Patents

Literature

192results about How to "Uniform elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Flour mixing machine

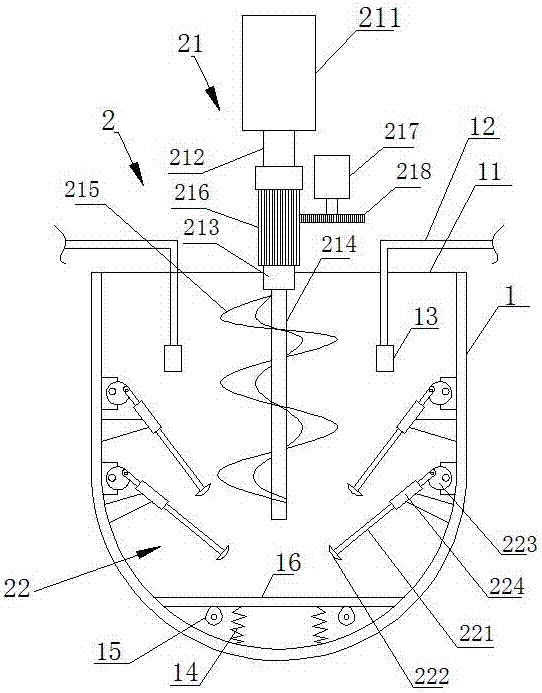

InactiveCN107019010AIncrease elasticityUniform elasticityMixing/kneading structural elementsMixing/kneading with vertically-mounted toolsEngineeringMotor shaft

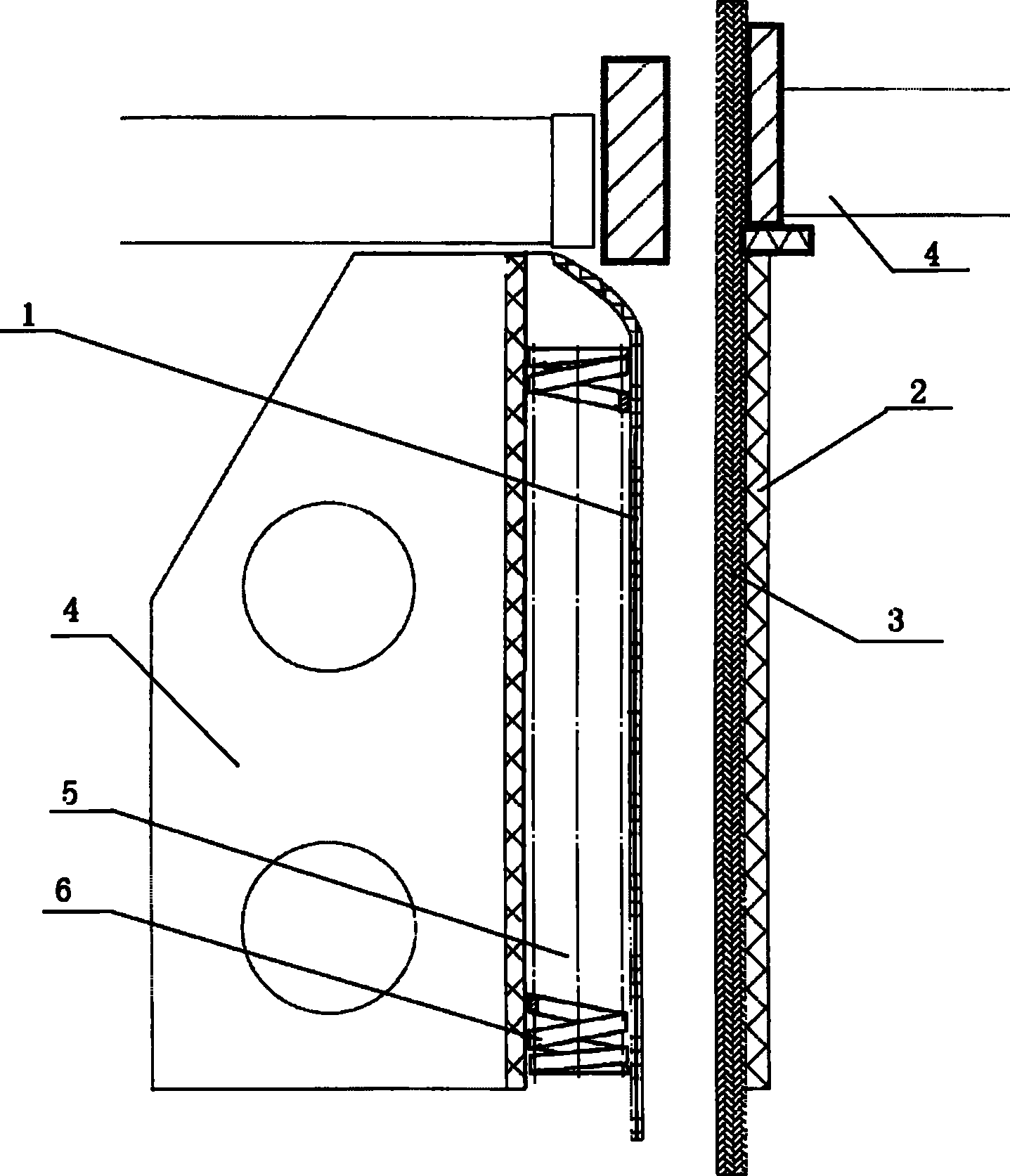

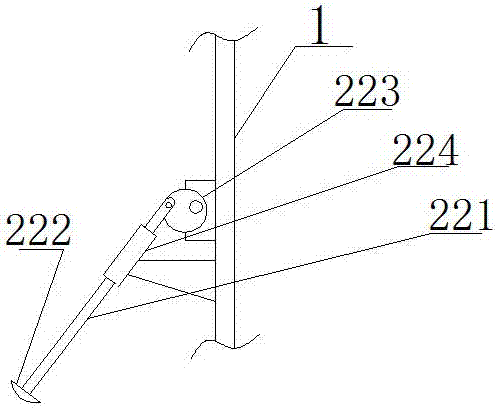

The invention relates to a noodle kneading machine, comprising a cylinder body and a dough kneading device arranged in the cylinder body; a dough inlet is arranged at the upper end of the cylinder body; a telescopic water inlet pipe which can be stretched The end is a cylindrical self-rotating nozzle; the kneading device includes a stirring device that can be raised and lowered as in the cylinder and a beating device that is evenly distributed on the inner periphery of the cylinder; the beating device includes a plurality of The stroke rod; one end of the stroke rod toward the center of the bottom of the cylinder is provided with a hemispherical hammer, and the other end is hinged on the outer periphery of a turntable; the turntable is driven by a first motor, and the motor shaft is eccentric on the turntable Setting; the middle part of the strike rod is slidingly sleeved in a limit sleeve.

Owner:林娜娜

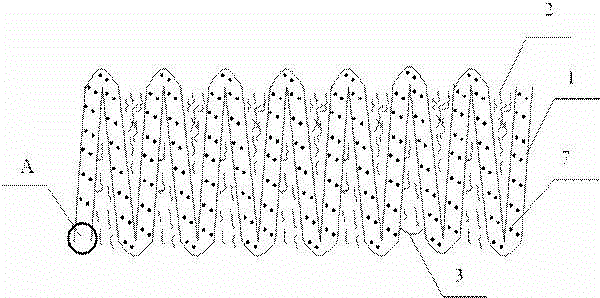

High-elastic flame-retardant non-woven cloth of honeycomb structure and preparation method thereof

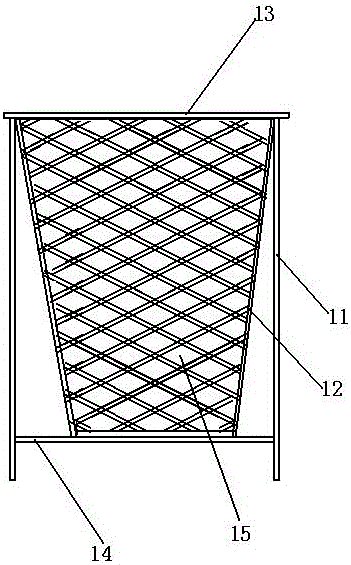

The invention relates to a high-elastic flame-retardant non-woven cloth of a honeycomb structure. The high-elastic flame-retardant non-woven cloth of the honeycomb structure comprises a plurality of compound fiber webs which are stacked in a round-trip Z shape. The inner sides of the fiber webs are spread with mixed powders of hot-melting powders and flame-retardant powders. The compound fiber webs are connected from heads to ends in sequence. Hot-melting fibers are clamped between adjacent compound fiber webs. When the high-elastic flame-retardant non-woven cloth of honeycomb structure is manufactured, an upper layer fiber web, an elastic fiber web and a lower layer fiber web are prepared respectively through the processes of reparation before web forming and carding web by a machine. The hot-melting powders and flame-retardant powders are spread on the upper layer fiber web, the elastic fiber web and the lower layer fiber web. The upper layer fiber web, the elastic fiber web and the lower layer fiber web are overlapped into a compound fiber web. The upper layer fiber web and the lower layer fiber web are a mixture of low-melting-point dacron staple fibers and three-dimensional crimped hollow dacron staple fibers. The elastic fiber web is a mixture of low-melting-point dacron staple fibers and elastic polyester staple fiber. Vertical lapping is conducted through the process of vertical lapping, hot-melting fibers are spread between the compound fiber webs, and the high-elastic flame-retardant non-woven cloth of the honeycomb structure is manufactured through the processes of drying, trimming and winding.

Owner:WUHAN TEXTILE UNIV

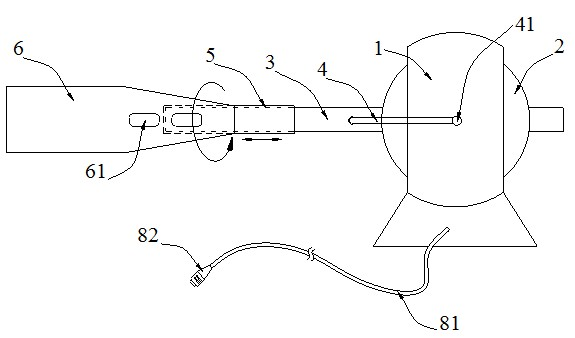

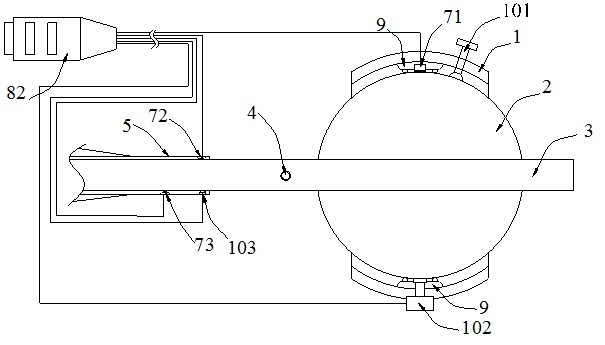

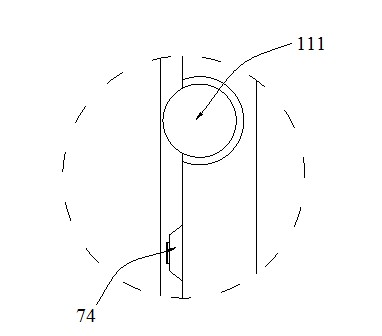

Improved endoscope simulation device

ActiveCN102306471ARealize a realistic simulationHigh degree of simulationEducational modelsFree rotationJoystick

The invention relates to an improved endoscope simulation device, belonging to the field of analogue simulation exercise equipment of surgical instruments. The technical scheme is that: the improved endoscope simulation device comprises a bracket, a ball body and a control rod, wherein the ball body is installed in the bracket in a free rotation mode; at least two orientation sensors are arranged between the inner side of the bracket and the ball body; one end of the control rod is fixed on the diameter direction of the ball body to control the ball body to rotate; a handle sleeve is sleeved on the other end of the control rod and rotates and slides relative to the control rod;; the inner cavity of the handle cover and the cross section of the control rod are round; a depth sensor and an rotation angle sensor are arranged between the control rod and the handle sleeve; an arc-shaped sliding rod sharing the center with the ball body is inserted on the position between the ball body and the handle sleeve in a relative sliding mode; and two ends of the arc-shaped sliding rod are in through connection on the bracket. In the invention, the defect of the prior art is effectively overcome through the artful design of the handle sleeve and the arc-shaped sliding rod, various actions of tools can be precisely simulated, and the sensor is used for precise measurement. The improved endoscope simulation device has the advantages of simple structure and high simulation degree.

Owner:广州医科大学附属第五医院(广州再生医学与健康广东省实验室附属医院)

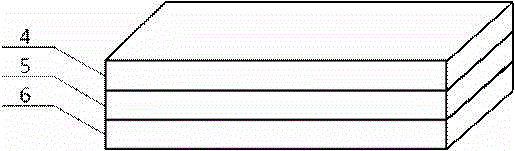

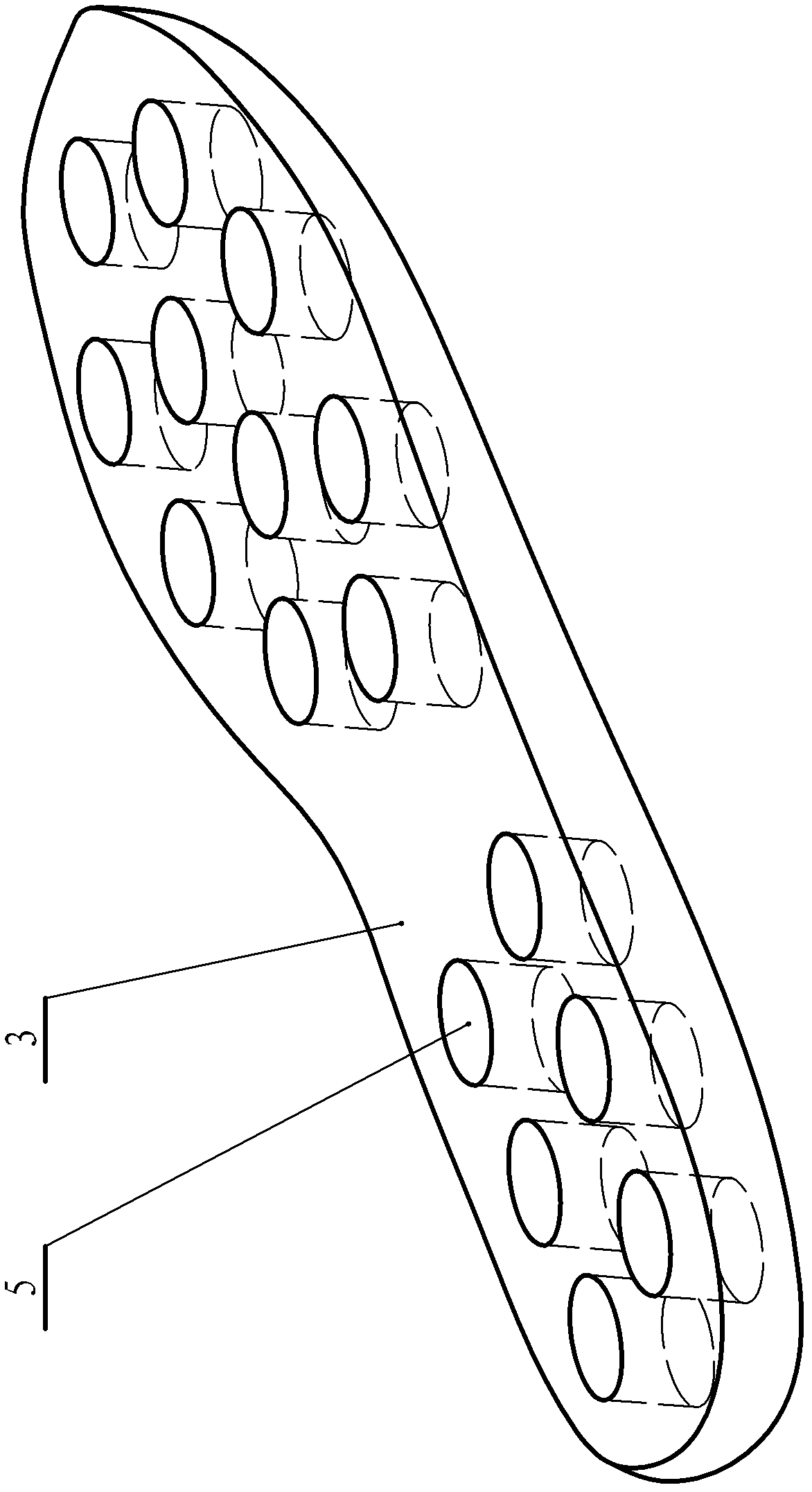

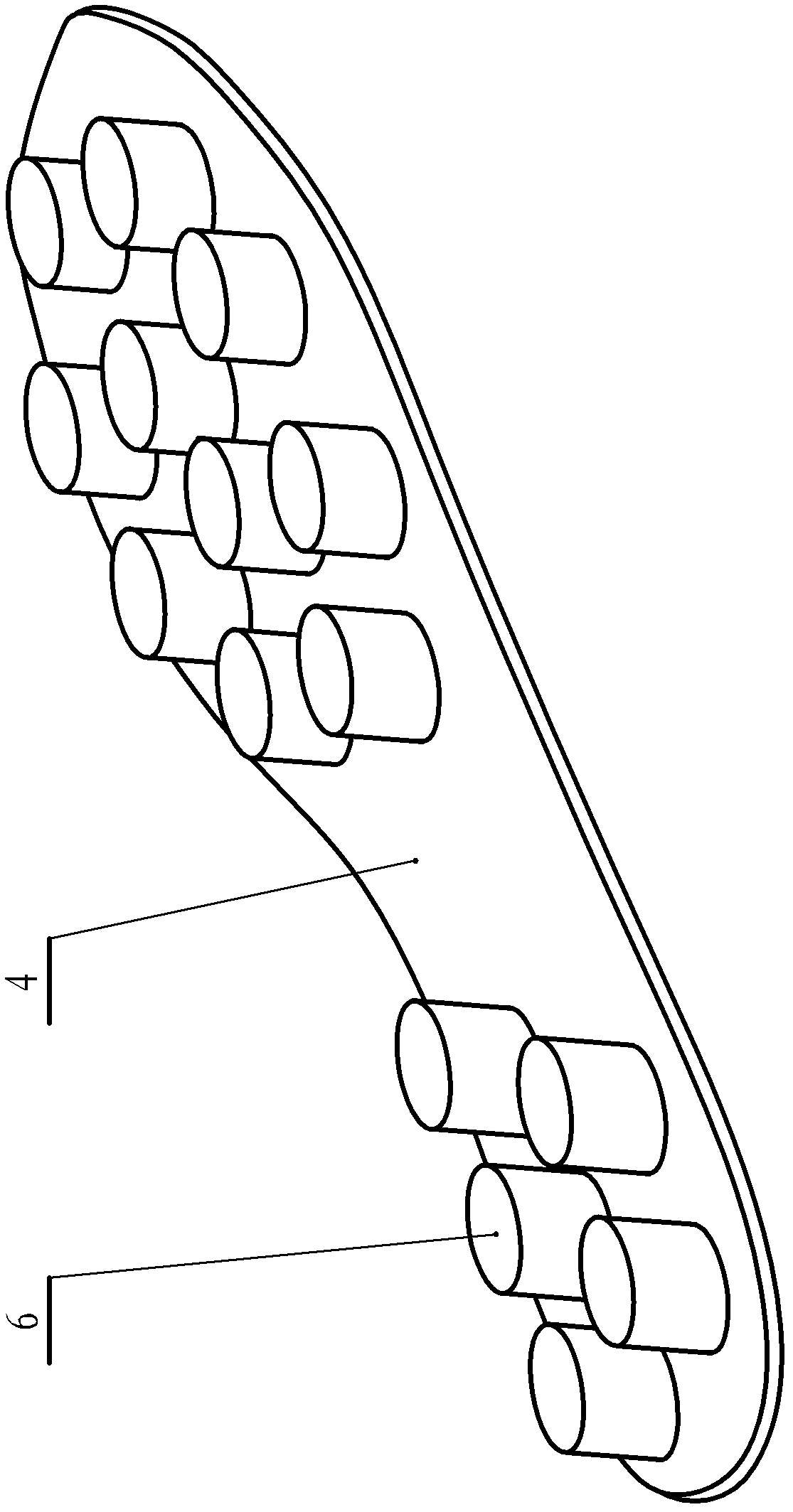

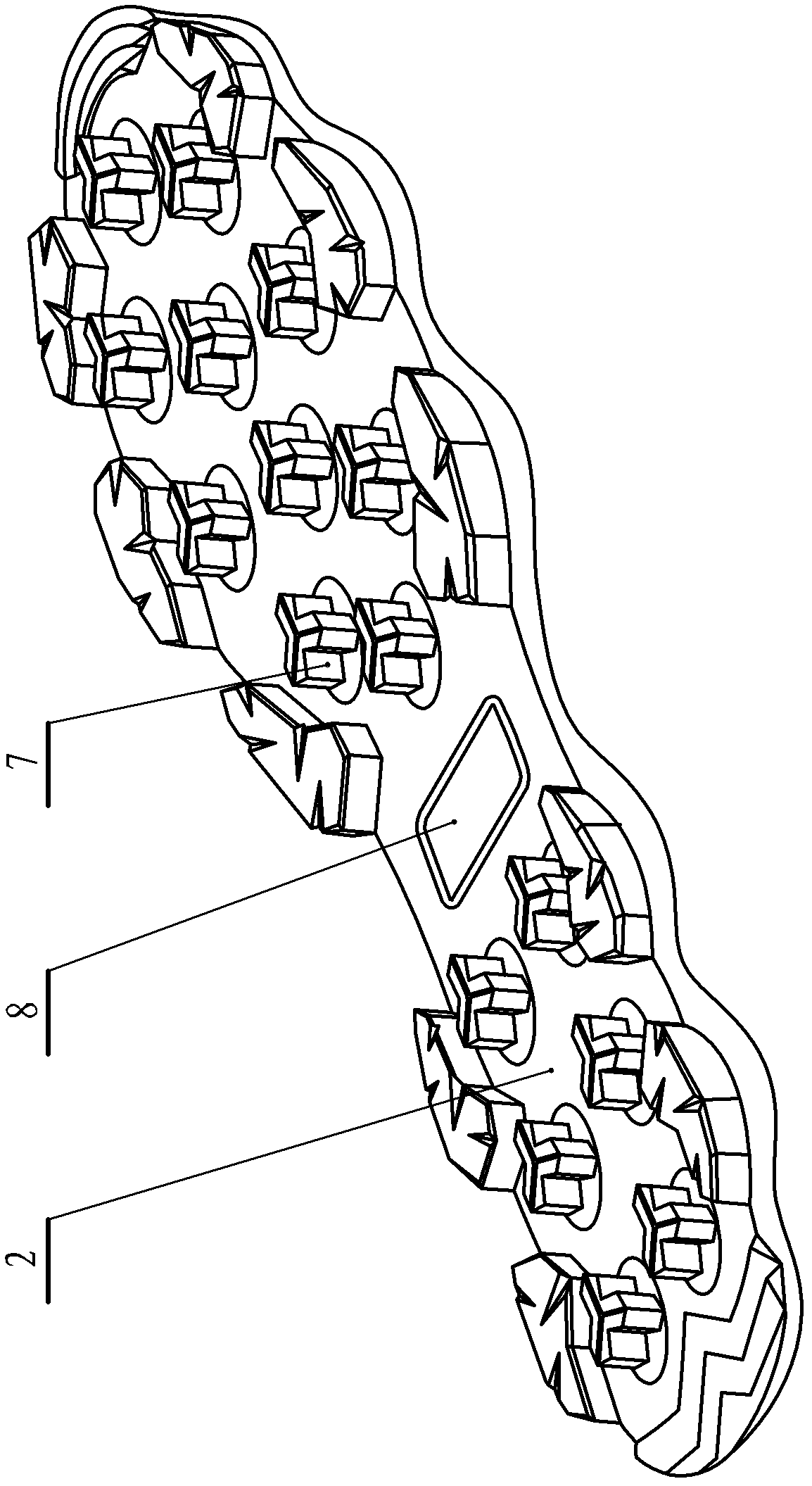

Shock-absorbing comfortable sole

A shock-absorbing comfortable sole comprises an outsole in contact with the ground and a midsole fixed on the upper surface of the outsole. The midsole comprises an upper layer and a lower layer. One or a plurality of through holes penetrating through the midsole in the thickness direction are respectively reserved on a heel, a rear sole and / or a front sole of the upper midsole. Projections corresponding to the through holes on the upper midsole are arranged on the upper surface of the lower midsole. The projections on the lower midsole are connected with the through holes on the upper midsole respectively in an embedded manner. Bottom grains protruding the lower surface of the outsole and corresponding to the projections on the lower midsole in position are arranged on the lower surface of the outsole. The upper midsole is hard, the lower midsole is soft, and when the surface of the upper midsole is stepped by a foot in walking, the upper surfaces of the soft projections are recessed highly and the upper surface of the hard upper midsole is recessed lowly, so that the upper surface of the upper midsole is flat or slightly uneven alternately, a foot sole of a wearer can be massaged, walking fatigue can be relieved, and the effect is evident.

Owner:MAOTAI FUJIAN SOLES CO LTD

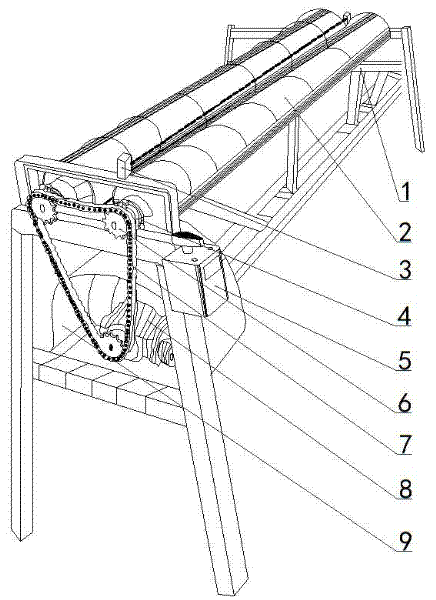

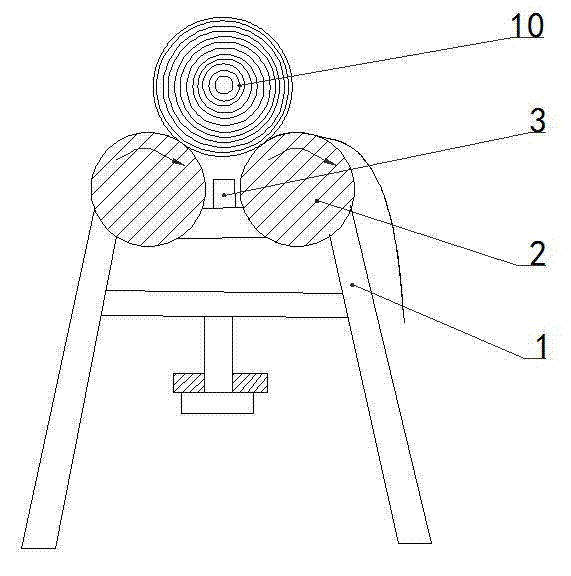

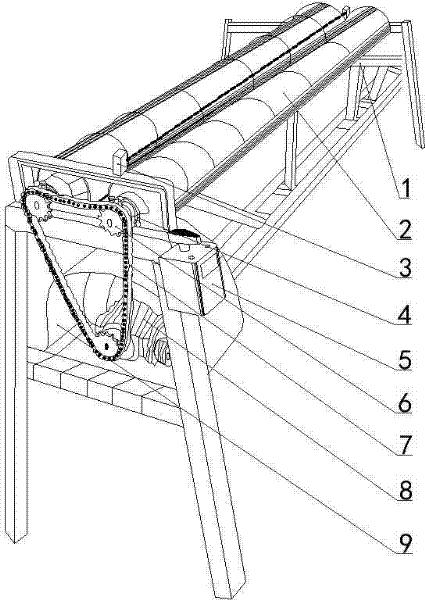

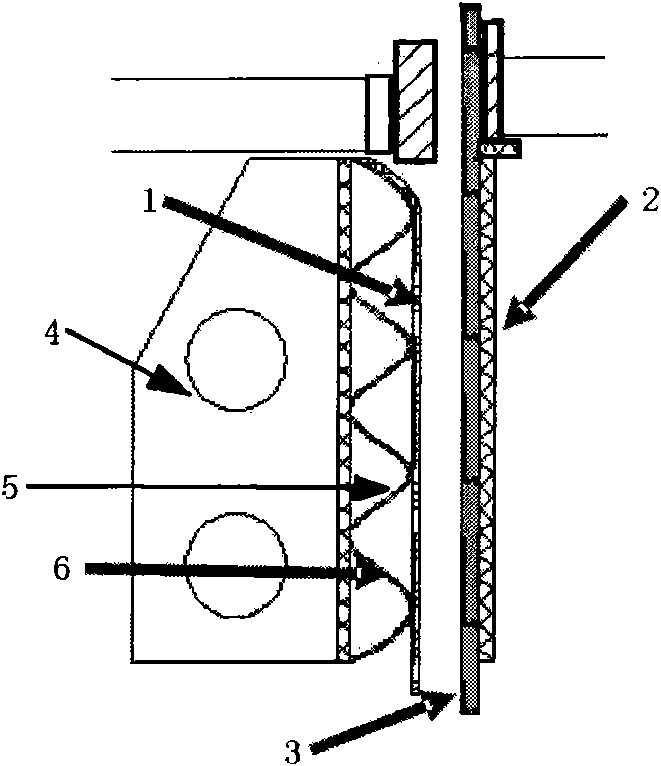

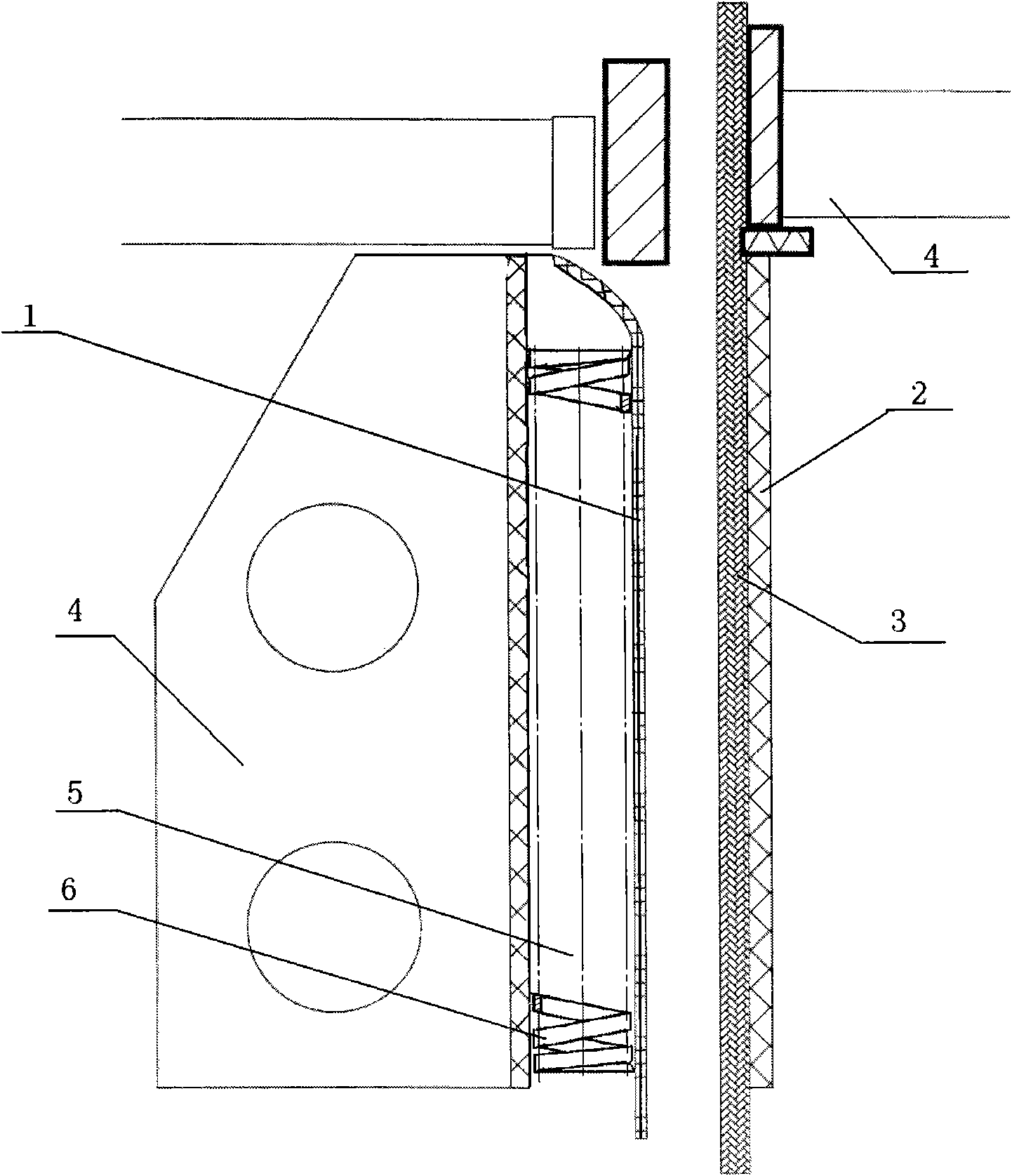

Method and device for loosening fabric of yardage roll

The invention discloses a method and device for loosening a fabric of a yardage roll. The method comprises the following steps of: arranging a cylindrical yardage roll on two horizontally adjacent rollers with the same rotation direction and linear speed, and enabling a loosening direction of the yardage roll to be same as the rotation direction of the rollers. The corresponding device comprises a stand, two rollers and a motor, wherein the stand is connected with two ends of each roller through bearings horizontally, and the two rollers are mutually parallel with each other; and the motor is arranged on the stand, and the two rollers are connected with the motor through transmission devices. According to the method for loosening the fabric of the yardage roll, disclosed by the invention, the two rollers rotating in the same direction are used for loosening the fabric such that the yardage roll can keep uniform elasticity and products finally produced by the yardage roll has better precision in size; and in addition, compared with a manual fabric-loosening manner, by utilizing the device for loosening the fabric of the yardage roll to loosen the fabric, the operating efficiency can be greatly improved.

Owner:ZHEJIANG LANGE IND

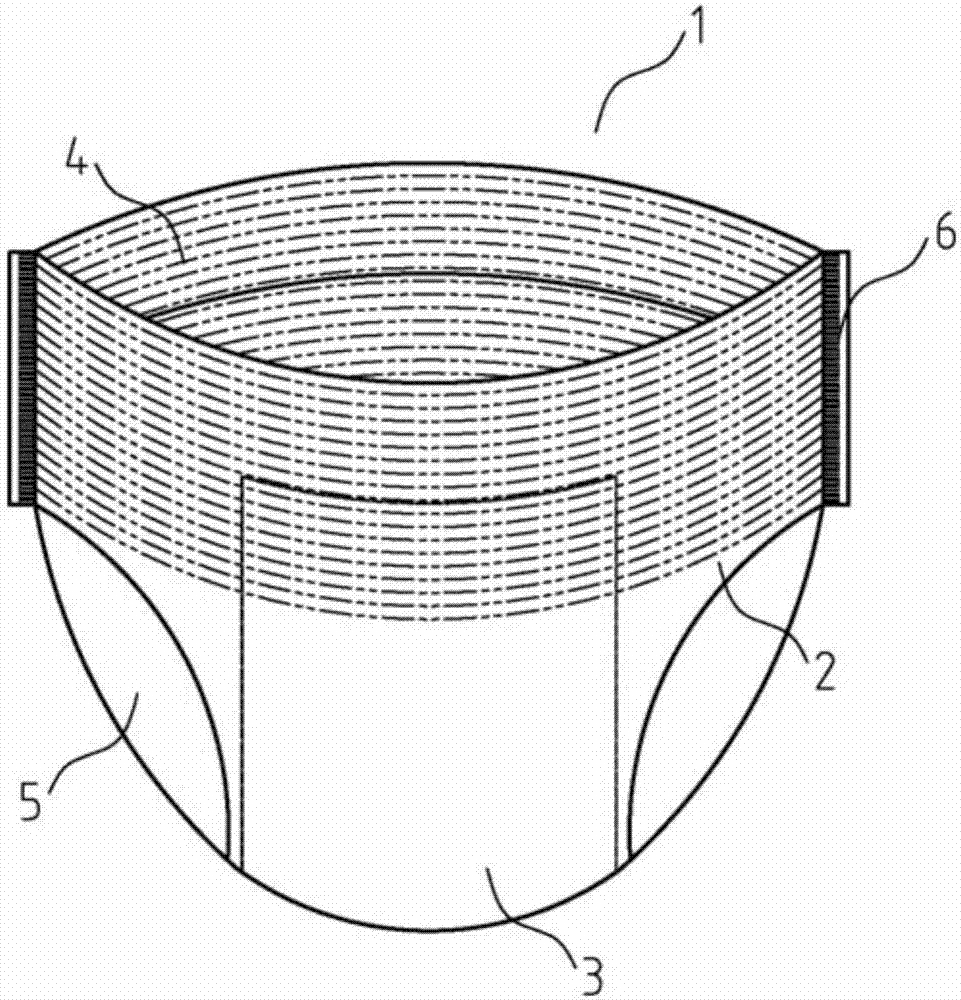

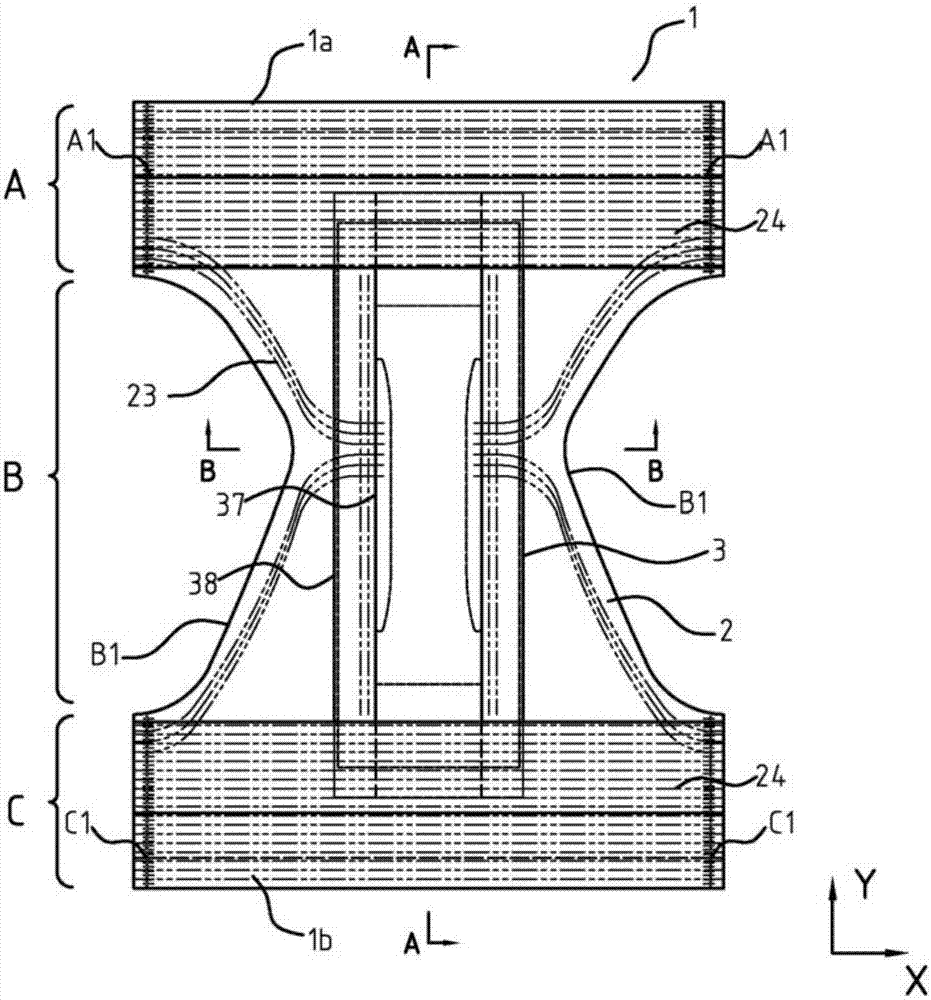

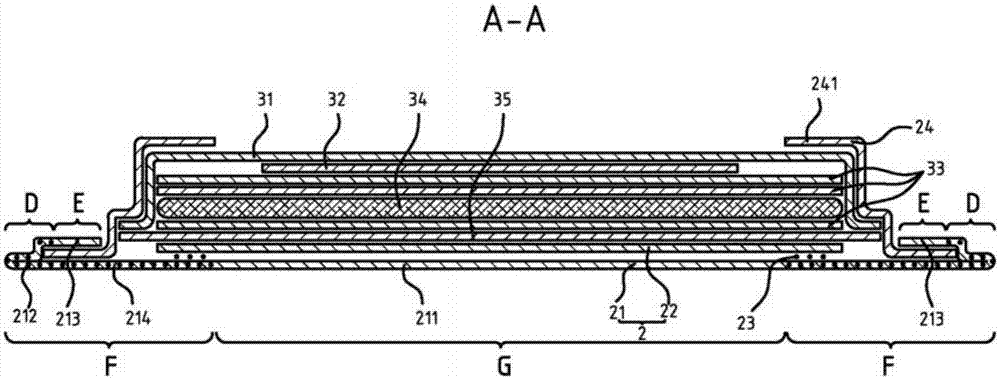

Preparation method of gradually-changed elastic waistband for paper diapers with unidirectional moisture-conducting function

ActiveCN110141428ASimple processGradient Elastic Thickness ThinAbsorbent padsBandagesElectrospinningChemistry

The invention provides a preparation method of a gradually-changed elastic waistband for paper diapers with unidirectional moisture-conducting function. The preparation method is characterized in thatthe preparation method includes the following steps: step 1, preparing hydrophobic polyurethane spinning solution into hydrophobic fiber membranes by an electrospinning device; step 2, using the hydrophobic fiber membranes prepared in the step 1 as substrates, and preparing hydrophilic polyurethane spinning solution into hydrophilic fiber membranes by using the electrospinning device, thereby obtaining composite fibre membranes with unidirectional moisture-conducting function; and step 3, cutting the above-mentioned composite fiber membranes with unidirectional moisture-conducting function into bands with upper part thin and lower part thick as the gradually-changed elastic waistband for paper diapers with unidirectional moisture-conducting function. The gradually-changed elastic waistband for paper diapers prepared by the invention is directly prepared by electrospinning process. The process is simple, and the gradually-changed elastic waistband is relatively thin in thickness and soft and comfortable.

Owner:DONGHUA UNIV

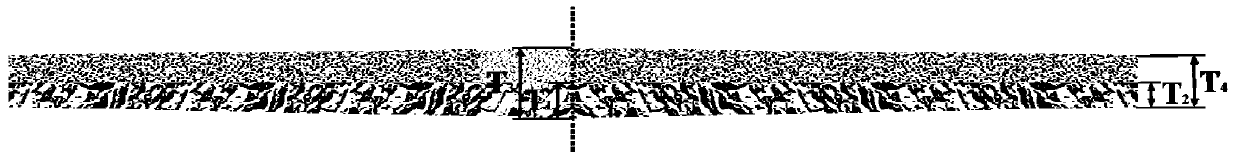

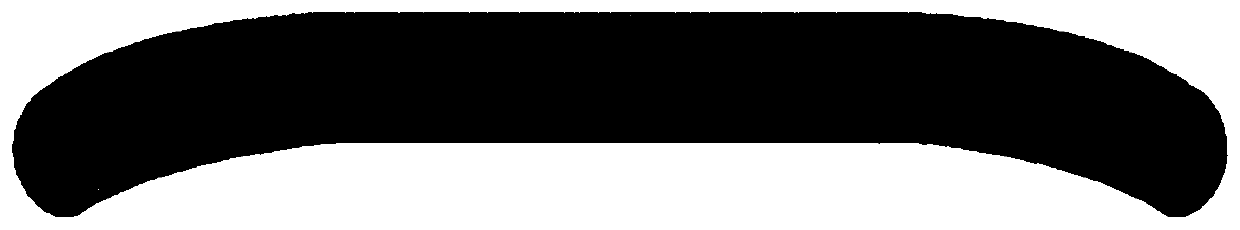

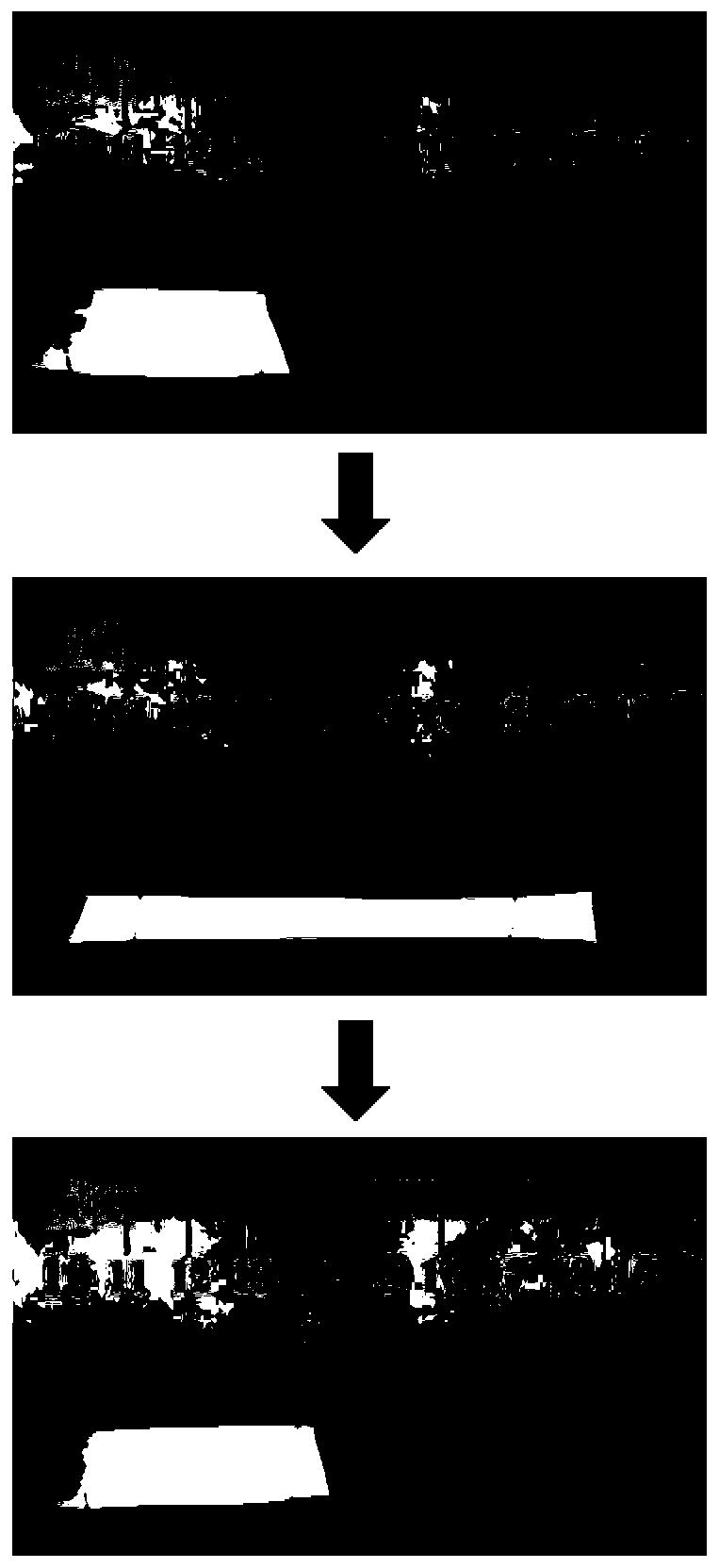

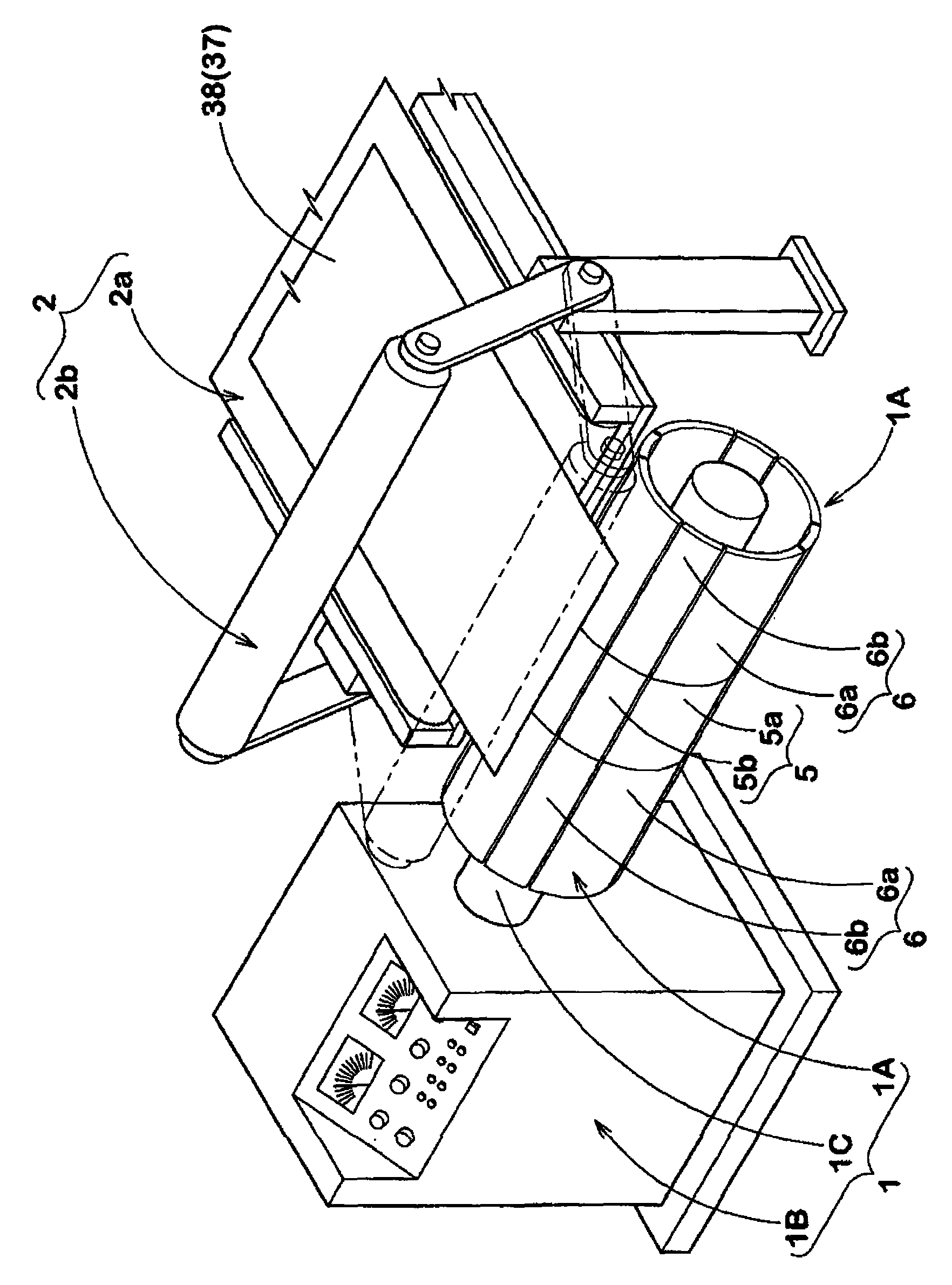

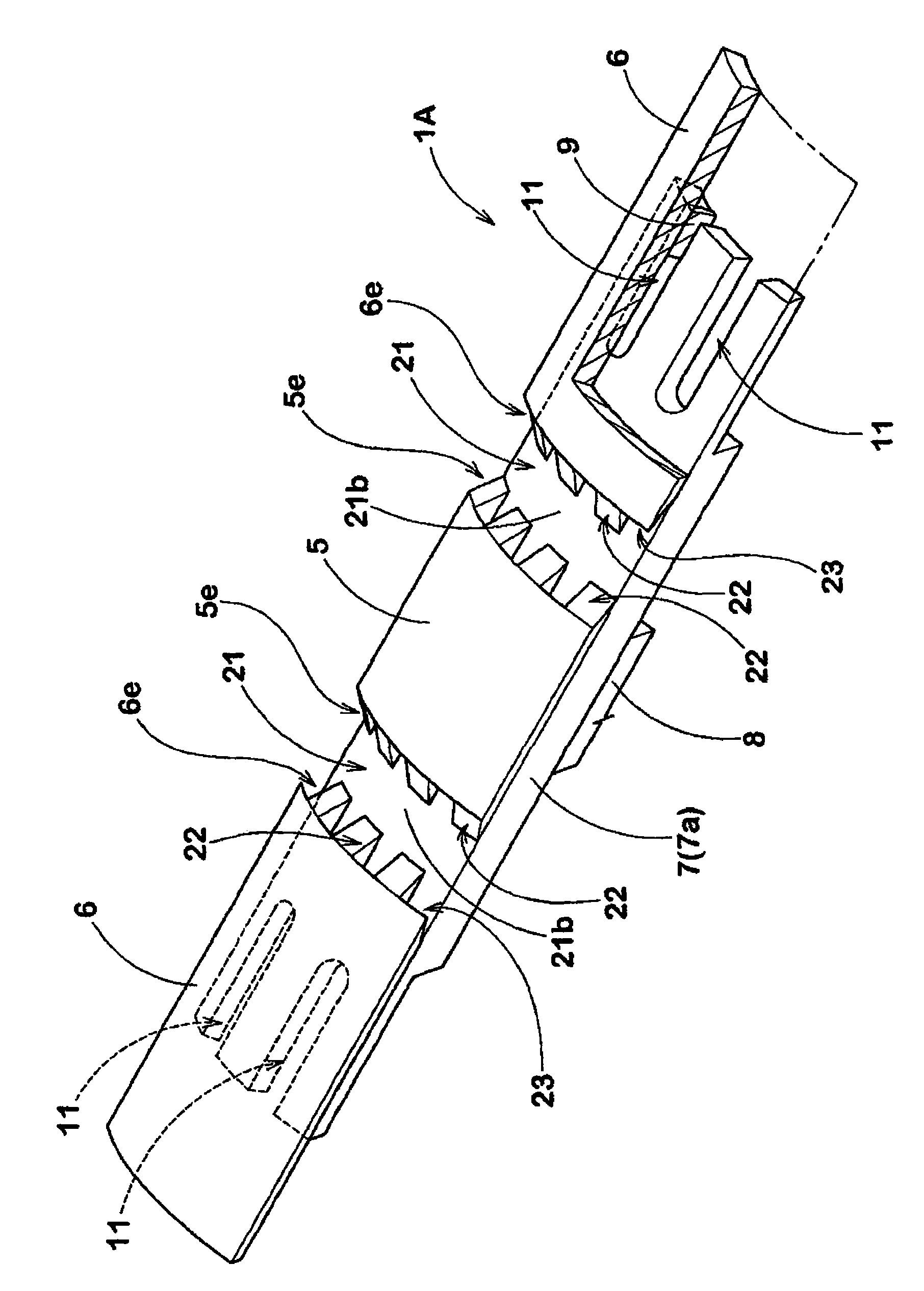

Method for making run-flat tire and assembly drum device for same

ActiveCN101659127AImprove pasting accuracyUniform elasticityTyresPneumatic tyre reinforcementsBand shapeEngineering

The invention can improve the homogeneity of a run-flat tire. A method for making the run-flat tire of which a tire side part is provided with a tire side reinforcing glue with the cross section approximately in the crescent shape is provided. The method includes: winding flaky inner lining glue on the external circumstance of a cylindrical drum main body; winding and sticking band-shaped tire side reinforcing glue in the region of the external circumstance of the cylindrical inner lining glue equivalent to a pair of tire sides to form a first cylindrical object; arranging a pair of circumferential channels on the external circumstance of the drum main body and the inner side of the tire side reinforcing glue, expanding the drum main body, thereby the portion of the first cylindrical object, reinforced with the tire side reinforcing glue goes down into the circumferential channels; and winding the flaky carcass cord fabric by means of the external circumstance of the sinking and flat first cylindrical object to form a basal body of the tire.

Owner:SUMITOMO RUBBER IND LTD

Hydrogel microcapsule and application thereof in anti-ageing cosmetic

InactiveCN104398392AUniform strengthUniform elasticityCosmetic preparationsToilet preparationsPolymer scienceSoftgel

The invention discloses a hydrogel microcapsule and application thereof in an anti-ageing cosmetic. The hydrogel microcapsule disclosed by the invention is a translucent spherical soft capsule in a core-shell structure, wherein a capsule wall is a hydrogel shell membrane, and a capsule core is an active substance mixture with an anti-ageing effect; the hydrogel microcapsule is formed from the capsule core and the capsule wall through an interface transmission reaction; the embedding rate of the hydrogel microcapsule is as high as 95% and steady under the illumination. The hydrogel microcapsule disclosed by the invention can be used as an additive for the anti-ageing cosmetic, and the microcapsule has the care effects of extreme moistening, crease resistance, freckle removing, whitening and the like on skin, so that the skin ageing is effectively delayed.

Owner:CHONGQING PELLETS TECHN & TRADE

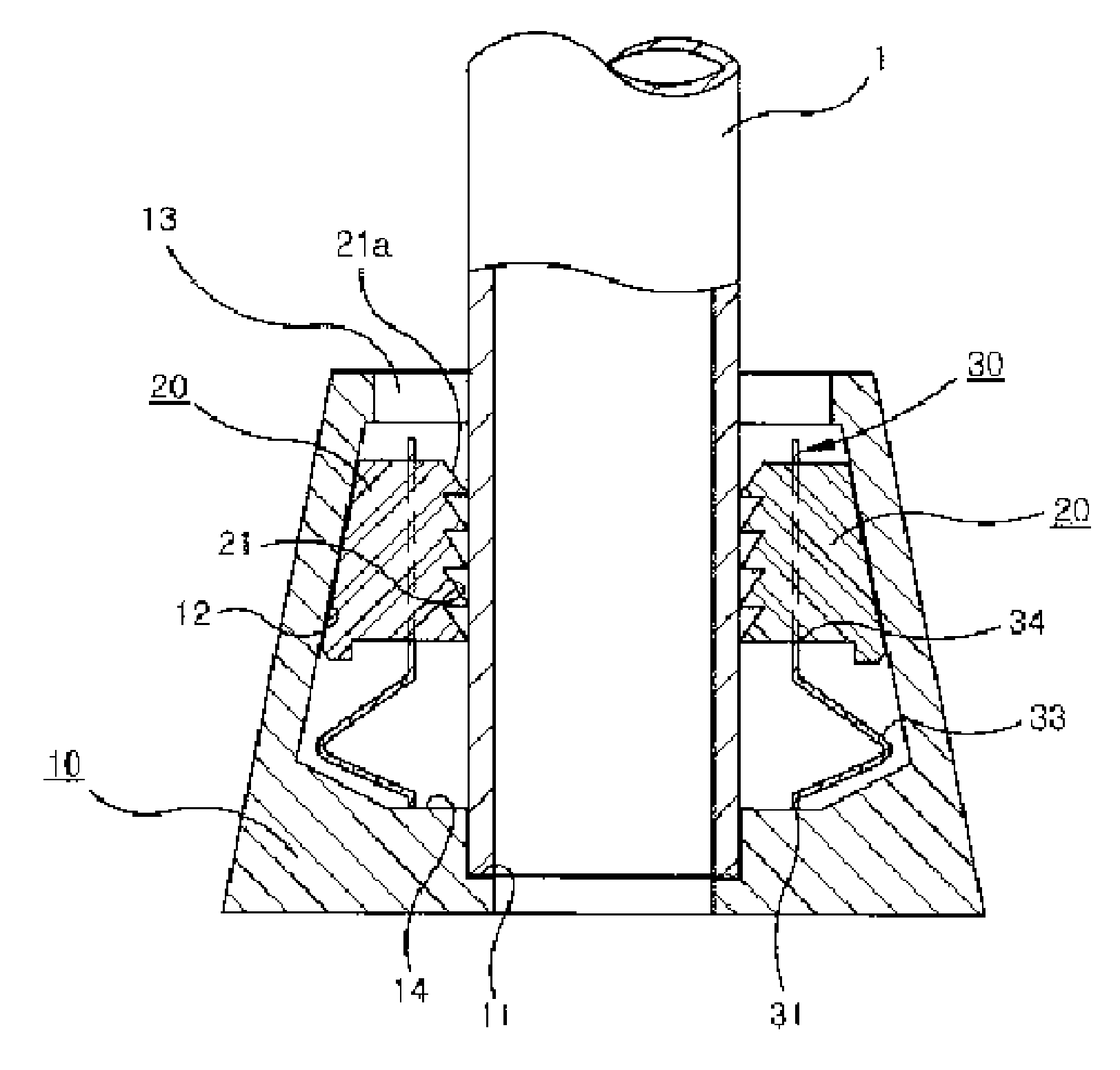

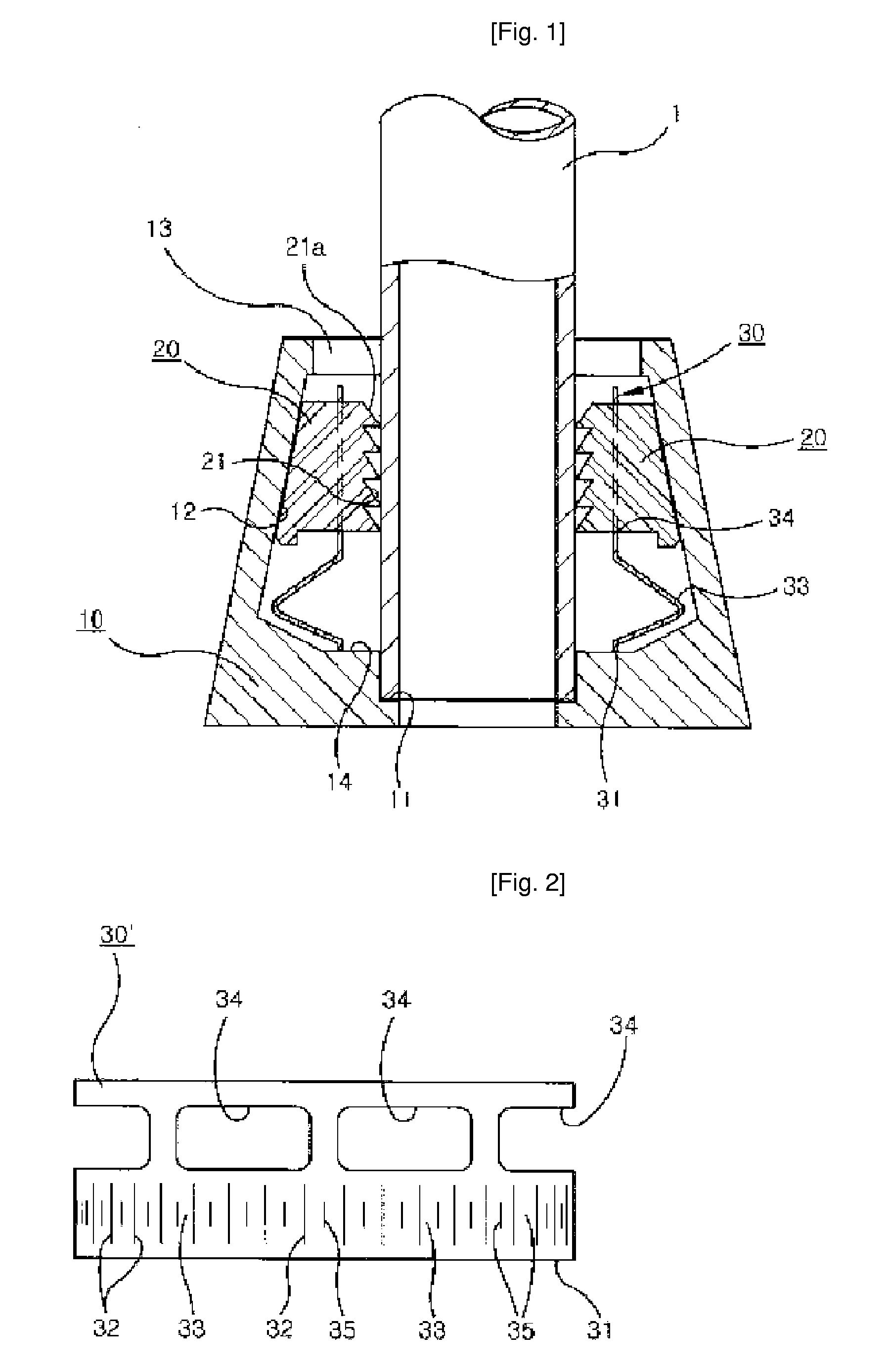

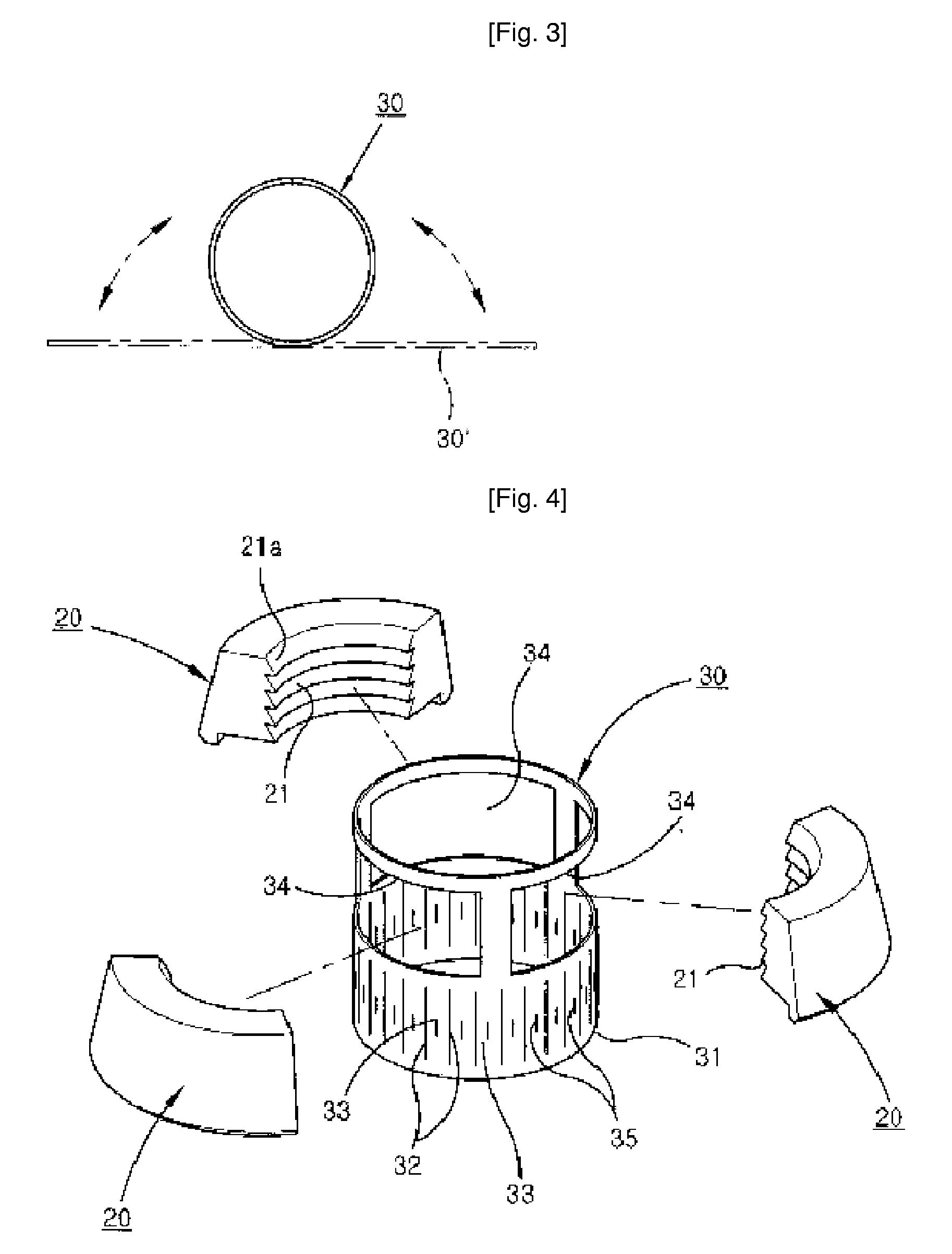

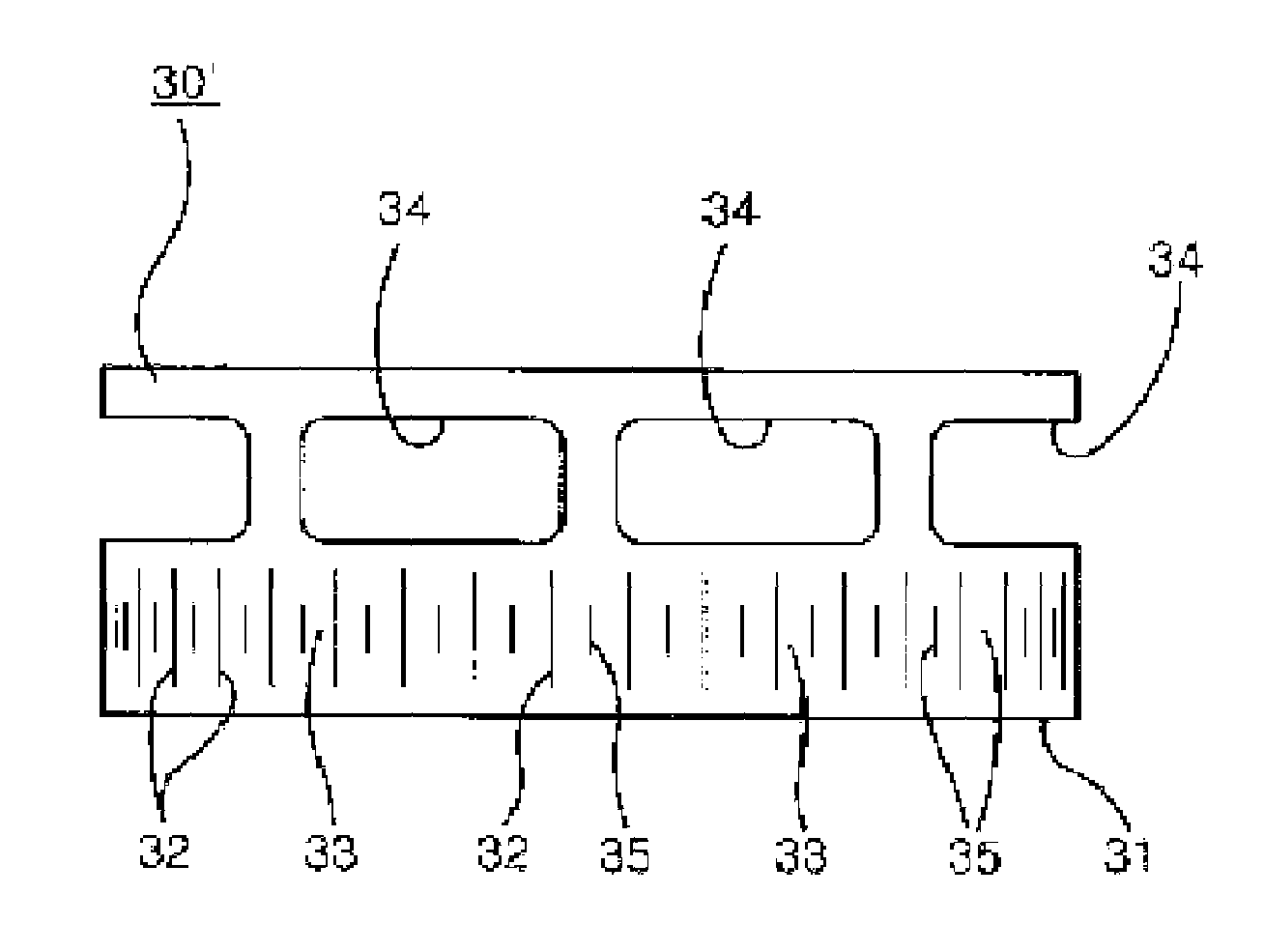

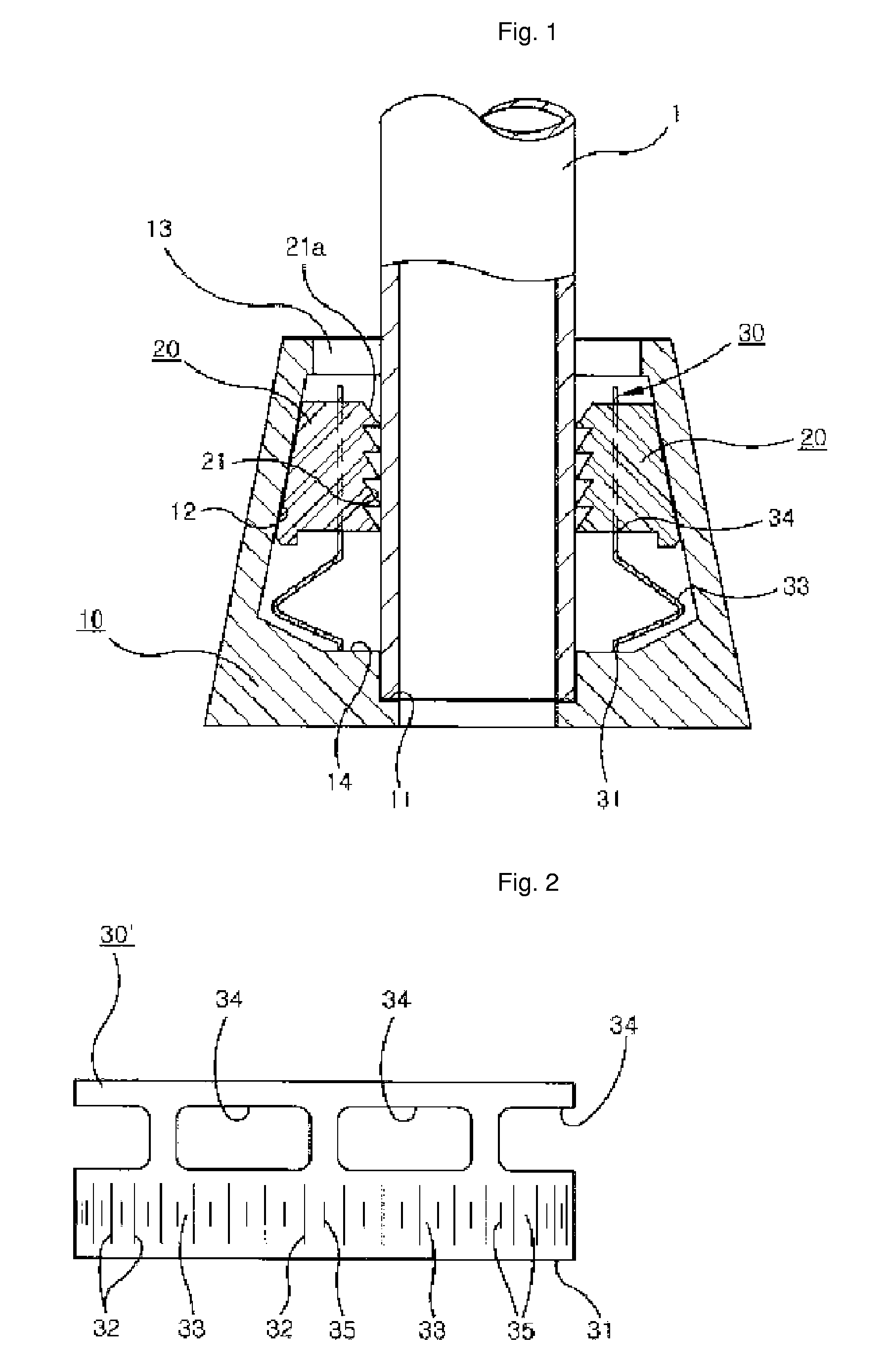

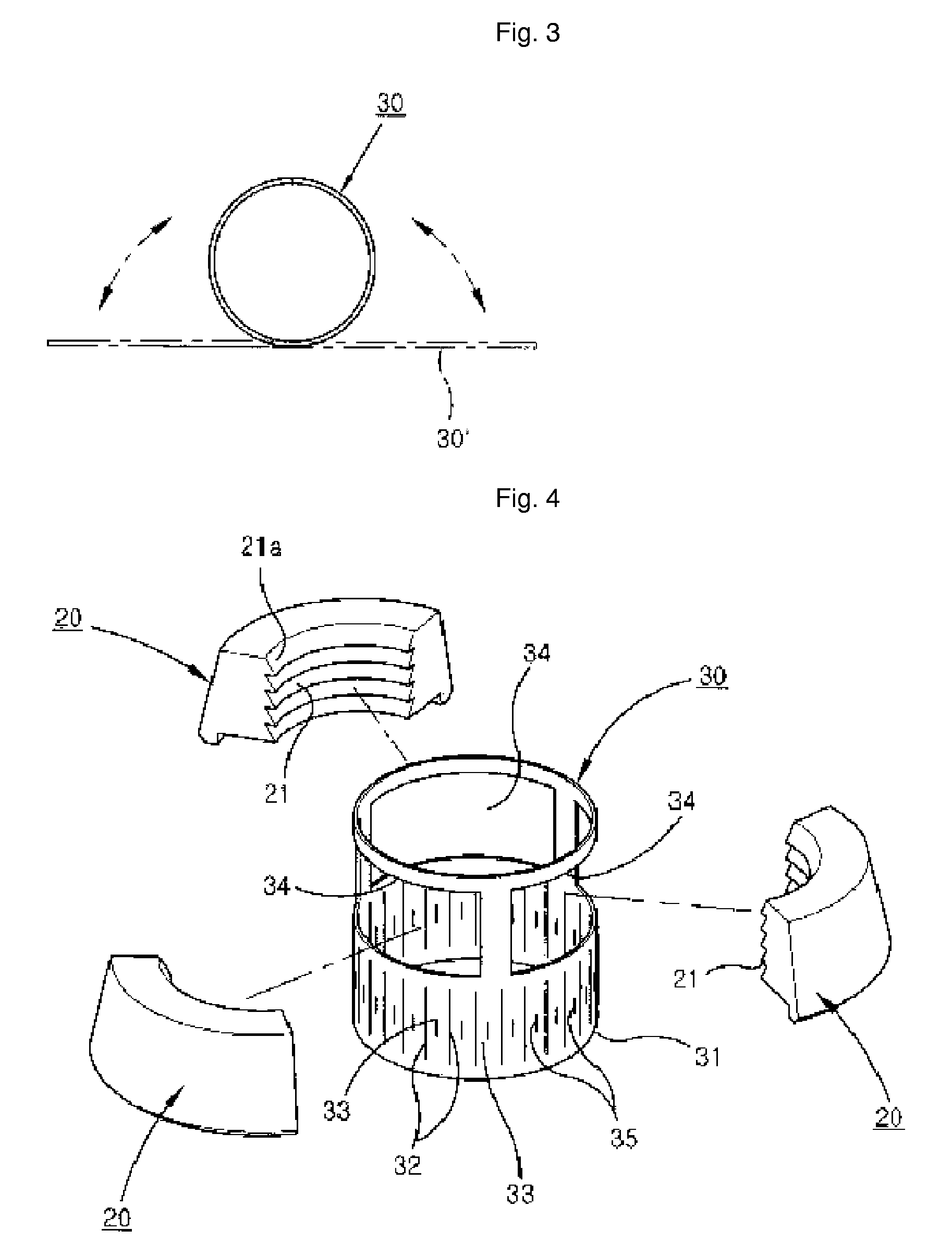

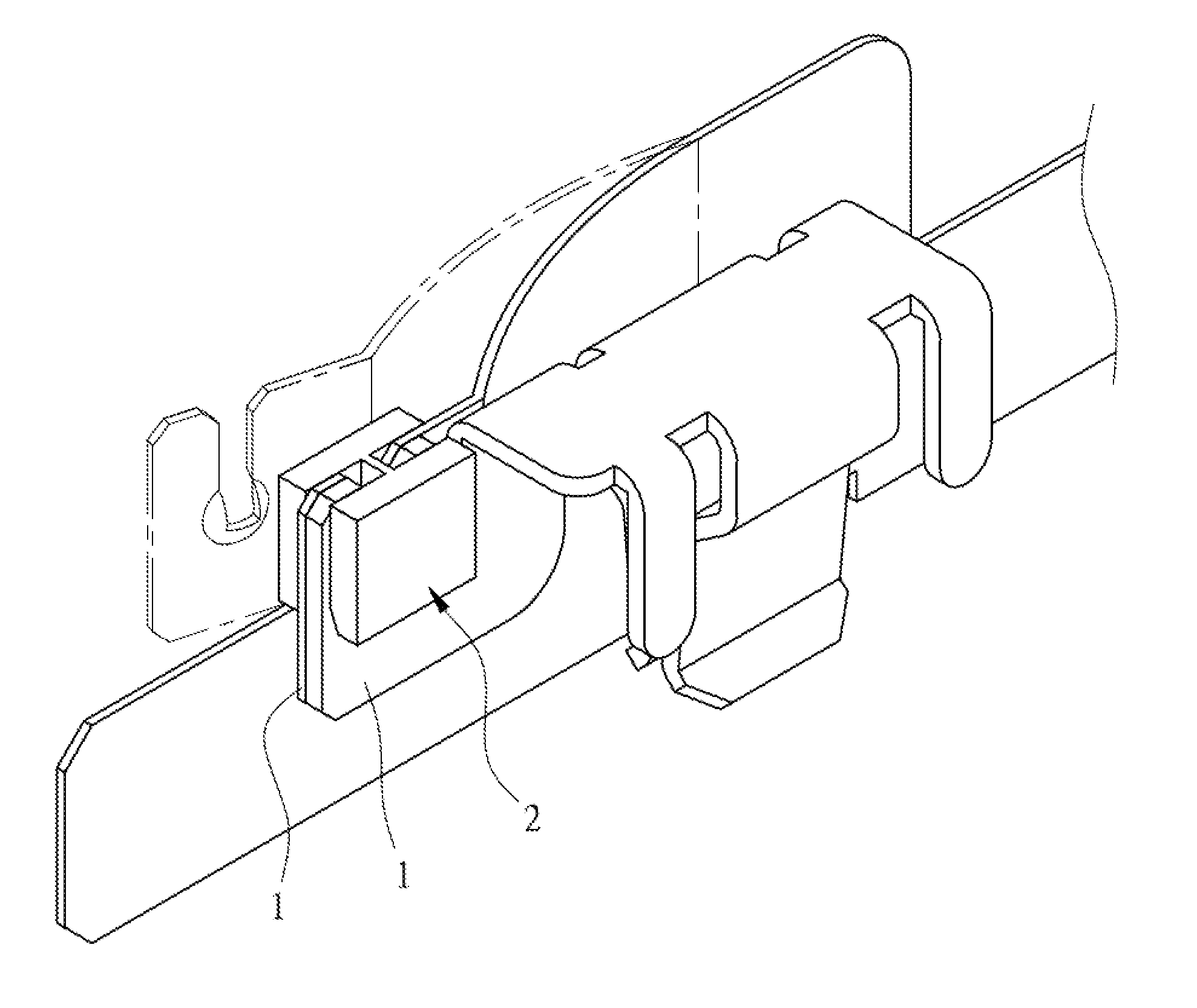

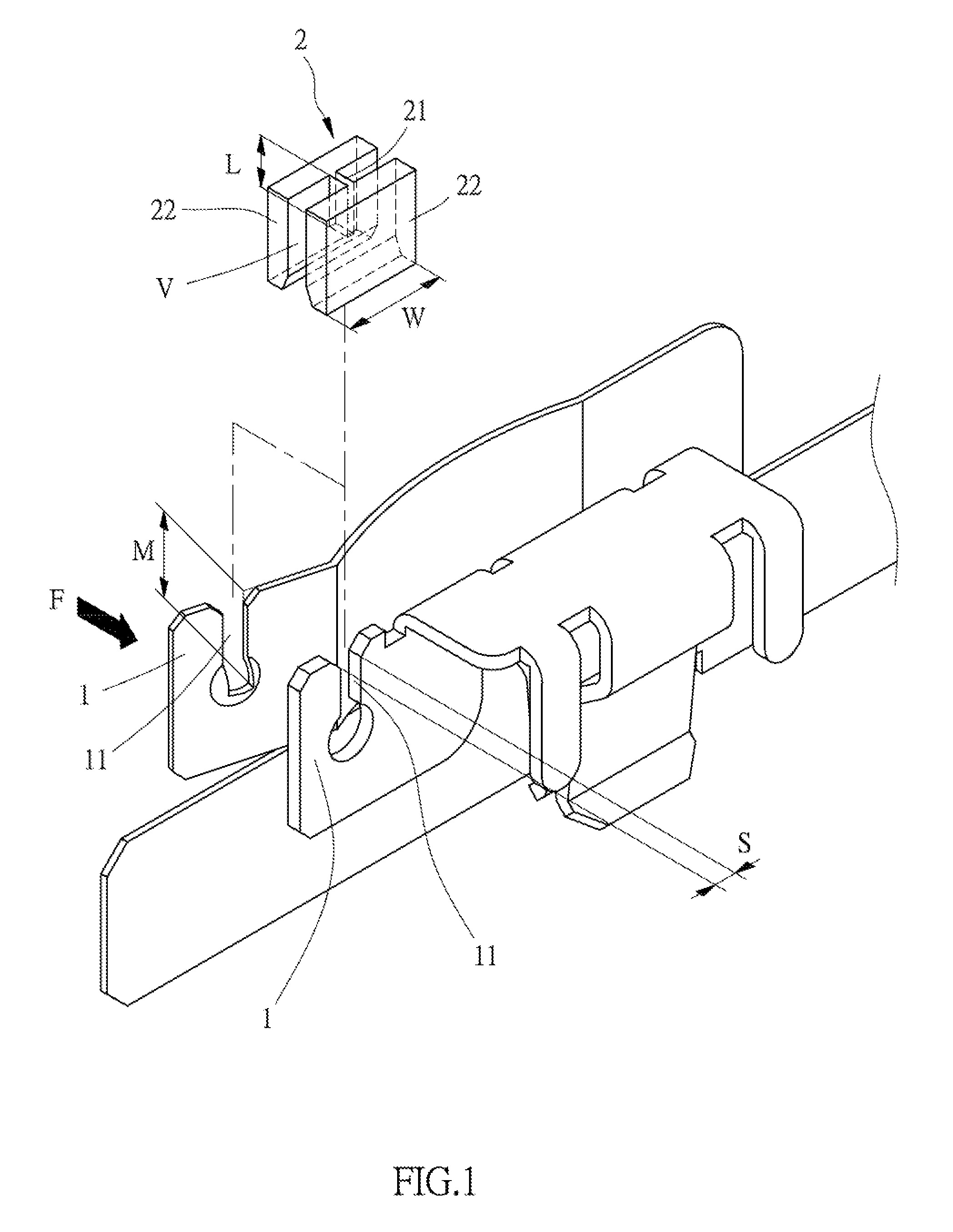

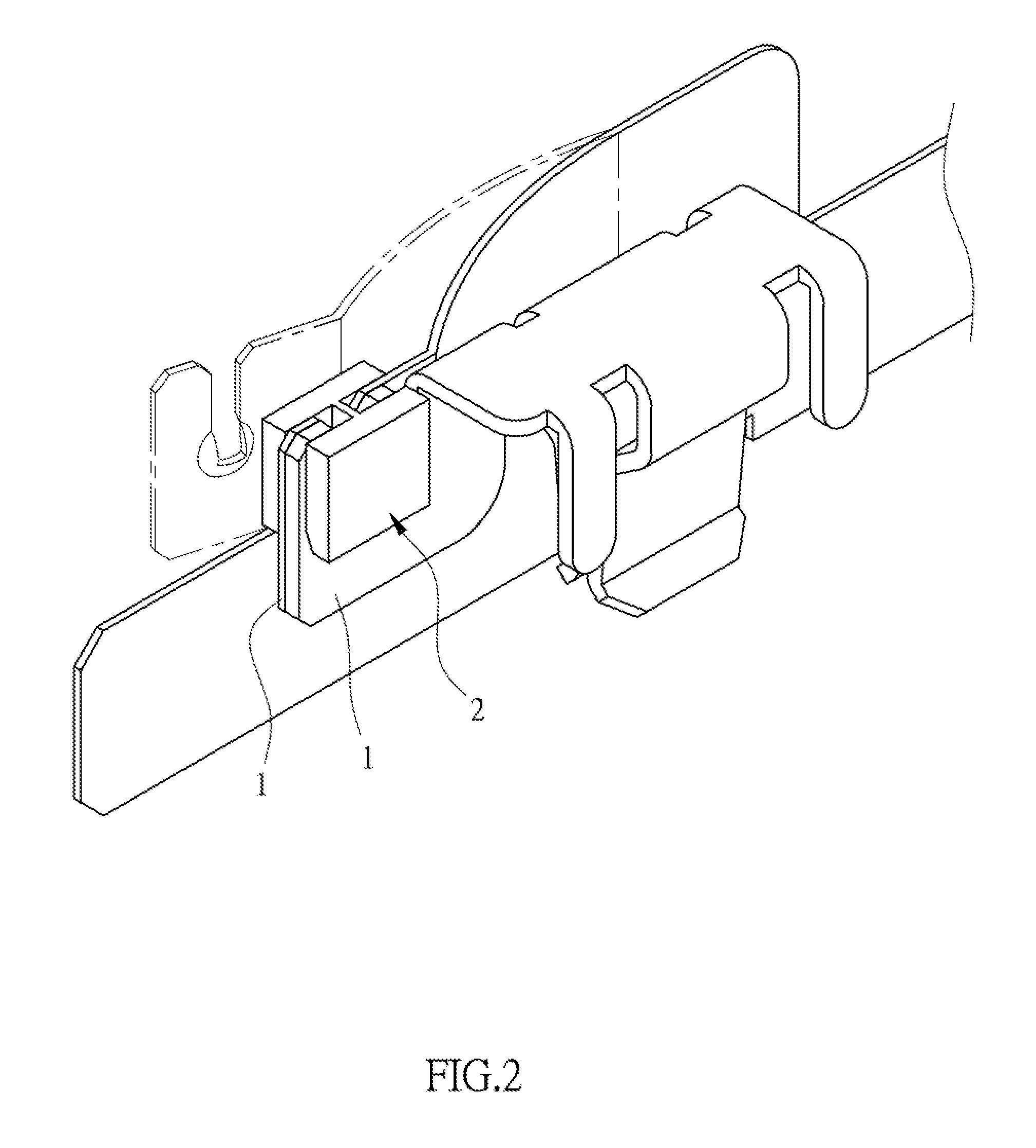

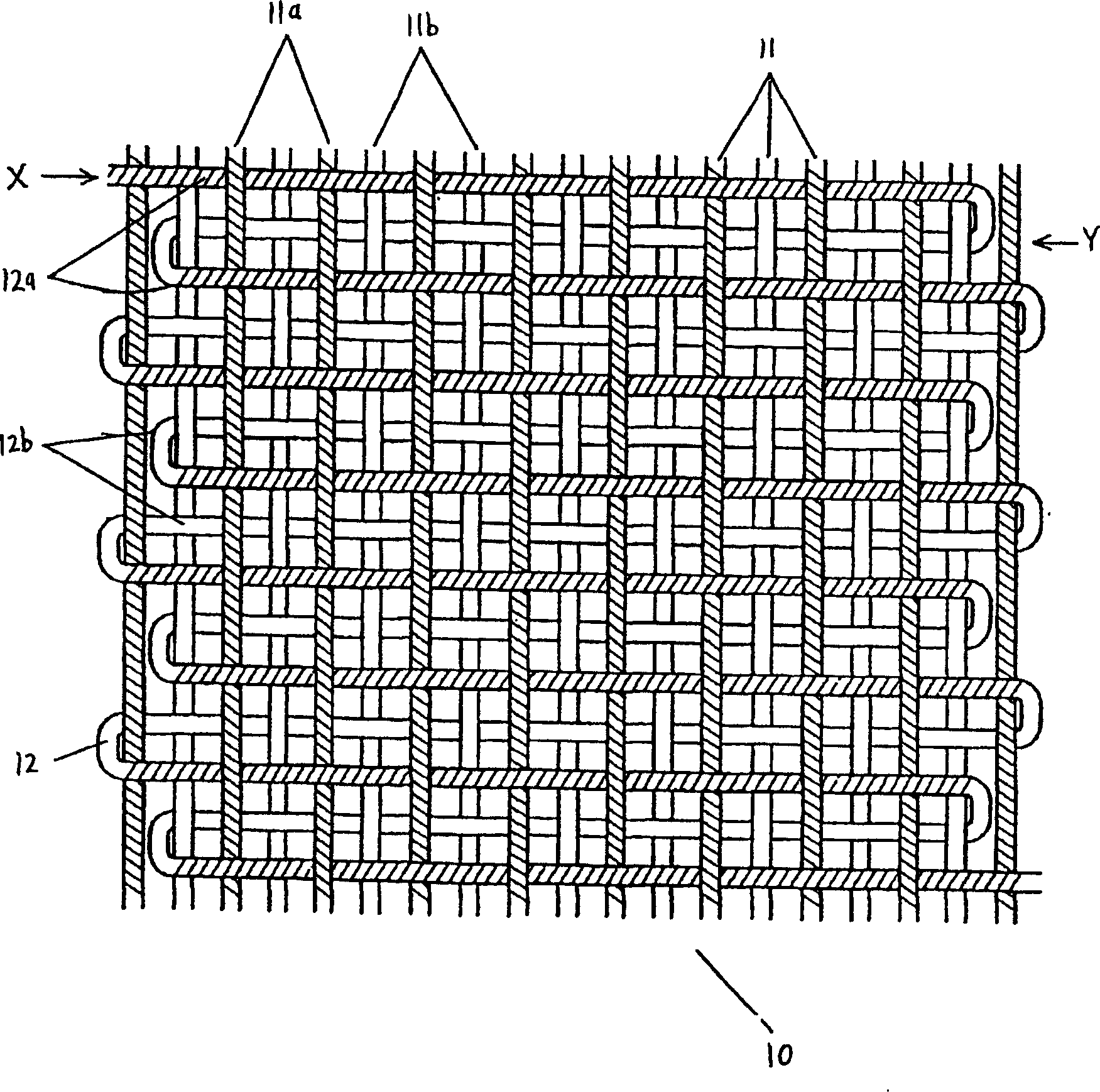

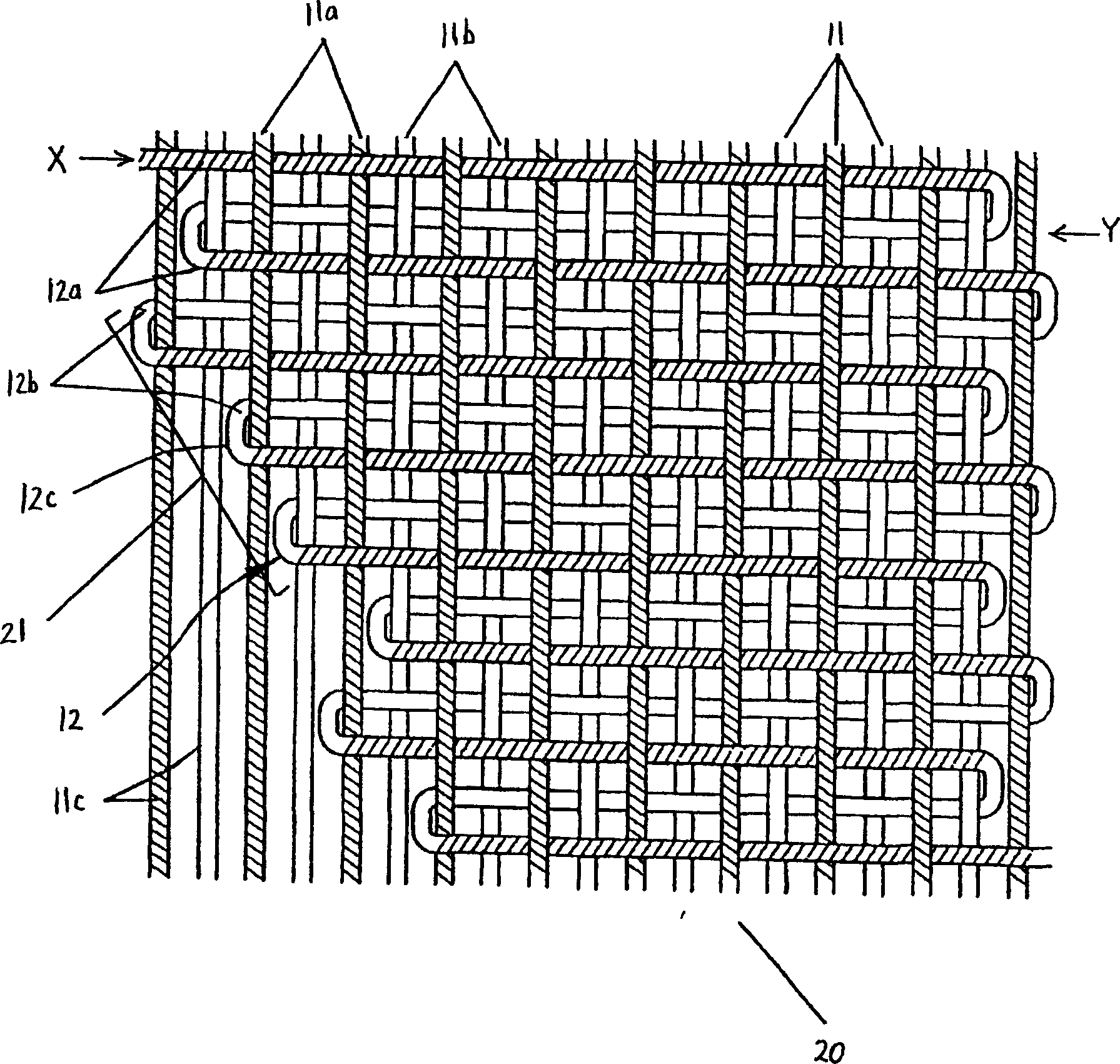

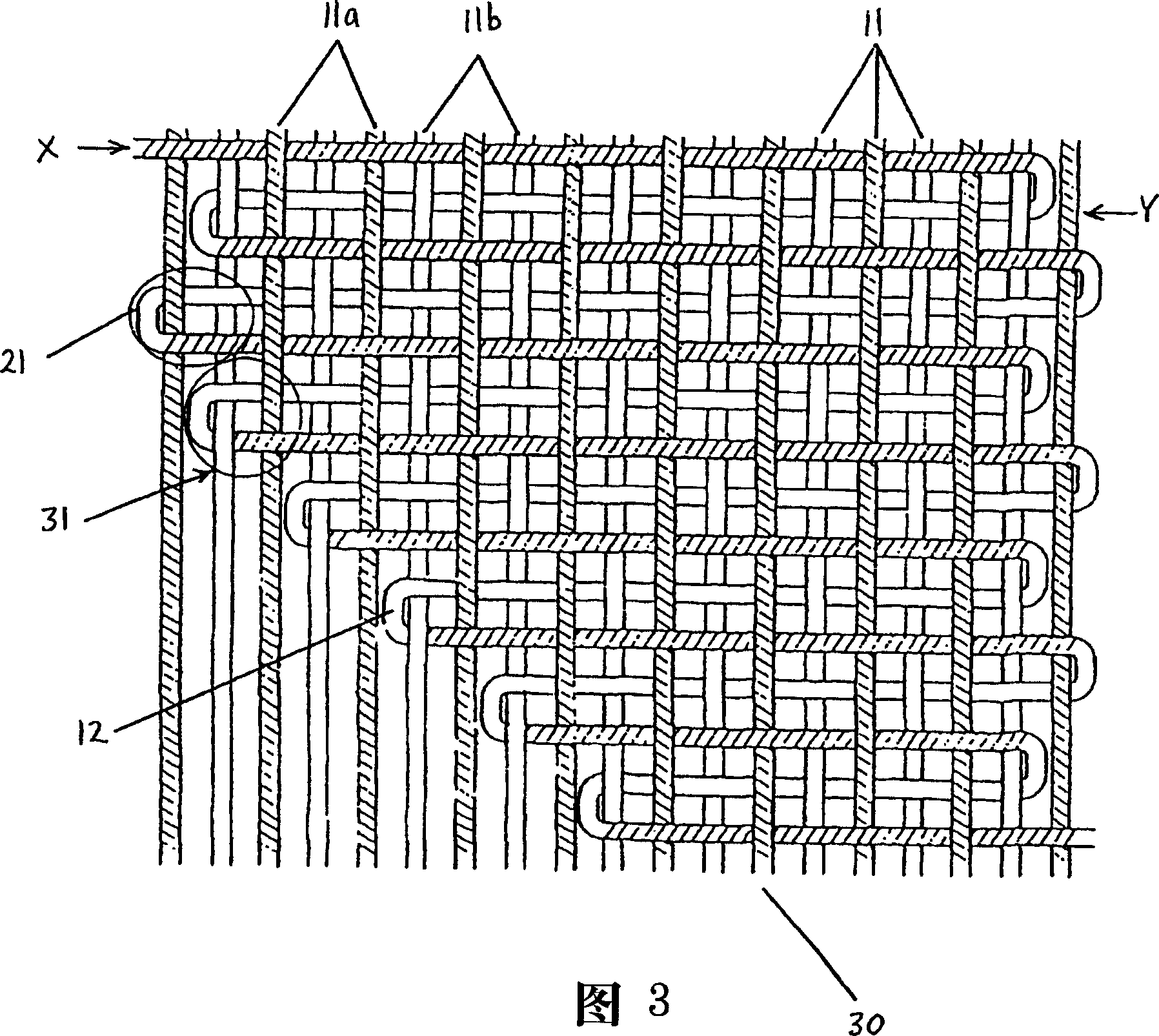

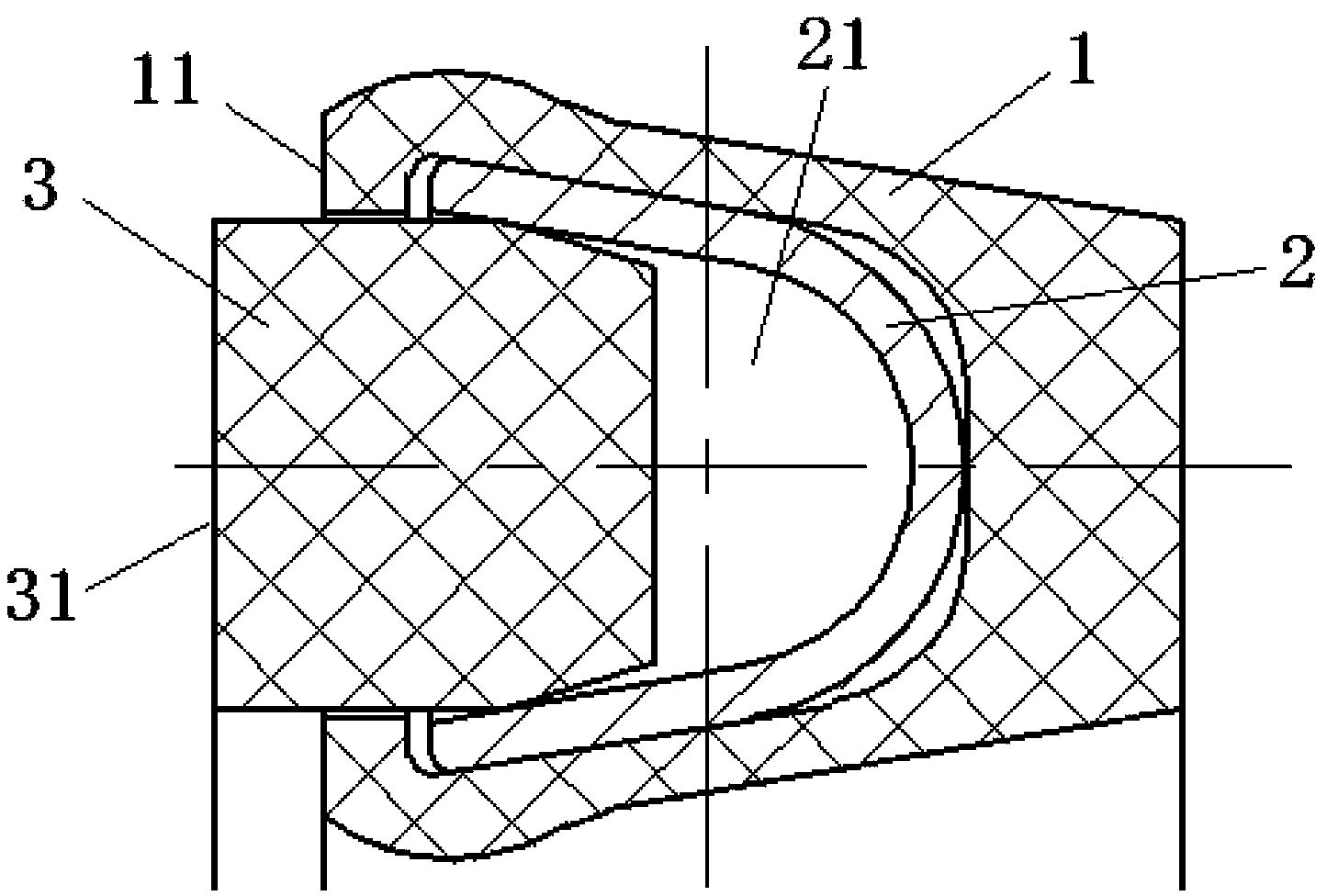

Pipe fixing system

InactiveUS20070272805A1Uniform elasticityImprove product reliabilityPipe supportsJoints with sealing surfacesCouplingEngineering

The present invention discloses a pipe fixing system that can provide generally uniform elasticity to a plurality of jaws movably disposed along the tapered inner peripheral surface at the inside of a body thereof, thus making a pipe fixed in a more rigid way. The pipe fixing system comprises a body 10, a plurality of jaws 20 in such a manner as to be moved toward an inlet 13 of the body 10, a jaw-coupling cylindrical plate spring member 30 mounted at the inside of the body 10 in such a manner as to be supported at the lower end thereof by the inner bottom surface of the body 10. The jaw-coupling cylindrical plate spring member 30 has a plurality of cut lines 32 formed vertically from distance from the lower end thereof to the middle portion thereof in such a manner as to be equally spaced at relatively narrow intervals in a circumferential direction, a plurality of elastic piece parts 33 each formed of a plate-like shape and each disposed between the two adjacent cut lines 32 in such a manner as to be bent outwardly to provide an elastic force toward the upper portion thereof, and a plurality of coupling holes 34 formed on the upper side of the plurality of elastic piece parts 33 for inserting the plurality of jaws 20 thereinto such that the plurality of jaws 20 are kept at a horizontal level.

Owner:WITHUS

Pipe fixing system

InactiveUS7484696B2Uniform elasticityImprove product reliabilityPipe supportsClosuresCouplingEngineering

The present invention discloses a pipe fixing system that can provide generally uniform elasticity to a plurality of jaws movably disposed along the tapered inner peripheral surface at the inside of a body thereof, thus making a pipe fixed in a more rigid way. The pipe fixing system comprises a body 10, a plurality of jaws 20 in such a manner as to be moved toward an inlet 13 of the body 10, a jaw-coupling cylindrical plate spring member 30 mounted at the inside of the body 10 in such a manner as to be supported at the lower end thereof by the inner bottom surface of the body 10. The jaw-coupling cylindrical plate spring member 30 has a plurality of cut lines 32 formed vertically from distance from the lower end thereof to the middle portion thereof in such a manner as to be equally spaced at relatively narrow intervals in a circumferential direction, a plurality of elastic piece parts 33 each formed of a plate-like shape and each disposed between the two adjacent cut lines 32 in such a manner as to be bent outwardly to provide an elastic force toward the upper portion thereof, and a plurality of coupling holes 34 formed on the upper side of the plurality of elastic piece parts 33 for inserting the plurality of jaws 20 thereinto such that the plurality of jaws 20 are kept at a horizontal level.

Owner:WITHUS

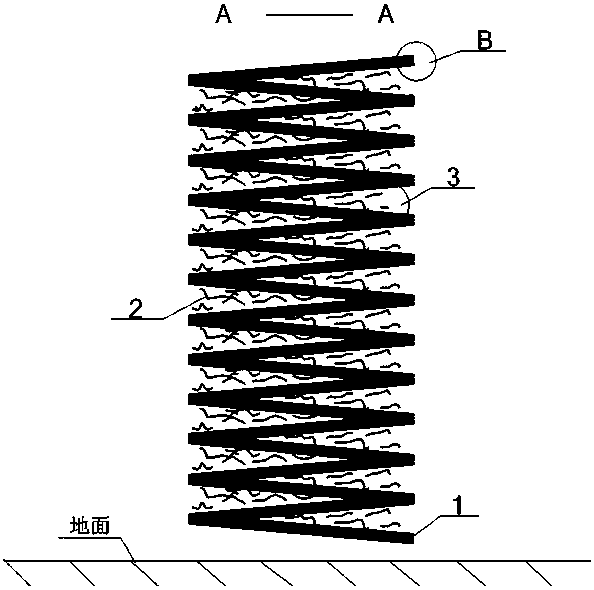

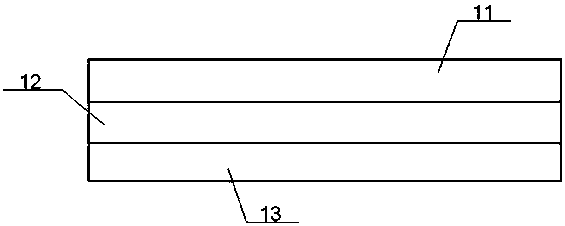

A kind of bionic honeycomb cotton and its manufacturing method

A bio-inspired cellular cotton comprises a plurality of bio-inspired cellular cotton sub-layers repeatedly and sequentially stacked in a zigzag fashion in a vertical direction. The bio-inspired cellular cotton sub-layers are successively connected end to end. An acute included angle is formed between adjacent bio-inspired cellular cotton sub-layers. Long filaments are disposed side-by-side with an equal distance therebetween on both surfaces of the bio-inspired cellular cotton sub-layer in a width direction thereof. The bio-inspired cellular cotton sub-layer is manufactured by mixing, loosening, carding and web-forming a fiber material. The bio-inspired cellular cotton sub-layer can be formed by sequentially stacking from top to bottom an upper layer of fiber web, an elastic fiber web and a lower layer of fiber web, disposing the filaments on both surfaces of the bio-inspired cellular cotton sub-layer, and then sequentially performing drying, trimming and winding to form the bio-inspired cellular cotton. The design is highly elastic, simple in structure, low-cost and environmentally friendly.

Owner:TENGFEI TECH CO LTD

Conductive terminal

The present invention discloses a conductive terminal including two conductive members or further comprising a hot melt fixing member. Each conductive member is provided with a groove which is concaved in from an edge of the host conductive member. The grooves on the two conductive members are opposite to each other and a gap is maintained between the two conductive members by an elastic force between the conductive members. The hot melt fixing member is put into the grooves of the two conductive members and is combined on the conductive members to overcome the elastic force, enabling the two conductive member to form contact limit, the hot melt fixing member to be damaged when overheat, and the two conductive members to be opened by the elastic force to form open circuit. The conductive member can be applied to overheat protection of a plug and a socket.

Owner:GREEN IDEA TECH INC

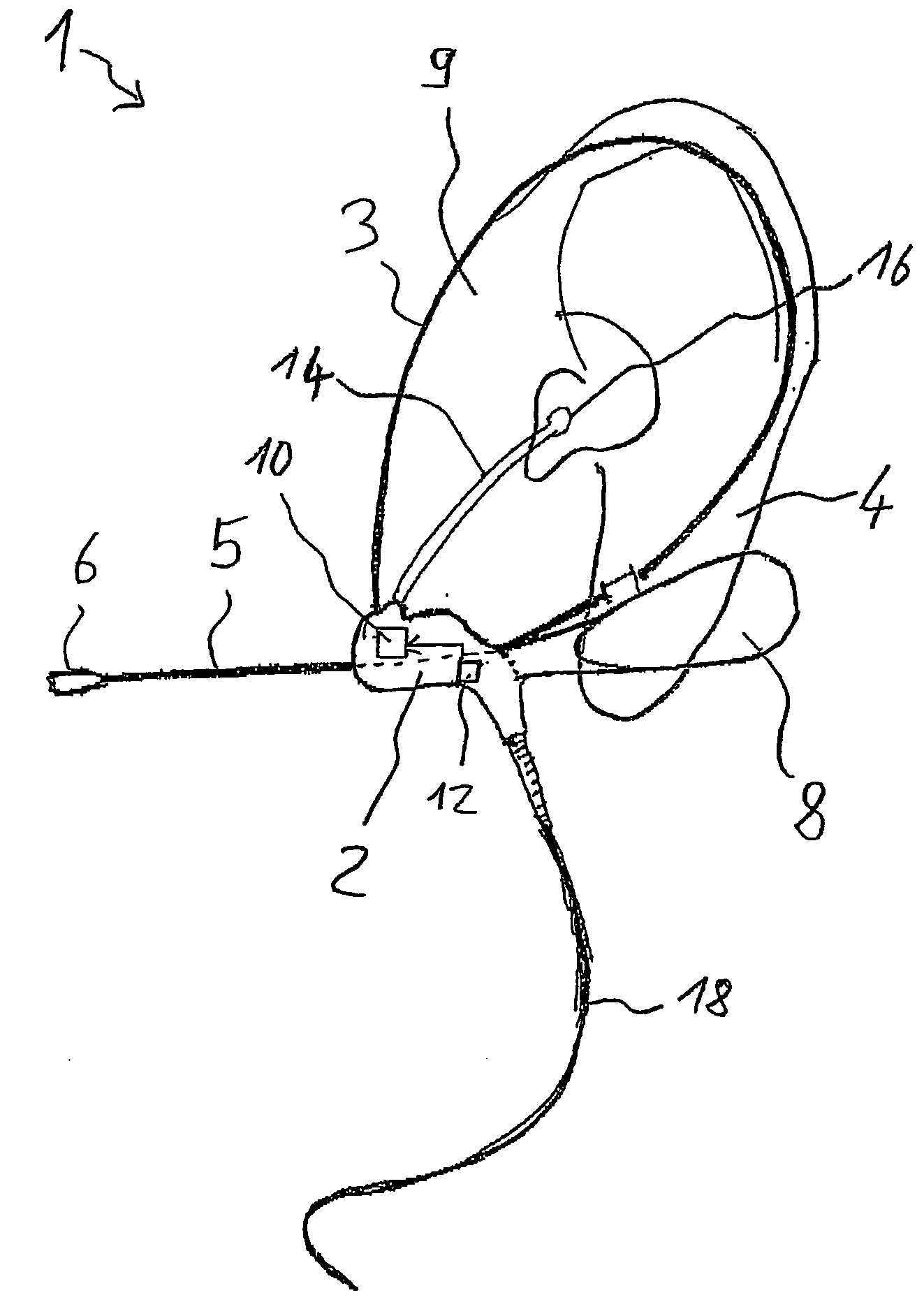

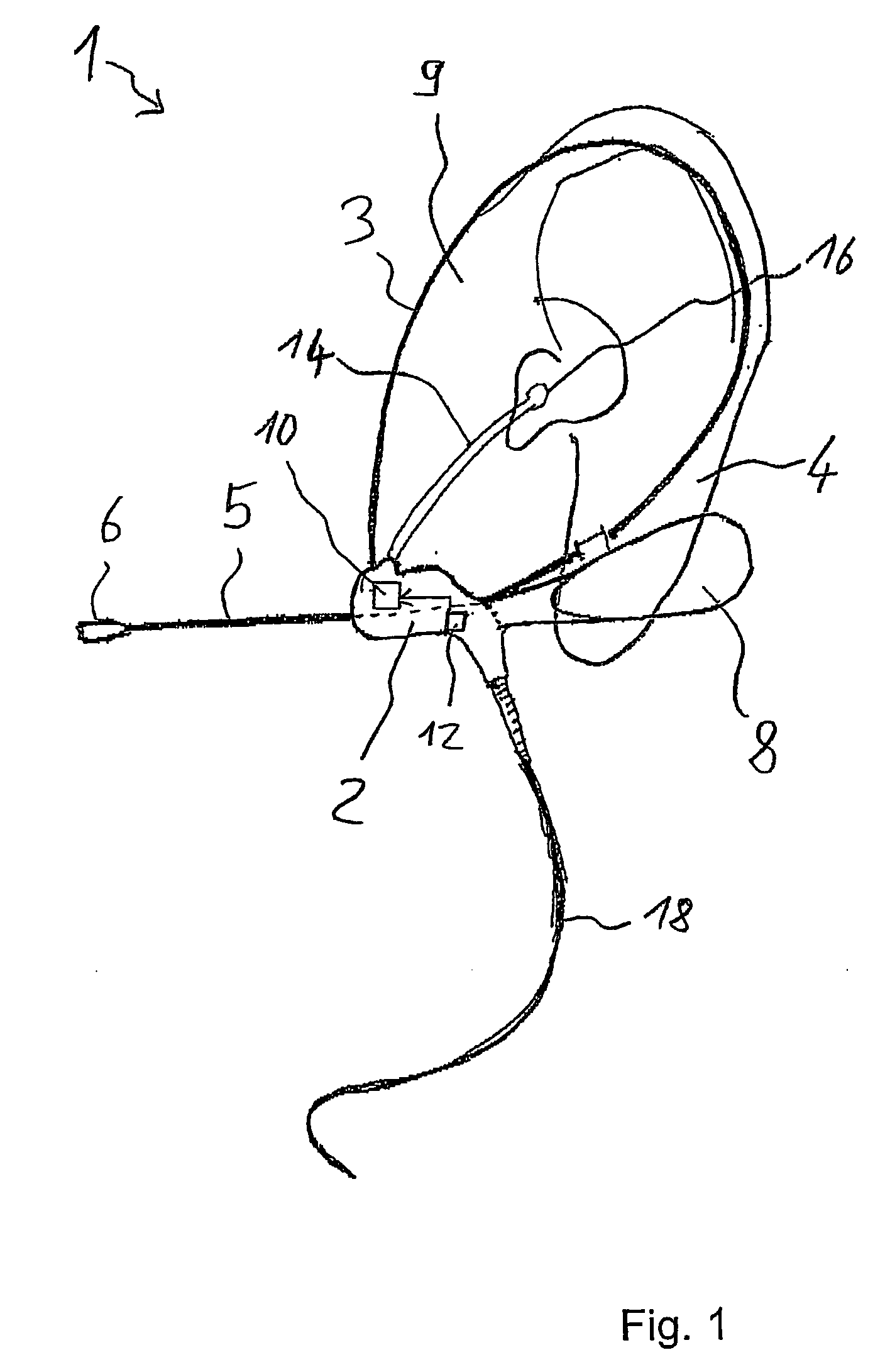

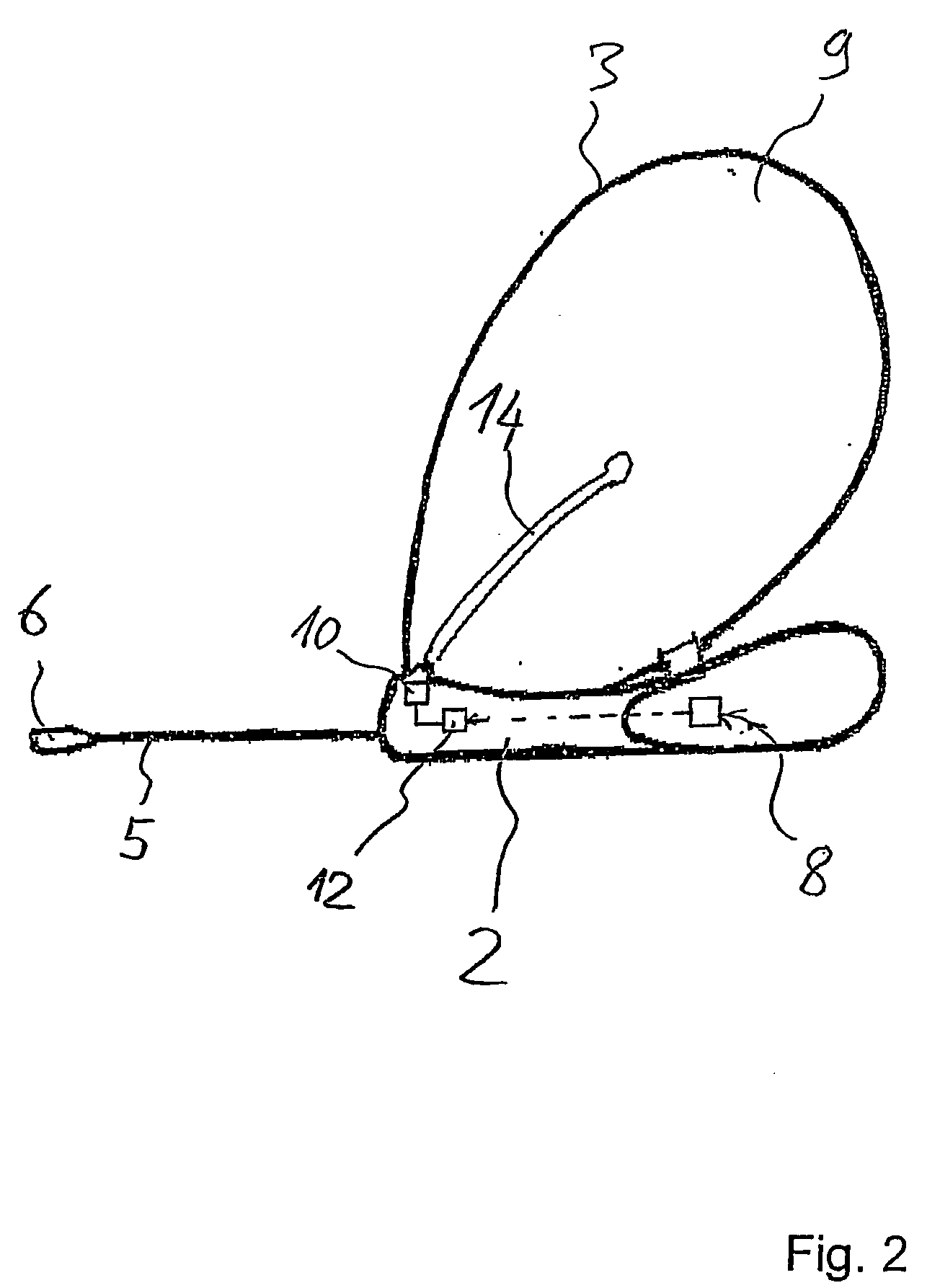

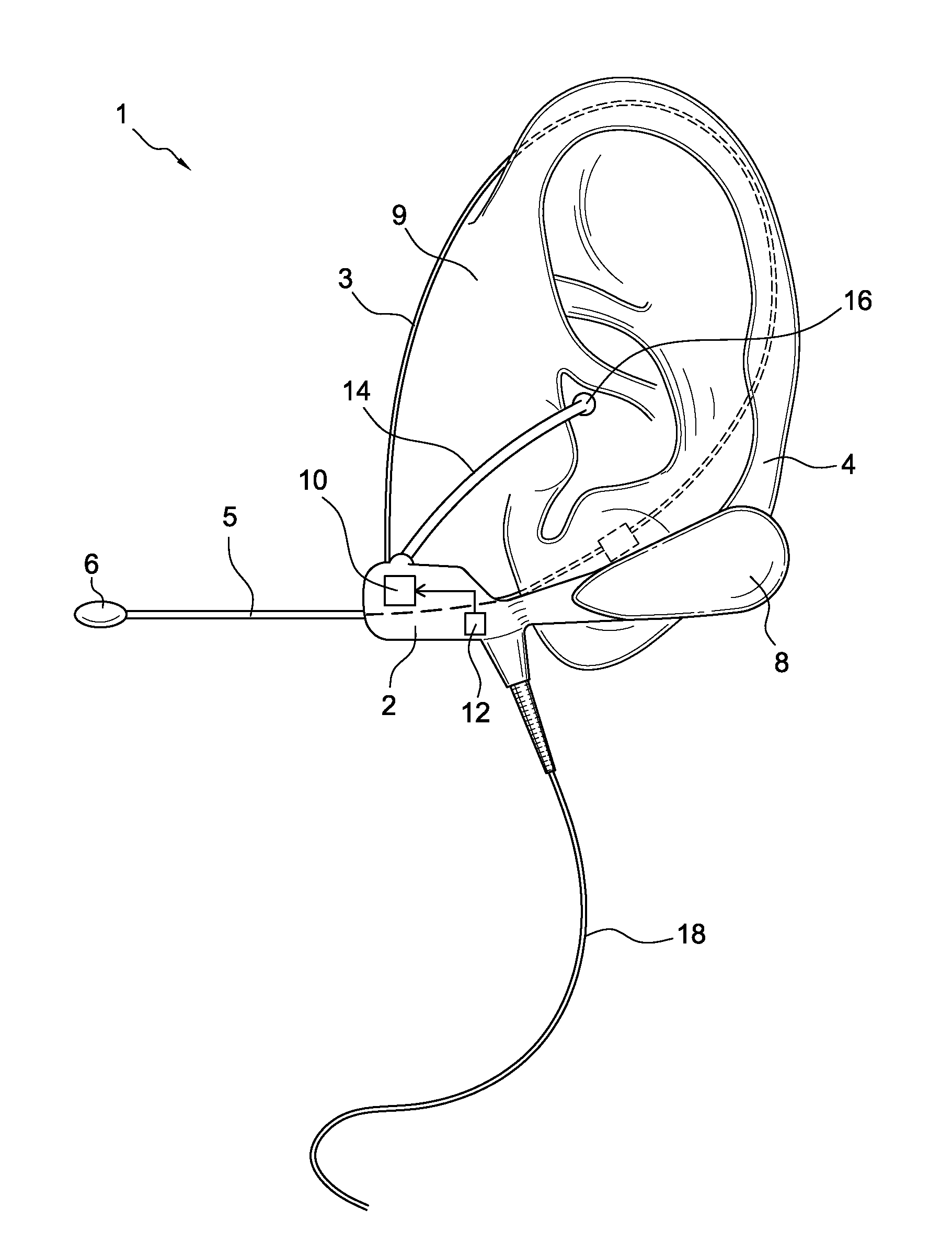

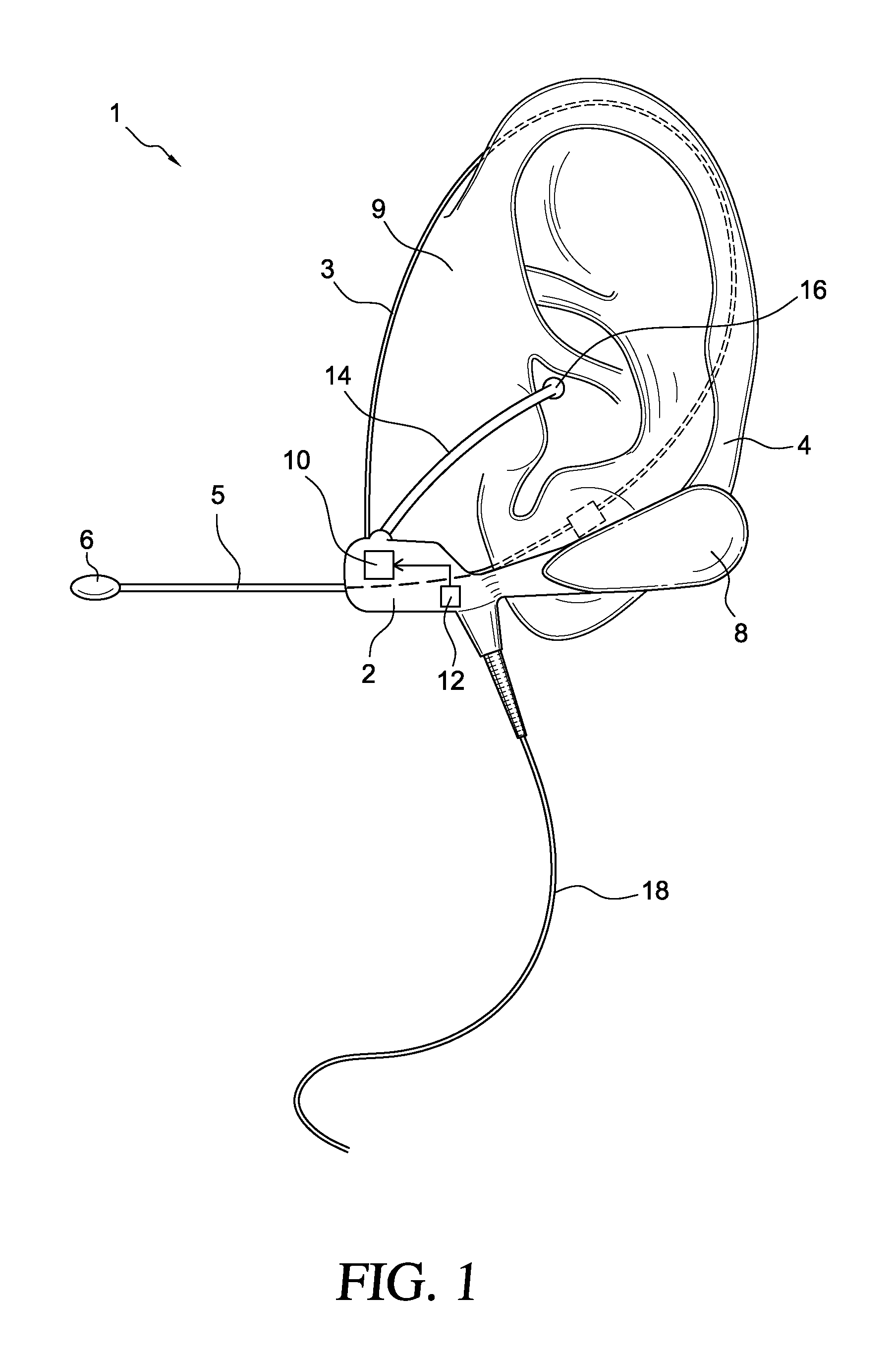

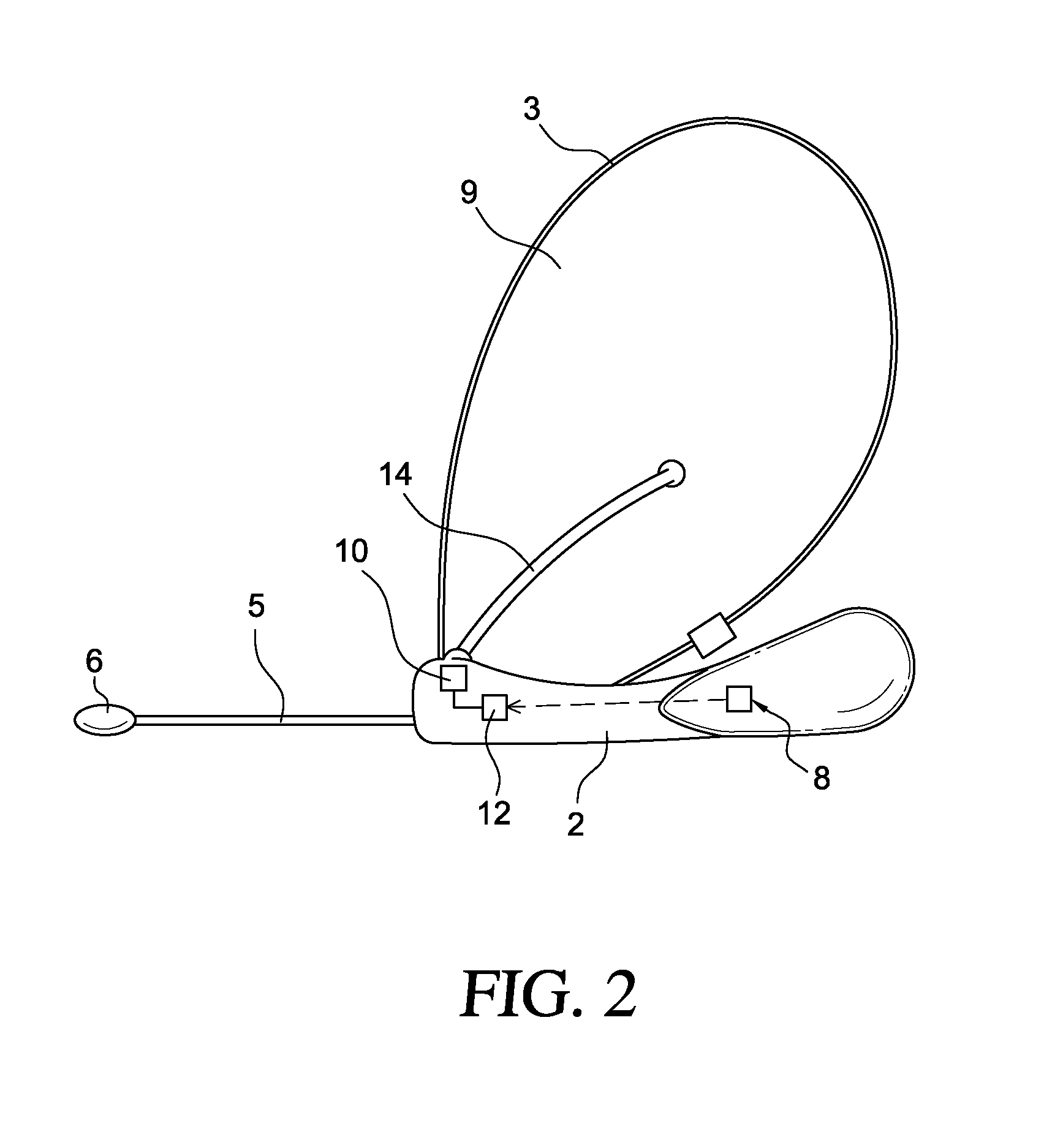

Headset for fitting of an earpiece

InactiveUS20090103765A1Ensure safe positioningAvoid adjustmentMicrophonesEar supported setsEngineeringHeadphones

Headset for fitting an earpiece that has a lock housing in or on which a fixing device is provided. A flexurally rigid and elastic ear loop which forms a loop for accommodating the outer ear of a user, and one end of the ear loop is received longitudinally displaceable in the fixing device of the lock housing, and for adjusting the size of the loop is adjustably received in various length positions, creating a fixing effect. There is a control device for receiving and outputting electrical signals and a signal interface for receiving and / or outputting electrical signals to and / or from the control device.

Owner:BRUCKHOFF APPBAU

Peach tree grafting device

The invention relates to the field of planting, in particular to a peach tree grafting device. The peach tree grafting device comprises a fixed barrel and a cutting mechanism, wherein an air bag is fixed on the inner periphery of the fixed barrel, a fixed cavity communicated with the air bag is formed in the side wall of the fixed barrel, a fixed piston is glidingly connected into the fixed cavity, and fixed springs are further arranged in the fixed cavity; the cutting mechanism comprises a cutting barrel, a scion cutter, a rotating shaft and a stock cutter, positioning holes are formed in oneend of the fixed barrel, and positioning rods are fixed on the cutting barrel; the rotating shaft is in thread fit with the cutting barrel, rolling balls are arranged between the rotating shaft and the cutting barrel, and the stock cutter is fixed on one side, close to the fixed barrel, of the rotating shaft; a scion cutting tank is arranged on the rotating shaft, and the scion cutter is spiral and is fixed on the inner wall of the scion cutting tank. The grafting device in the scheme can cut scions and the stock simultaneously.

Owner:宿州市睿鼎信息科技有限公司

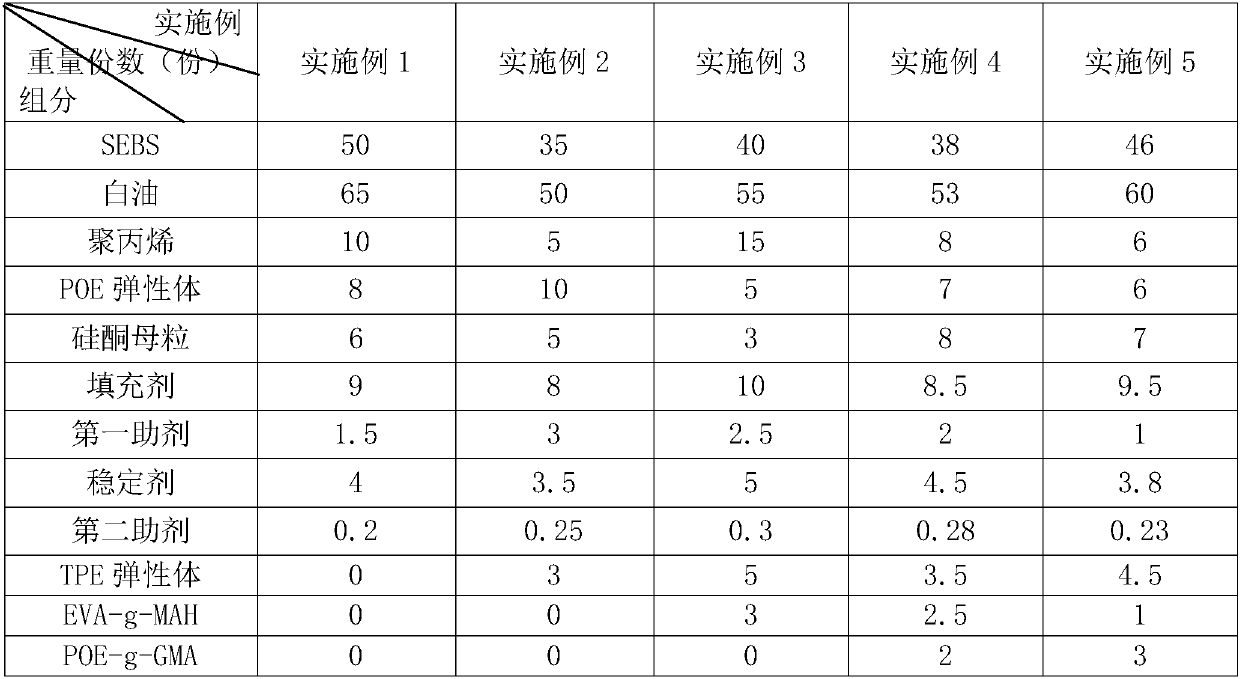

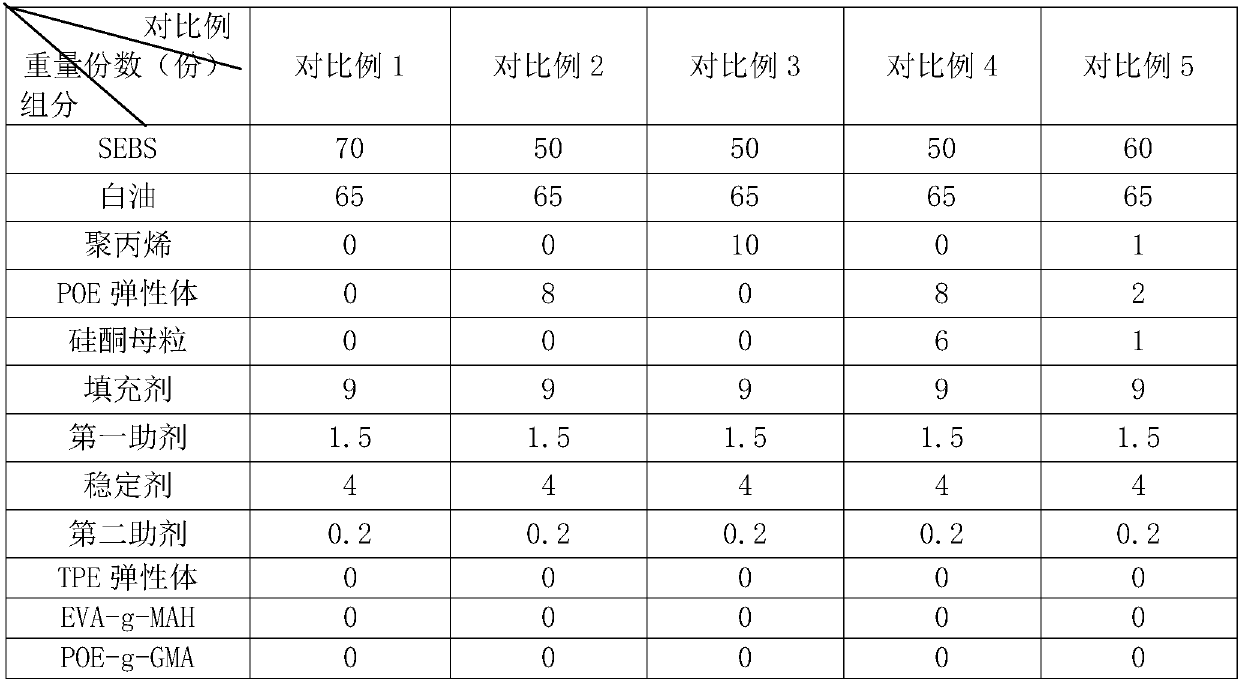

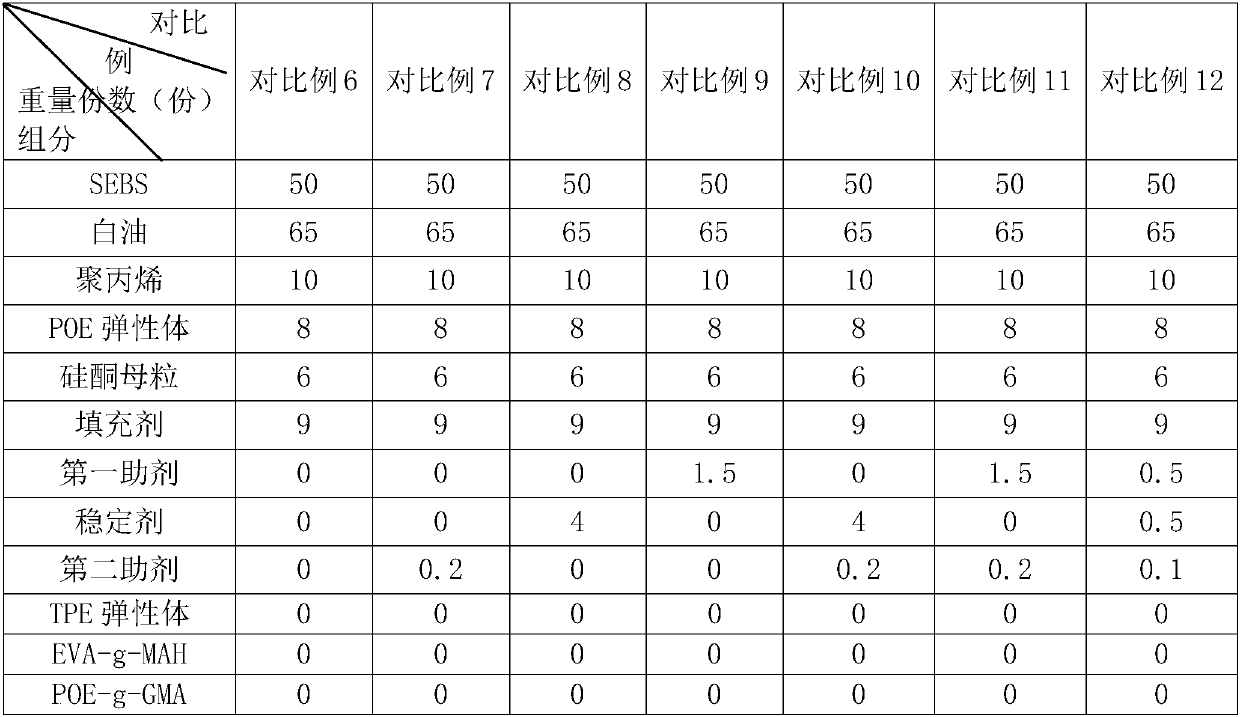

Thermoplastic elastomer specially used for yoga belt and preparation process thereof

The invention discloses a thermoplastic elastomer special for a yoga belt and a preparation process thereof, and belongs to the technical field of plastic materials. The thermoplastic elastomer comprises 35-50 parts of SEBS; 50-65 parts of white oil, 5-15 parts of polypropylene, 5-10 parts of a POE elastomer, 3-8 parts of silicone masterbatch, 8-10 parts of a filler, 1-3 parts of a first auxiliary, 3-5 parts of a stabilizer and 0.2-0.3 part of a second auxiliary. The first auxiliary includes at least one of erucylamide and oleamide. The second auxiliary includes at least one of an anti-ultraviolet absorbent and an antioxidant. The thermoplastic elastomer has advantages of excellent elasticity, strength and toughness, no odor and good touch sense.

Owner:浙江耀隆塑业有限公司

Headset for fitting of an earpiece

InactiveUS7983439B2Ensure safe positioningAvoid adjustmentMicrophonesEar supported setsEngineeringHeadphones

Headset for fitting an earpiece that has a lock housing in or on which a fixing device is provided. A flexurally rigid and elastic ear loop which forms a loop for accommodating the outer ear of a user, and one end of the ear loop is received longitudinally displaceable in the fixing device of the lock housing, and for adjusting the size of the loop is adjustably received in various length positions, creating a fixing effect. There is a control device for receiving and outputting electrical signals and a signal interface for receiving and / or outputting electrical signals to and / or from the control device.

Owner:BRUCKHOFF APPBAU

Preparing method of high-performance polyurethane buffer cushion

The invention discloses a preparing method of a high-performance polyurethane buffer cushion. The preparing method sequentially comprises the steps of antibiosis polyol preparing, prepolymer preparing, blending, casting moulding and vulcanizing. In the step of antibiosis polyol preparing, polyester polyol from plants is adopted, and self-made traditional Chinese medicine antibiosis composition is added in the preparing process. In the step of prepolymer preparing, low-single-alcohol polyol is adopted as polyether polyol, and nano glass micro powder and modified isocyanate are added in the preparing process. The raw materials for preparing the high-performance polyurethane buffer cushion mostly stem from the plants, and therefore the environment load can be reduced for responding to the social tendency facing the global environment protection recently. The high-performance polyurethane buffer cushion has balanced hardness, rebound resilience, superior durability and good antibacterial capability.

Owner:江苏向阳科技有限公司

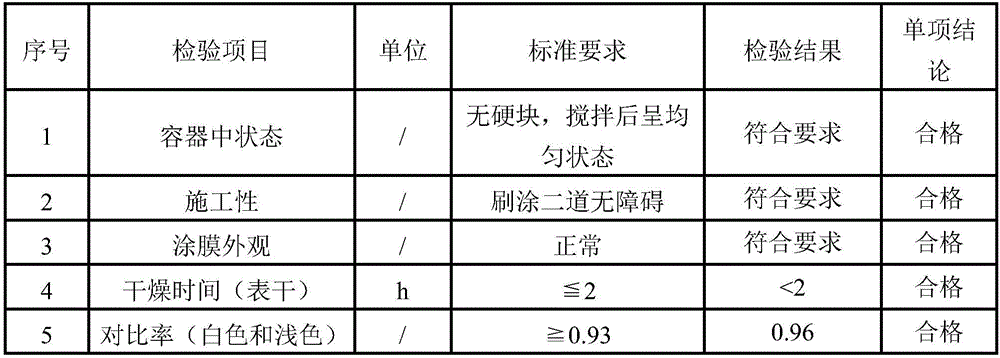

Antifouling dry-powdered emulsion paint and preparation method thereof

The invention relates to an antifouling dry-powdered emulsion paint. Global hardness is provided by the utilization of network-like mineral formed by white cement hydration; an ash-calcium modifying agent is added to improve properties of ash-calcium, and ash-calcium is carbonized to generate netted calcium carbonate which interpenetrates to reinforce middle and late hardness; supported by VAE redispersible latex powder, the system's flexibility and elasticity are improved; by the addition of a composite water reduction material, it is guaranteed that various materials are uniformly dispersed in the system, and micropore structure of the system is improved; by the addition of talcum powder and kaolin, construction performance is improved; by the addition of hydroxyethyl cellulose ether, the system's denseness and water retention capacity are increased; by the introduction of superfine nano-silica, compactness of the system is improved; by the addition of a water repellent, the coating is endowed with overall waterproofing property; and polyaluminum chloride is further added to react with calcium hydroxide in the system so as to generate expansile aluminium hydroxide and hydrated chloroaluminate. Thus, the coating becomes a compact integral body and has strong antifouling performance and good air permeability.

Owner:许英男

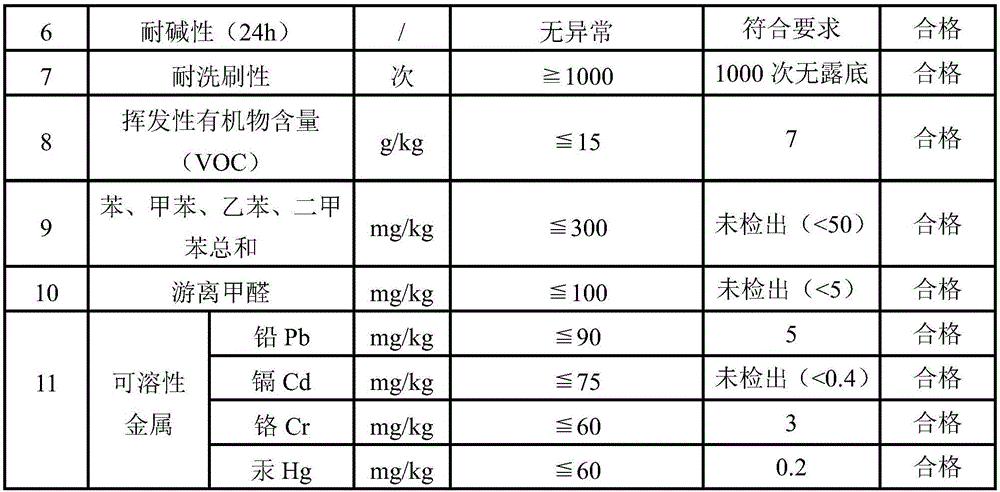

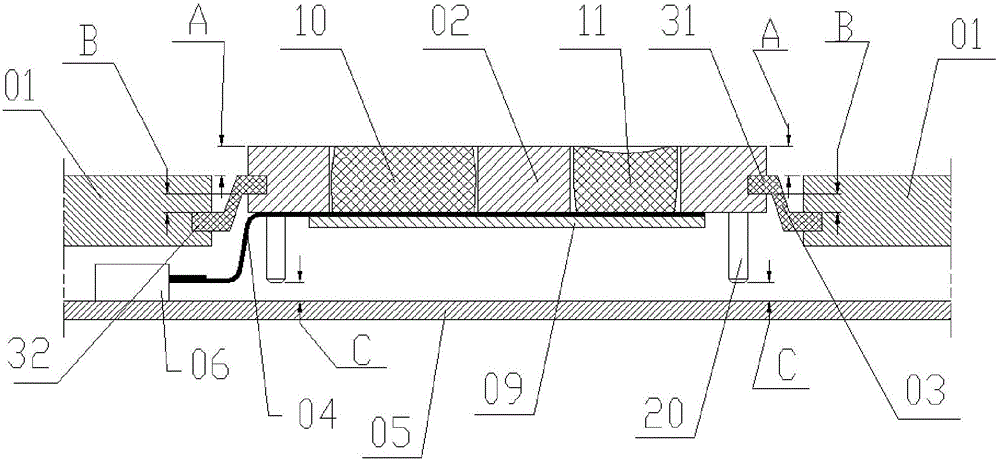

Wrist accessory-free blood oxygen measurement equipment capable of being attached to skin automatically and manufacturing method of wrist accessory-free blood oxygen measurement equipment

ActiveCN105919602ASimple structureImprove performanceDiagnostic recording/measuringSensorsContact forceLight-emitting diode

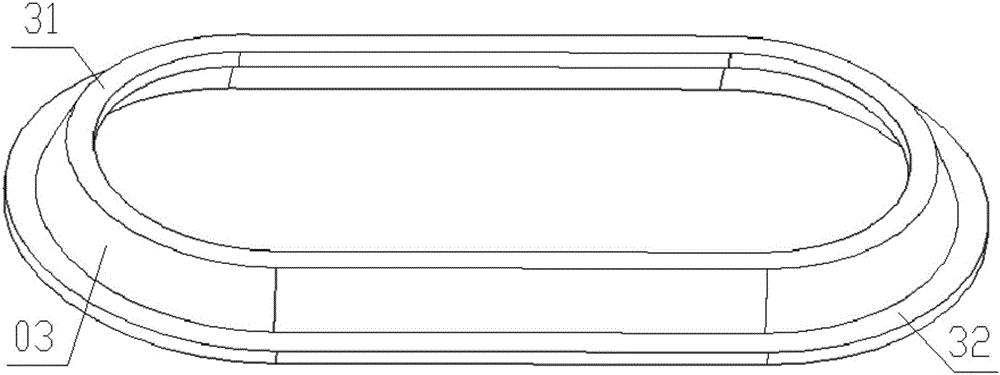

The invention discloses wrist accessory-free blood oxygen measurement equipment capable of being attached to skin automatically. The wrist accessory-free blood oxygen measurement equipment comprises a casing (01), a PCBA (printed circuit board assembly) circuit mainboard (05) and an FPC (flexible printed circuit) (04) arranged on the PCBA circuit mainboard (05), wherein a photosensitive sensor (10) and a red / infrared dual-light-source light emitting diode (11) are arranged on the FPC (04); an FPC bearing part (02) is further arranged on the FPC (04); the casing (01) and the FPC bearing part (02) are connected into a whole through an elastic arm (03); the elastic arm (03) adopts a hollow ring ladder shape and is big-end-down. The contact force of a signal collecting part and the skin can be automatically regulated by the elastic arm (03) and can automatically adapt to the wrist diameter, and the attachment degree of signal collection is guaranteed, so that the comfort level of wearing and the accuracy of blood oxygen measurement are remarkably improved.

Owner:CHENGDU ICARETECH

Heat setting device of pillow core

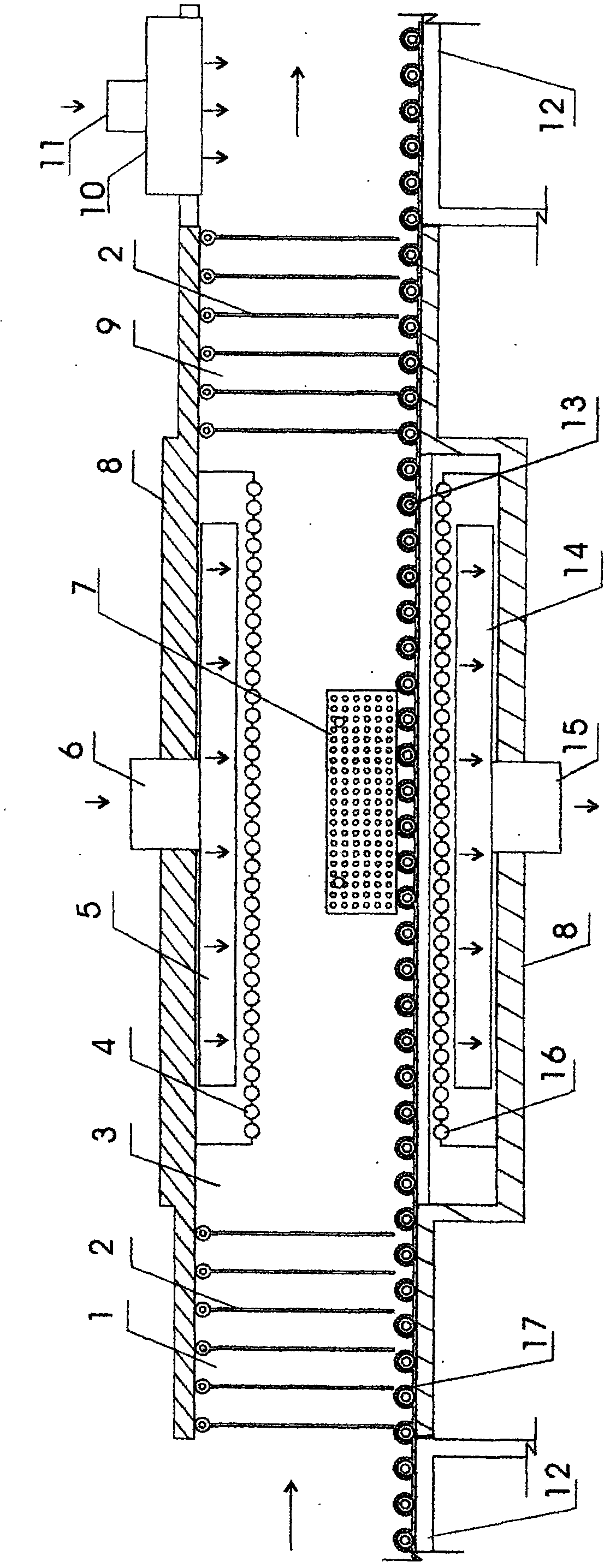

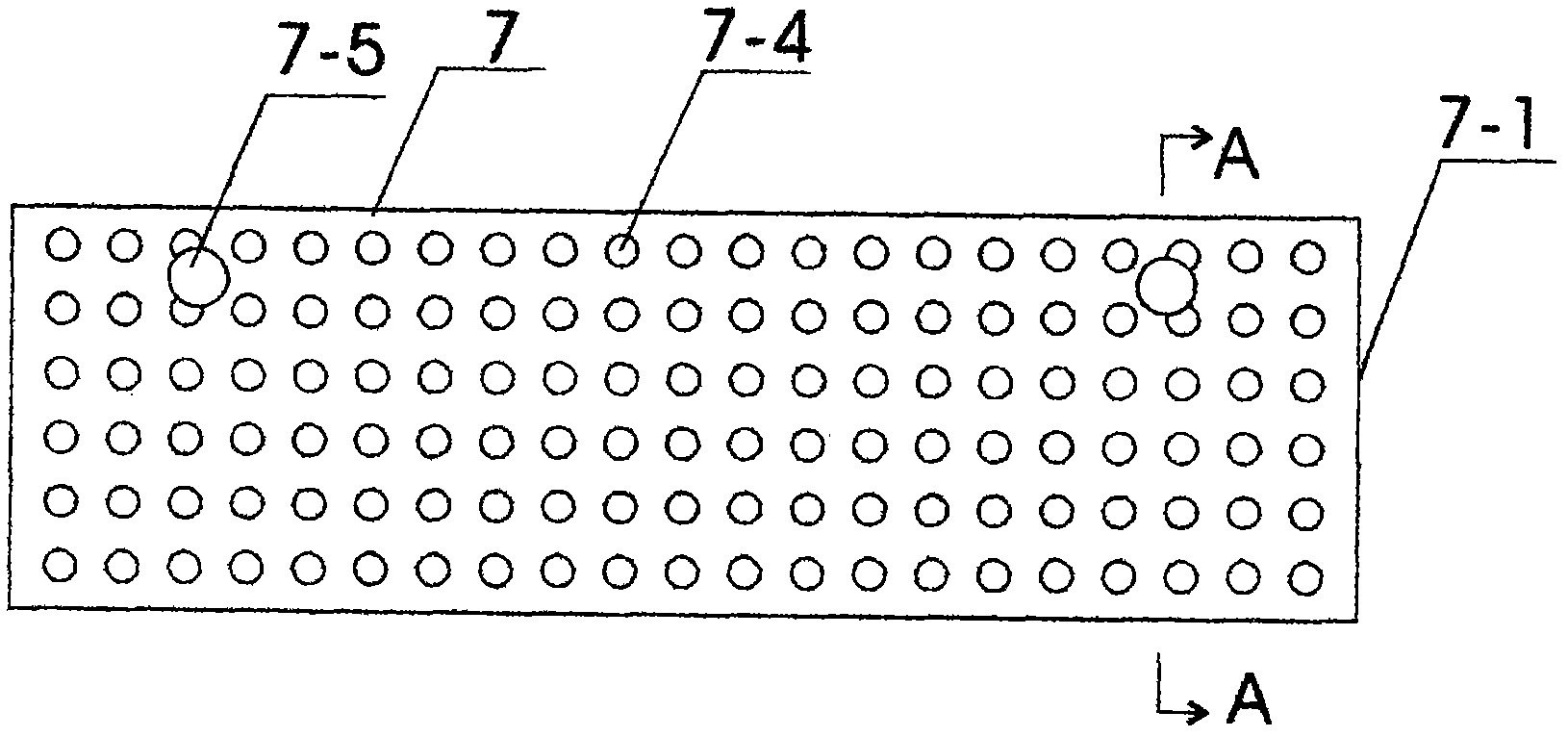

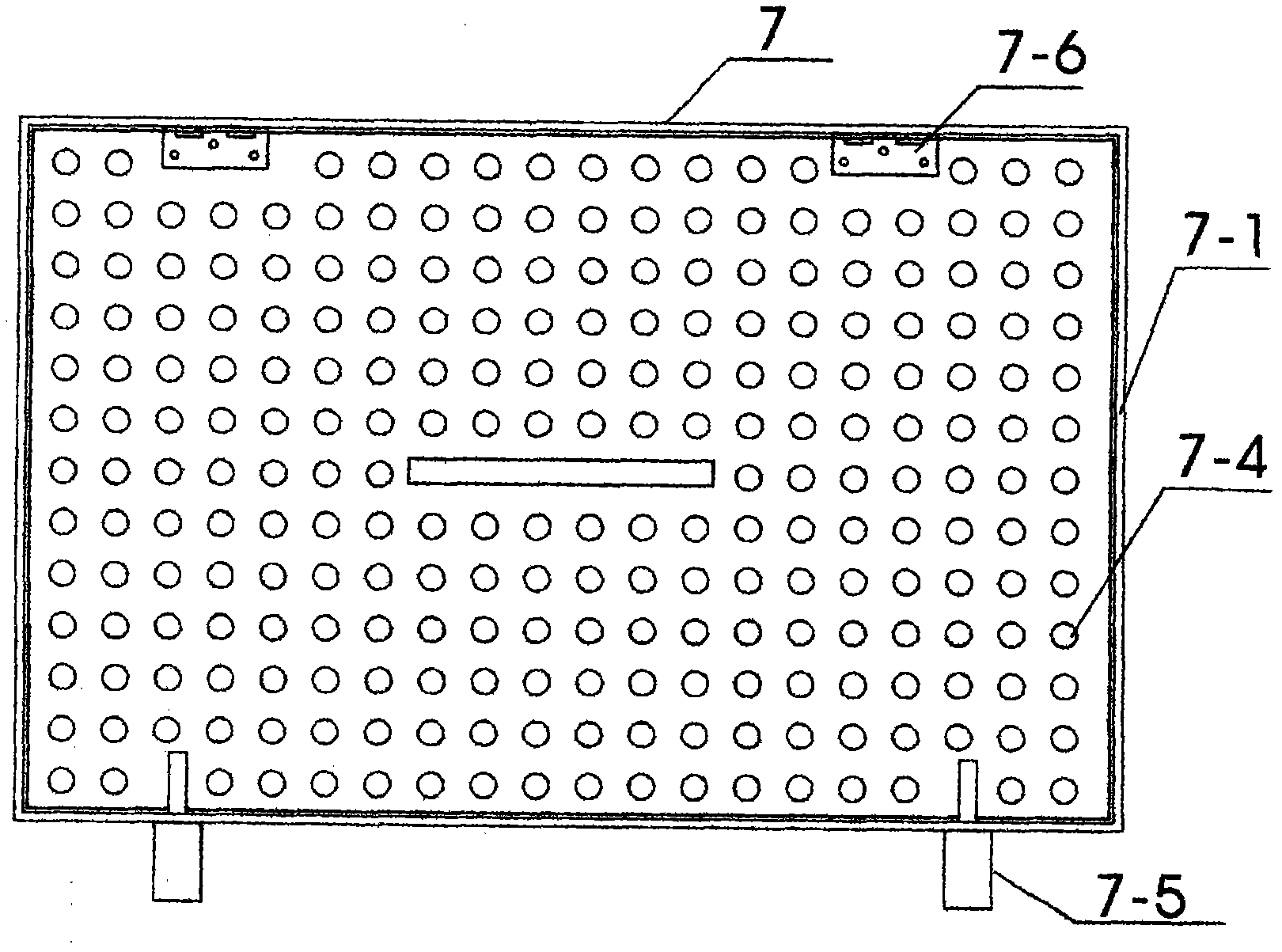

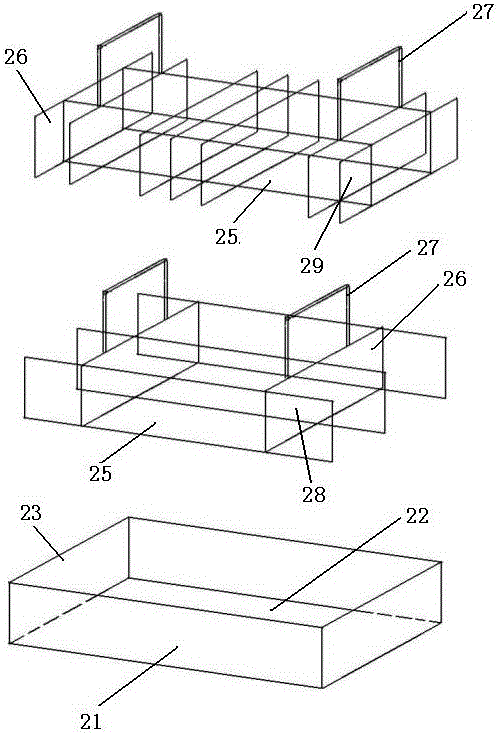

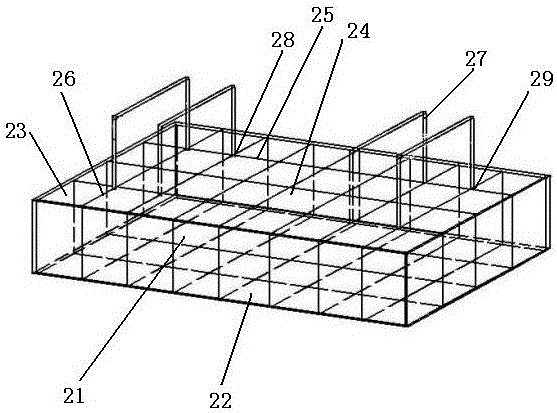

ActiveCN102029707AComfortable pillowAccelerated heat-melt setting timeDomestic articlesCold airTemperature control

The invention discloses a heat setting device of a pillow core, which enables a pillow core which uses loose materials of blended fiber cotton as main raw materials to quickly realize heat setting of the whole pillow core, thereby greatly improving the elastic comfort, product quality and production efficiency of the pillow core. The device has obvious energy-saving effect. The device comprises aheating furnace, a roller type conveying belt, a hot air circulating system, a heat setting mold and a cold air cooling device, wherein the heating furnace comprises a middle furnace chamber, a left furnace chamber and a right furnace chamber; the middle furnace chamber is provided with the hot air circulating system in the vertical direction; the upper part and the lower part of the middle furnace chamber are respectively provided with a row of far-infrared heating pipes; the heat setting mold on which a plurality of ventilated through holes are distributed is placed on the conveying belt; the left furnace chamber and the right furnace chamber are respectively provided with multiple movable heat insulation doors which are mutually parallel and are vertically arranged; the cold air cooling device is arranged above the outlet of the right furnace chamber; and the heating furnace, the conveying belt, the hot air circulating system and the cold air cooling device are fully automatically controlled by a program controller and a temperature controller.

Owner:FOSHAN SHUNDE ZHENMENGYUAN HOME TEXTILE CO LTD

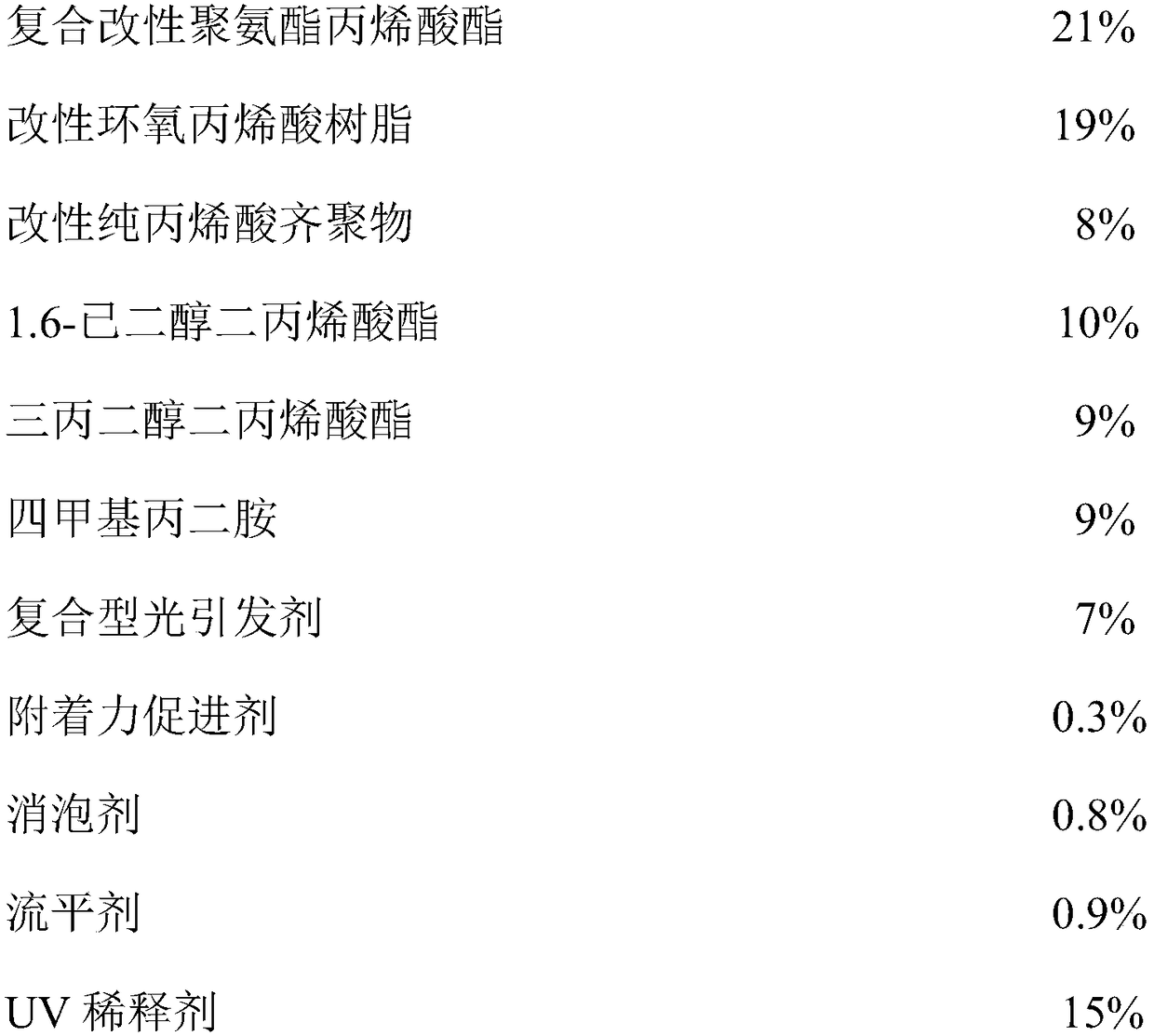

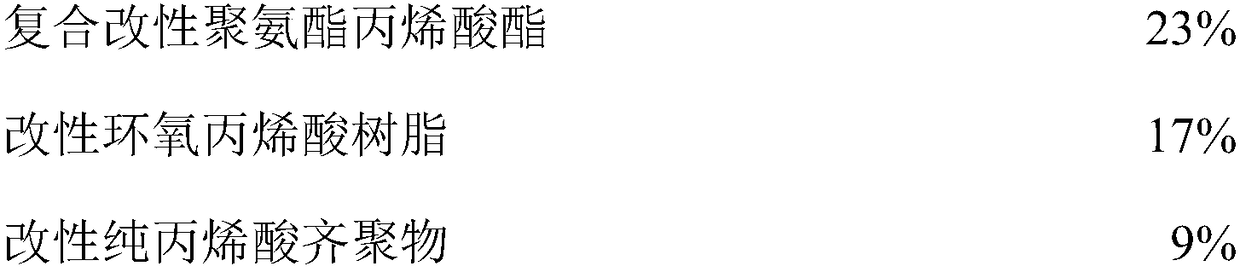

UV nano metallic coating material

PendingCN108192495AGood flexibilityImprove impact resistancePolyurea/polyurethane coatingsEpoxy resin coatingsAcrylic resinAdhesion strength

The invention relates to an UV nano metallic coating material. The UV nano metallic coating material is prepared from composite modified polyurethane acrylate, modified epoxy acrylic resin, modified pure acrylic oligomer, 1,6-hexanediol diacrylate, monomer tripropylene glycol diacrylate, monomer tetramethyl propylene diamine and a complex type photoinitiator. The UV nano metallic coating materialprovided by the invention is excellent and balanced in various properties, all ingredients of the formula are matched with one another, and properties such as the metal surface adhesion power of the coating material, the impact resistance, the elasticity of a cured film, the hardness and flexibility of the cured film, the bonding strength and durability of the coating material and the yellowing resistance and transparency of the coating material are balanced, so that the coating material has the above-mentioned characteristics, particularly excellent adhesive power, flexibility and impact resistance. Meanwhile, the coating material provided by the invention is a nano coating material and is fine in particle, so that metal surfaces can be uniformly coated with the coating material; and thesurface of a coating film is very flat and does not occur defects such as trickling or vortex eyes, so that the coating film is attractive and can protect the surface of a metallic substrate, and thecoating material has a broad application prospect.

Owner:北京钢研新冶工程设计有限公司

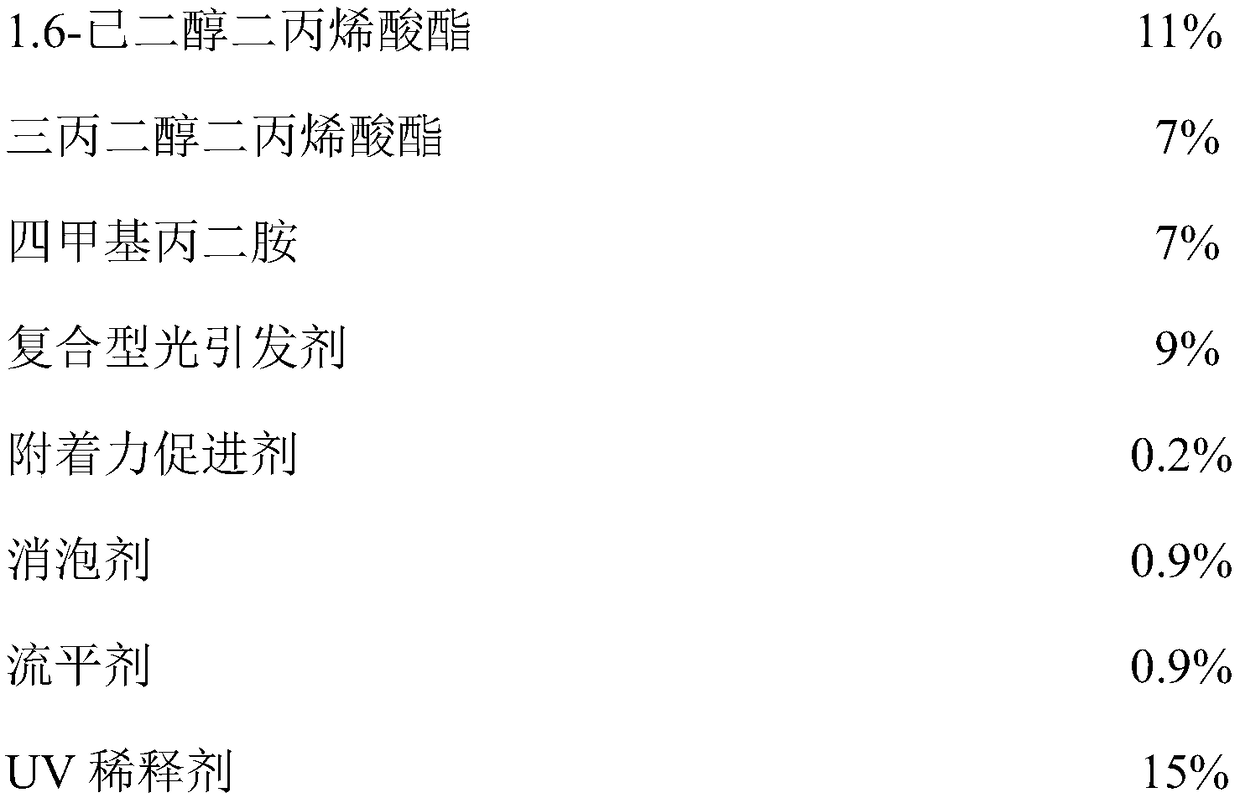

Process for machining isolated steel belt of slewing bearing steel ball

ActiveCN102152080AAvoid Polygonal CirclesConsistent elasticityLaser beam welding apparatusButt weldingRounding

The invention discloses a process for machining an isolated steel belt of a slewing bearing steel ball, comprising the steps of: machining strip materials by the procedures of feeding bar materials, leveling and milling end faces; roughly rounding: roughly rounding the strip materials to process arced strip materials with the radiuses approaching that of product rings; welding: carrying out butt welding on the arced strip materials to obtain rings with the radiuses approaching that of the product rings; finely rounding: finely rounding the rings till a finally required cylindricity of a product is obtained; cutting orifices: sequentially carrying out laser cutting on the finely rounded rings to obtain rolling-body orifices; and boring: boring and trimming the rolling-body orifices to obtain the diameter of the orifice required finally. In the invention, because the process is regulated in that the rolling-body orifices are subjected to laser cutting after fine rounding is carried out, the strength of the strip materials is consistent along the length direction; elastic deformation and plastic deformation of the materials are uniform and consistent in the processes of roughly rounding and finely rounding and no inflection points are generated along an arc direction, so that ribbed roundness of a workpiece is effectively avoided; and reshaping is not needed so that the cylindricity precision of products is ensured.

Owner:SHANDONG GOLDEN EMPIRE PRECISION MACHINERY TECH CO LTD

Elastic electrode in ionic membrane electrolytic bath

The invention discloses an elastic electrode in an ionic membrane electrolytic bath. The electrolytic bath comprises cathode screens and anode screens which are oppositely and parallelly arranged at intervals; the cathode screens and / or the anode screens are provided with ionic membranes; the cathode screens are connected on a bracket; an accommodating cavity is formed between the cathode screens and the bracket; a helical spring type elastic screen is arranged in the cavity; the elastic screen is formed by winding a tape-shaped nickel foil; and the outer side of the elastic screen is connected with the cathode screens and the bracket respectively. The elastic electrode in the ionic membrane electrolytic bath has uniform conductivity, uniform elasticity and high durability, and can be suitable for ionic membrane electrolytic baths with different electrode distances or membrane polar distances.

Owner:JIANGYIN ANCAN ELECTROCHEM EQUIP

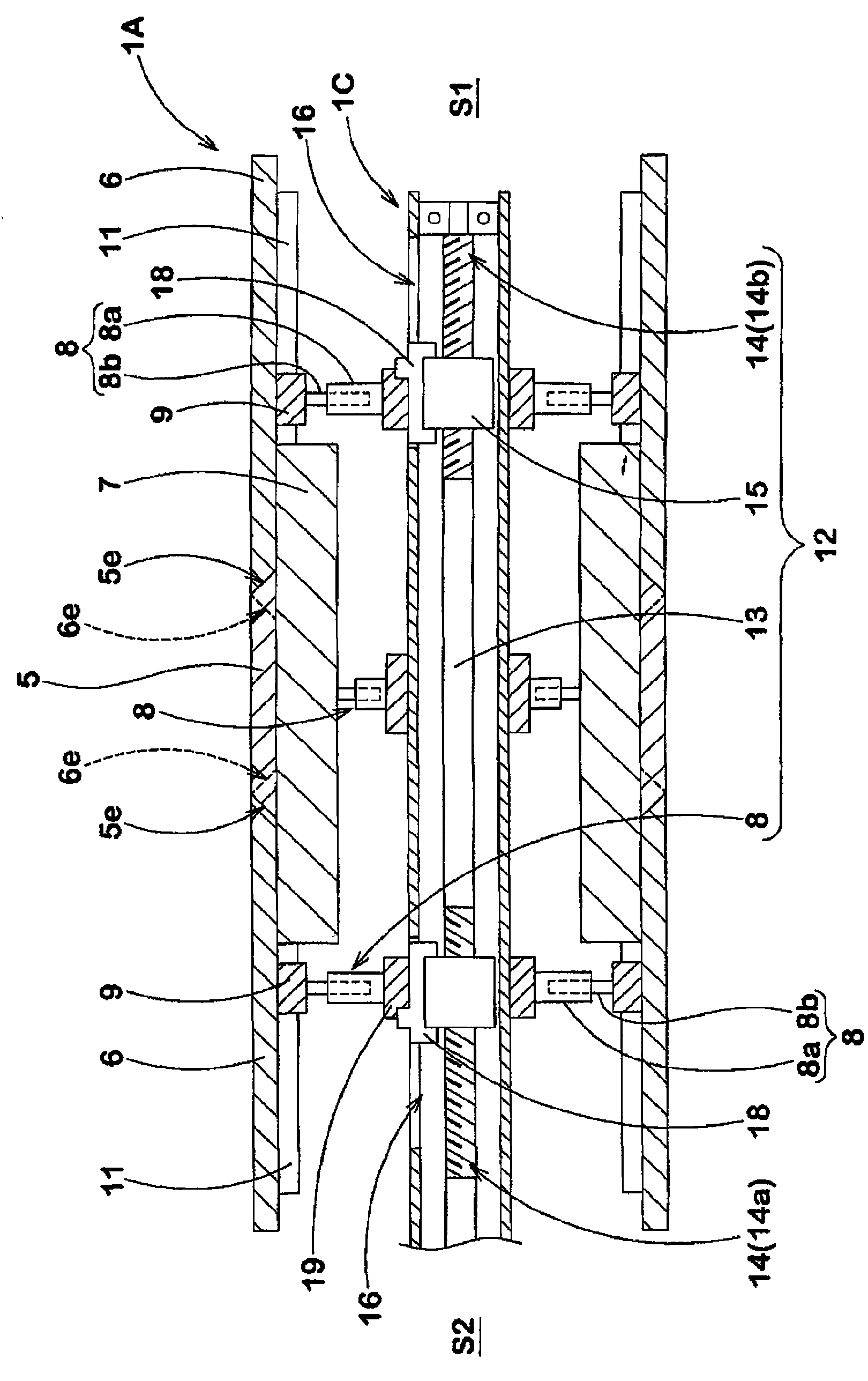

Torsional vibration damper

ActiveCN102072277AMaintain mean stressEasy to processRotating vibration suppressionEngineeringTorsional vibration

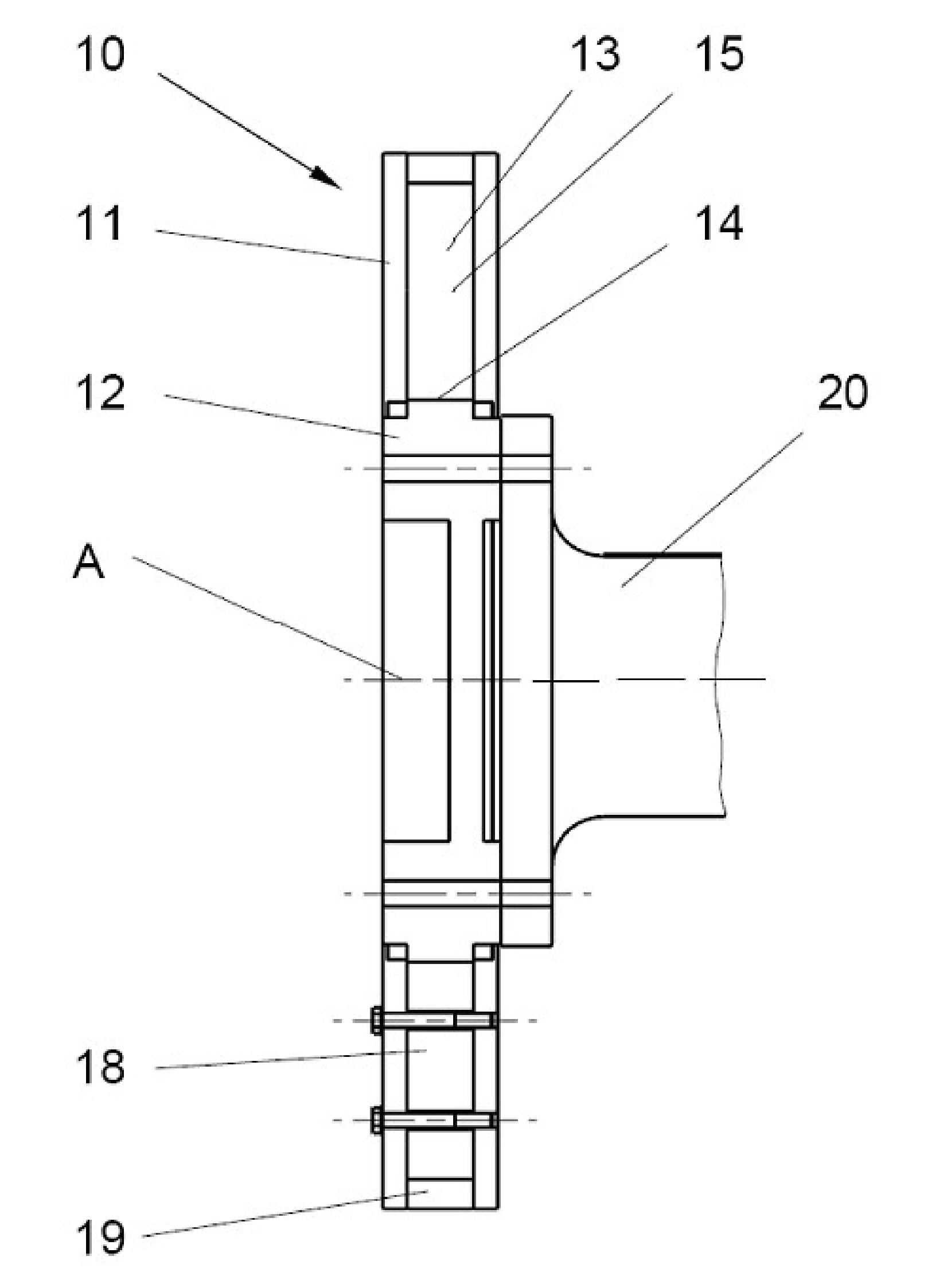

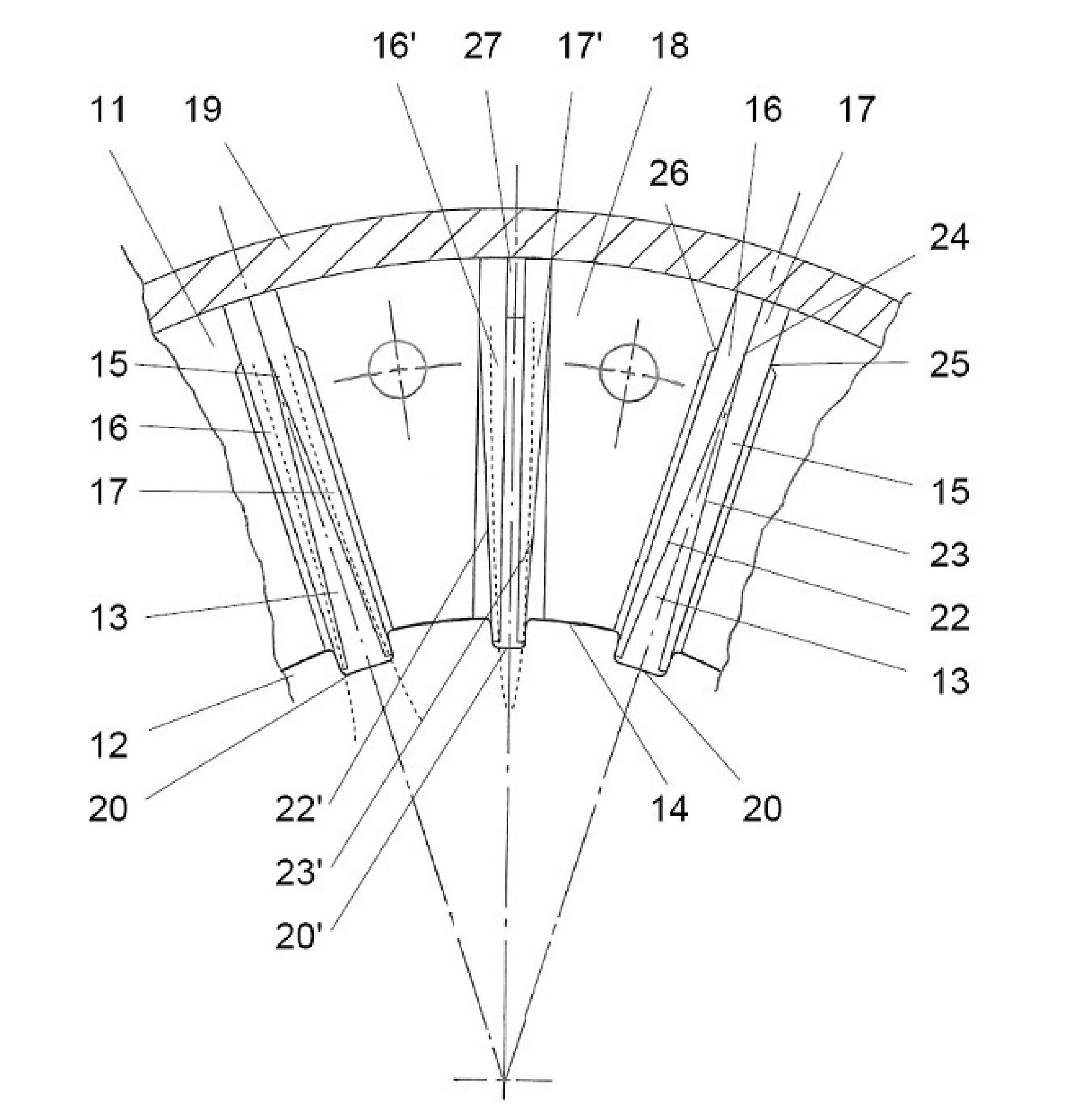

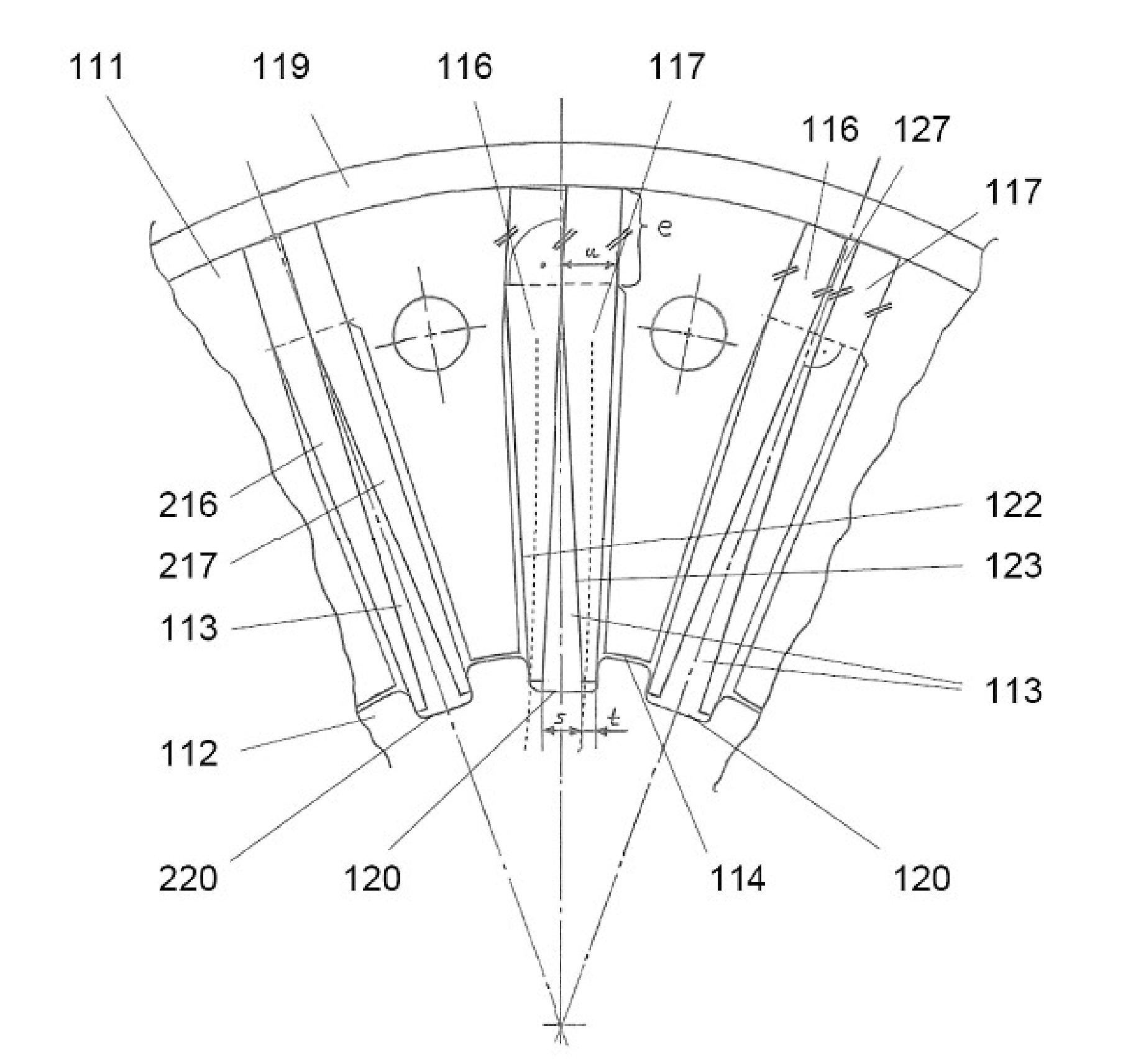

A torsional vibration damper comprises an outer housing (11), an inner part (12) that is concentric relative to the outer housing (11), a plurality of chambers (13) formed between the outer housing (11) and the inner part (12), which arc filled with a damping medium and are connected to one another through overflow channels (14), and a plurality of leaf spring configurations (16, 17, 16', 17') that are arranged in the chambers (13) and join the outer housing (11) and the inner part (12) with one another in a torsionally flexible manner. The leaf spring configurations (16, 17, 16', 17') have machining-induced deflections. Two leaf springs with substantially similar deflections are each arranged within a chamber (13). The leaf spring pairs may be arranged in a mirror-image array or in parallel to one another. Thus, the manufacturing cost of a torsional vibration damper can be reduced, while its compact outer dimensions can be maintained.

Owner:ELLERGON ANTRIEBSTECHN

Soft-tissue tubular prostheses with seamed transitions

Single tubular woven or bifurcated prostheses are disclosed having varying diameters and tapered transitions. The prostheses comprise a seam along the tapered edges, thereby providing a substantially fluid-tight transition between sections or extents of the prostheses. The seam may be located at an edge where fabric of the prosthesis tapers from one diameter to a different diameter and / or a point where the prosthesis splits such as a bifurcation. The seamed crotch may be used for tapered and non-tapered bifurcated grafts. The seam may be woven directly on a weaving loom or joined together after weaving is completed.

Owner:ATEX TECH INC

U-shaped spring energy accumulation pressurizing sealing ring

The invention discloses a U-shaped spring energy accumulation pressurizing sealing ring, which consists of a nonmetal covering sleeve, a metal U-shaped ring and a baffle ring, wherein the cross section of the metal U-shaped ring is in a U shape, in addition, a U-shaped groove is formed in an inner space of the metal U-shaped ring, the opening end surface of the metal U-shaped ring faces one side or the pressure side of a sealed medium, the non metal covering sleeve covers outside the metal U-shaped ring, in addition, the nonmetal covering sleeve has a sealing end surface parallel to the opening end surface of the metal U-shaped ring, the baffle ring is plugged into the U-shaped groove of the metal U-shaped ring, and in addition, the outwards exposed surface, parallel to the opening end surface of the metal U-shaped ring, of the baffle ring is higher than the sealing end surface of the nonmetal covering sleeve. The U-shaped spring energy accumulation pressurizing sealing ring is mainly used in low-temperature (below -110 DEG C) and ultra-low-temperature (-196 DEG C to -256 DEG C) environment, can be used for static sealing and dynamical sealing, and is particularly applicable to low-temperature high-pressure environment.

Owner:WOTAI VALVE KUSN

Method for producing absorptivity products

InactiveCN107468426ASave Hot Melt AdhesiveSimple processAbsorbent padsBaby linensEngineeringHot-melt adhesive

The invention discloses a method for producing absorptivity products. The method includes the following working procedures that a, arc leg-circumference elastic parts corresponding to leg openings are clamped between inner sheets and outer sheets; b, the portions, joined with inner absorption structures, of the leg-circumference elastic parts in stacking bodies are fused; c, the inner absorption structures are produced; d, the inner absorption structures are arranged between first elastic parts, corresponding to the front waistline areas and the back waistline areas of the absorptivity products, cross the two sides of the stacking bodies in the width direction. According to the method, compared with the prior art, the technological process is simplified, a large amount of hot melt adhesive is saved, and the production cost is reduced; meanwhile, improved outer wrapping structures have the better breathability and the better attachment degree on the front-back waistline areas and skin, and the practical requirements of consumers are met; the method has the advantages of being even in elasticity, good in attachment degree, soft, breathable, simple in structure and low in production cost.

Owner:HUANGSHAN FUTIAN MACHINERY CO LTD

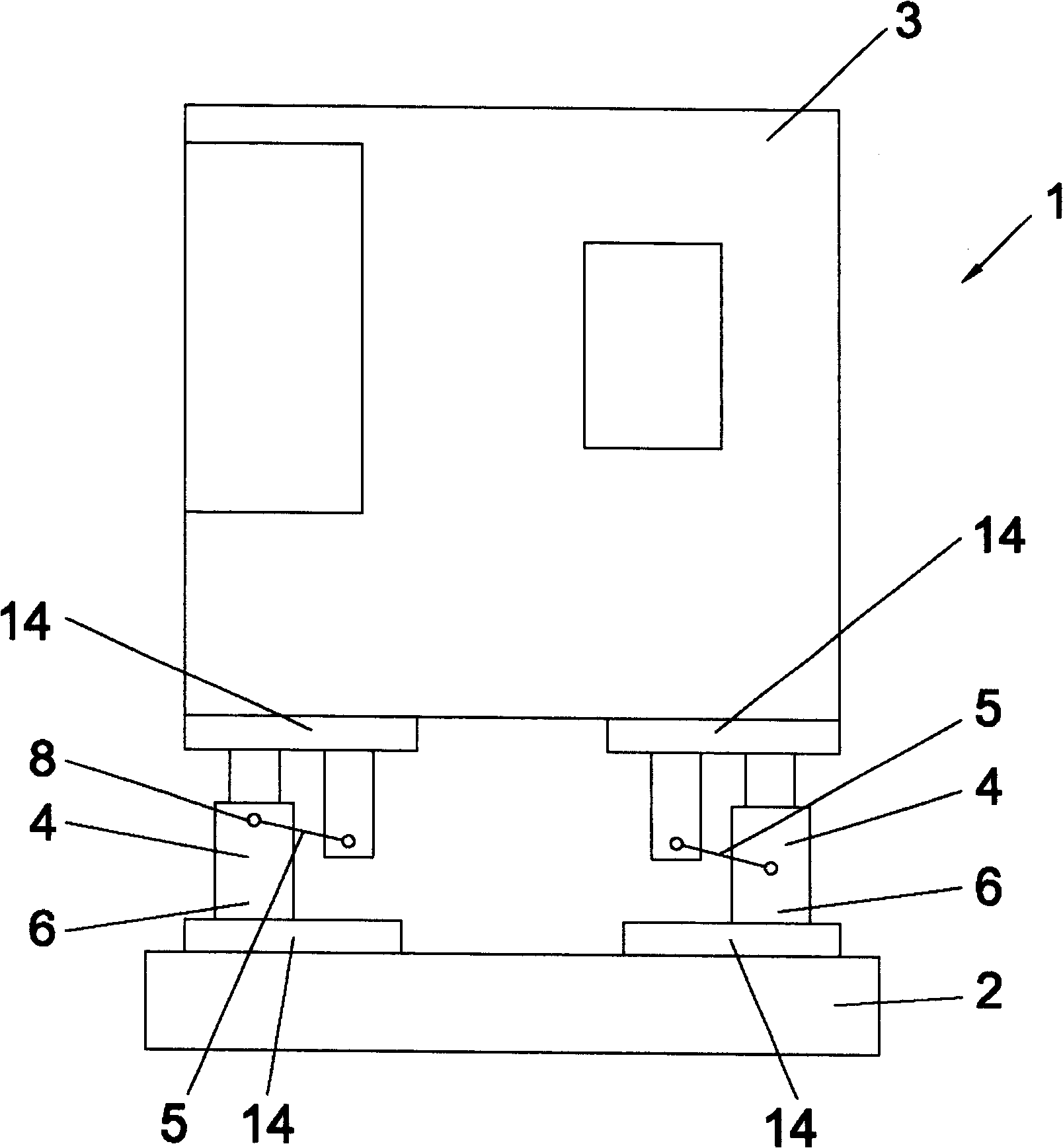

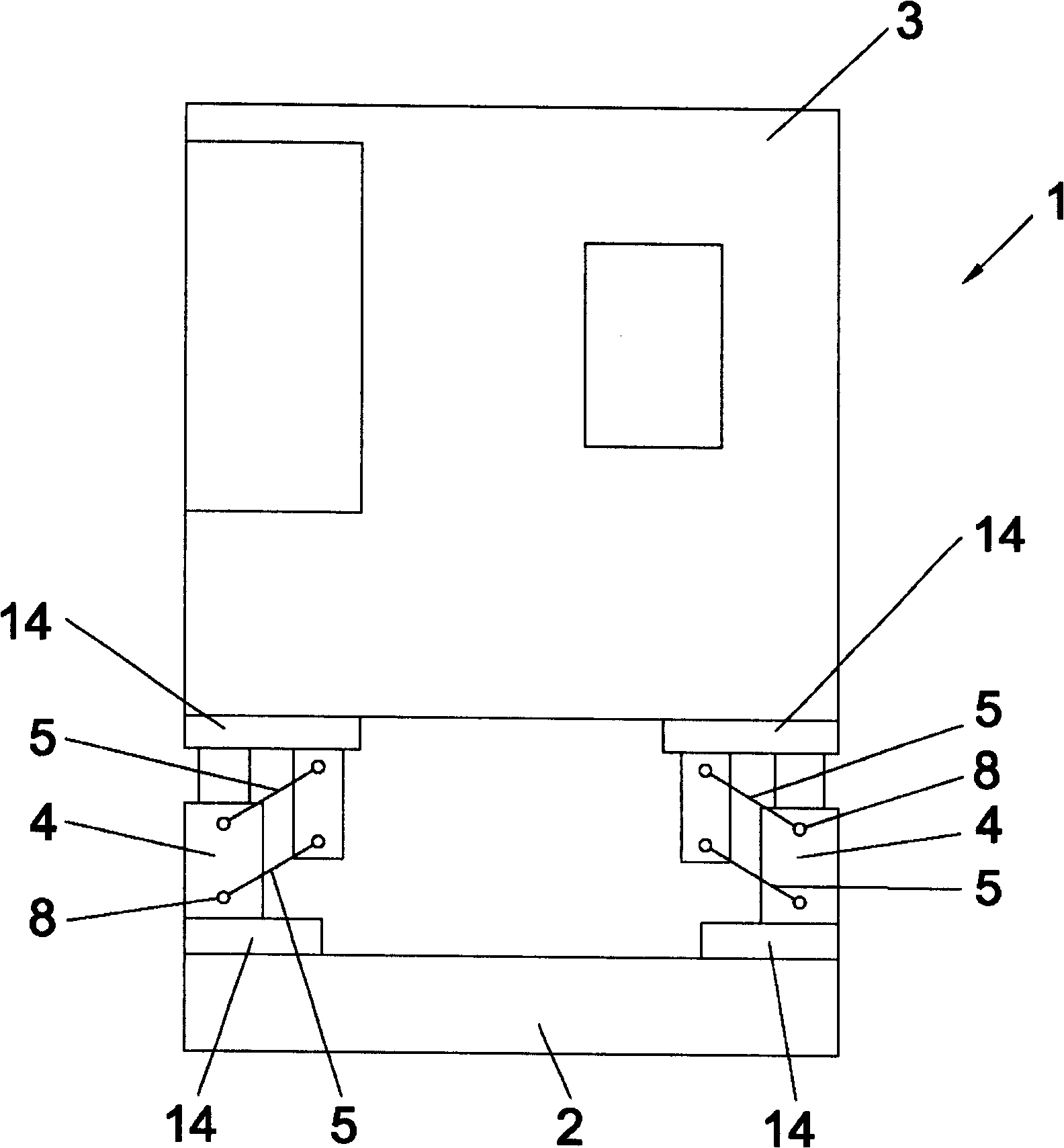

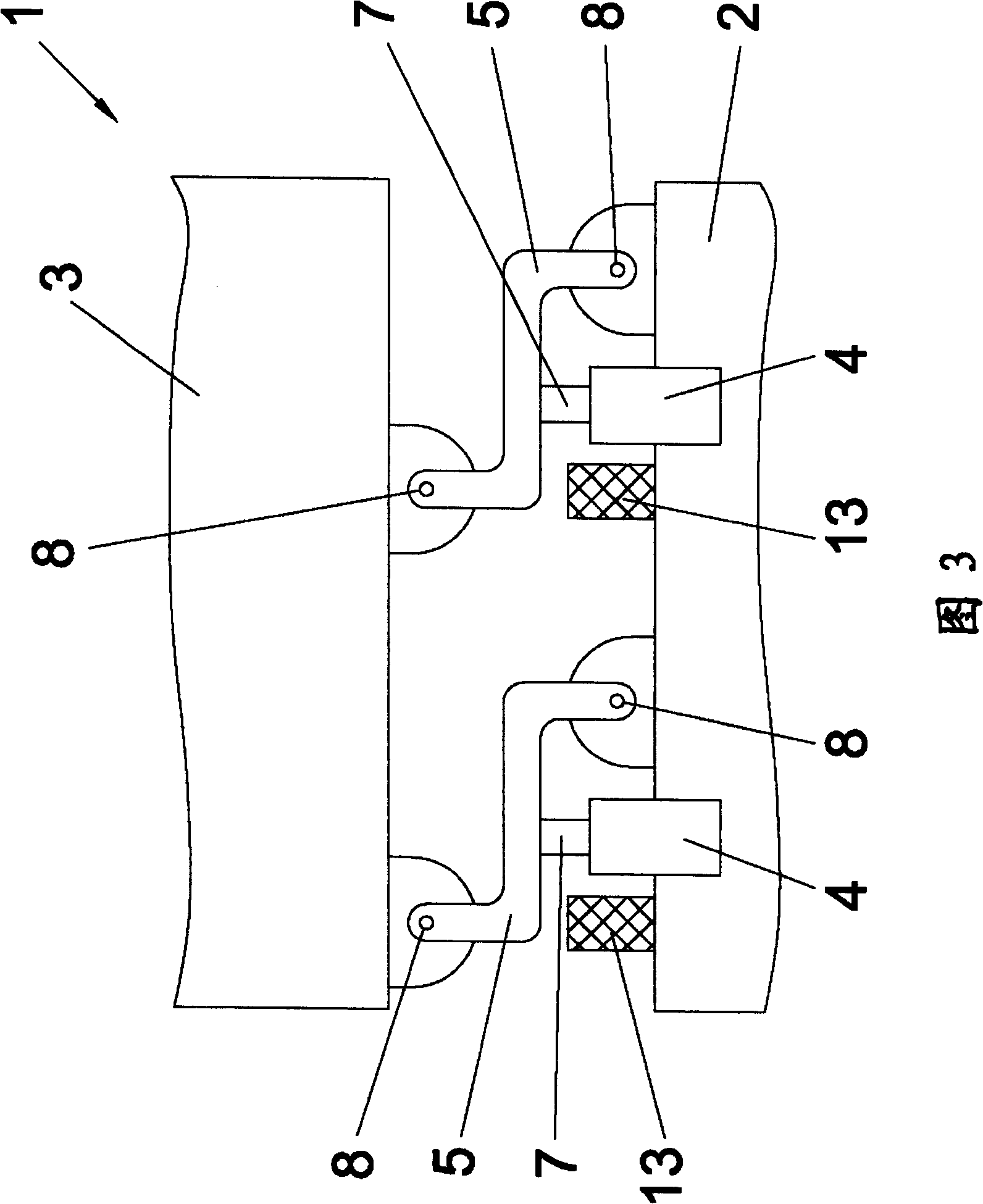

Vehicle with a frame and a cabin

InactiveCN101284550ASave construction spaceReduce exerciseLoading-carrying vehicle superstructuresVehicle frameEngineering

Owner:CARL FREUDENBERG KG

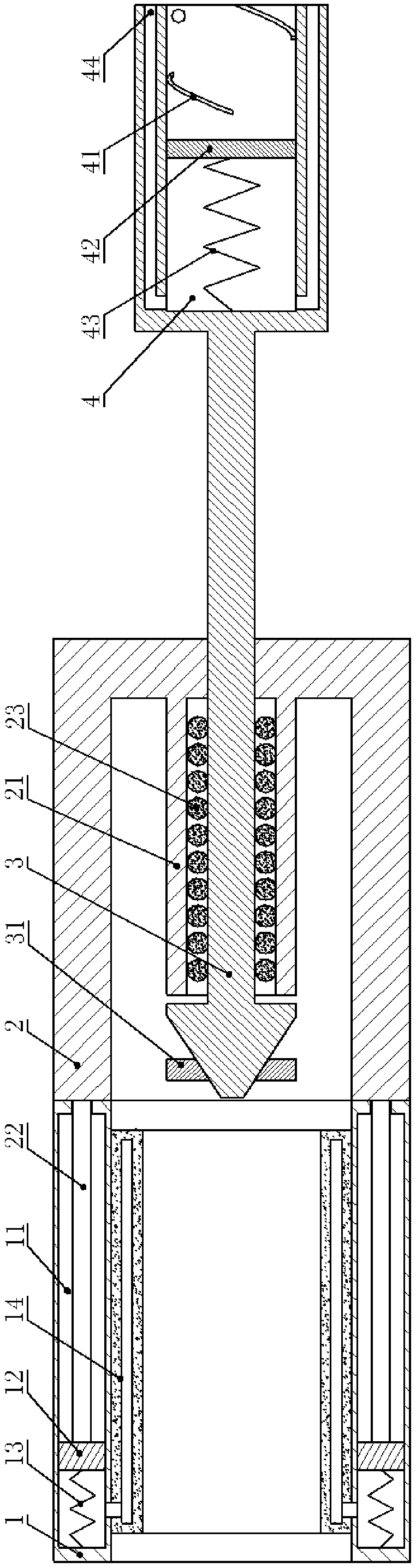

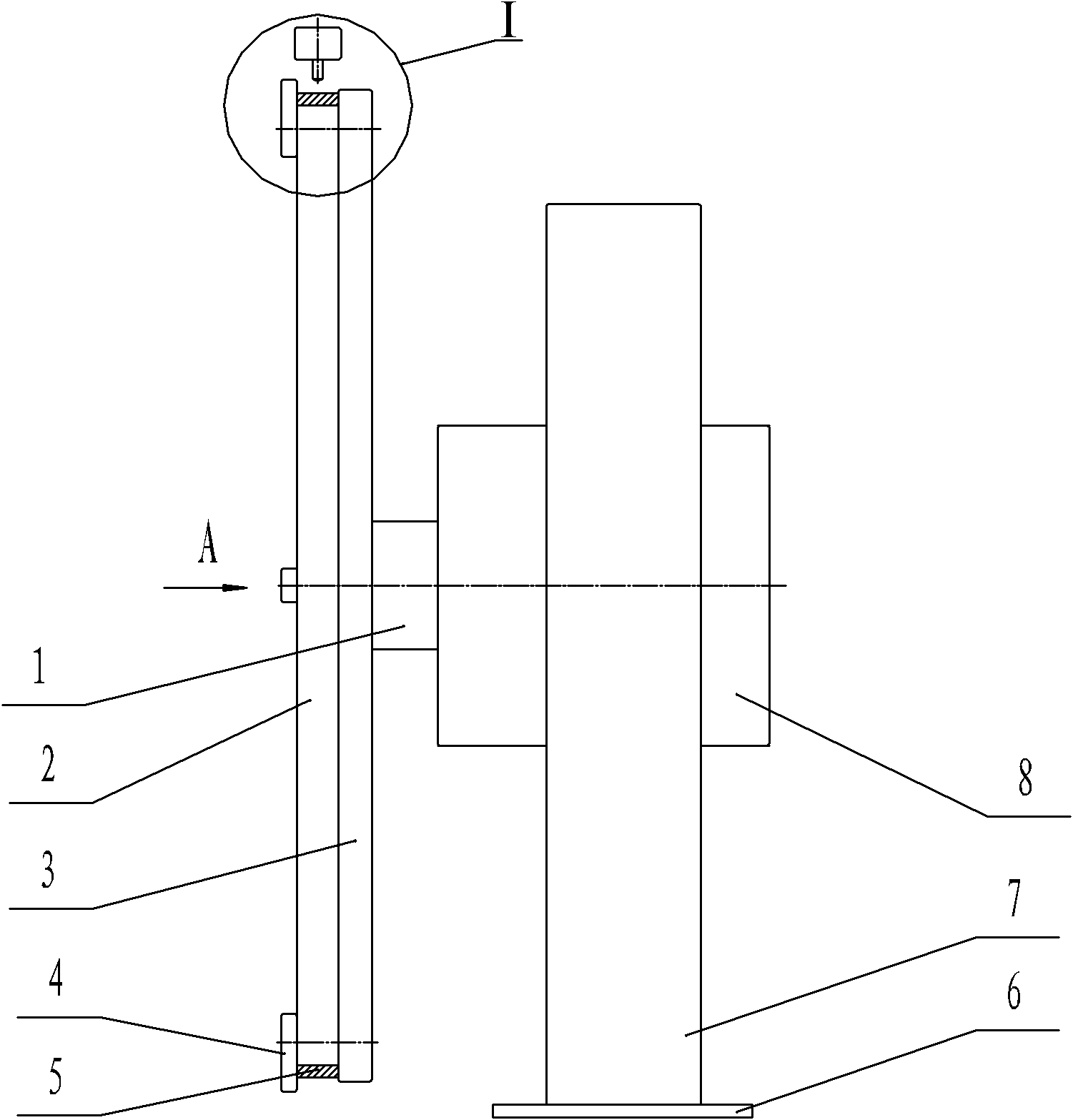

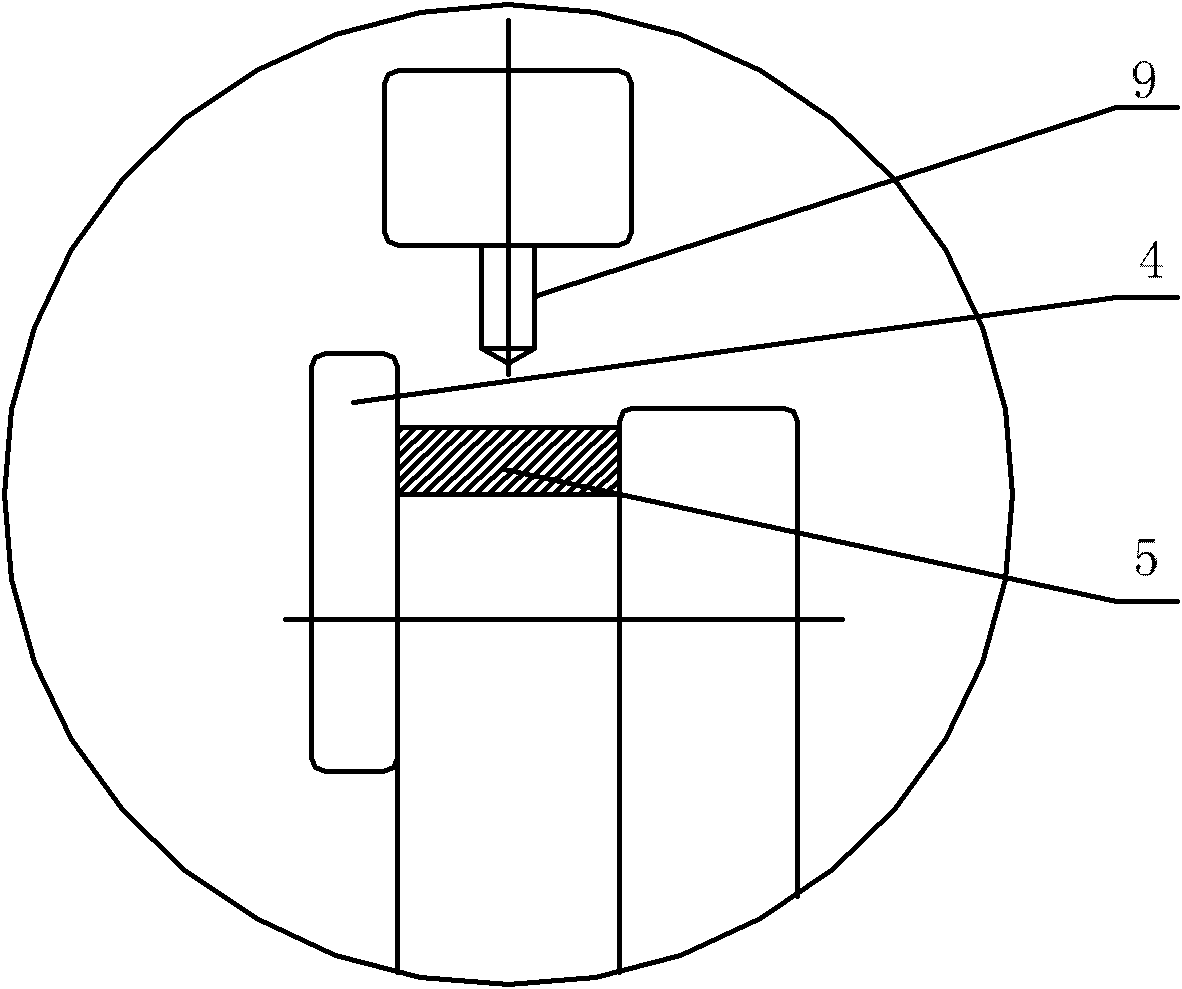

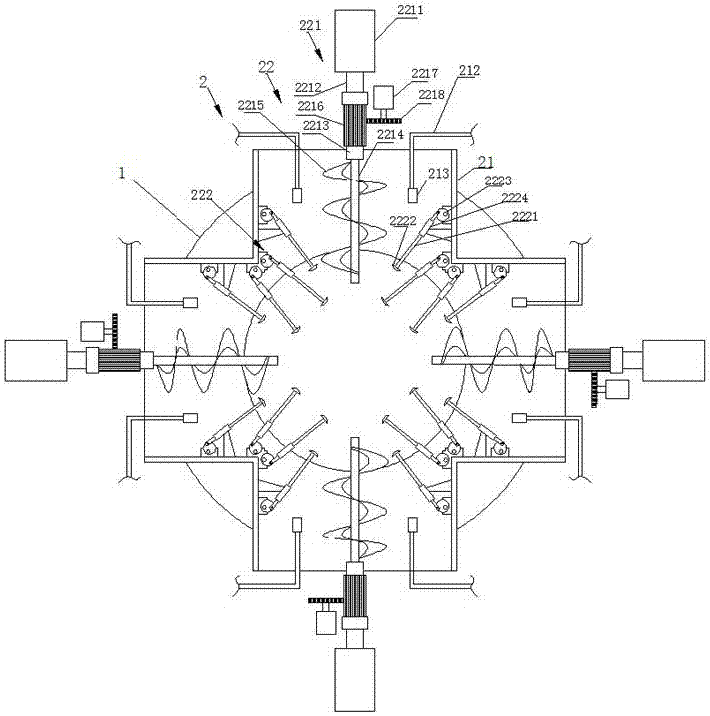

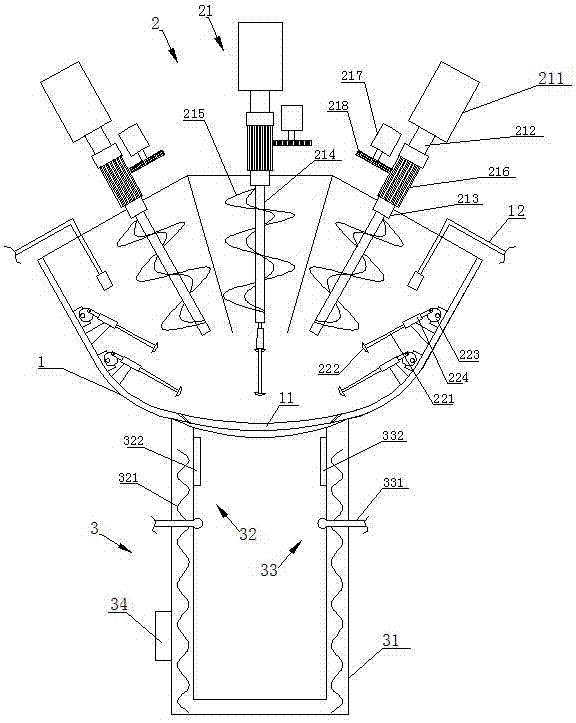

Rapid flour kneading machine

InactiveCN106982879AIncrease elasticityUniform elasticityMixing/kneading structural elementsMixing/kneading with inclined rotationEngineeringMotor shaft

The invention relates to a fast flour kneading machine, comprising a basin body and a plurality of kneading noodle kneading devices arranged obliquely on the basin body; The kneading device in the body; the telescopic water inlet pipe facing the basin is arranged in the cylinder; the end of the telescopic water inlet pipe is a cylindrical self-rotating nozzle; the kneading device includes a stirring device that can be lifted and inserted into the basin along the cylinder and striking devices evenly distributed on the inner periphery of the cylinder; the striking devices include a plurality of striking rods facing the basin; one end of the striking rods facing the basin is provided with a hemispherical hammer, and the other end is hinged on the outer periphery of a turntable above; the turntable is driven and rotated by a first motor, and the shaft of the motor is set eccentrically on the turntable; the middle part of the striker is slidably set in a limit sleeve; the bottom of the basin is provided with an opening and closing port; the A fermentation device is arranged below the opening and closing opening.

Owner:林娜娜

Preparation method of konjak tofu

The invention relates to a preparation method of konjak tofu. The method is completed through nine major steps of cleaning, steaming, dicing, water milling, alkaline milling, pouring into a mold, steaming and boiling, drawing and rinsing. The method has the beneficial effects that firstly, peels of konjak tubers are steamed to be soft, so that peeling is convenient; the irritation of alkaloid on work personnel is reduced; meanwhile, pulp milling is also easier; konjak blocks are subjected to pulp milling through two major steps of first water milling and then alkaline milling; alkaline water can be directly in contact with konjak pulp particles; then, the konjak pulp particles are put into a special steaming and boiling forming box for the konjak tofu; then, the special steaming and boiling forming box is put into a steamer to be directly steamed and boiled; the konjak pulp can be simultaneously cooked, so that the elasticity is uniform; the texture is exquisite and uniform; small squares with spaces can be formed on the konjak tofu blocks; the rinsing for alkaline taste removal can be convenient; the clean water consumption and the labor can be greatly reduced. Therefore the manufactured konjak tofu has bright and gray color and luster; the block shape is complete; the elasticity is uniform; the tofu is fine, fresh and tender; the alkaline taste is fresh and pure; the konjak tofu is deeply popular in people.

Owner:重庆乐滋滋食品有限责任公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com