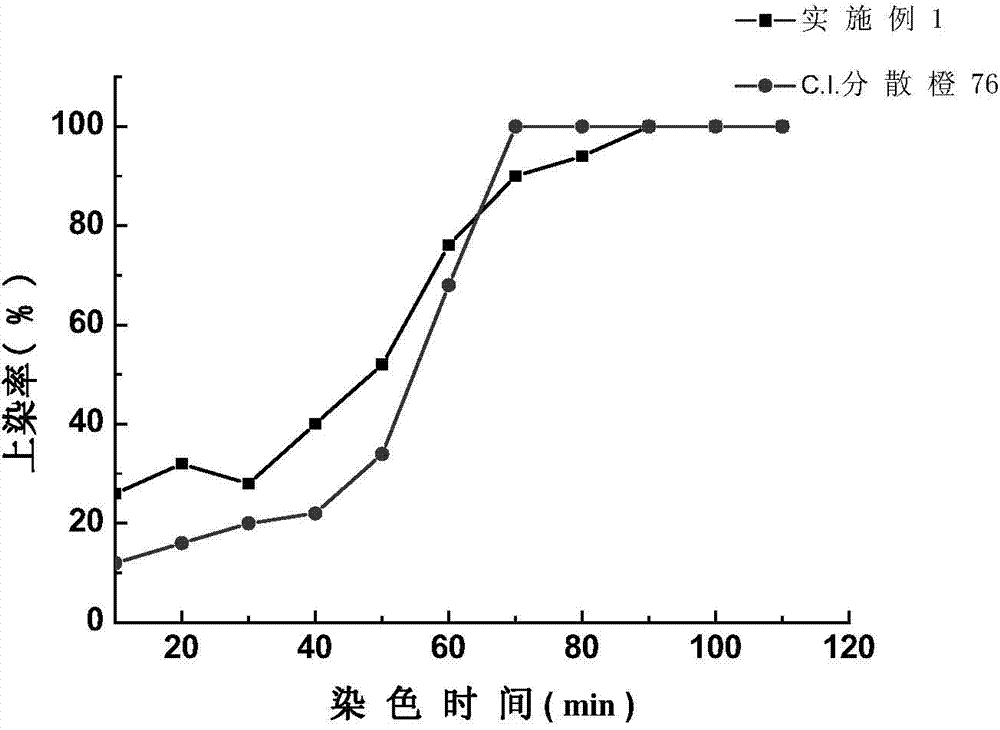

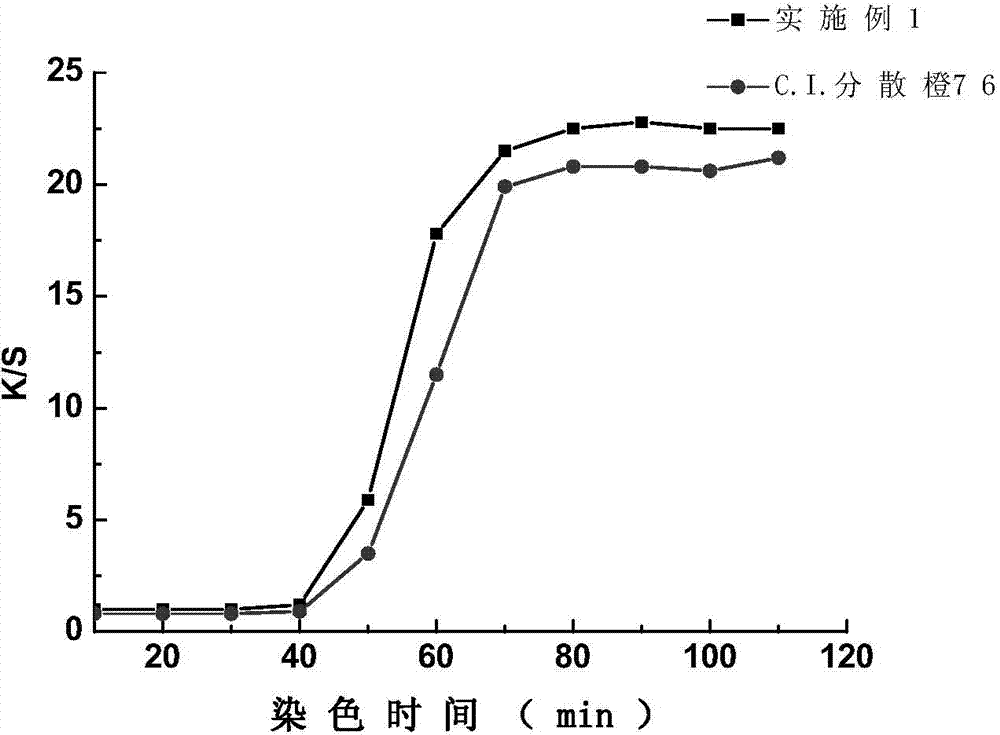

Environment-friendly type high-efficiency washing disperse orange dye composition and application thereof

ActiveCN104119695AStructural environmental protectionGood alkali resistanceOrganic dyesDyeing processColor intensityStructural formula

The invention relates to an environment-friendly type high-efficiency washing disperse orange dye composition and an application thereof. The dye composition comprises dyes and auxiliaries, wherein the dyes consist of a dye A, a dye B and a dye C; a structural formula of the dye A is as shown in the specification; the structural formula of the dye B is as shown in the specification; the structural formula of the dye C is as shown in the specification. The environment-friendly type high-efficiency washing disperse orange dye composition disclosed by the invention is applied to fabric dyeing. The dye disclosed by the invention is good in lifting power, fixation rate, leveling property, compatibility and alkali resistance, and especially extremely excellent in washing fastness. Especially, compared with the existing C.I. disperse orange 76 dye, the dye composition disclosed by the invention has similar color intensity and dyeing performance, overcomes the defect that the existing dye is not environment-friendly, and can be used for substituting the existing C.I. disperse orange 76 dye.

Owner:ZHEJIANG WANFENG CHEM

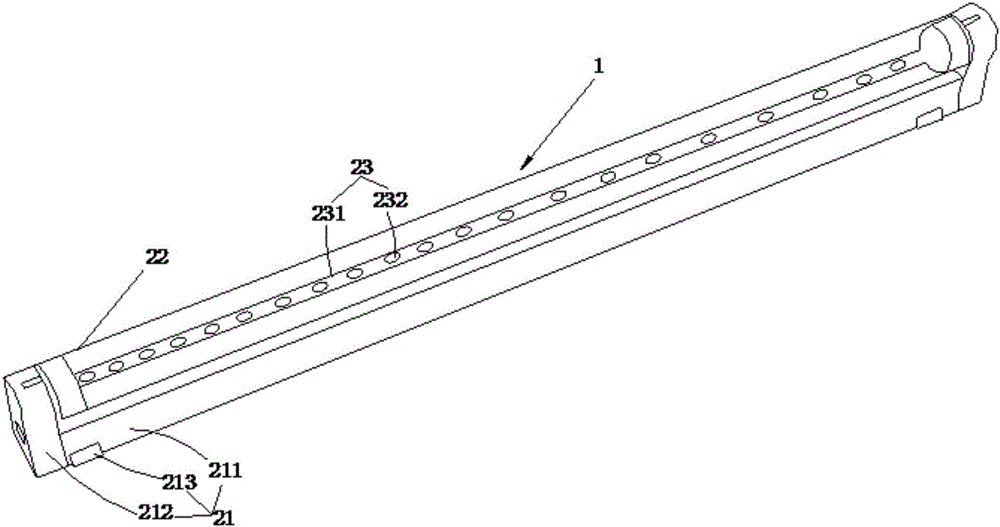

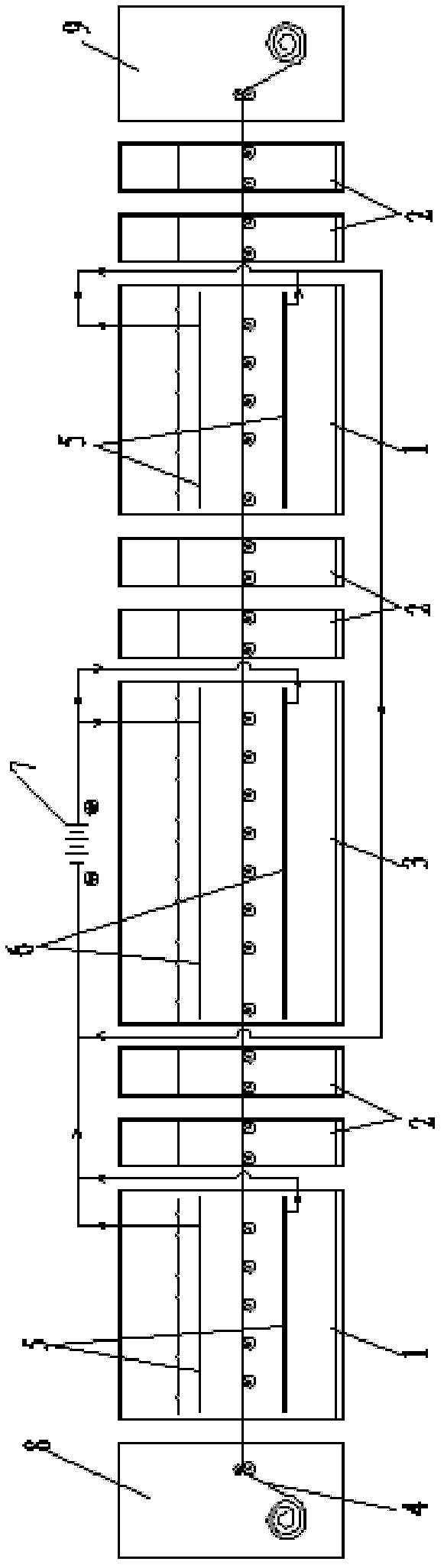

Processing method for textile

ActiveCN103898701AQuality improvementImprove efficiencyTextile treatment containersTextile treatment machine arrangementsTemperature controlMicrowave

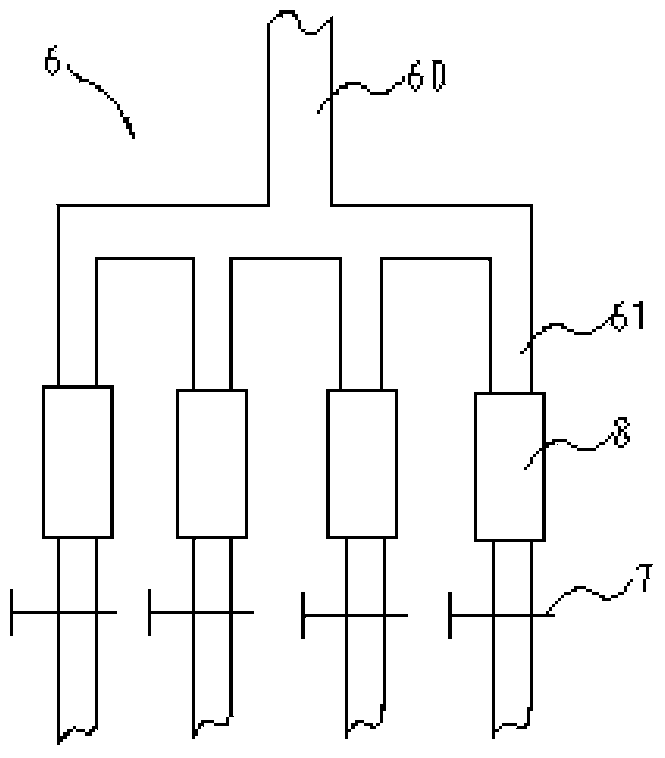

The invention relates to a processing method for a textile. The processing method for the textile adopts a special processing device. The special processing device comprises a box body, a conveying system, a liquid spraying system, a microwave heating system, a temperature control system and a sampling system, wherein an interlayer is formed at the top of the box body, box doors capable of being opened and closed are arranged at two opposite sides of the box body, a seam is reserved between each box door and the bottom of the box body, a liquid discharging hole is formed in the bottom of the box body, the conveying system comprises a movement guide rail moving in the length direction of the box body and a fixing device which is arranged on the movement guide rail and used for fixing the textile, the liquid spraying system comprises a plurality of atomization spraying nozzles and a liquid supply device, the microwave heating system is installed in the interlayer of the box body, the temperature control system comprises a temperature controller and a temperature detector, the temperature controller is installed in the interlayer of the box body, the temperature detector is installed at the bottom of the box body, and the sampling system is used for collecting processing liquid inside the box body. The processing method for the textile is more environmentally friendly in process step, saves more raw materials, reduces energy consumption, improves the use efficiency and the effect of chemical additives, and improves the quality of the textile.

Owner:SUZHOU TANGHUA NANO TECH

Conductive polymer porous membrane

ActiveCN103846011AConductiveStable structureSemi-permeable membranesPolymer scienceConductive polymer

The invention discloses a conductive polymer porous membrane. The conductive polymer porous membrane has a surface specific resistance of more than 160 omega.m. The conductive polymer porous membrane is prepared by the following method comprising the steps: carrying out ultrasonic dispersion on carbon black for 1-3 hours in water at 25 DEG C, wherein the ultrasonic wave power is 0-300 w; then stirring, adding a binding agent into the mixture, and fully stirring to obtain a uniform dynamic membrane casting solution; washing a polymer basement membrane with water; continuously running under the operation pressure of 0.1-0.3 MPa and at the temperature of 25-90 DEG C by using a depositional mode with the uniform dynamic membrane casting solution obtained in the step (1) as a solution to be filtered and the polymer basement membrane obtained in step (1) as a filter material to obtain a dynamic composite membrane; and naturally drying to obtain the conductive polymer porous membrane. The preparation method is simple in process, has no environmental pollution and no special requirement on equipment, is low in cost and achieves convenience for industrial application.

Owner:TIANJIN POLYTECHNIC UNIV

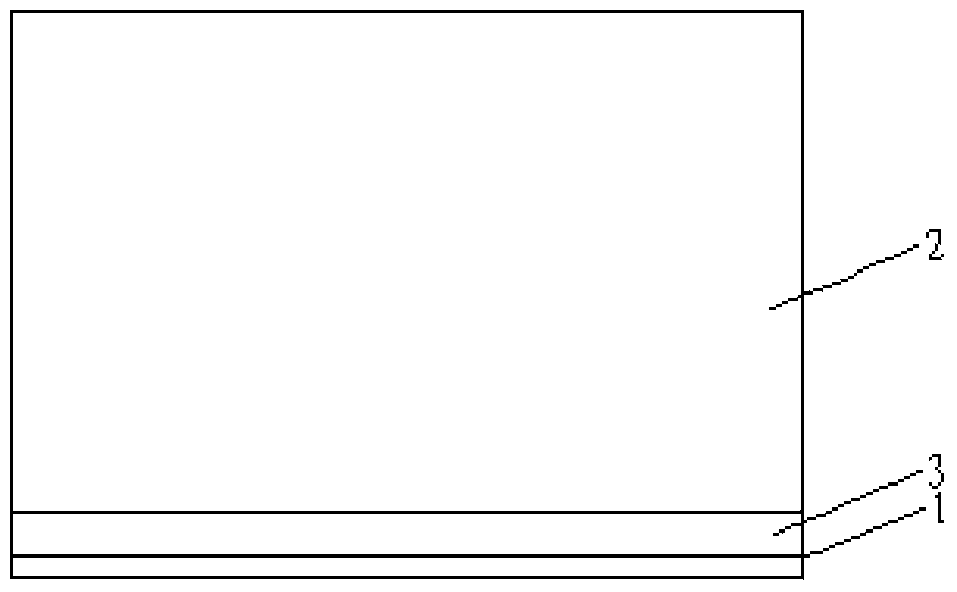

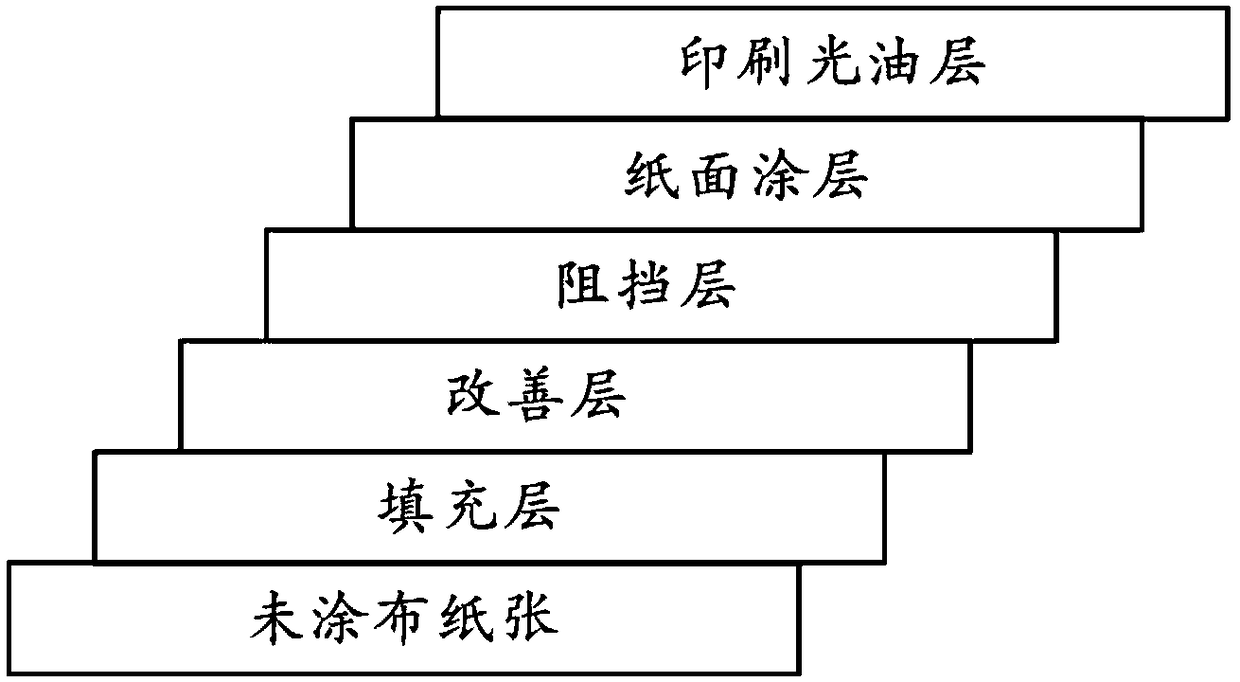

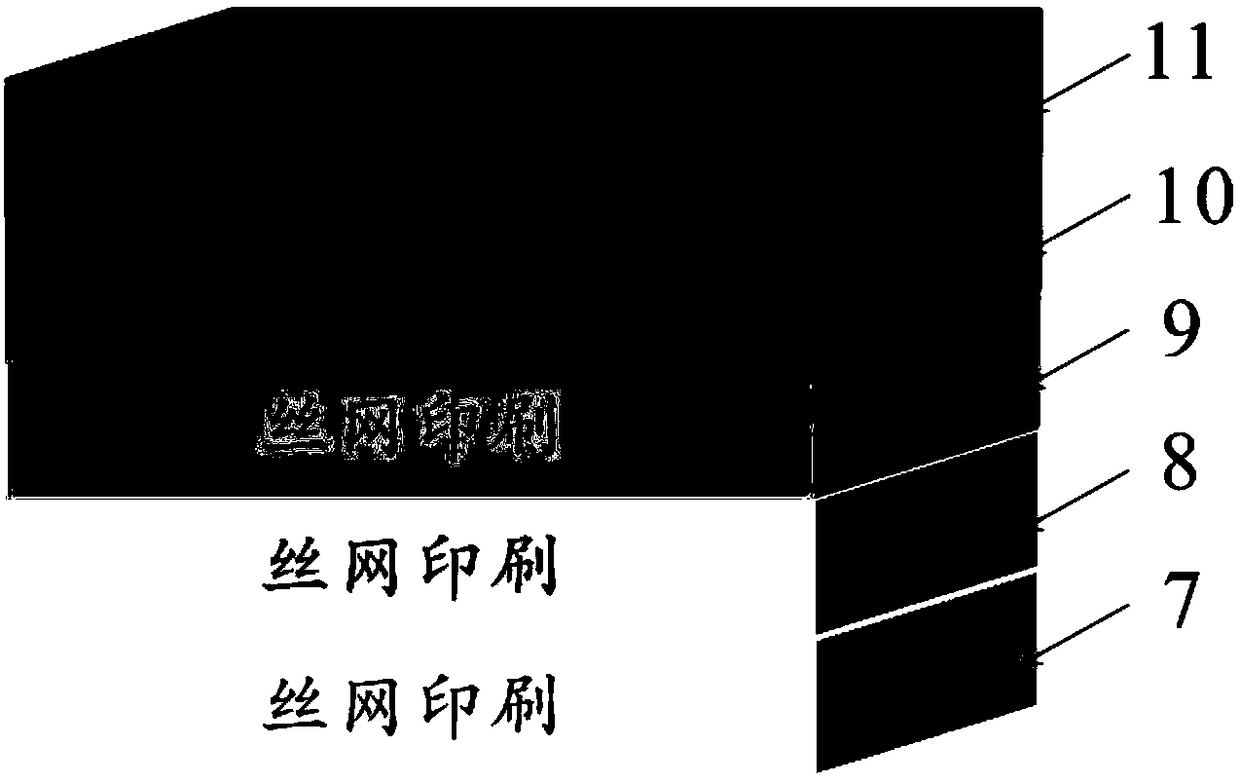

A paper luminescent structure and a preparation method based on a full printing process

ActiveCN109004107AStructure greenStructural environmental protectionSolid-state devicesPattern printingPorositySurface coating

The invention discloses a paper luminescent structure and a preparation method based on a full printing process, which relates to a material used for each functional layer of paper luminescent, a printing method and a treatment method of paper. The printing methods used include screen printing and ink-jet printing. Treatment of paper includes: fill layer, improvement layer, barrier layer, paper coating, printing varnish layer, which are used to adjust the surface roughness and porosity of paper. The paper light-emitting structure functional layer provided by the invention has the following layers from bottom to top: a paper substrate, a filling layer, an improvement layer, a barrier layer, a paper surface coating layer, a printing light oil layer, a conductive anode layer, a hole transportlayer, a light-emitting layer, an electron injection layer and a conductive cathode layer. The invention is used for realizing the patterning of luminescence on wrapping paper, and provides technicalsupport for the application of the technology in printing intelligent packaging products in the future.

Owner:SHAANXI UNIV OF SCI & TECH

High-elastic antibacterial non-woven fabric with honeycomb structure and preparation method thereof

A high-elastic antibacterial non-woven fabric with a honeycomb structure comprises a plurality of compound fiber meshes sequentially stacked in a back-and-forth Z shape. Antibacterial agents are sprayed into the compound fiber meshes, the compound fiber meshes are sequentially in end-to-end connection, and hot melting fiber is clamped between the adjacent compound fiber meshes. When the high-elastic antibacterial non-woven fabric is manufactured, through preparation prior to mesh formation and a process of mesh formation through mechanical combing, an upper layer fiber mesh, an elastic fiber mesh and a lower layer fiber mesh are prepared respectively and then are overlaid into the compound fiber meshes through a fiber mesh compounding process; the upper layer fiber mesh and the lower layer fiber mesh are mixture of low melting point polyester short fiber and three-dimensional curly hollow polyester short fiber, and the elastic fiber mesh is mixture of low melting point polyester short fiber and elastic polyester short fiber. After the antibacterial agents are sprayed into the compound fiber meshes, the meshes are vertically laid through a vertical mesh laying process, the hot melting fiber is scattered between the compound fiber meshes, and then the high-elastic antibacterial non-woven fabric with the honeycomb structure is obtained through a drying, trimming and winding process.

Owner:WUHAN TEXTILE UNIV

High-elastic flame-resistant upright cotton of fiber bonding type honeycomb structure and preparation method thereof

The invention discloses high-elastic flame-resistant upright cotton of fiber bonding type honeycomb structure. The high-elastic flame-resistant upright cotton of the fiber bonding type honeycomb structure comprises round-trip Z-type successively laminated fiber webs; the mixed powders of hot melting powders and flame-resistant powders are sprayed in the fiber webs; the fiber webs are successively connected end to end; and hot melting fibers are clamped between the neighboring fiber webs. During the preparation, the fiber webs are prepared by the web forming pre-preparation and mechanical combing web forming processes; the web net is the mixture of low-melting-point polyester staple fibers and elastic polyester staple fibers; and the weight percentage of the low-melting-point polyester staple fibers is 15%-35%, and the weight percentage of the elastic polyester staple fibers is 65%-85%. After the mixed powders of the hot melting powders and the flame-resistant powders are sprayed to the fiber webs, the fiber webs performs the vertical web through the vertical web process, and the hot melting fibers are sprayed between the fiber webs, so the high-elastic flame-resistant upright cotton of the fiber bonding type honeycomb structure is prepared by drying, edge-cutting and winding processes. The high-elastic flame-resistant upright cotton of the fiber bonding type honeycomb structure has the characters of high elasticity, good fire resistance, simple structure, low cost, and environment friendliness.

Owner:WUHAN TEXTILE UNIV

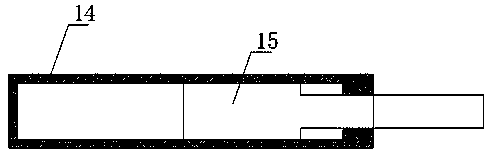

Continuous-electroplating liquid conduction apparatus and continuous liquid electroplating method

The invention discloses a continuous-electroplating liquid conduction apparatus. The apparatus comprises a conduction tank, a water washing tank and an electroplating tank which are sequentially arranged, a member for plating sequentially traverses through the conduction tank, the water washing tank and the electroplating tank to form a continuous electroplating line, first pole plates positioned along the direction of the continuous electroplating line are arranged in the tank bodies of the conduction tank, second pole plates positioned along the direction of the continuous electroplating line are arranged in the tank bodies of the electroplating tank, a power supply is also arranged, the first pole plates are electrically connected with the negative pole of the power supply, and the second pole plates are electrically connected with the positive pole of the power supply; and an electrolyte having a depth higher than the height of the first pole plates is filled in the conduction tank, and an electroplating liquid higher than the second pole plates is filled in the electroplating tank. The apparatus and the method solve an electroplating uniformity problem, and can also solve an electroplating surface damage problem.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

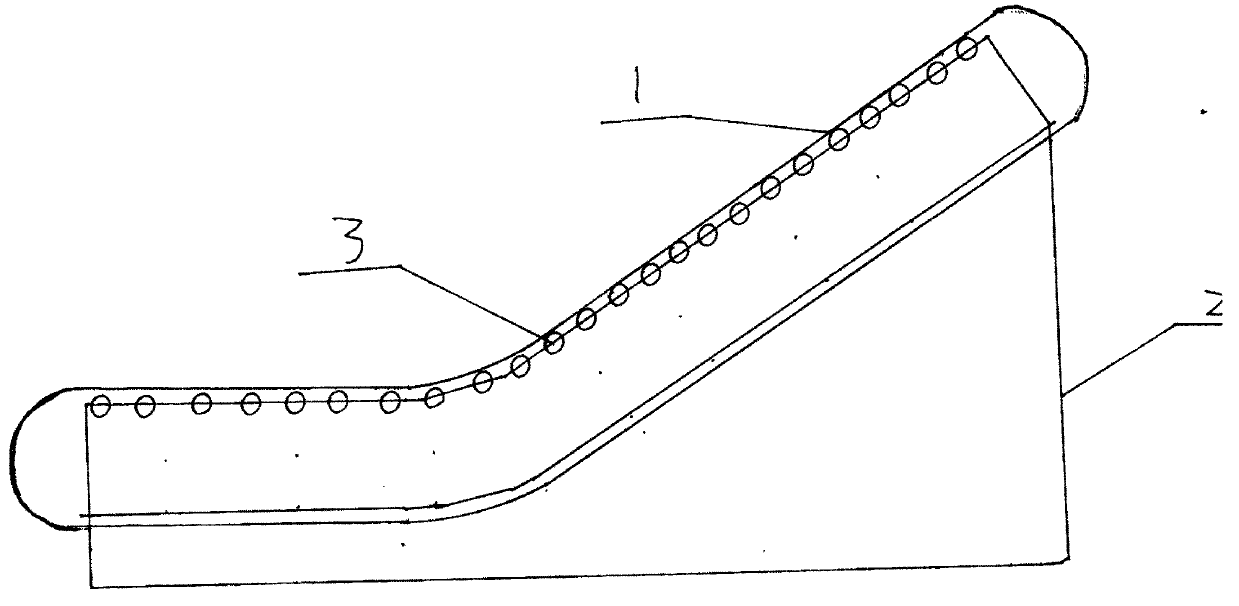

Running machine

InactiveCN103861238AStructural environmental protectionSimple structureMovement coordination devicesCardiovascular exercising devicesPhysical exerciseEngineering

Owner:范伟俊

Filament yarn bonding type honeycomb structure high-elastic antibiosis non-woven cloth and preparation method thereof

ActiveCN104911815AImprove adhesionAvoid distractionNon-woven fabricsAnti bacterialAntibacterial agent

The invention provides filament yarn bonding type honeycomb structure high-elastic antibiosis non-woven cloth. The filament yarn bonding type honeycomb structure high-elastic antibiosis non-woven cloth comprises a plurality of synthetic fiber nets sequentially stacked in a reciprocating Z shape, an antibacterial agent is sprayed inside the synthetic fiber nets, the synthetic fiber nets are sequentially connected in an end-to-end mode, the fiber net included angle between the adjacent synthetic fiber nets is an acute angle smaller than 2 degrees, hot melting filament yarns are arranged on the front surfaces and the back surfaces of the synthetic fiber nets in the width directions of the synthetic fiber nets at equal intervals in a side by side mode, and the hot melting filament yarns are folded in the reciprocating Z shape with the synthetic fiber nets. Each synthetic fiber net is a layer-shaped fiber net and formed by overlapping an upper layer fiber net, an elastic fiber net and a lower layer fiber net. The preparation method comprises the following steps that 1, preparation before net forming is conducted; 2, machinery carding for net forming is conducted; 3, fiber net synthetization is conducted; 4, the antibacterial agent is sprayed, 5, the nets are vertically laid; 6, drying is conducted; 7, edge cutting is conducted; 8, winding is conducted. The filament yarn bonding type honeycomb structure high-elastic antibiosis non-woven cloth has the advantages that not only is the high elasticity achieved, the antibacterial performance good, the structure simple, but also the cost is low, and the environment protection is achieved.

Owner:WUHAN TEXTILE UNIV

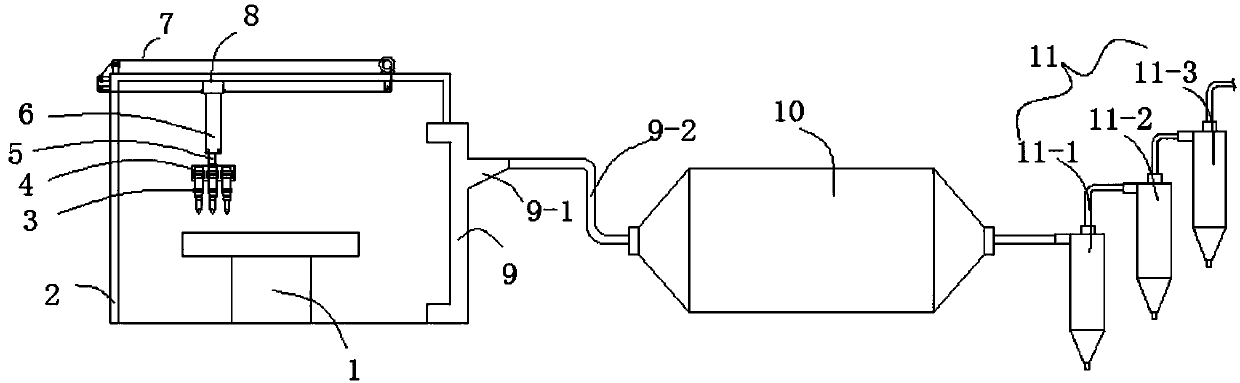

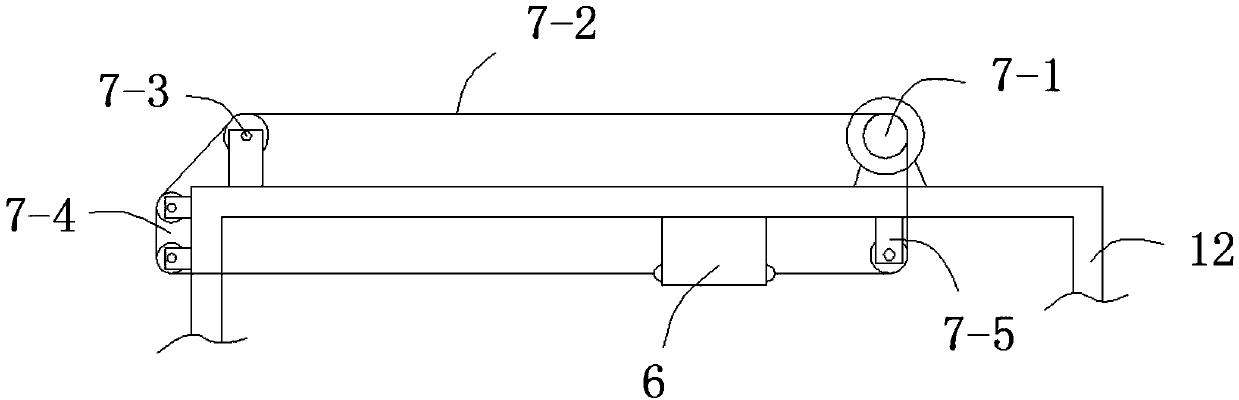

Environment-friendly wing spray booth

InactiveCN107552290ASimple structureStructural environmental protectionSpraying apparatusActivated carbonEngineering

The invention discloses an environment-friendly wing spray booth, which relates to the technical field of spray booths. The invention includes a spray booth, in which a working table is arranged, and a side dirt collection cover assembly is provided on one side of the spray cabin 2, and the spray booth There is a water curtain cabinet on one side of the compartment. The air outlet of the water curtain cabinet is connected to the main absorption pipe. The end of the main absorption pipe is connected to the activated carbon adsorption tower and the multi-stage cyclone dust removal assembly in turn. A mounting seat that reciprocates along the horizontal guide rail is clamped inside the guide rail. A lifting mechanism is arranged under the mounting seat. A spray gun fixing plate is connected to the bottom of the lifting mechanism. The spray gun fixing plate is detachably provided with multiple spray guns. There is a driving system for driving the mounting seat to move. The invention has the advantages of simple structure, high spraying efficiency, good collection effect, environmental protection, and exhaust gas emission up to the emission standard.

Owner:成都鑫晨航空科技有限公司

Multifunctional test table for laboratory

The invention relates to a multifunctional test table for a laboratory. The multifunctional test table comprises bottom cabinets, a seat, a cover plate, guide rails, a water groove, a waste liquid cabin, a dust suction device and an installing frame, wherein the bottom cabinets are arranged at the left side and the right side of the lower end of the cover plate; the seat is arranged between the bottom cabinets; the two ends of the seat are connected with the bottom cabinets through the guide rails; the seat comprises an installing plate and rolling wheels; the rolling wheels are arranged at the left end and the right end of the installing plate and are matched with the guide rails; the water groove is formed in the upper surface of the cover plate and is connected with the waste liquid cabin through a guide pipe; the waste liquid cabin is arranged in the bottom cabinet at the right side; the installing frame is arranged above the cover plate; the dust suction device is arranged on theinstalling frame. The multifunctional test table has the advantages that the defects of the prior art are overcome; the guide rails are installed for being connected with the seat; when not being used, the seat can be pushed to a position under the cover plate; the space is saved; meanwhile, the dust suction device is installed, so that harmful substances can be ensured not to overflow to pollutethe environment and cause the harm to the human body health; the structure is simple; the environment is protected; the use is convenient; the multifunctional test table is suitable for being popularized.

Owner:安徽沃屹智能装备有限公司

Film bonded type honeycomb structured high-elastic upright cotton and preparation method thereof

Film bonded type honeycomb structured high-elastic upright cotton comprises a plurality of fiber webs formed in a sequentially repeated Z-shaped laminated mode, the fiber webs are sequentially connected end to end, and hot melting films are sandwiched between adjacent fiber webs. The fiber webs are prepared through processes of web forming preparation and mechanical carding web forming. The fiber webs are a mixture of low-melting polyester staple fiber and elastic polyester staple fiber, the low-melting polyester staple fiber is 15% to 35% by weight, and the elastic polyester staple fiber is 65% to 85% by weight. The prepared fiber webs is subjected to processes of fiber web film laying by laying the hot melting films on both sides of every fiber web, vertical layering, drying, trimming and winding to obtain the film bonded type honeycomb structured high-elastic upright cotton. The film bonded type honeycomb structured high-elastic upright cotton is high in elasticity, simple in structure, low in cost and environmentally friendly.

Owner:WUHAN TEXTILE UNIV

Lifting wash basin

Owner:XENO CO SHANGLUO LTD

A kind of highly elastic antibacterial nonwoven fabric with honeycomb structure and preparation method thereof

Owner:WUHAN TEXTILE UNIV

High-elasticity antibacterial non-woven fabric with membrane adhering type honeycomb structure and preparation method thereof

A high-elasticity antibacterial non-woven fabric with a membrane adhering type honeycomb structure comprises a plurality of composite fiber nets which are sequentially overlapped in a back-and-forth Z shape; antibacterial agents are sprayed in the composite fiber nets; the composite fiber nets are connected end to end in sequence; a hot smelting membrane is clamped between the adjacent composite fiber nets. In a manufacturing process, an upper-layer fiber net, an elastic fiber net and a lower-layer fiber net are prepared respectively through procedures of doing preparation before forming the net, and mechanically carding to form the net; then the three layers of fiber nets are overlapped by a fiber net composite procedure to form the composite fiber net; the upper-layer fiber net and the lower-layer fiber net are mixtures of low-smelting-point polyester staple fibers and three-dimensional crimped hollow polyester staple fibers; the elastic fiber net is a mixture of the low-smelting-point polyester staple fibers and elastic polyester staple fibers. After the antibacterial agents are sprayed into the composite fiber nets, the composite fiber nets are subjected to a fiber net membrane covering procedure, and the hot smelting membranes cover the front and back surfaces of the composite fiber nets; the high-elasticity antibacterial non-woven fabric with the membrane adhering type honeycomb structure is manufactured by vertically paving the nets, drying, trimming and winding.

Owner:WUHAN TEXTILE UNIV

Grub trapping device and method

PendingCN113875713ASimple structureStructural environmental protectionInsect catchers and killersAgainst vector-borne diseasesBiologySoil science

Owner:LIAOCHENG UNIV

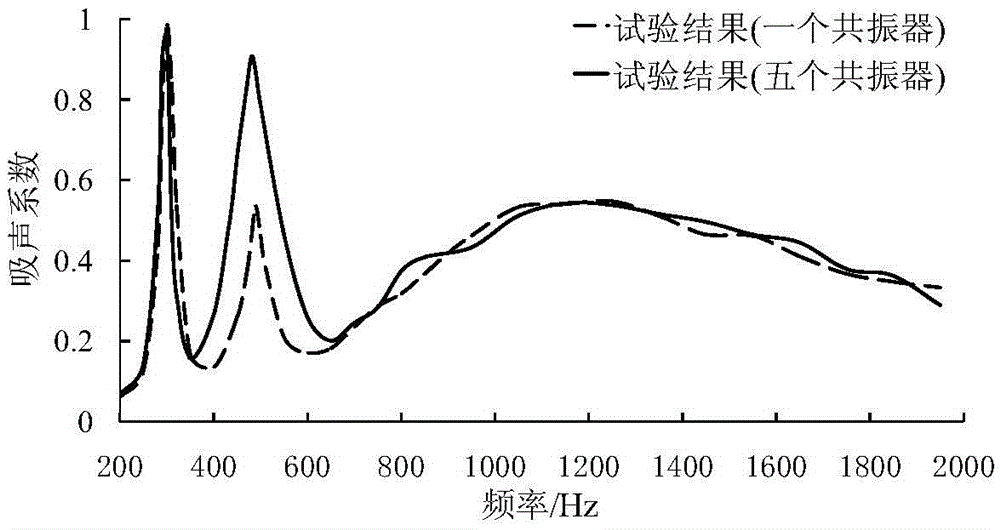

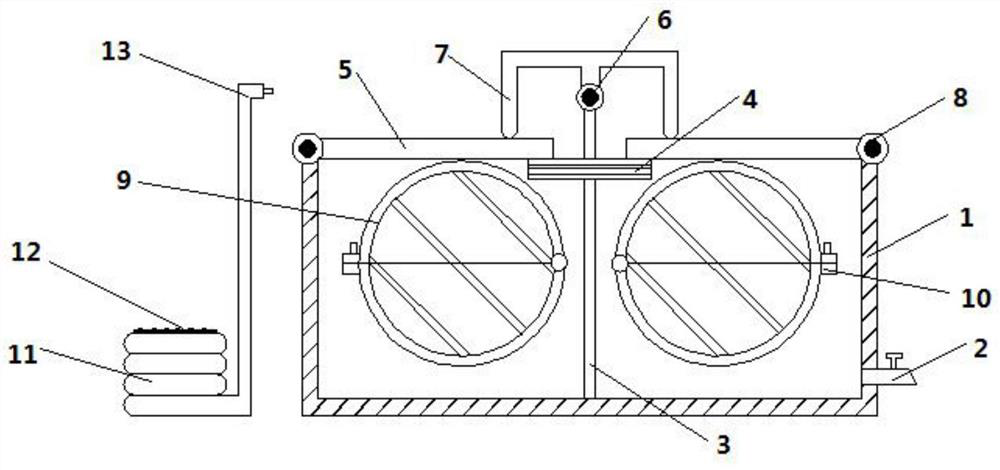

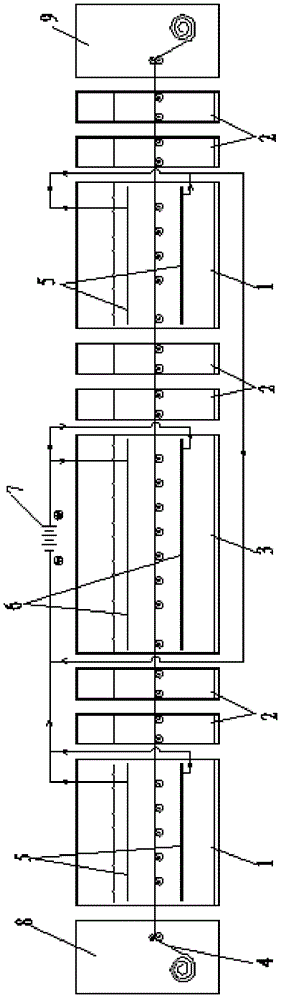

Broadband Sound Absorbing Structure Combined with Mechanical Impedance of Composite Resonant Cavity and Microperforated Plate

InactiveCN103700366BImprove sound absorptionStructural environmental protectionSound producing devicesEnvironmental noiseHelmholtz resonator

The invention relates to a wideband sound absorption structure combing mechanical impedance of composite resonance cavities with micropunch plates, and belongs to the technical field of environmental noise control. The wideband sound absorption structure comprises one or more layers of micropunch plates in the front of the structure and a mechanical impedance plate at the rear part of the structure, wherein the micropunch plates and the mechanical impedance plate are all fixed on a bracket; the mechanical impedance plate is formed by an elastically supported thin plate; Helmholtz resonance cavities are compositely arranged on the mechanical impedance plate; each Helmholtz resonance cavity consists of a cavity body and an insertion tube. According to the wideband sound absorption structure, Helmholtz resonance units are designed on the mechanical impedance plate, and the thicknesses of the resonance cavities are smaller, thus the whole structural thickness does not change too much. The micropunch plates can have good sound absorption effect for middle-frequency and high-frequency noises, and a plurality of absorption peaks can be generated at low frequency through a mechanical impedance unit and the Helmholtz resonance units, so that the whole structure can ensure good middle-frequency and high-frequency sound absorption performance and also has good sound absorption effect at low frequency.

Owner:JIANGSU UNIV

A polymer conductive porous film

ActiveCN103846011BConductiveStable structureSemi-permeable membranesPolymer scienceConductive polymer

The invention discloses a conductive polymer porous membrane. The conductive polymer porous membrane has a surface specific resistance of more than 160 omega.m. The conductive polymer porous membrane is prepared by the following method comprising the steps: carrying out ultrasonic dispersion on carbon black for 1-3 hours in water at 25 DEG C, wherein the ultrasonic wave power is 0-300 w; then stirring, adding a binding agent into the mixture, and fully stirring to obtain a uniform dynamic membrane casting solution; washing a polymer basement membrane with water; continuously running under the operation pressure of 0.1-0.3 MPa and at the temperature of 25-90 DEG C by using a depositional mode with the uniform dynamic membrane casting solution obtained in the step (1) as a solution to be filtered and the polymer basement membrane obtained in step (1) as a filter material to obtain a dynamic composite membrane; and naturally drying to obtain the conductive polymer porous membrane. The preparation method is simple in process, has no environmental pollution and no special requirement on equipment, is low in cost and achieves convenience for industrial application.

Owner:TIANJIN POLYTECHNIC UNIV

Large ball airtightness detection device

InactiveCN112304518AStructural environmental protectionThe result is accurateDetection of fluid at leakage pointRotational axisStructural engineering

The invention discloses a large ball airtightness detection device which comprises a shell, a water outlet, a partition plate, a limiting block, a baffle, a rotating shaft, a pressing rod, a movable shaft, a ball frame, a buckle, a treading type inflator, a pedal and an inflation nozzle. The device is characterized in that the water outlet is formed in the lower end of one side of the shell; the treading type inflator is arranged on the other side of the shell; the pedal is arranged on the treading type inflator; the inflation nozzle is connected with the treading type inflator; and the shellis filled with water and is made of a transparent material so that the detection condition of the ball body is convenient to observe.

Owner:TIANJIN HEALTH SPORTING GOODS

Continuous electroplating liquid conductive device and continuous liquid electroplating method

The invention discloses a continuous-electroplating liquid conduction apparatus. The apparatus comprises a conduction tank, a water washing tank and an electroplating tank which are sequentially arranged, a member for plating sequentially traverses through the conduction tank, the water washing tank and the electroplating tank to form a continuous electroplating line, first pole plates positioned along the direction of the continuous electroplating line are arranged in the tank bodies of the conduction tank, second pole plates positioned along the direction of the continuous electroplating line are arranged in the tank bodies of the electroplating tank, a power supply is also arranged, the first pole plates are electrically connected with the negative pole of the power supply, and the second pole plates are electrically connected with the positive pole of the power supply; and an electrolyte having a depth higher than the height of the first pole plates is filled in the conduction tank, and an electroplating liquid higher than the second pole plates is filled in the electroplating tank. The apparatus and the method solve an electroplating uniformity problem, and can also solve an electroplating surface damage problem.

Owner:KUNSHAN DONGWEI MACHINERY CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com