Soft-tissue tubular prostheses with seamed transitions

A tubular and prosthetic technology, applied in the direction of prosthesis, human tubular structure devices, blood vessels, etc., can solve the problems of suture seam occupation, increased thrombosis latency, fracture, etc., and achieve the effect of improving leakage and preventing leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

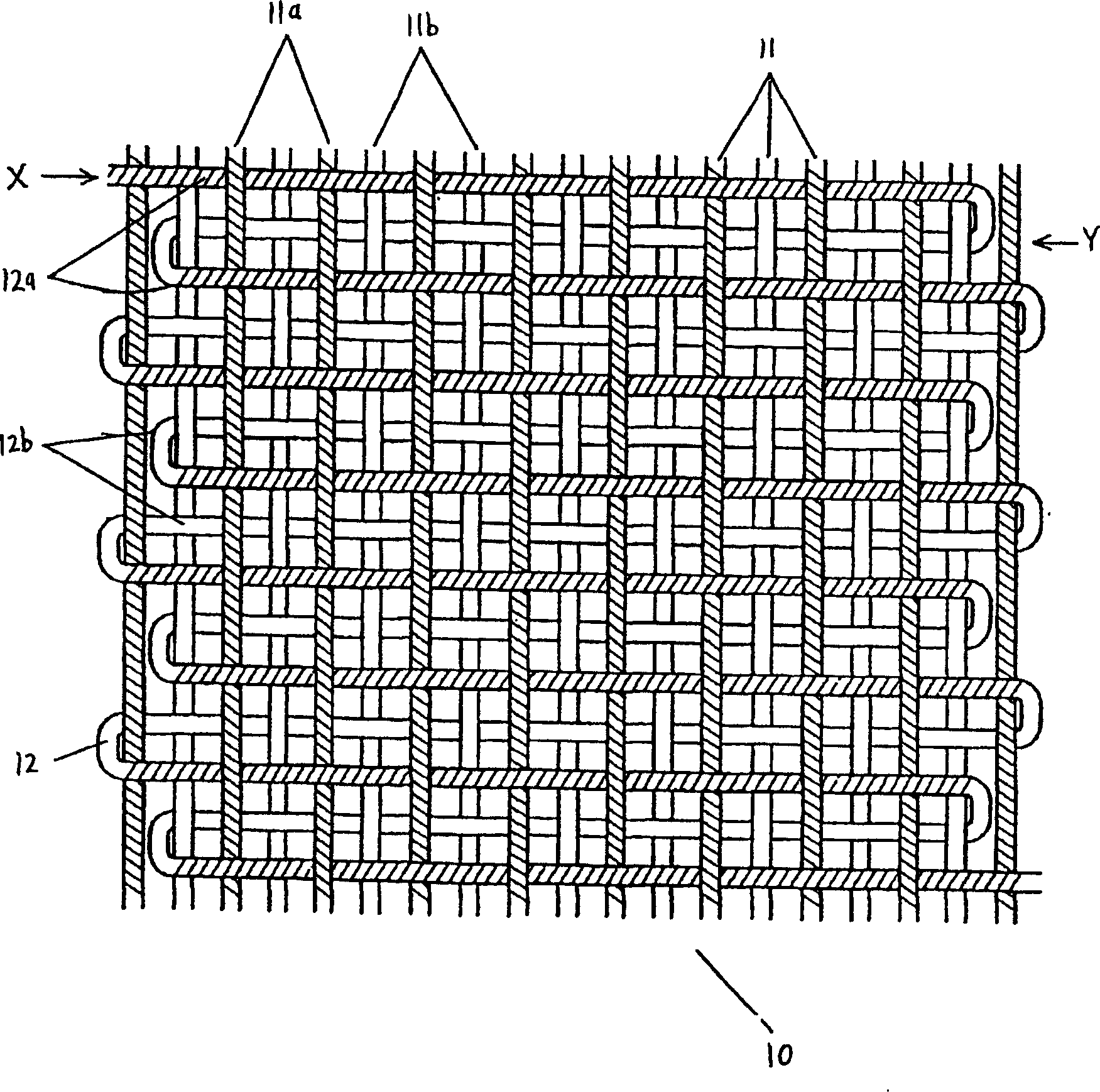

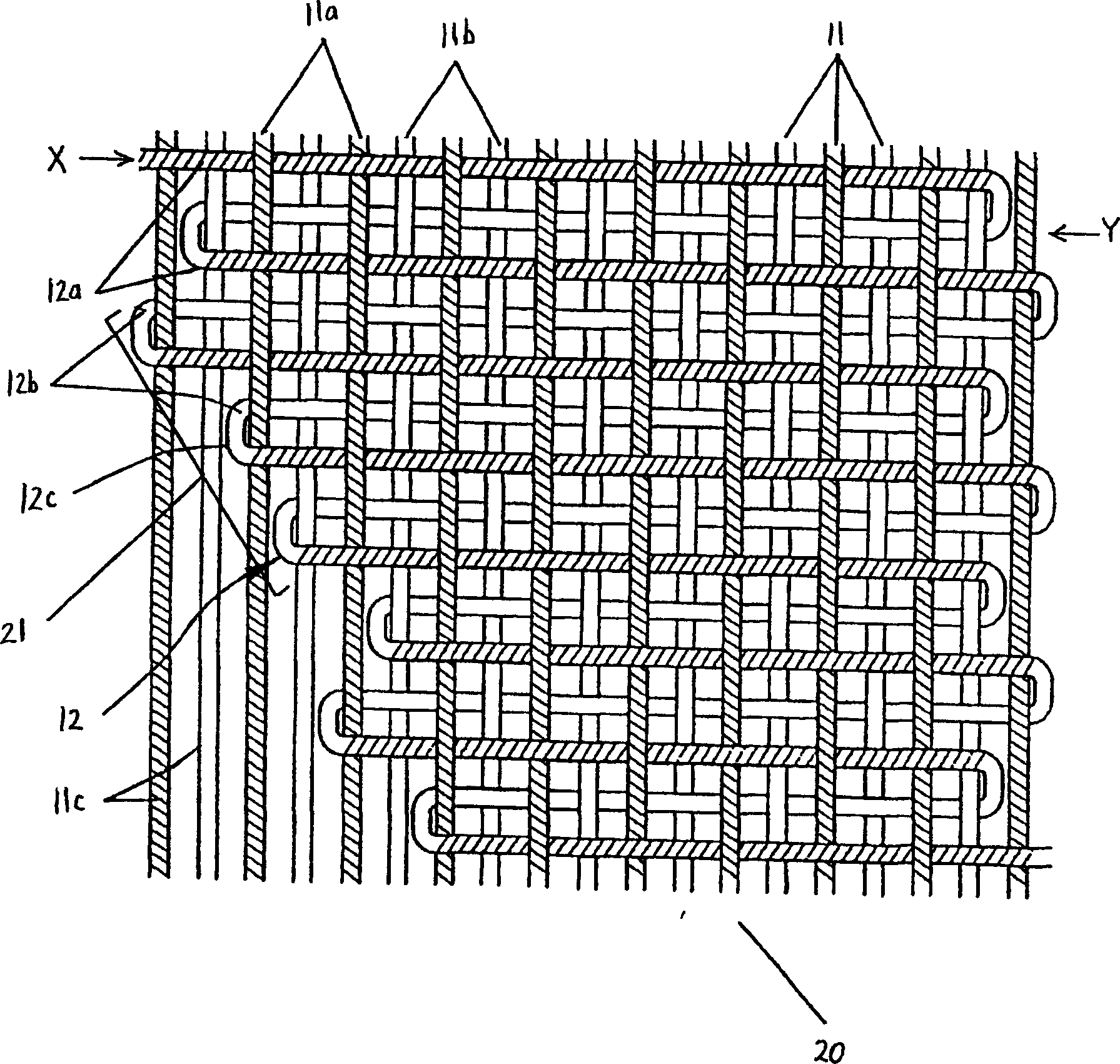

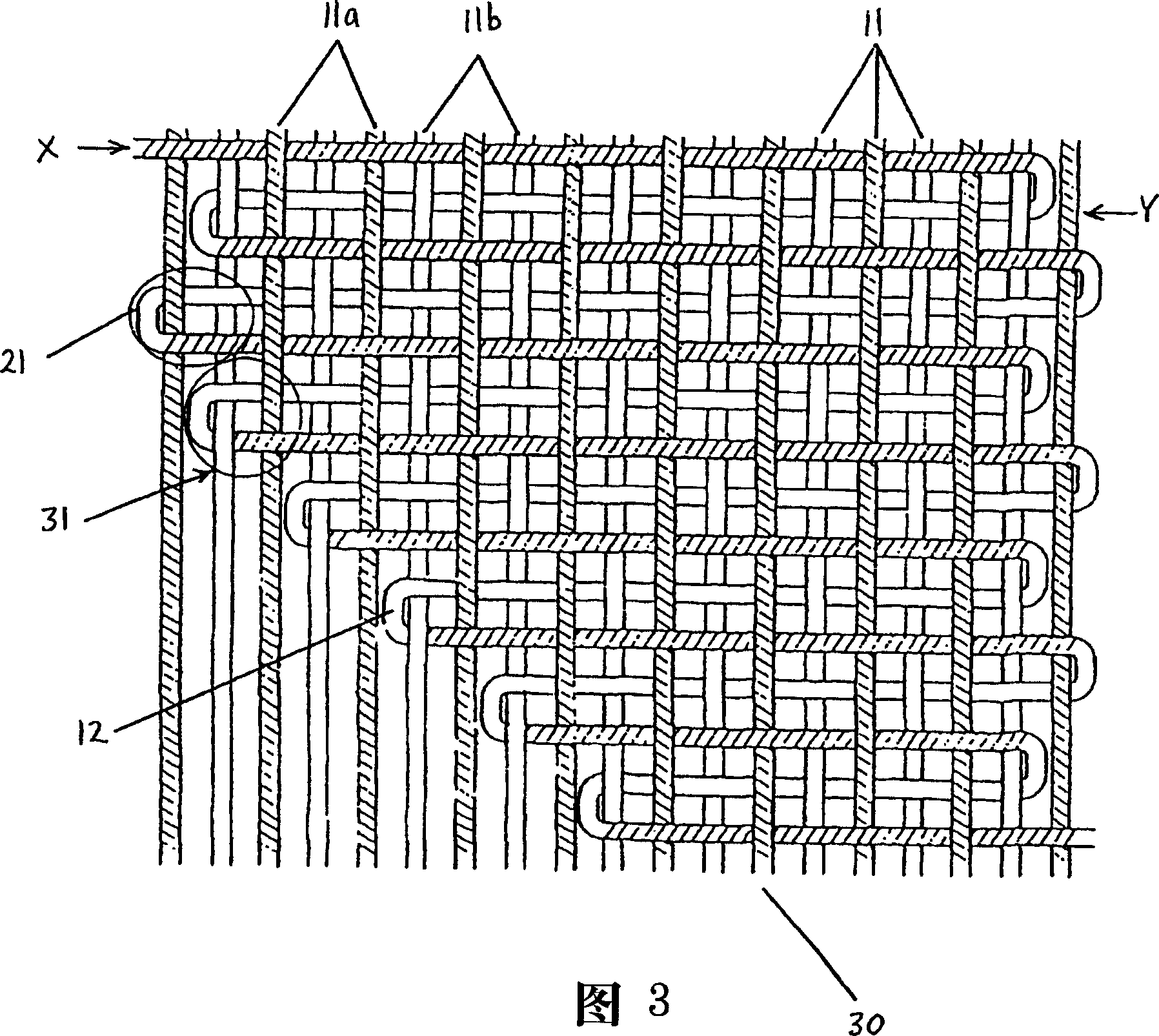

[0053] Embodiments of the present invention include a braided implantable tubular prosthesis having a variable diameter and a tapered transition comprising a seam along the opening of the tapered transition or transition region. The seam of the present invention provides a substantially fluid-tight transition between the first tubular portion or region and the second tubular region. Seams may be placed at the edges where the tapered fabric of the prosthesis changes from one diameter to a different diameter and / or where the prosthesis splits at a point, such as a bifurcation. Margins are defined as the outer limits of the graft width and along the longitudinal axis since the graft is a flat fabric on the loom.

[0054] In an embodiment, the seams are sewn directly on the loom by sewing together the upper and lower portions of the tubular prosthesis. In other embodiments, the seams are joined after the weaving is complete.

[0055] Conventional braiding techniques can be incor...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com