Filament yarn bonding type honeycomb structure high-elastic antibiosis non-woven cloth and preparation method thereof

A technology of honeycomb structure and non-woven fabrics, applied in the field of non-woven fabrics, can solve the problems of high elasticity, low cost and simple structure at the same time, and achieve the effects of strong elasticity, increased cohesion, and fast recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A method for preparing a high-elastic antibacterial nonwoven fabric of the above-mentioned filament bonding type honeycomb structure, the method comprises the steps of:

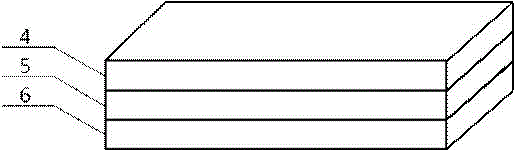

[0029](1) Preparation before web formation: first mix and open various fiber raw materials required for preparing the upper layer fiber web 4 , the elastic fiber web 5 and the lower layer fiber web 6 . The non-woven mixed opening equipment runs at a high speed. Since the raw materials are all chemical fibers, the hygroscopicity is poor compared with natural ones. Static electricity is easily generated during the mixed opening process. Adding an oil agent during the opening process can prevent static electricity from being generated. And affect product quality. The preparation material of the upper layer fiber web 4 and the lower layer fiber web 6 is a mixture of low-melting point polyester staple fiber and three-dimensional crimped hollow polyester staple fiber. In the upper layer fiber web 4 and the l...

Embodiment 1

[0038] A highly elastic and antibacterial nonwoven fabric with a filament bonded honeycomb structure and a preparation method thereof with a thickness of 200 mm.

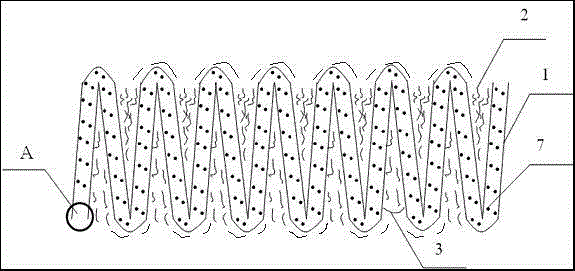

[0039] See figure 1 , figure 2 , a high-elastic antibacterial nonwoven fabric with a filament bonded honeycomb structure with a thickness of 200mm, including a plurality of composite fiber webs 1 stacked in sequence, the interior of the composite fiber web 1 is sprayed with an antibacterial agent 7, and the composite fiber webs 1 are connected end to end in sequence , the arrangement is in a reciprocating Z-shape, there is an angle 3 between adjacent composite fiber webs 1, and the angle 3 between the fiber web layers approaches 0 degrees, on the front and back surfaces of the composite fiber web 1 Equidistant and side-by-side hot-melt filaments 2 are arranged along its width direction, and are folded in Z-shape back and forth along with the composite web 1 .

[0040] The thickness of the hot-melt filament 2 is a...

Embodiment 2

[0052] A highly elastic and antibacterial nonwoven fabric with a filament bonded honeycomb structure and a preparation method thereof with a thickness of 5 mm.

[0053] See figure 1 , figure 2 , a high-elastic antibacterial nonwoven fabric with a filament bonded honeycomb structure with a thickness of 5mm, including a plurality of composite fiber webs 1 stacked in sequence, the interior of the composite fiber web 1 is sprayed with an antibacterial agent 7, and the composite fiber webs 1 are connected end to end in sequence , the arrangement is in a reciprocating Z-shape, and there is an angle 3 between adjacent composite fiber webs 1, the angle 3 between the fiber web layers is less than 2 degrees and close to 2 degrees, in the composite fiber web 1 Equidistant and side-by-side hot-melt filaments 2 are arranged on the front and back surfaces along the width direction thereof, and are folded in Z-shape back and forth along with the composite web 1 .

[0054] The thickness of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com