Patents

Literature

31results about How to "Consistent elasticity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Processing method of deproteinized rice

ActiveCN103211163APromote dissolutionImprove removal effectFood preparationFlavorReaction temperature

The invention provides a processing method of deproteinized rice. The processing method comprises the following steps of: (1) washing and removing impurities; (2) carrying out enzymolysis and fermentation: in a reaction tank, adding processed rice, purified water, proteolytic enzyme and lactic acid bacteria according to proportion, wherein the weight proportion of rice to purified water is 1:(5-20), the reaction temperature is 10-60 DEG C, the reaction time is 3-20 hours, the initial pH of reaction liquid is between 4.5 and 9.5, the using amount of proteolytic enzyme accounts for 0.1% to 5% of total weight of rice, and the dropping amount of lactic acid bacteria is as follows: 109-1014 bacteria is added in every ton of reaction liquid; and (3) after enzymolysis and fermentation, leaching, washing and drying to obtain the deproteinized rice. According to the method, the technology is simple, the cost is low, the appearance, the color, the flavor and the taste of the deproteinized rice processed by adopting the technology are the same as those of ordinary rice; and the protein removal ratio can be more than 95% at most.

Owner:成都东洋百信制药有限公司

Method for preparing super-simulative fake breast

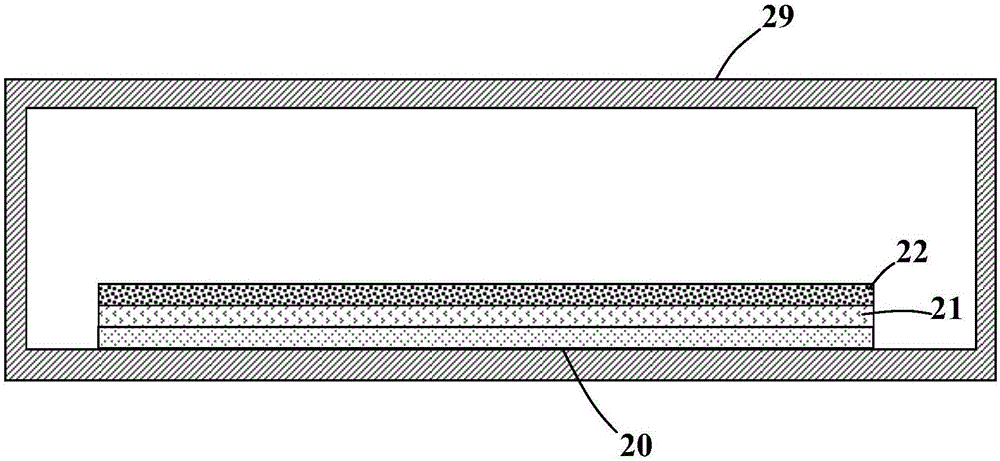

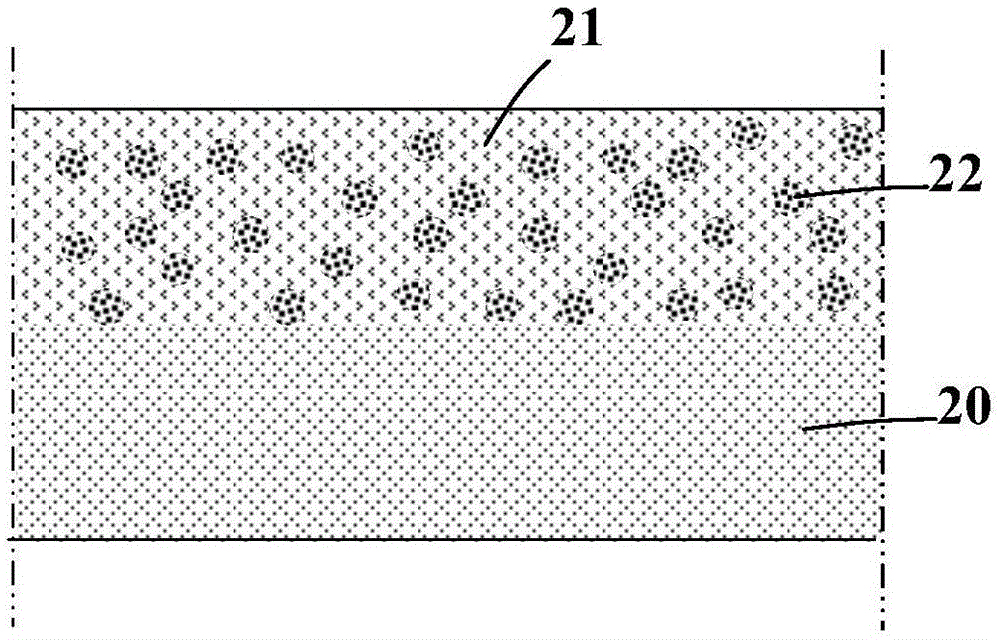

ActiveCN103144231AConsistent softnessConsistent elasticityHuman Mammary GlandsBiomedical engineering

The invention belongs to the technical field of plastic and aesthetic surgery and especially relates to a method for preparing a super-simulative fake breast. The method comprises the following steps of: (1) atomizing a release agent on the surface of a mold for preparing the fake breast, and then putting the mold in an oven for drying; (2) atomizing liquid silicon rubber on the surface of the mold in step (1), and then removing bubbles through vacuum equipment, and then putting the mold in the oven for solidification; (3) repeating step (2) three to six times, pouring liquid silica gel in the gap part of the mold for vulcanization, and then solidifying the mold in the oven; and (4) pouring the liquid silicon rubber on the outer layer of the product formed in step (3), then removing bubbles, drying and demoulding to finally obtain the super-simulative fake breast. The super-simulative fake breast prepared through the above-mentioned steps basically keeps consistent with the breast tissue of a human body in softness, elasticity, specific gravity and colour and lustre, and is more authentic and closer to the human body skin than the traditional silicon gel fake breast. Especially in touch aspect, the advantage of the product is well displayed.

Owner:DONGGUAN LANKE SILICONE TECH

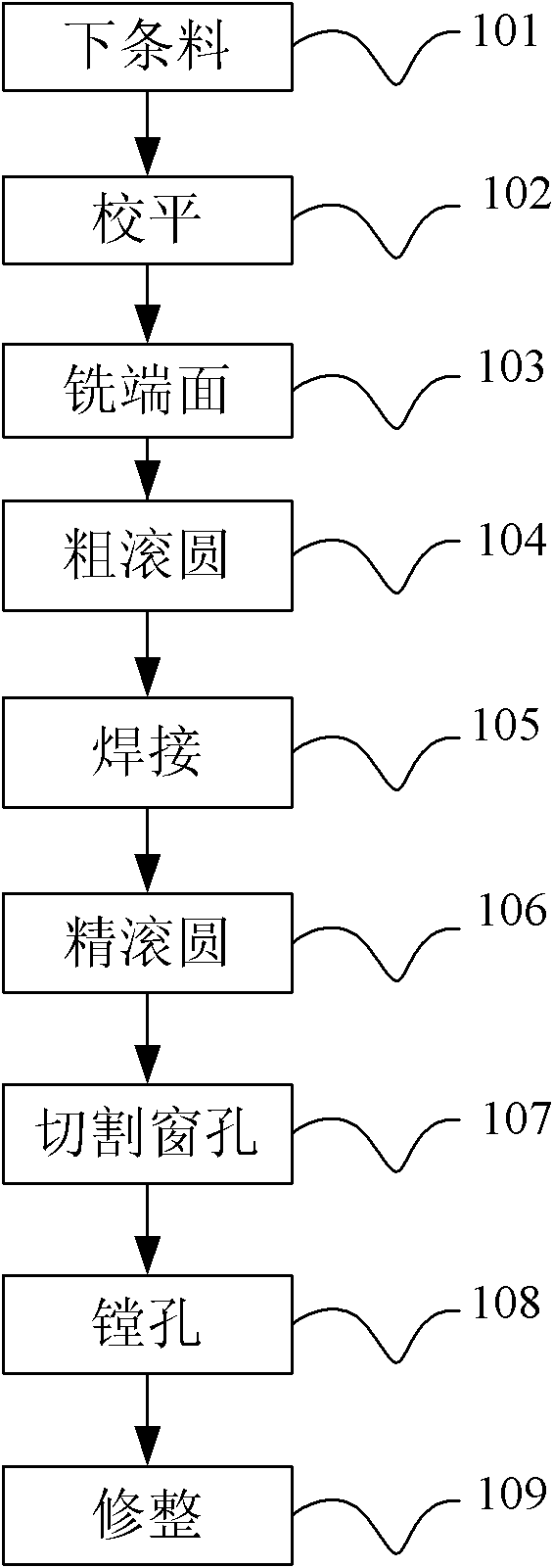

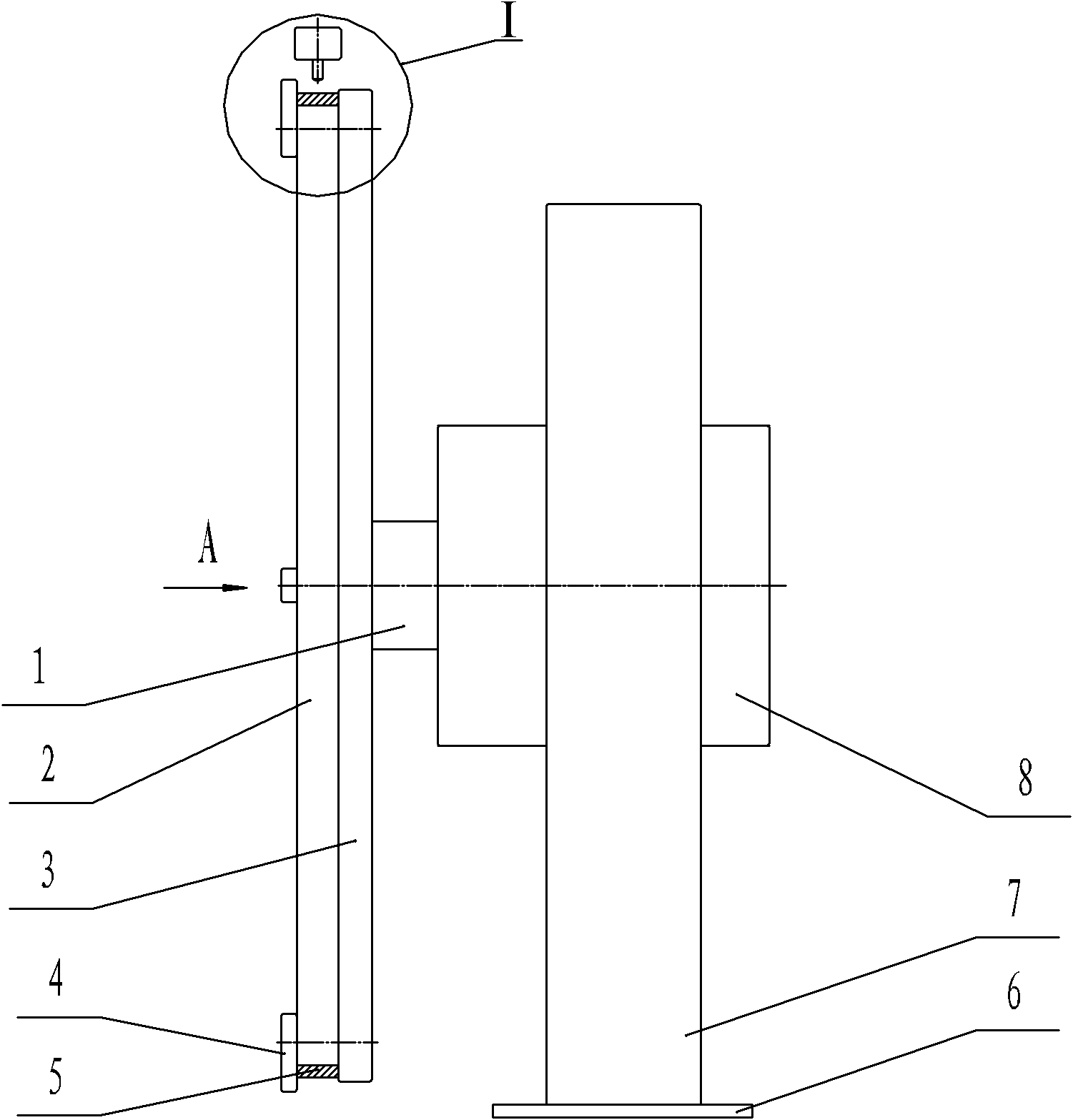

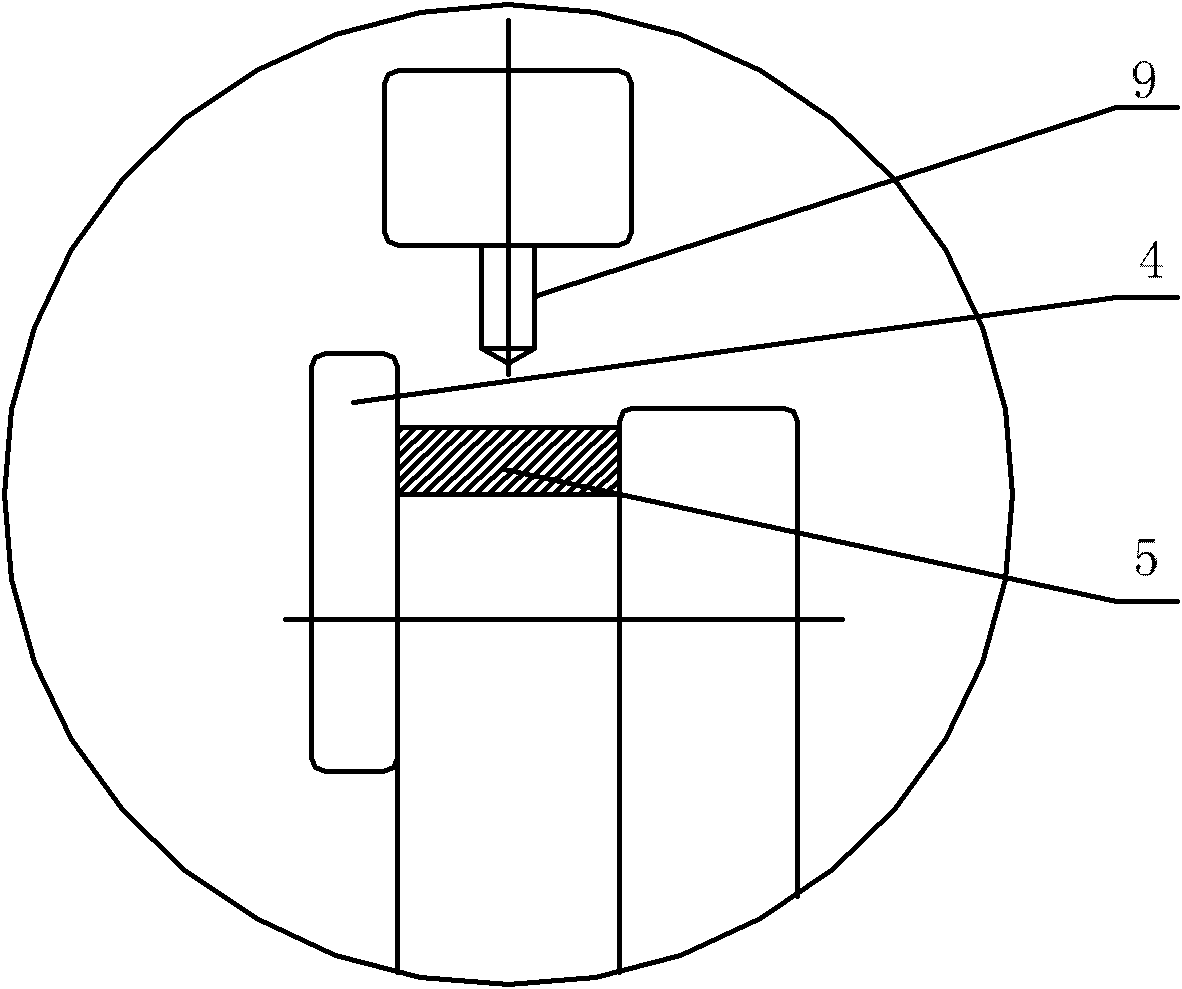

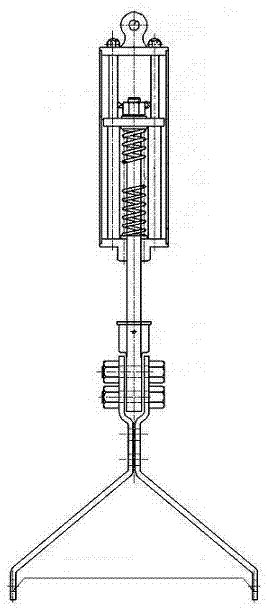

Process for machining isolated steel belt of slewing bearing steel ball

ActiveCN102152080AAvoid Polygonal CirclesConsistent elasticityLaser beam welding apparatusButt weldingRounding

The invention discloses a process for machining an isolated steel belt of a slewing bearing steel ball, comprising the steps of: machining strip materials by the procedures of feeding bar materials, leveling and milling end faces; roughly rounding: roughly rounding the strip materials to process arced strip materials with the radiuses approaching that of product rings; welding: carrying out butt welding on the arced strip materials to obtain rings with the radiuses approaching that of the product rings; finely rounding: finely rounding the rings till a finally required cylindricity of a product is obtained; cutting orifices: sequentially carrying out laser cutting on the finely rounded rings to obtain rolling-body orifices; and boring: boring and trimming the rolling-body orifices to obtain the diameter of the orifice required finally. In the invention, because the process is regulated in that the rolling-body orifices are subjected to laser cutting after fine rounding is carried out, the strength of the strip materials is consistent along the length direction; elastic deformation and plastic deformation of the materials are uniform and consistent in the processes of roughly rounding and finely rounding and no inflection points are generated along an arc direction, so that ribbed roundness of a workpiece is effectively avoided; and reshaping is not needed so that the cylindricity precision of products is ensured.

Owner:SHANDONG GOLDEN EMPIRE PRECISION MACHINERY TECH CO LTD

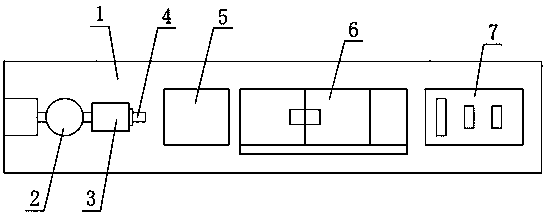

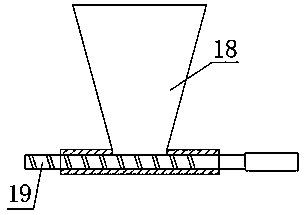

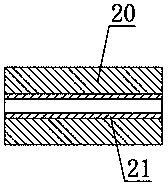

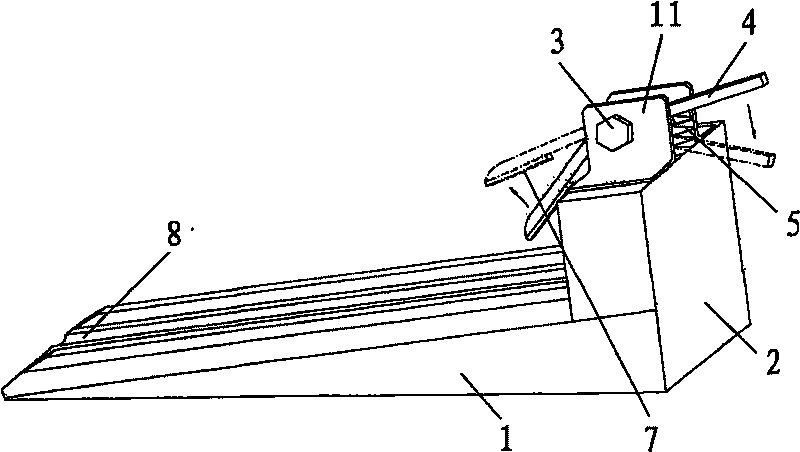

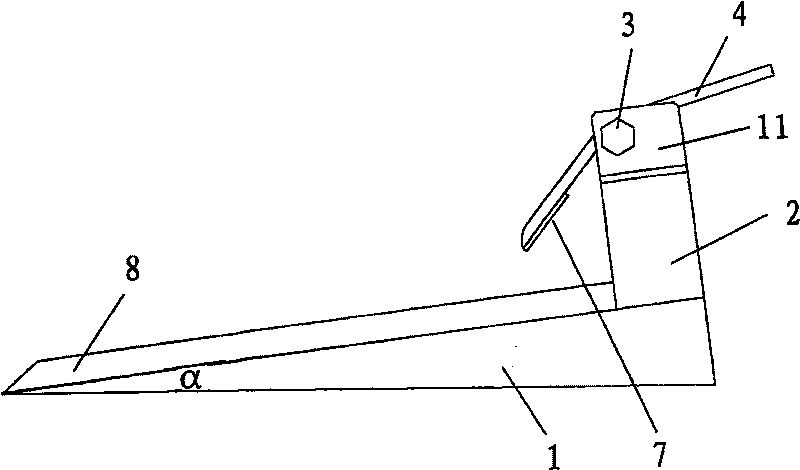

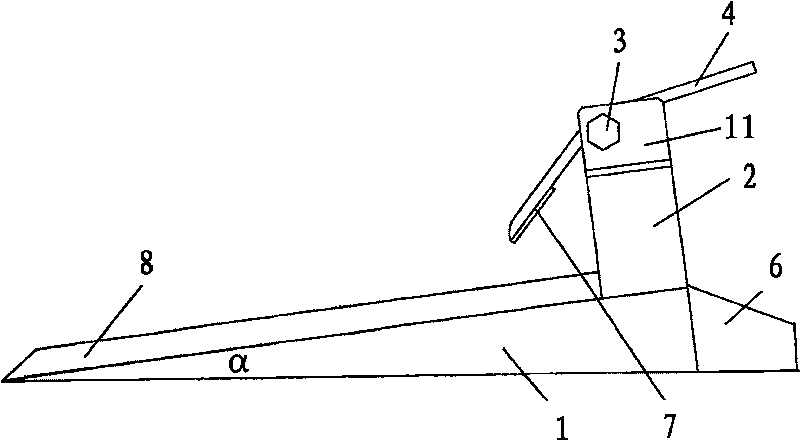

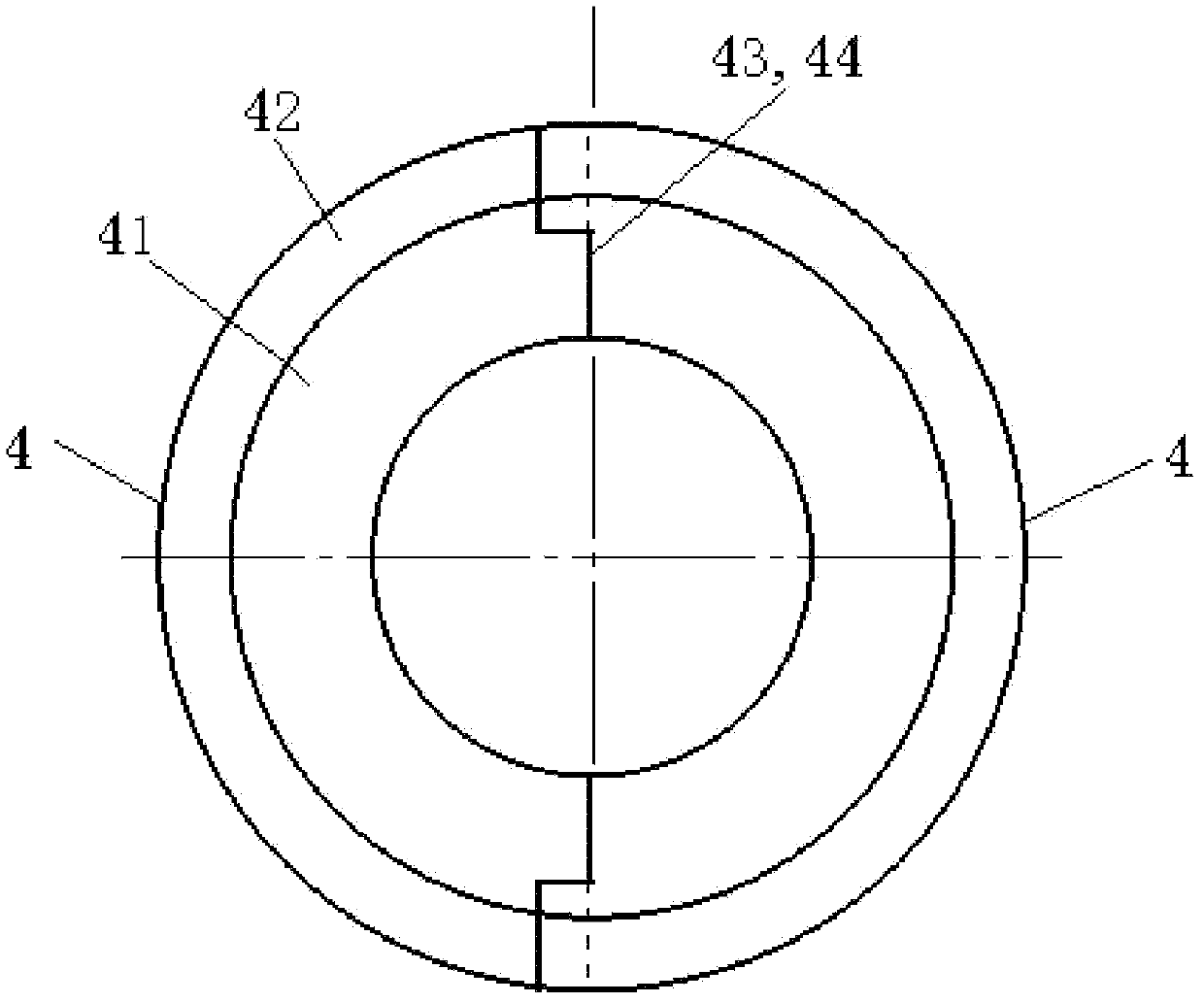

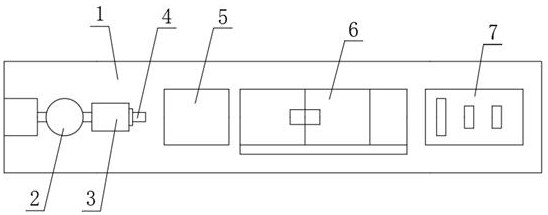

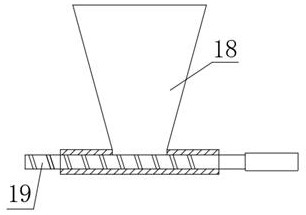

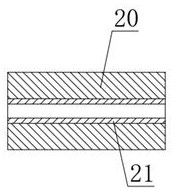

Interval flower color dovetail groove pipe head sucking pipe machining production line

ActiveCN110341159AConvenient distanceImprove cooling and shaping effectMetal working apparatusProduction lineEngineering

The invention discloses an internal flower color dovetail groove pipe head sucking pipe machining production line which comprises a rack (1), and a feeding device (2), a heating device (3), an extrusion molding die (4), a vacuum foam removing device (5), a cooling plastic device (6) and a cutting discharging device (7) which are sequentially arranged on the rack (1). The cooling plastic device (6)comprises a cooling box (8) fixedly connected with the rack. The two ends of the cooling box (8) are provided with a sealing feeding opening (9) and a sealing discharging opening (10) correspondingly, wherein the sealing feeding opening (9) and the sealing discharging opening (10) are the same in height. A partition plate (11) is arranged in the cooling box (8) and provided with a sealing transition opening (12). The height of the sealing transition opening (12) is the same as that of the sealing feeding opening (9). The production line is convenient to operate, and has the advantages of being low in cost, uniform in coloring, high in working efficiency and good in product quality.

Owner:义乌市城西机械有限公司

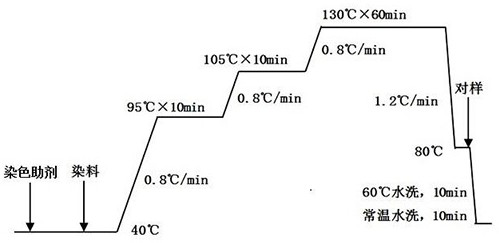

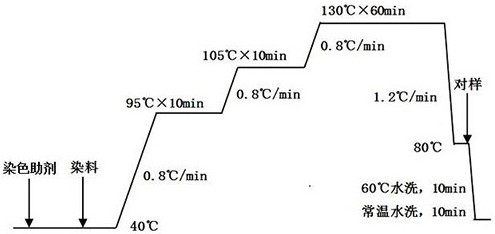

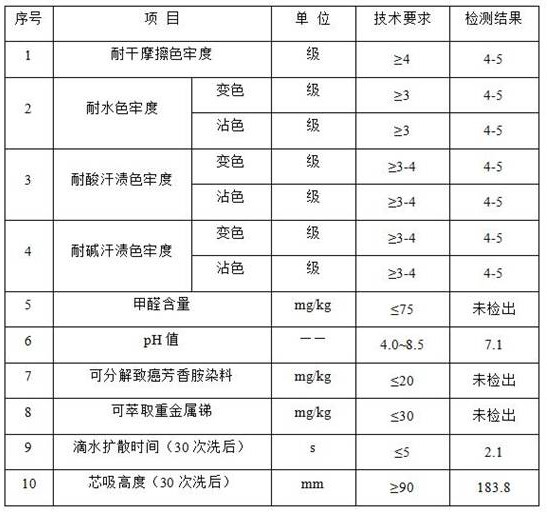

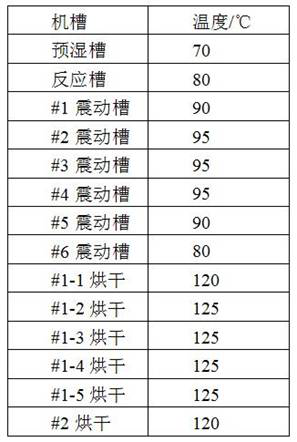

Dyeing and finishing processing technology of four-side stretch fabric based on antimony-free polyester

ActiveCN113186741AIncrease elasticityStress reliefHeating/cooling textile fabricsTextile treatment machine arrangementsPolyesterColour fastness

The invention discloses a dyeing and finishing technology of a four-side stretch fabric based on antimony-free polyester. The dyeing and finishing process comprises a pre-treatment process, a dyeing process and a post-treatment process which are carried out in sequence, the pretreatment process comprises a tension-free preshrinking process and a pre-shaping process; a dyeing agent adopted in the dyeing process comprises a dyeing auxiliary agent and a dye; the dyeing auxiliary agent is prepared from a dyeing optimizing agent TF-256, a dyeing synergist TF-257 and a spandex degreaser TF-109A; the post-treatment process comprises a high-temperature drying process, a soaping process and a low-temperature setting process which are carried out in sequence, wherein in the low-temperature setting process, the soaped fabric is subjected to setting treatment by adopting a moisture-absorbing and sweat-releasing finishing agent; and soaping assistants adopted in the soaping process comprise Yakesai (a brand name of fiber) RC and an acidity slipping agent VS. According to the process, the processed fabric can be ensured to have better elasticity and rebound resilience, various technical indexes such as color fastness of the fabric can meet relatively high requirements, and the fabric can be endowed with relatively high moisture absorption and sweat releasing functions.

Owner:SHENGHONG GRP CO LTD

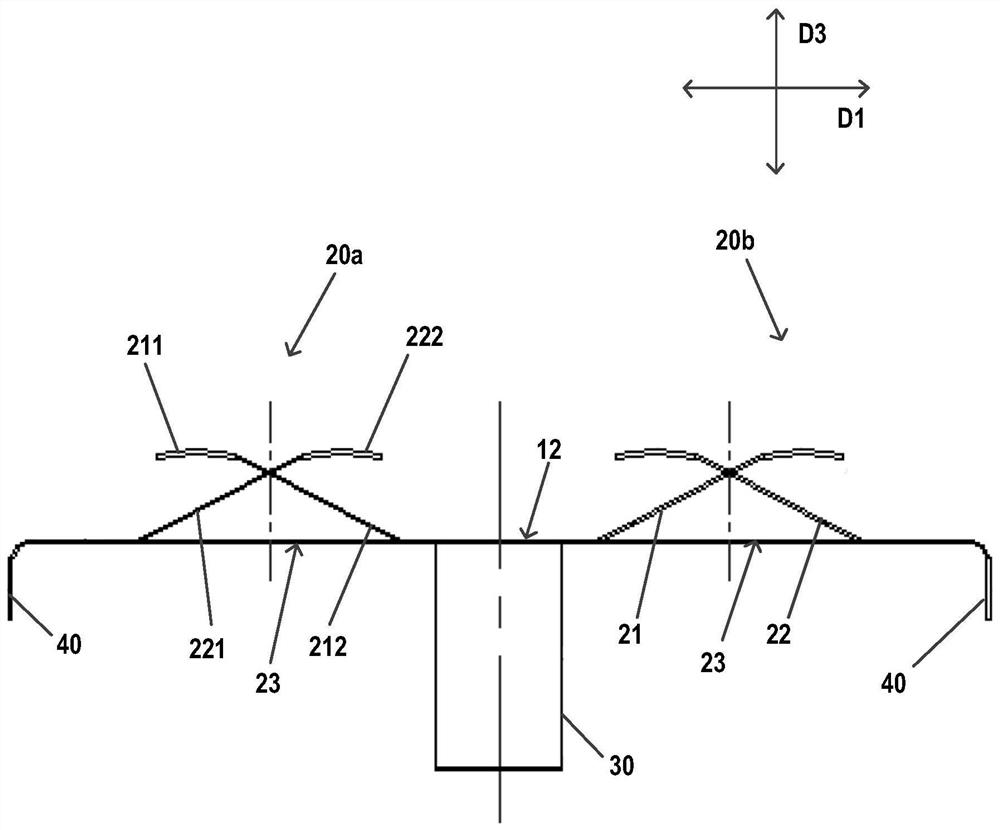

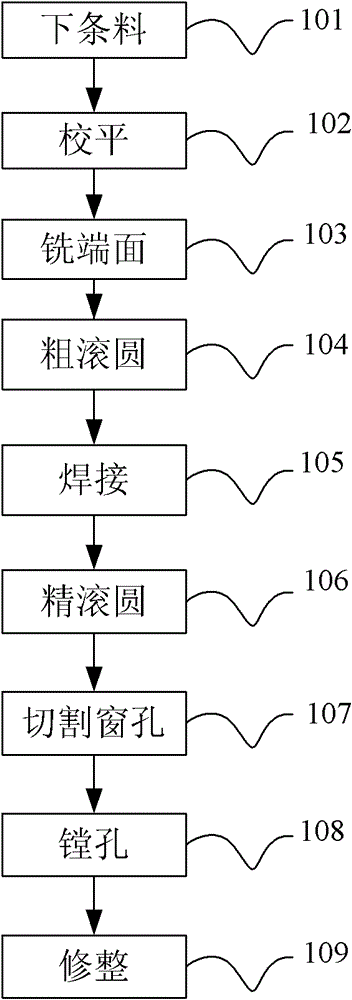

Automatic elasticity balancing device of hanger

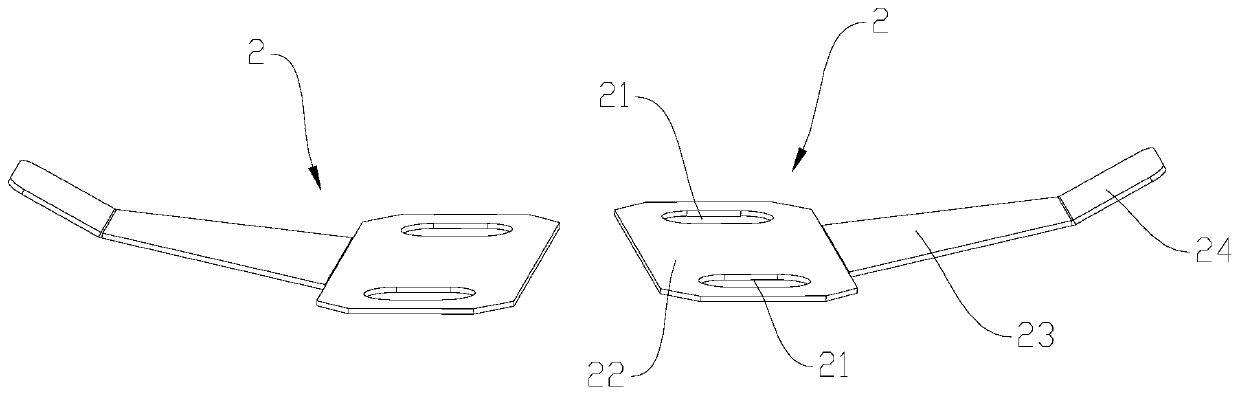

ActiveCN102874131AConsistent elasticityThe overall structure is light in weightTrolley linesDrive shaftSlide plate

Owner:李东生

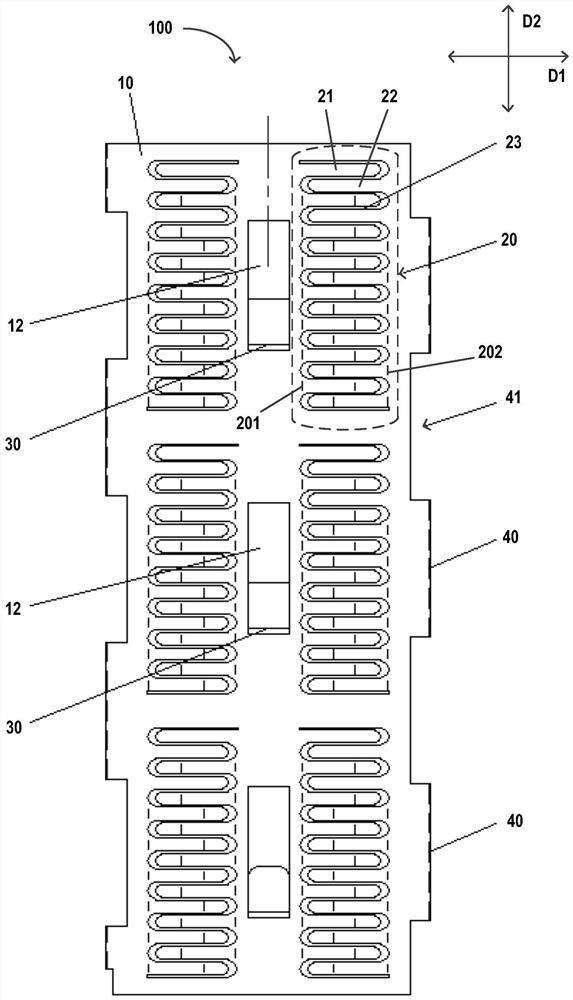

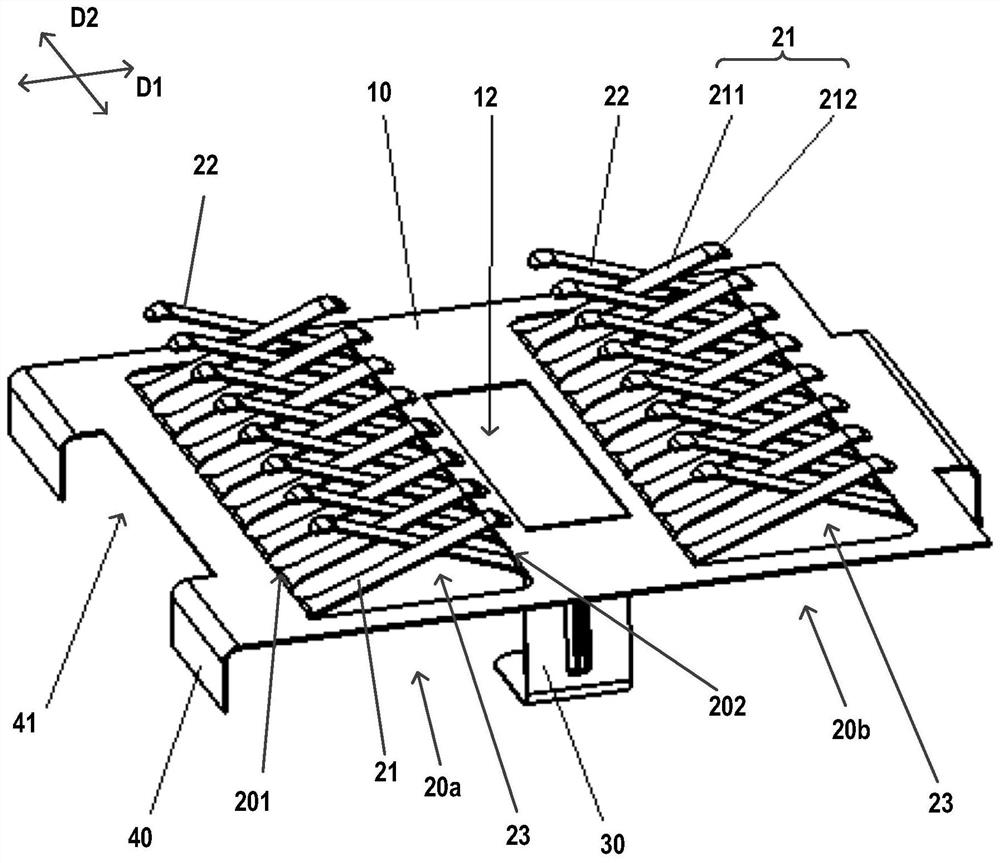

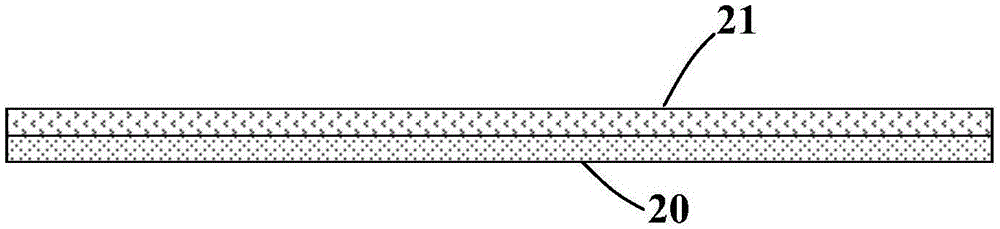

Eelastic supporting piece, electrolytic cell, manufacturing equipment and manufacturing method

ActiveCN113584510AConsistent Protrusion HeightConsistent elasticityCellsShaping toolsManufacturing engineeringElectrolytic cell

The invention provides an elastic supporting piece, an electrolytic cell with the elastic supporting piece, and manufacturing equipment and a manufacturing method for manufacturing the elastic supporting piece. The elastic supporting piece comprises a base plate, an elastic area part and middle supporting legs. Each elastic area part comprises an elastic sheet stamping hole, a first row of elastic sheets and a second row of elastic sheets. The contour lines of the elastic sheet stamping holes are closed on the substrate, the contour lines comprise a first contour line and a second contour line which are parallel to each other, and the elastic sheets in the first row of elastic sheets and the elastic sheets in the second row of elastic sheets are in elastic contact with the cathode component. The middle supporting legs are formed between the two adjacent elastic area parts. The elastic supporting piece has relatively good strength and stability, and can provide stable and uniform elastic support for the cathode assembly in the electrolytic cell, so that the use performance of the electrolytic cell is integrally improved.

Owner:JIANGYIN ANCAN ELECTROCHEM EQUIP

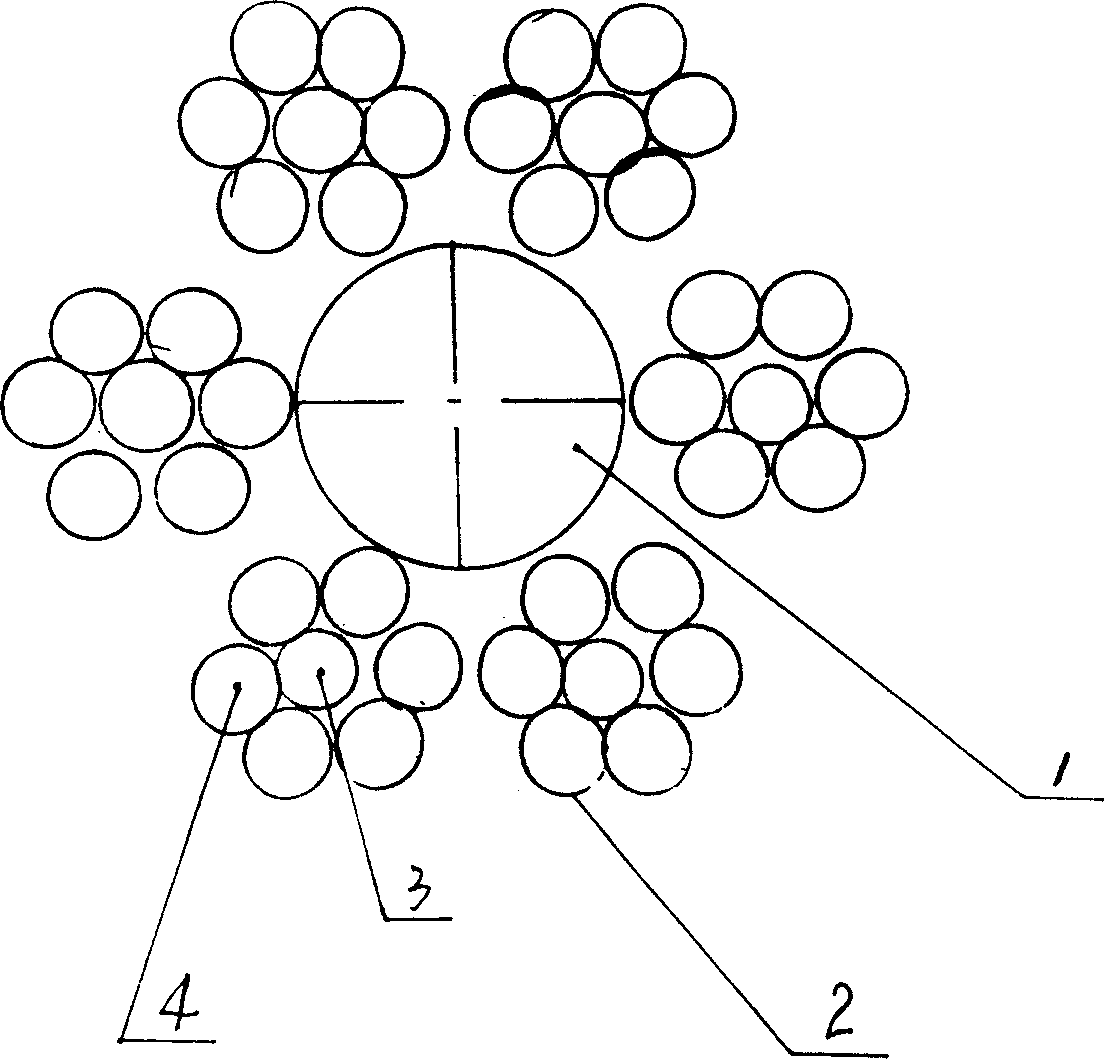

Ball sliding machine

The invention discloses a tool named a ball sliding machine which is used for measuring whether the elasticity of a storage edge of a billiard table is balanced and uniform. The ball sliding machine is provided with an approximate L-shaped frame body which is composed of a horizontal long edge (1) and a vertical edge (2) of an upper oblique surface of a ball sliding groove (8), the vertical edge (2) is provided with a pin (3) which is provided with a control rod (4) capable of clamping or releasing a ball (9) with the horizontal long edge (1) and the vertical edge (2), and an elastic body (5)which exerts acting force on the control rod (4) is arranged on the pin (3). The ball sliding machine has the advantages of simple structure, convenient use and good detection effect, can be taken asa detection device by a manufacturer and a billiard table user, and brings great convenience to users.

Owner:BEIJING XINGWEI SPORTS GOODS

Processing method of deproteinized rice

ActiveCN103211163BPromote dissolutionImprove removal effectFood preparationFlavorReaction temperature

The invention provides a processing method of deproteinized rice. The processing method comprises the following steps of: (1) washing and removing impurities; (2) carrying out enzymolysis and fermentation: in a reaction tank, adding processed rice, purified water, proteolytic enzyme and lactic acid bacteria according to proportion, wherein the weight proportion of rice to purified water is 1:(5-20), the reaction temperature is 10-60 DEG C, the reaction time is 3-20 hours, the initial pH of reaction liquid is between 4.5 and 9.5, the using amount of proteolytic enzyme accounts for 0.1% to 5% of total weight of rice, and the dropping amount of lactic acid bacteria is as follows: 109-1014 bacteria is added in every ton of reaction liquid; and (3) after enzymolysis and fermentation, leaching, washing and drying to obtain the deproteinized rice. According to the method, the technology is simple, the cost is low, the appearance, the color, the flavor and the taste of the deproteinized rice processed by adopting the technology are the same as those of ordinary rice; and the protein removal ratio can be more than 95% at most.

Owner:成都东洋百信制药有限公司

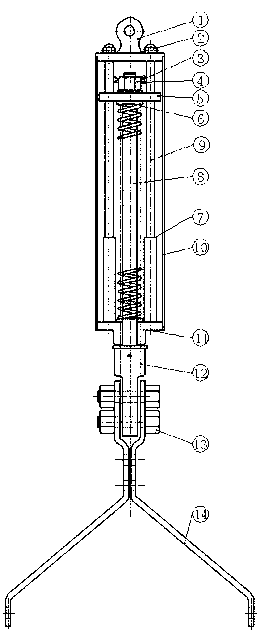

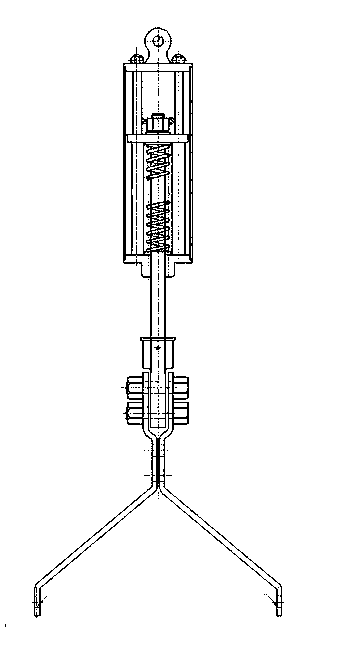

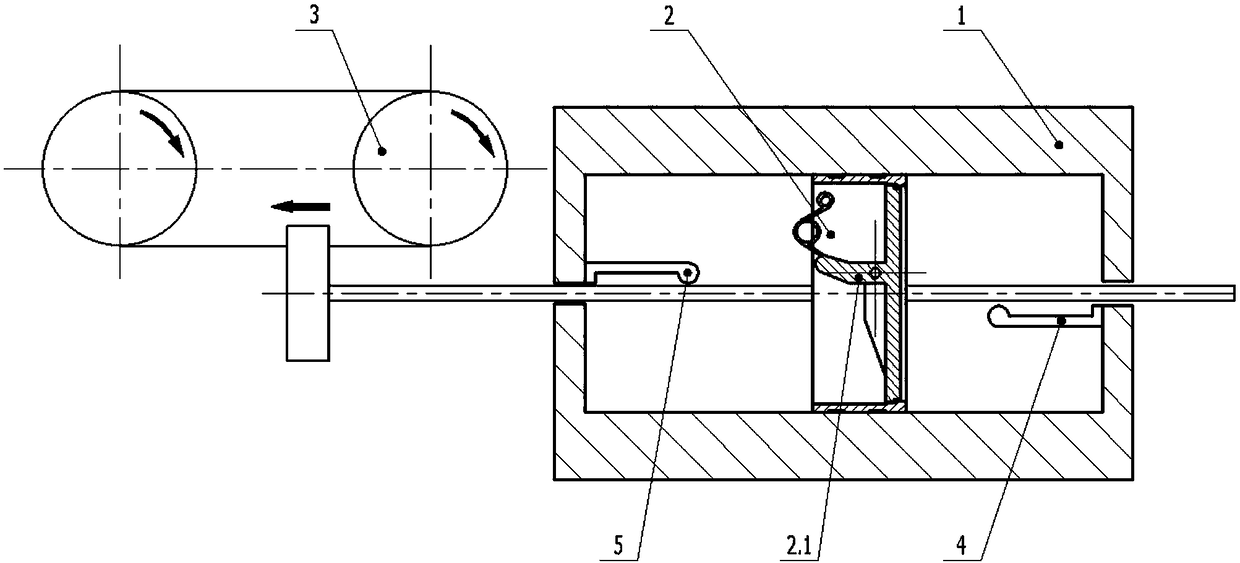

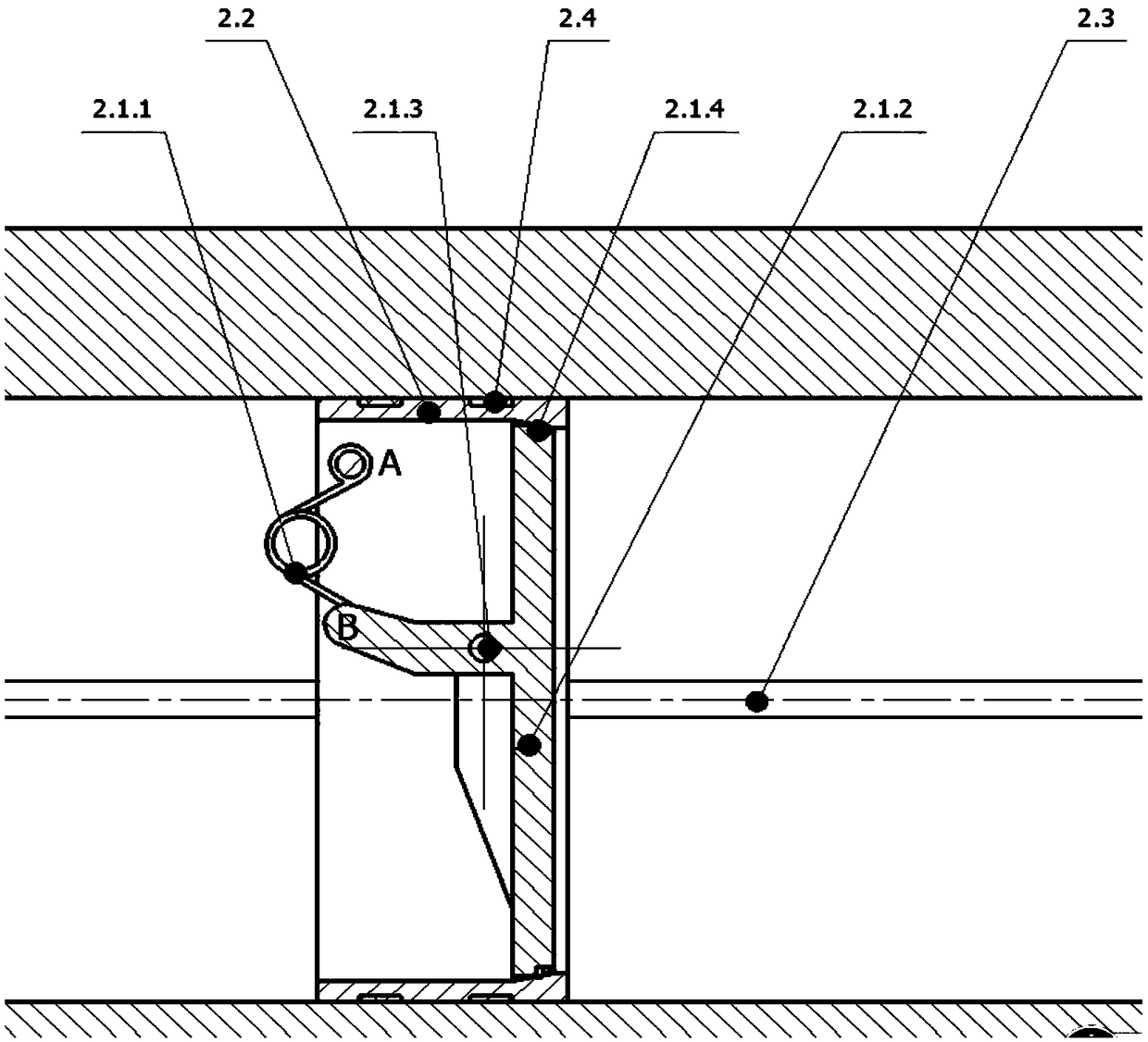

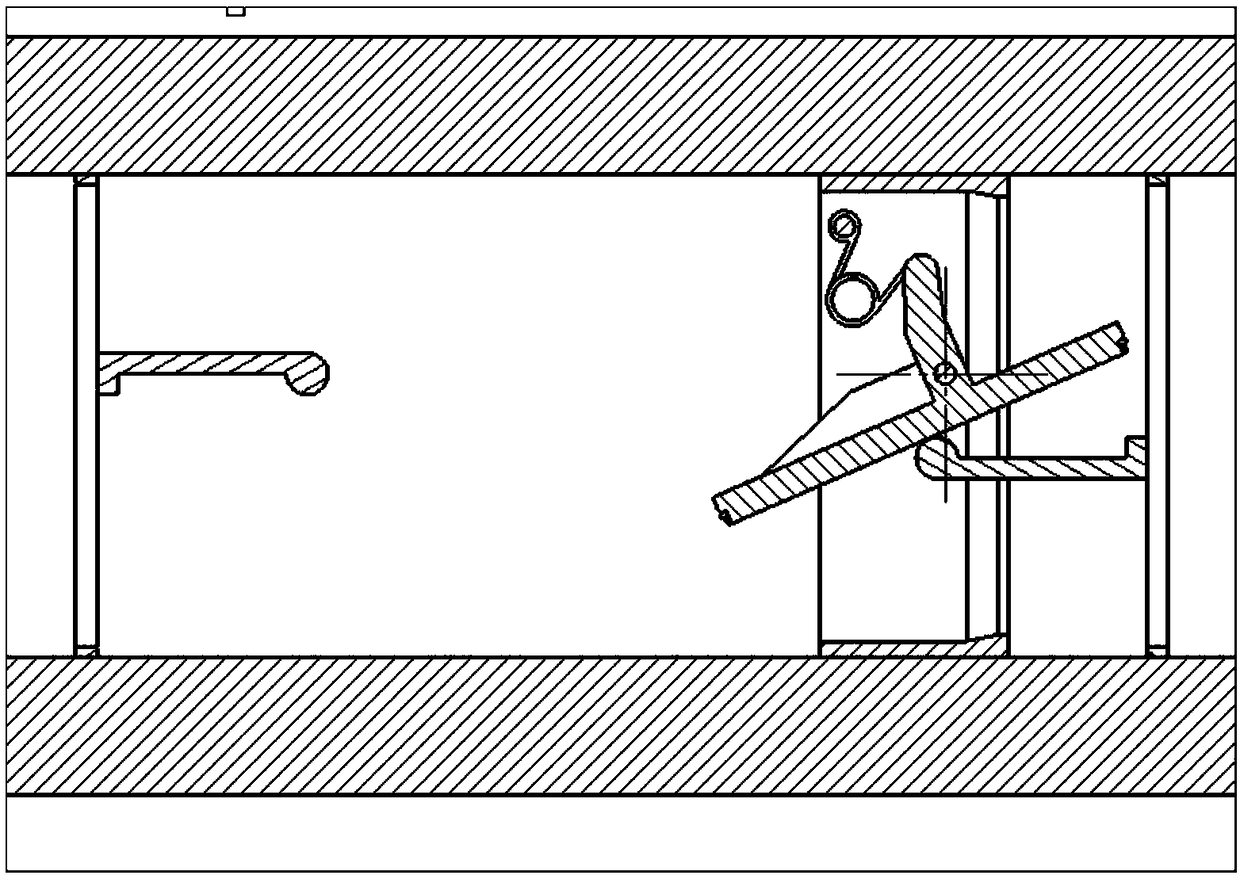

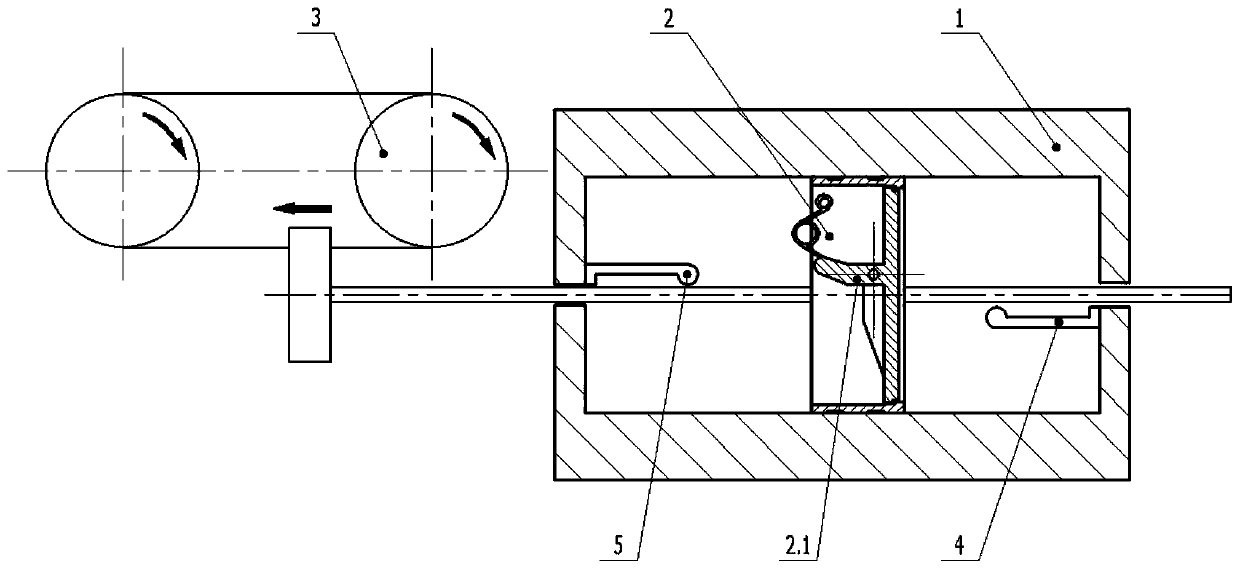

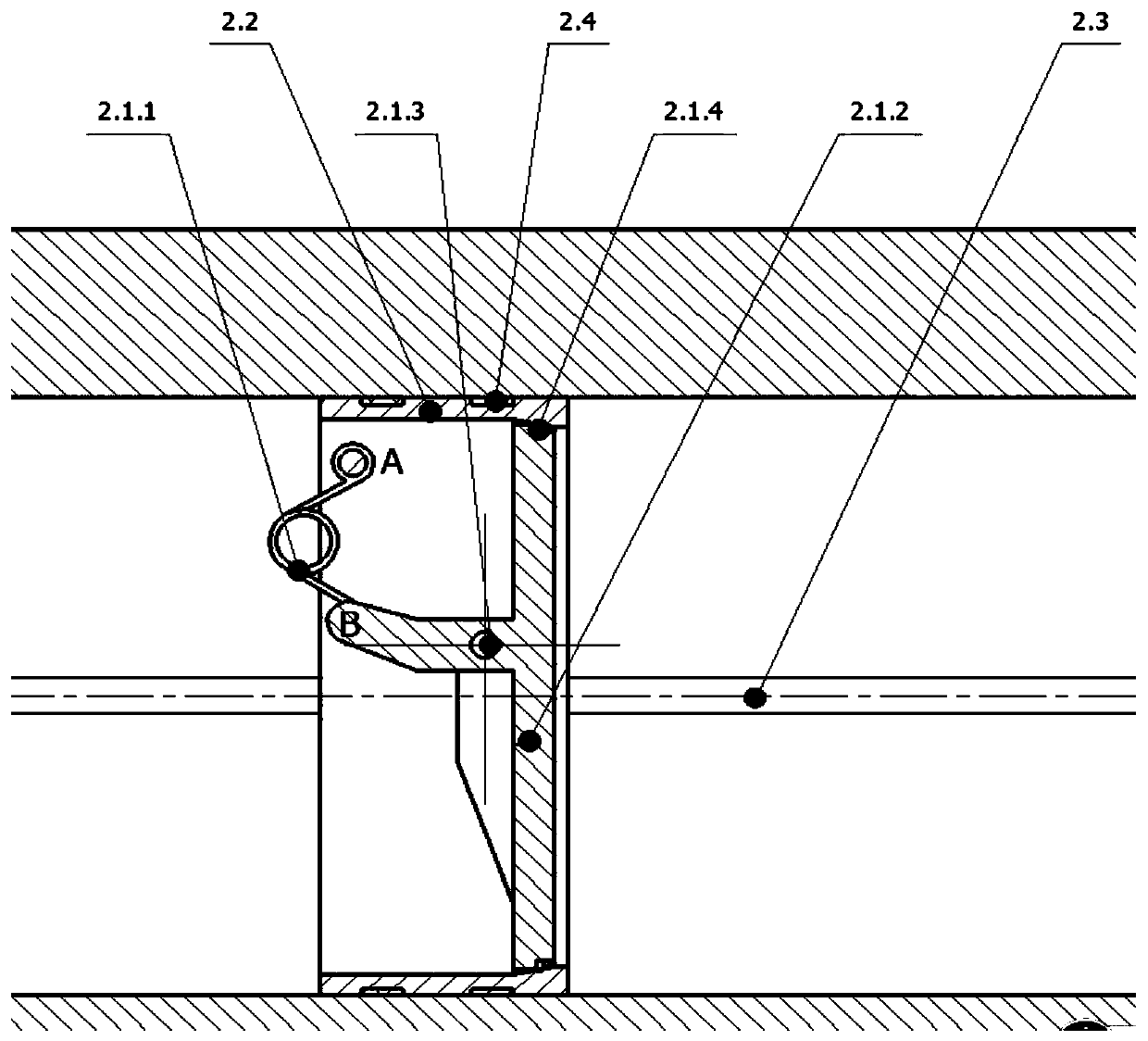

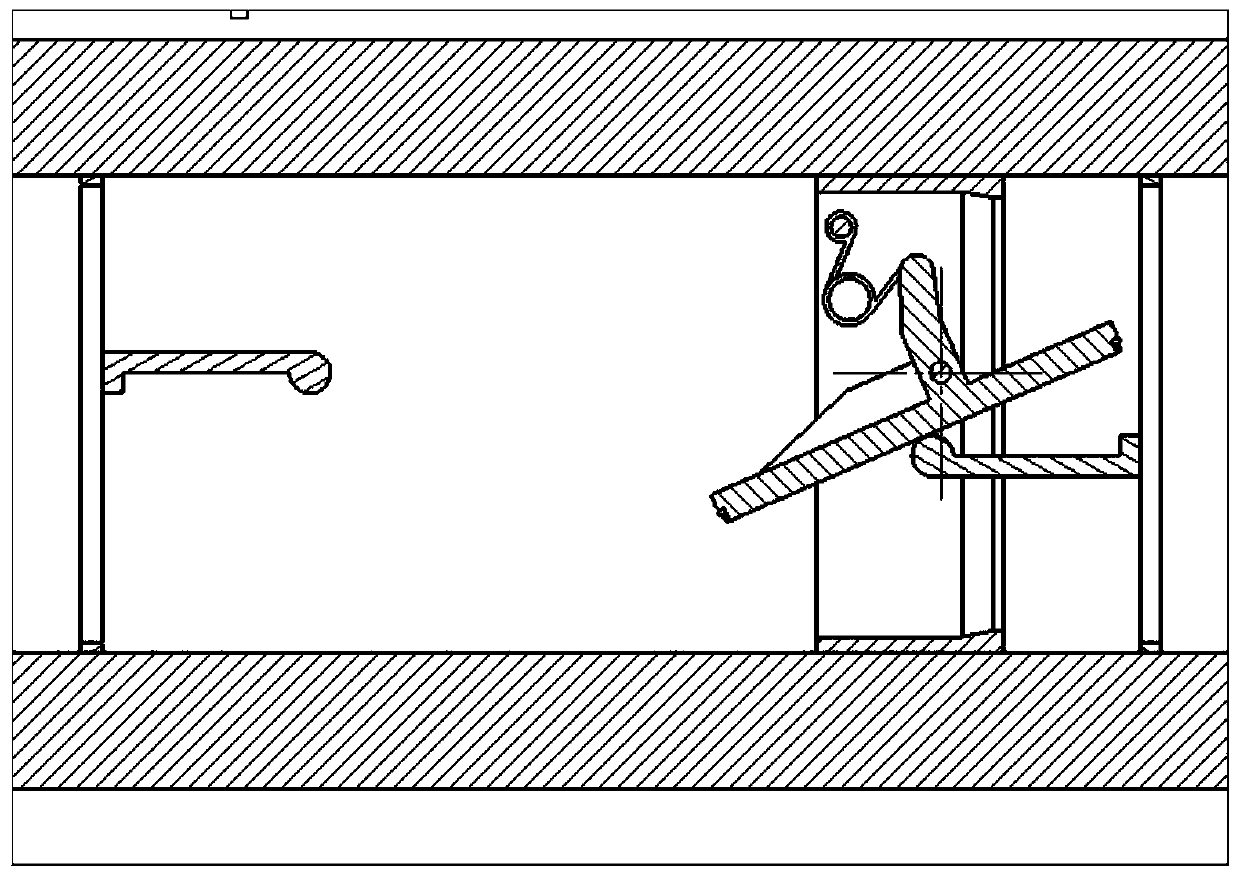

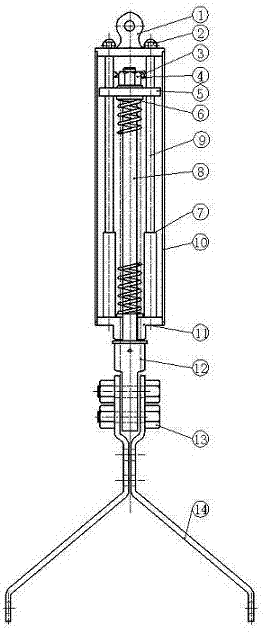

Overturning valve plug-type passive piston volume pipe

ActiveCN108168639AEasy to closeGuaranteed tightnessContracting/expanding measuring chambersEngineeringCylinder block

The invention discloses an overturning valve plug-type passive piston volume pipe, relating to a passive piston volume pipe which belongs to the field of liquid flow measurement. The overturning valveplug-type passive piston volume pipe comprises a cylinder body, a piston system and a return mechanism. The overturning valve plug-type passive piston volume pipe further comprises a lower ejection rod and an upper ejection rod. The lower ejection rod is used for ejecting an overturning valve plug open when the piston system moves at the downstream extreme position. The upper ejection rod enablesthe overturning valve plug to be closed when the piston system moves at the upstream extreme position. The piston system can operate in the cylinder body in a reciprocating manner so that continuousmeasurement of flow is achieved. The piston system comprises an overturning valve plug mechanism, a piston, a piston rod and a piston sealing part. The overturning valve plug mechanism comprises a torsion spring, the overturning valve plug, a rotary shaft and a sealing ring. In order to resolve the technical problem, loss of pressure and state transition impact during operation of the passive piston volume pipe are reduced and a return process is prevented from climbing. Therefore, the requirement for measurement accuracy of the passive piston volume pipe is ensured and service lifetime of equipment is prolonged.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

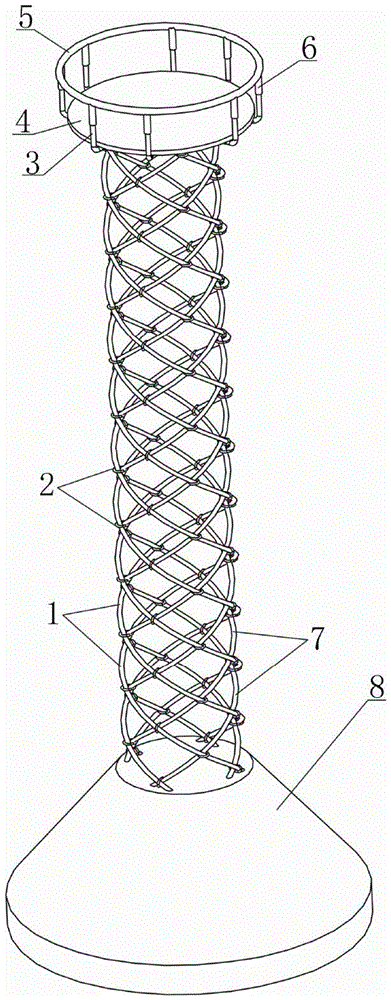

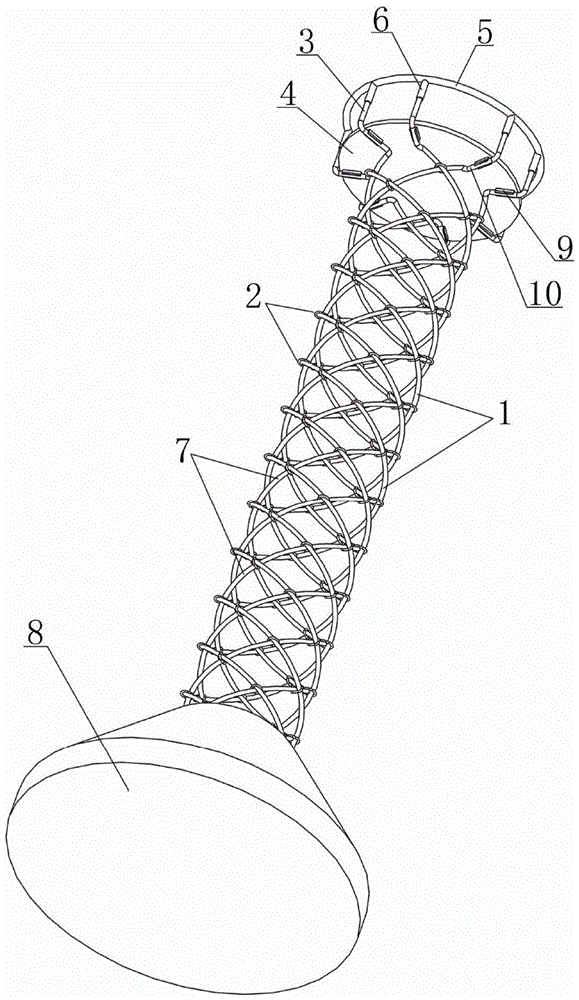

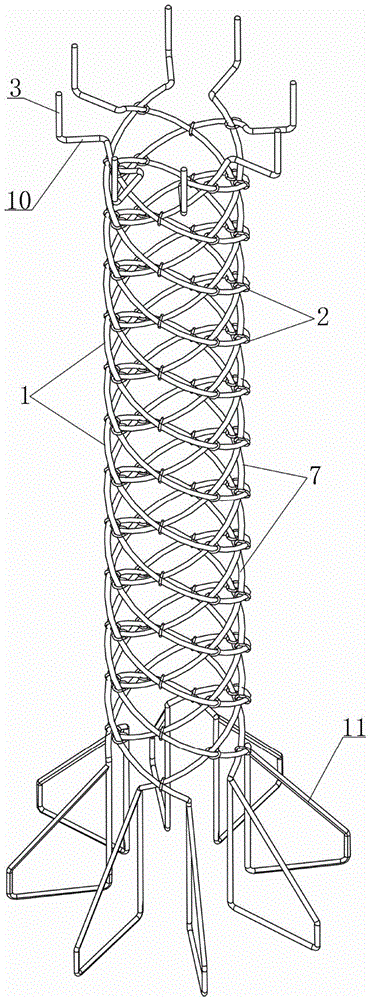

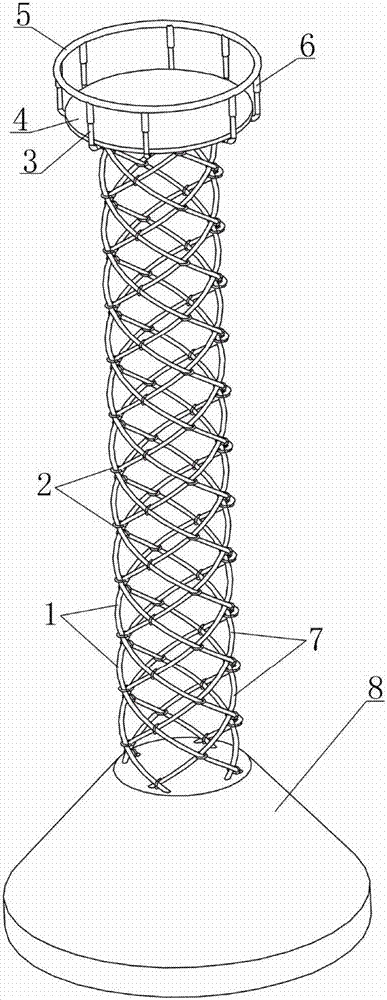

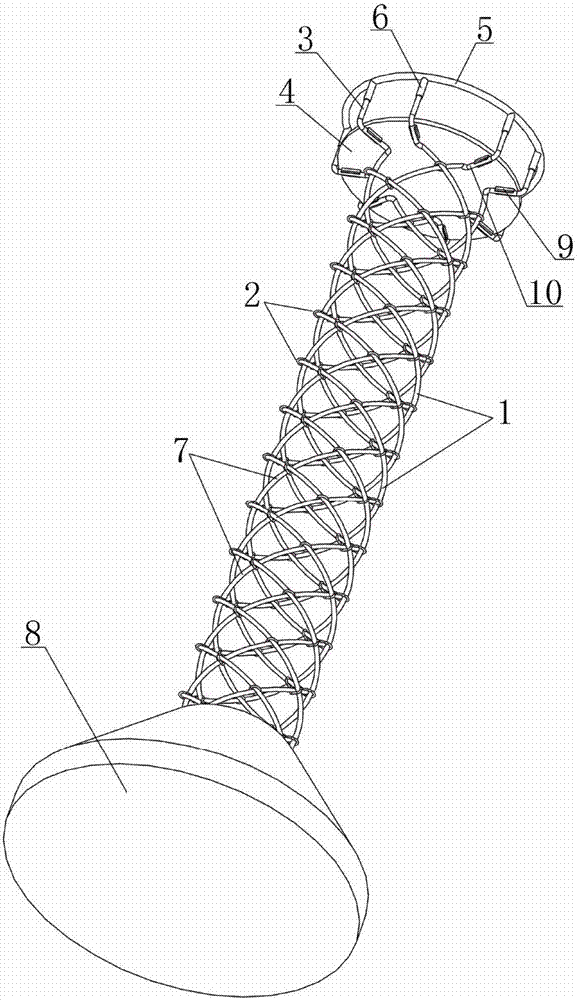

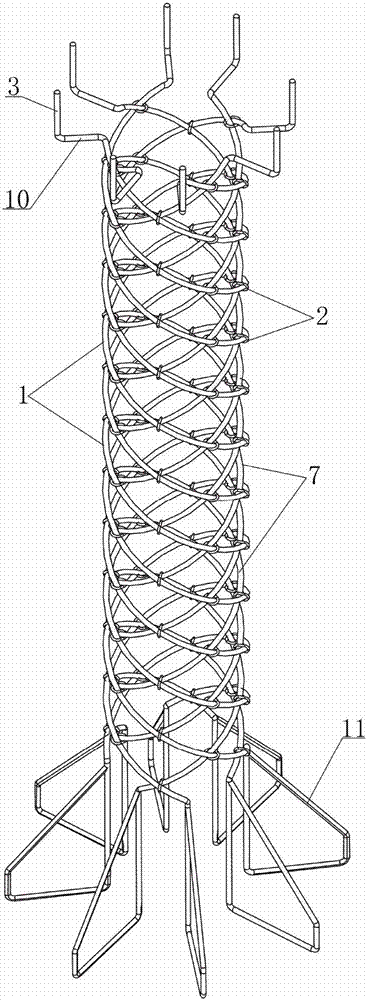

Communication iron tower

The invention discloses a communication iron tower which comprises four forward spiral frameworks distributed in an axial array and four backward spiral frameworks distributed in an axial array , wherein the backward spiral frameworks are wound on the forward spiral frameworks, and fixedly connected with the forward spiral frameworks via locking pieces, so as to form a cage-shaped tower body; eight foot margin embedding parts are arranged on the lower side of the tower body; a platform mounting part is arranged on the upper side of the tower body; the foot margin embedding parts are embedded in a cement tower base; a bearing platform is mounted in the platform mounting part; a combined hand rail is mounted at the upper end of the platform mounting part. The communication iron tower has the advantages that the number of components is small; the integrity and the intensity are high; the mounting is convenient; the tower body is relatively high in tenacity and elasticity; the intensity distribution of the tower body is uniform; the capabilities of resisting side forces in all directions are the same; the stability is high; lateral stress can be dispersed; the side force impact can be buffered; the damage resisting capacity is high.

Owner:YANGZHOU RUNYUAN LAMP DECORATION CO LTD

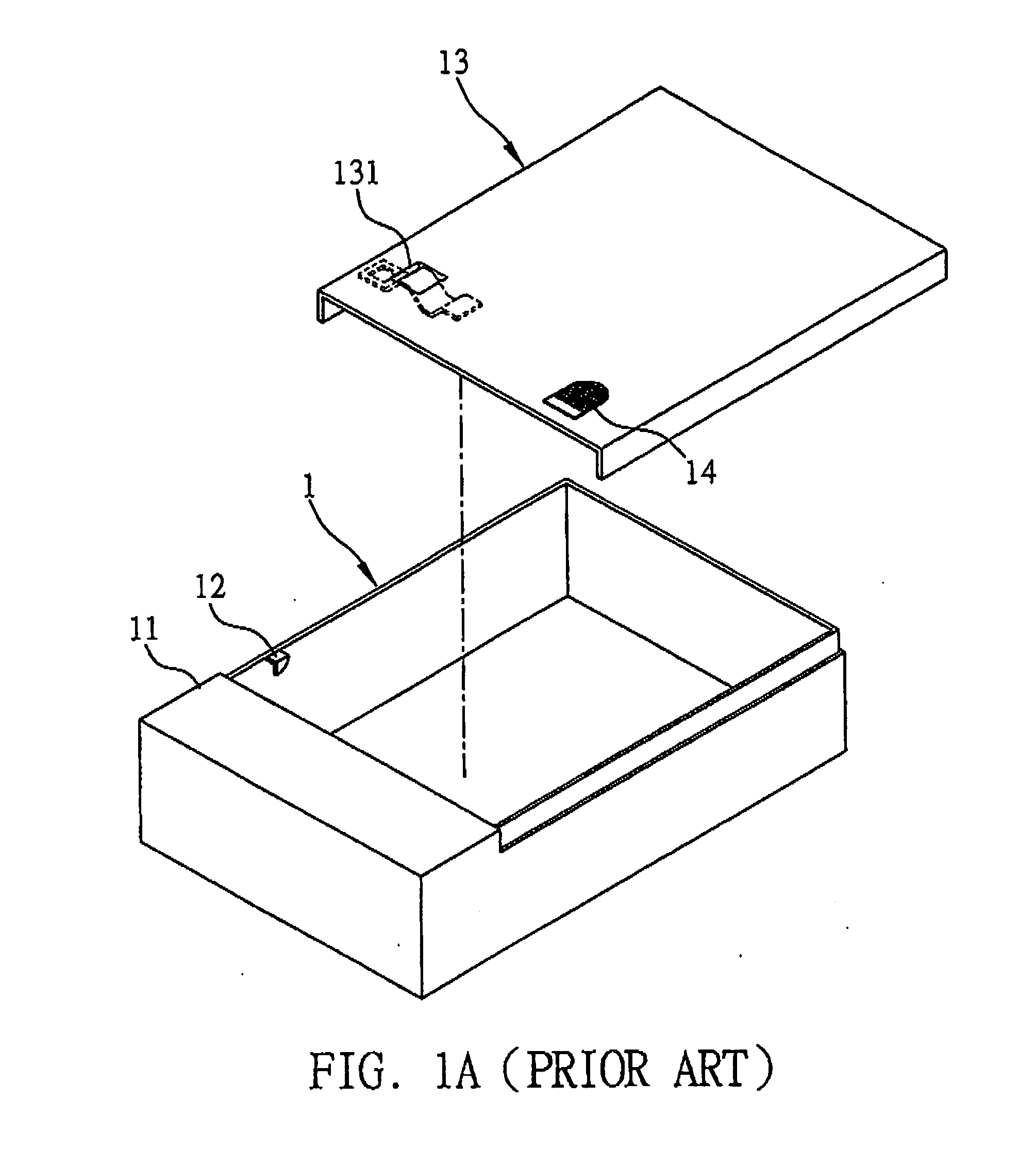

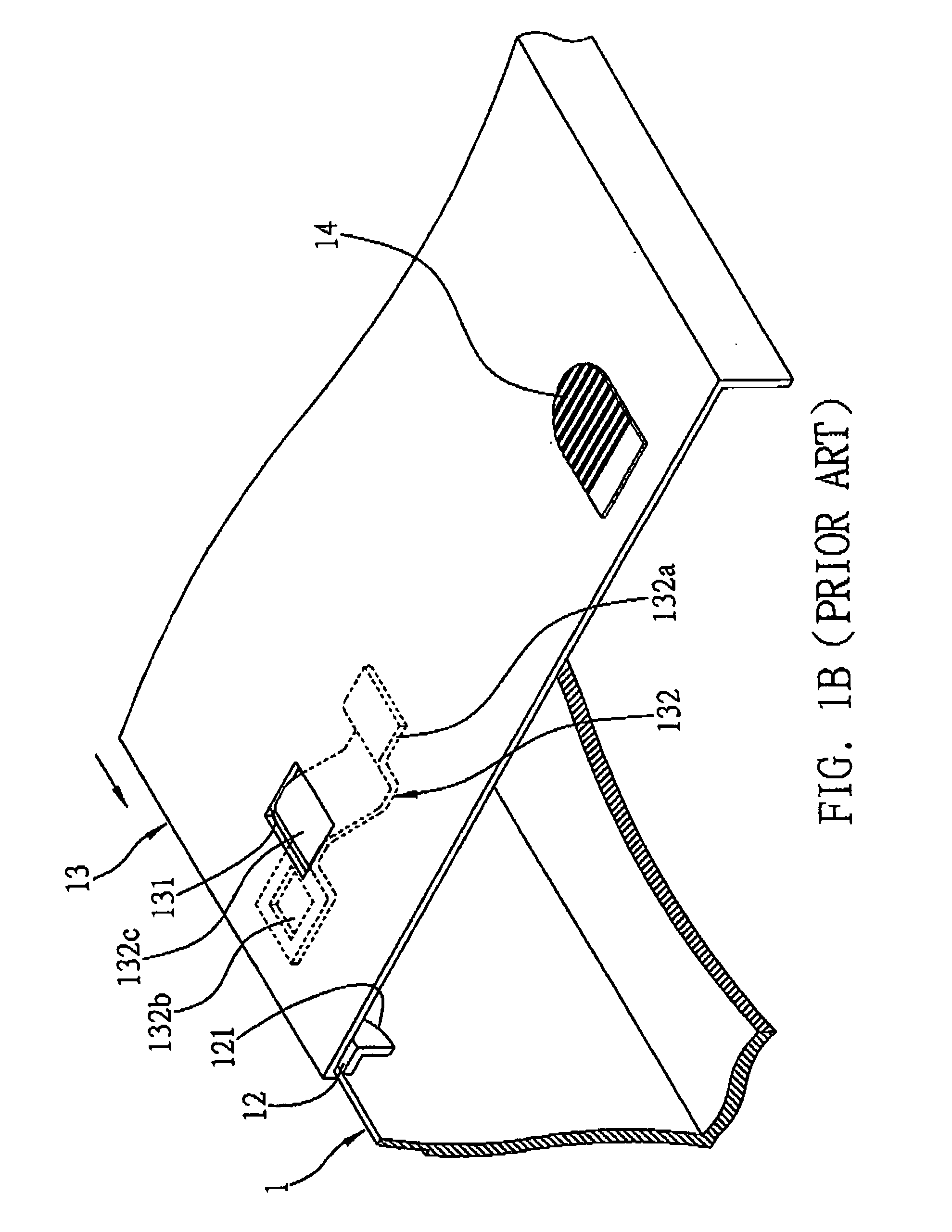

Lid body anchor system

InactiveUS20080136192A1Easy to operateConsistent elasticityDigital data processing detailsBuilding locksEngineeringMechanical engineering

Owner:INVENTEC CORP

Dedicated wire rope for lever block

The invention relates to a steel cable used for wrench gourd. The technical project of the invention is: arranging a fabric core in the steel cable central strand, forming the round six strands in plum blossom shape. Each of the six strands is made up of seven small strands including a central small strand and six round small strands. The central strand for adopting fabric core with high elasticity can keep same elasticity with the round six strands, by which, the useful life of the steel cable is extended to 10 times.

Owner:李兰松

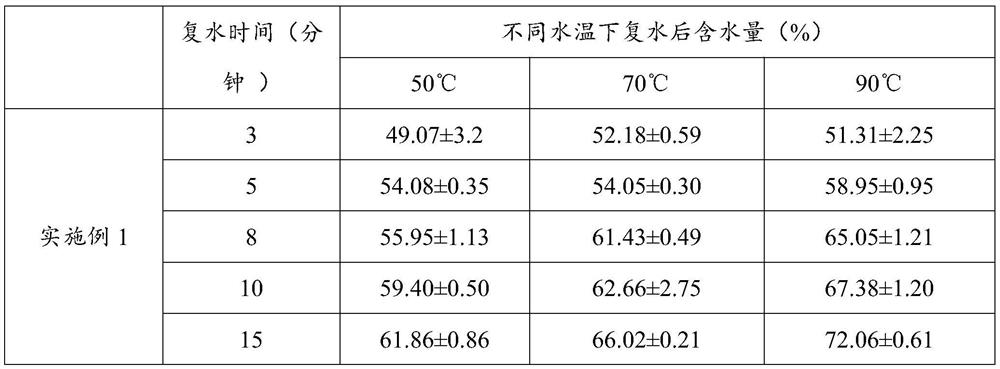

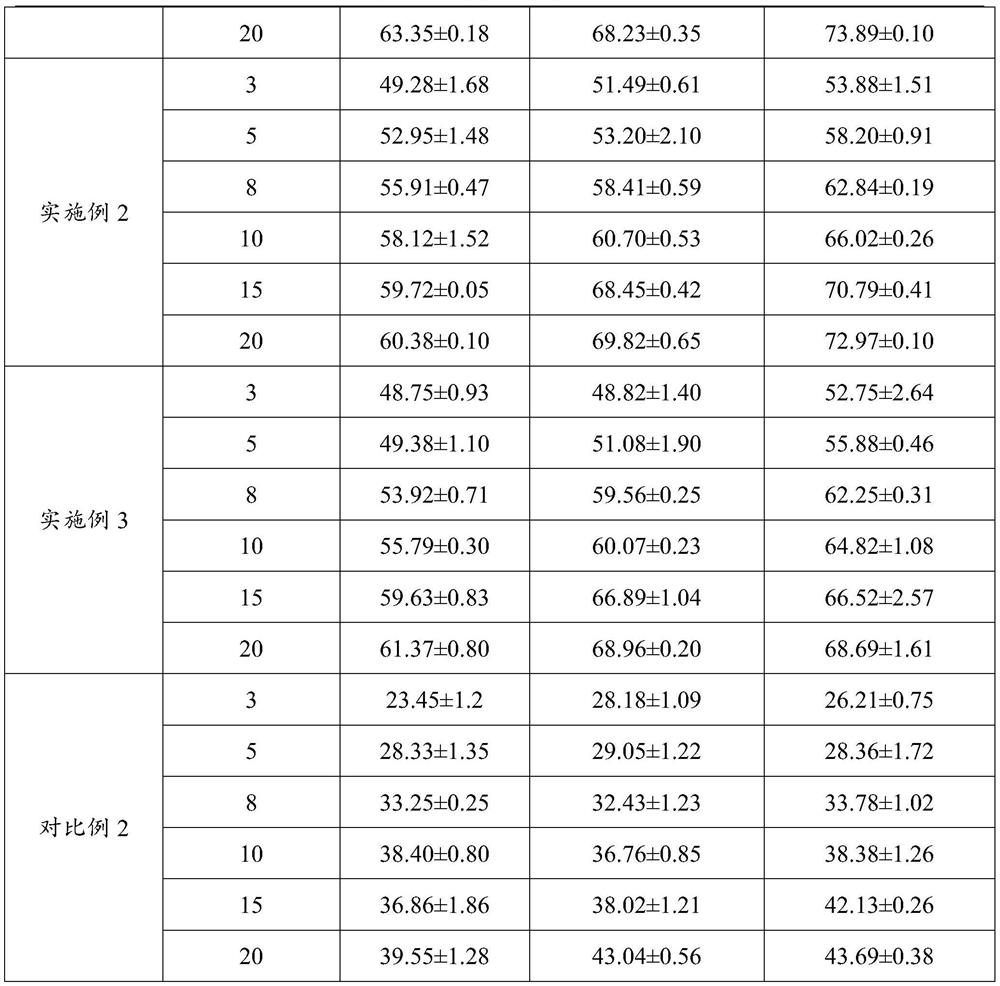

Vacuum freeze-drying method and preparation method of freeze-dried instant rice noodles

ActiveCN114651932AReduce water temperatureHigh rehydration rateFood freezingDrying solid materials without heatBiotechnologyFreeze-drying

The invention belongs to the technical field of food. The invention provides a vacuum freeze-drying method of freeze-dried instant rice noodles. According to the freeze-dried instant rice noodles disclosed by the invention, the contradiction that the rice starch increases pores and inhibits retrogradation is relieved by adopting a process step of slowly drying at a freezing temperature, so that the prepared freeze-dried instant rice noodles are high in rehydration rate and short in rehydration time, and the instant rice noodles only need to be soaked for 5-10 minutes; according to the freeze-dried instant rice noodles prepared by the vacuum freeze-drying method disclosed by the invention, the texture characteristics of hardness, viscosity, elasticity, adhesiveness and chewiness after rehydration are basically consistent with the taste of fresh and wet rice noodles. No modified material is added when the rice noodles are prepared, meanwhile, high efficiency and energy conservation are realized by adopting the temperature of-40 DEG C to 45 DEG C in the vacuum freeze-drying process, and the processing cost of the freeze-dried instant rice noodles is reduced.

Owner:AGRO PROD PROCESSING RES INST YAAS

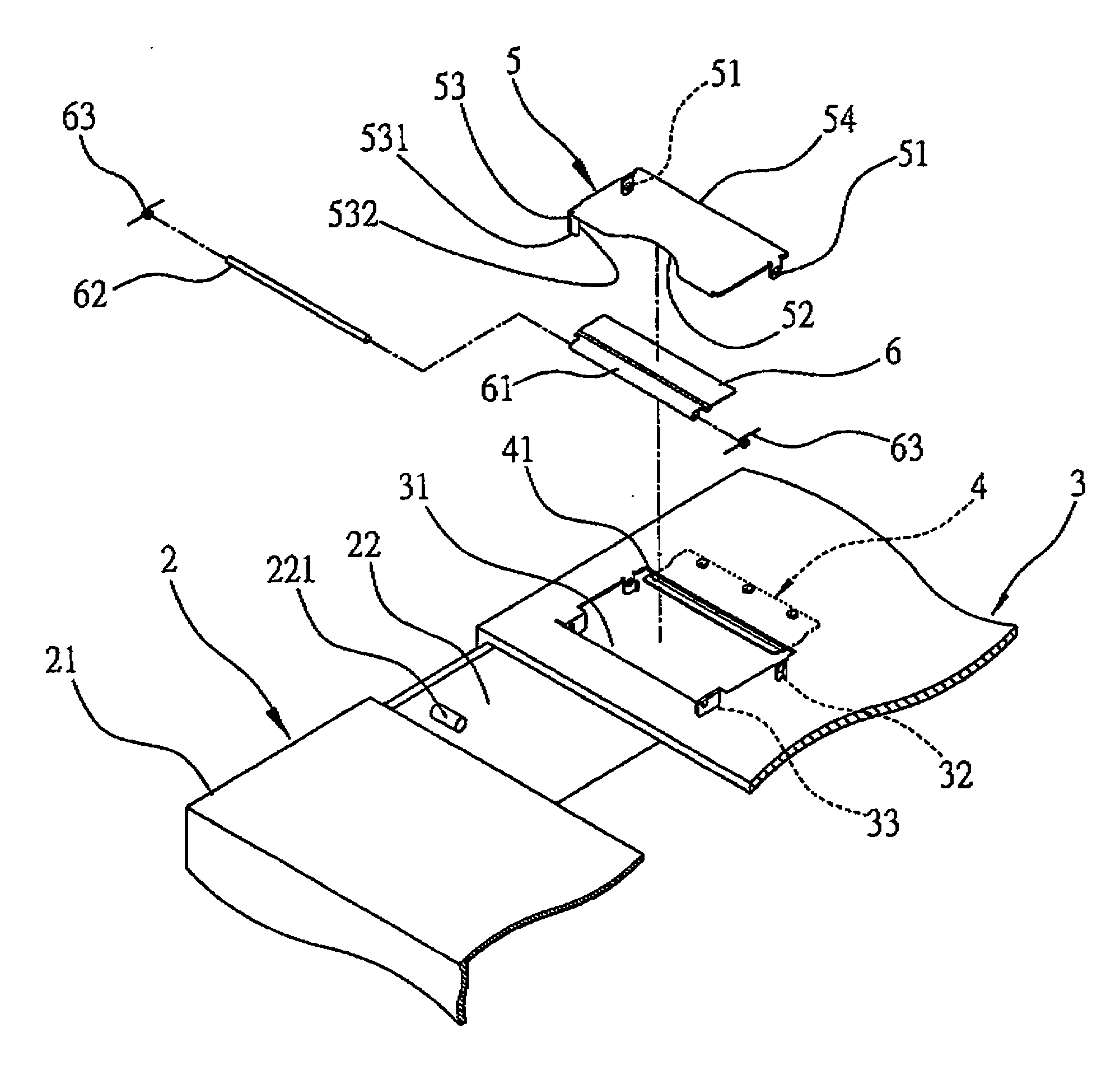

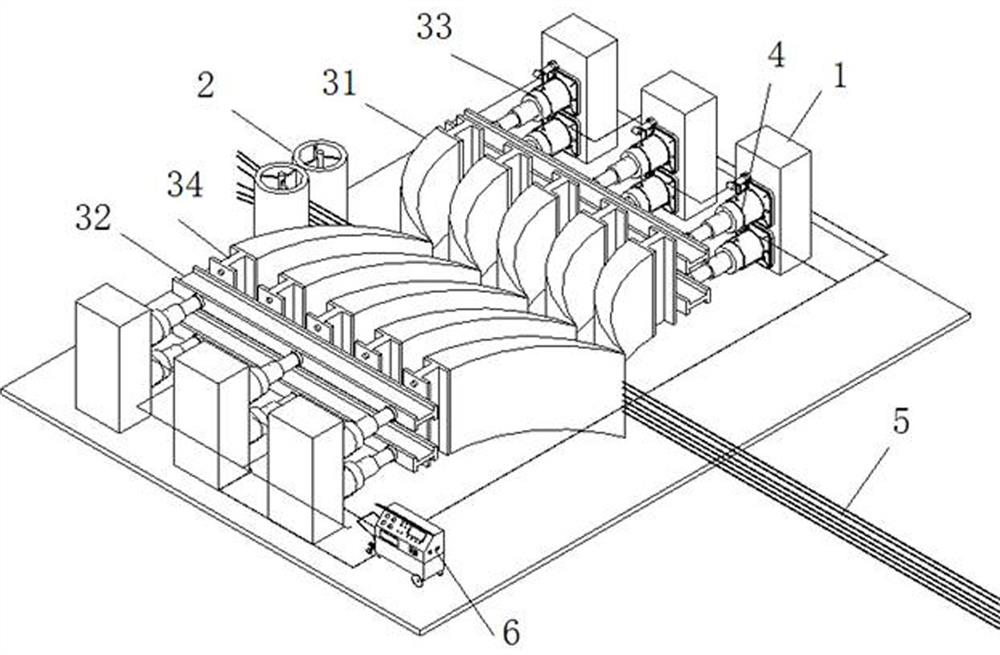

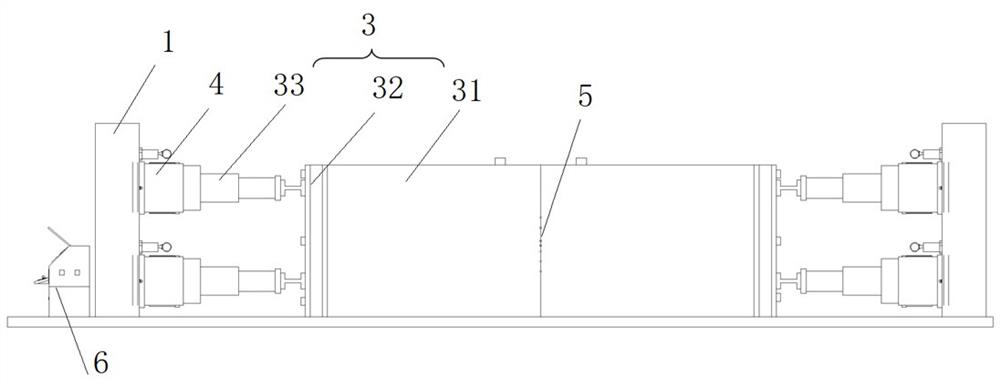

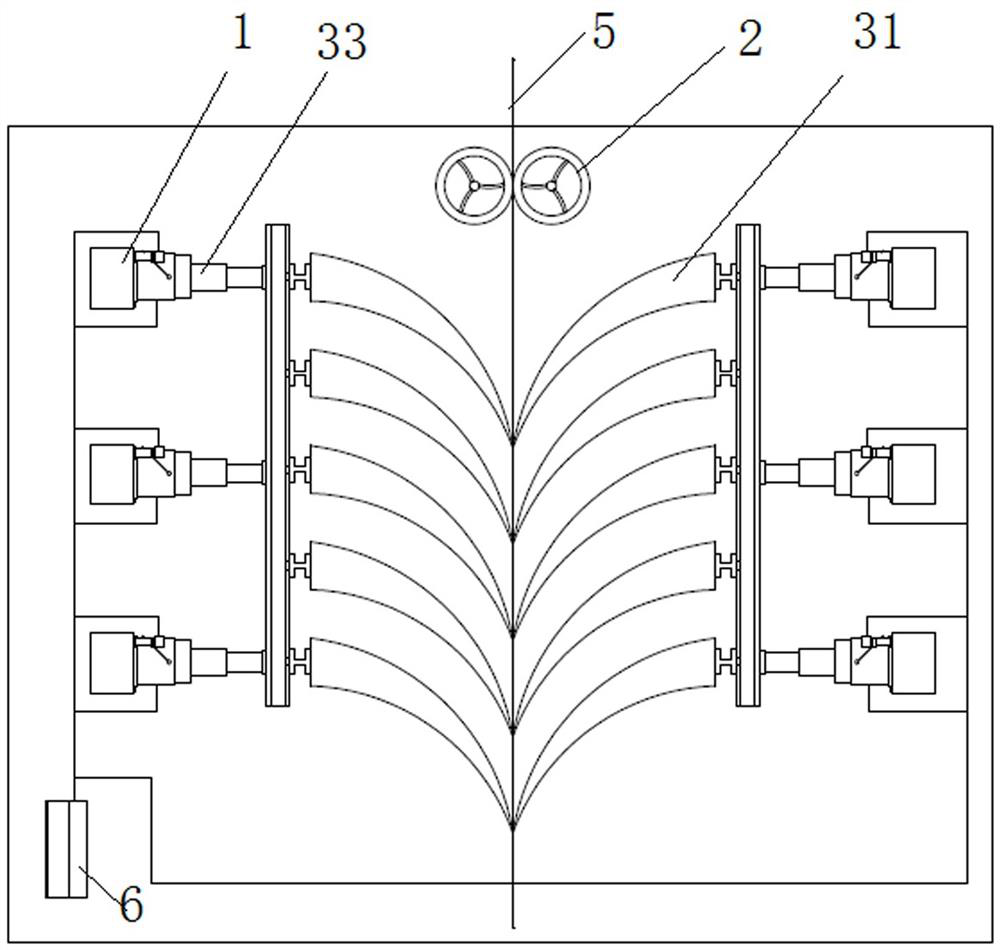

Steel strand braiding initial stress adjusting damping system

The invention discloses a steel strand braiding initial stress adjusting damping system which comprises an outer frame, a preliminary arrangement and positioning device, an initial stress adjusting device and a numerical control center, and the outer frame is used for providing a working face and a working foundation for the whole system; the preliminary arrangement and positioning device is arranged at the starting end of the traction movement direction of steel strands, the multiple steel strands enter the initial stress adjusting area from the preliminary arrangement and positioning device, and preliminary arrangement and positioning are conducted on the steel strands; the initial stress adjusting device is arranged in the initial stress adjusting area and comprises a rubber valve assembly, a fixed beam and a hydraulic jack, the two ends of the rubber valve assembly are fixedly connected with one side of the fixed beam, and the other side of the fixed beam is connected with the hydraulic jack so that pressure can be output through the hydraulic jack; a stress sensor is arranged at the end part of the hydraulic jack; and the numerical control center is respectively in signal connection with the hydraulic jack and the stress sensor.

Owner:中国建筑土木建设有限公司 +1

Preparation method of super-simulation fake breast

The invention belongs to the technical field of plastic and aesthetic surgery and especially relates to a method for preparing a super-simulative fake breast. The method comprises the following steps of: (1) atomizing a release agent on the surface of a mold for preparing the fake breast, and then putting the mold in an oven for drying; (2) atomizing liquid silicon rubber on the surface of the mold in step (1), and then removing bubbles through vacuum equipment, and then putting the mold in the oven for solidification; (3) repeating step (2) three to six times, pouring liquid silica gel in the gap part of the mold for vulcanization, and then solidifying the mold in the oven; and (4) pouring the liquid silicon rubber on the outer layer of the product formed in step (3), then removing bubbles, drying and demoulding to finally obtain the super-simulative fake breast. The super-simulative fake breast prepared through the above-mentioned steps basically keeps consistent with the breast tissue of a human body in softness, elasticity, specific gravity and colour and lustre, and is more authentic and closer to the human body skin than the traditional silicon gel fake breast. Especially in touch aspect, the advantage of the product is well displayed.

Owner:DONGGUAN LANKE SILICONE TECH

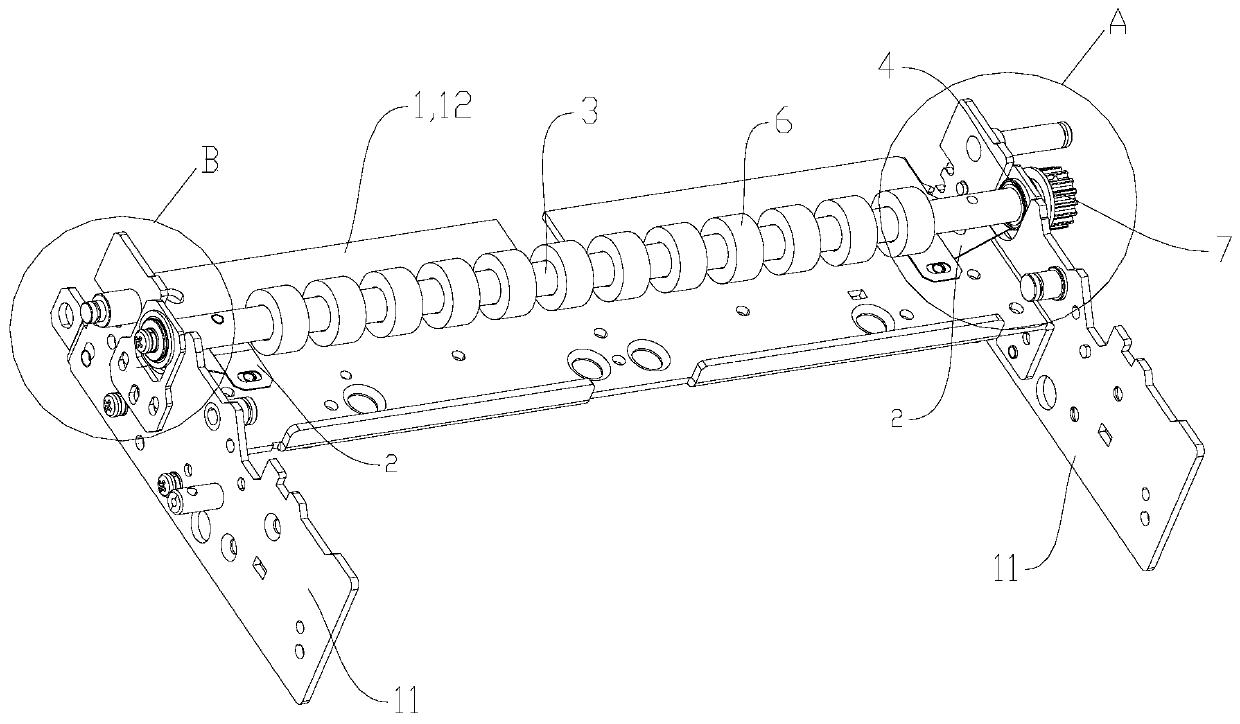

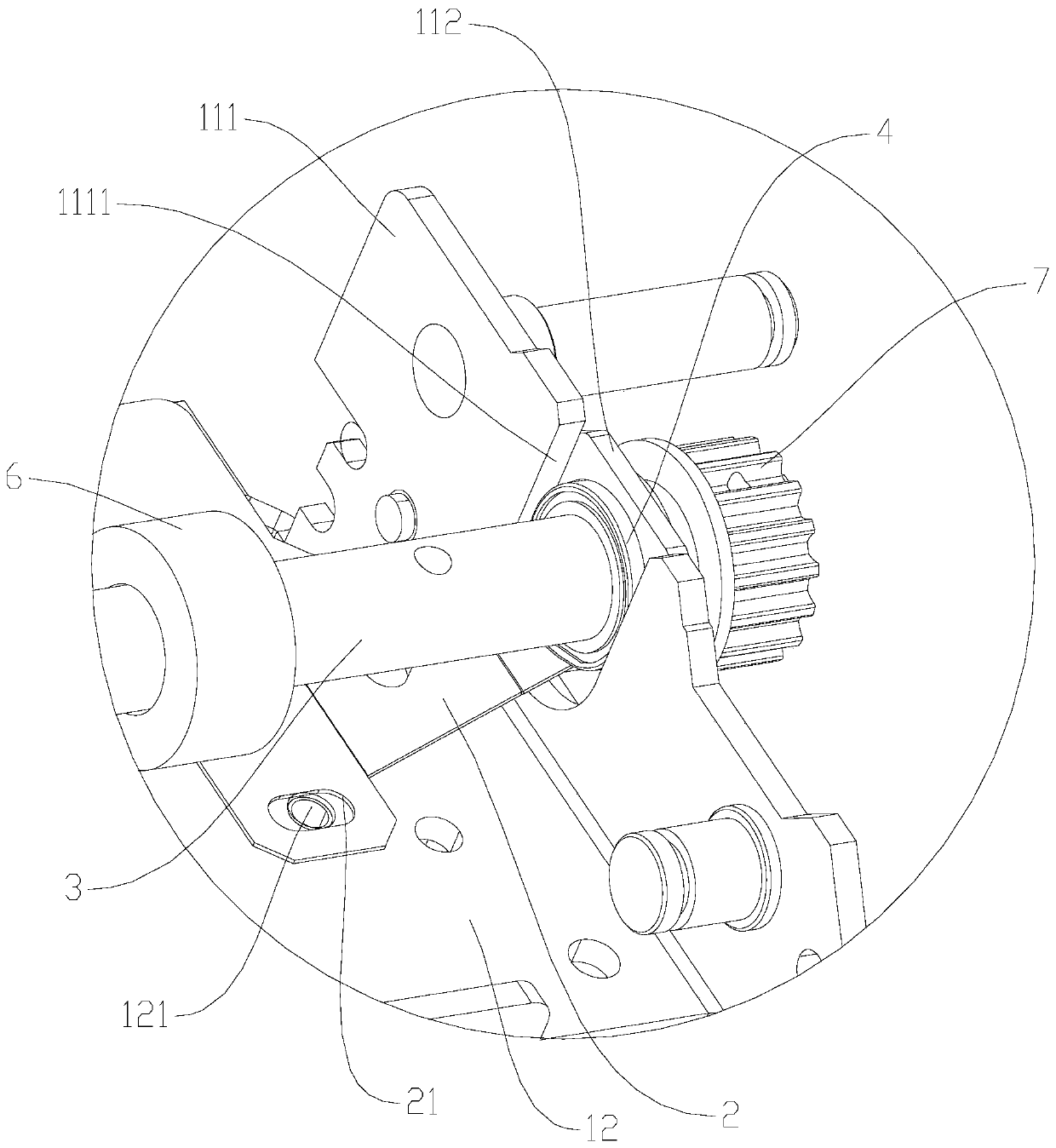

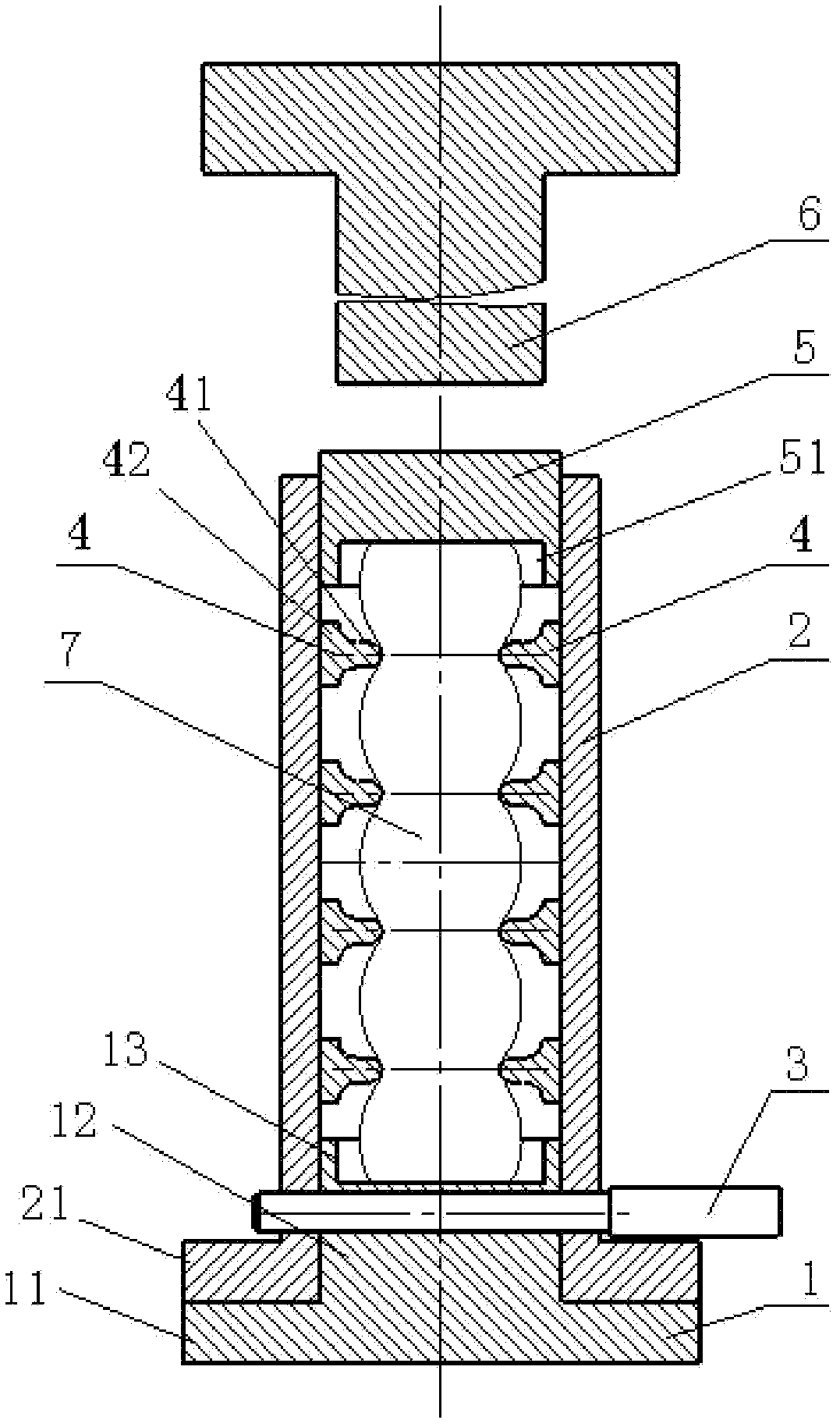

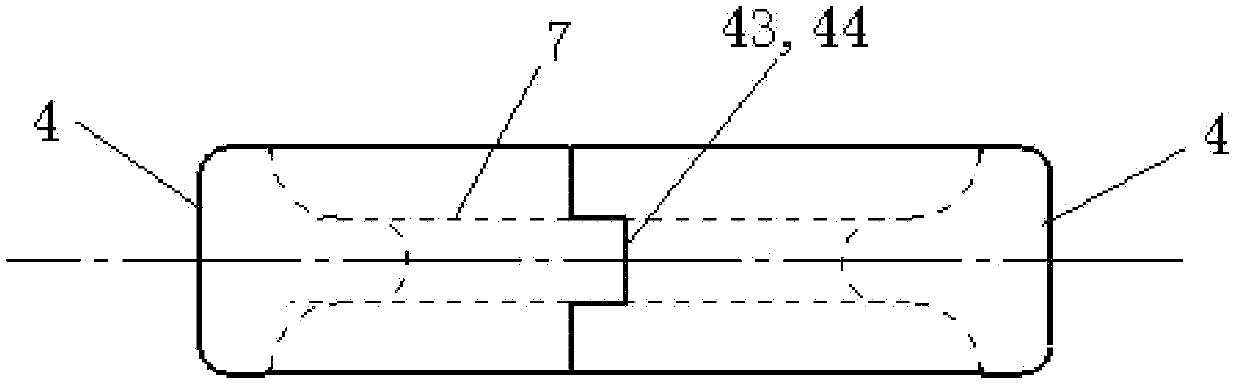

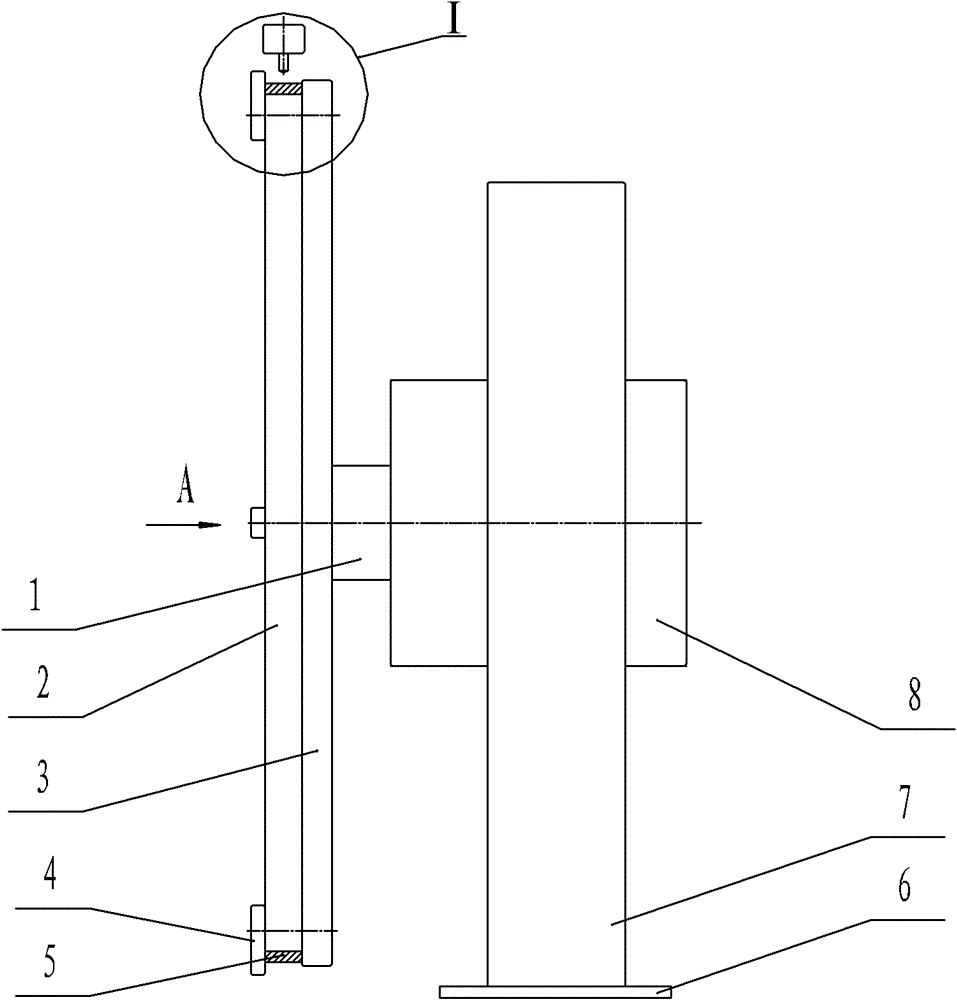

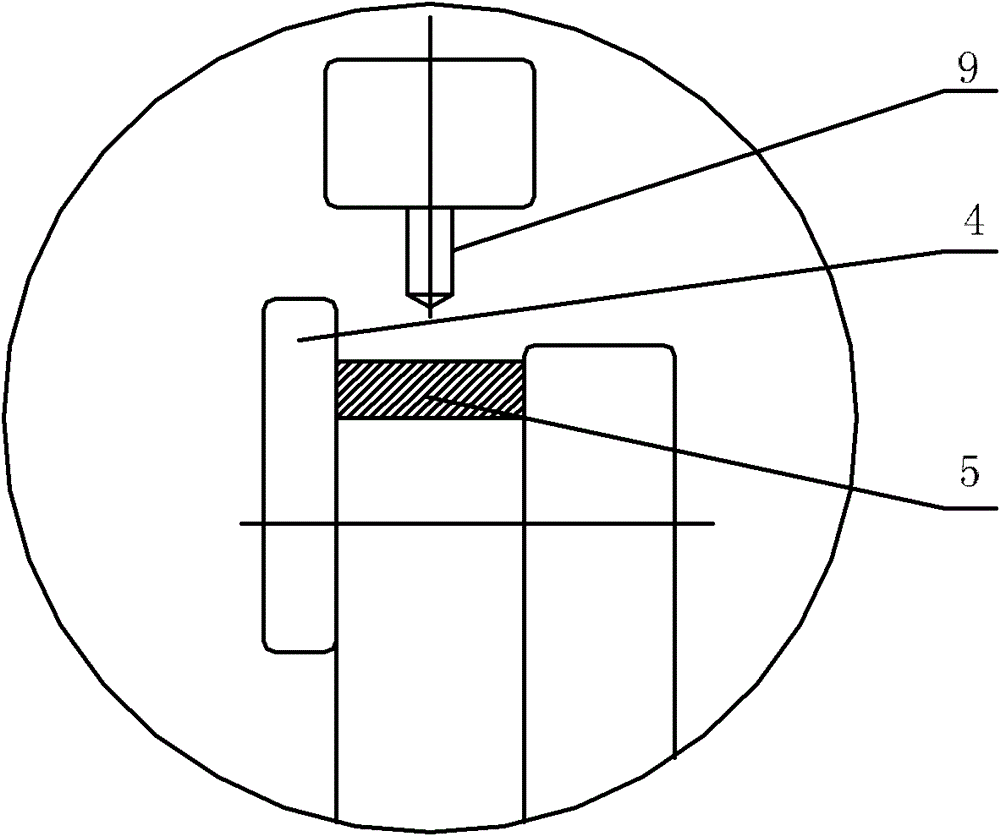

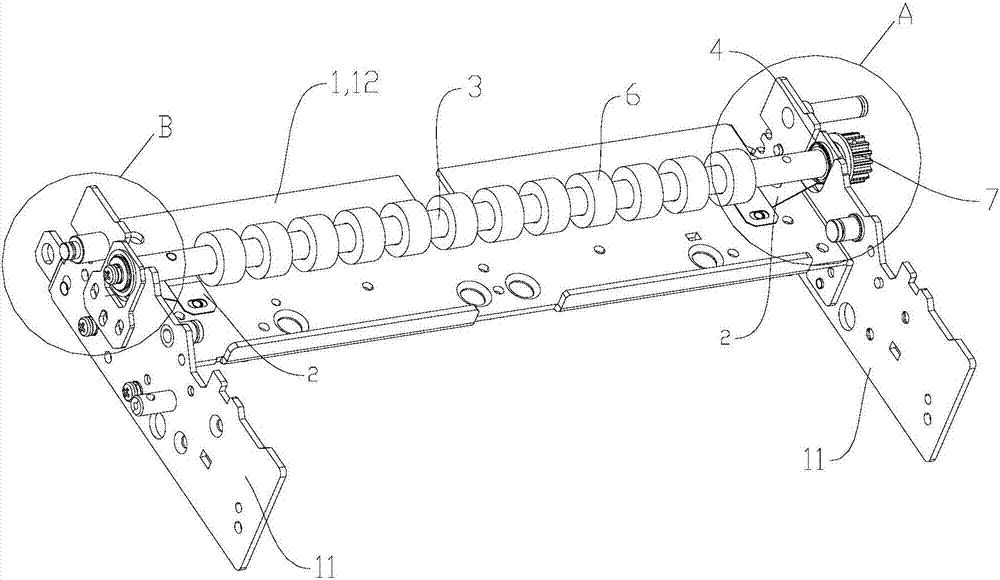

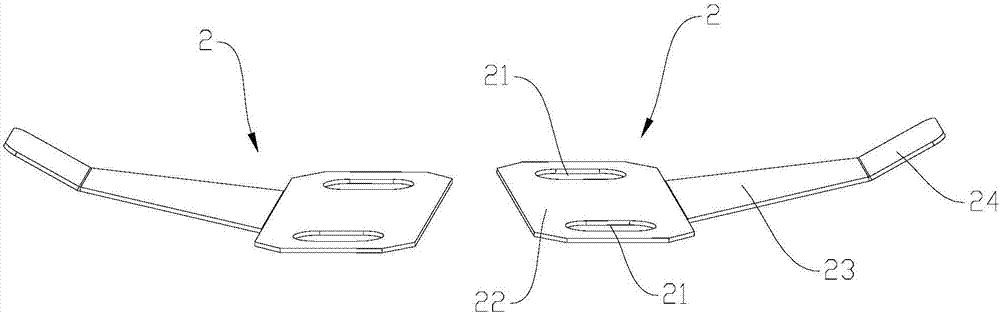

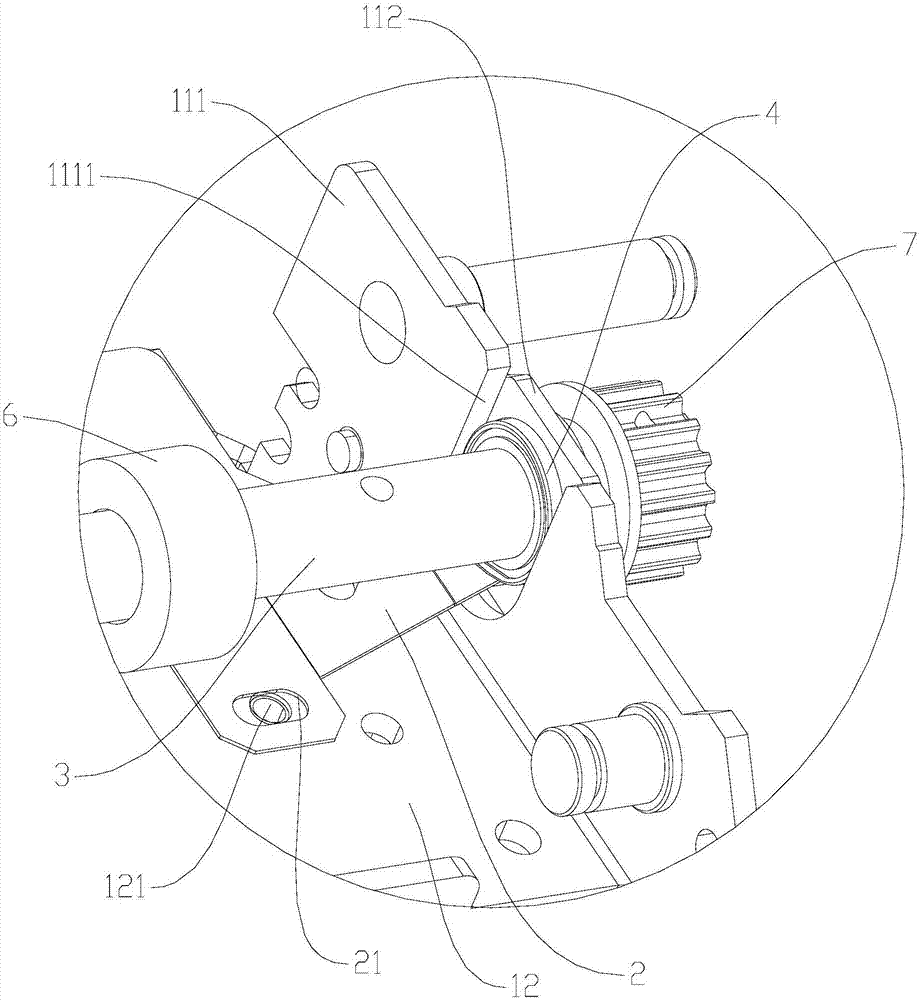

Floating Mechanism of Money Detecting Device and Money Detecting Device

A bank note verification floating mechanism and a bank note verifier. The floating mechanism comprises a support (1), two elastic strips (2), and a floating shaft (3). A flanged bearing (4) sleeves each of the left and right ends of the floating shaft (3). The support (1) comprises two support plates (11) parallel to each other and a fixed plate (12) disposed between the two support plates (11). Each end of the floating shaft (3) is mounted on a corresponding support plate (11) by means of a corresponding flanged bearing. One end of each elastic piece is fixed on the fixed plate (12), and the other end presses against one side of a corresponding flanged bearing (4) close to the fixed plate (12). The bank note verifier comprises a magnetic sensor (5) and the floating mechanism. A floating roller (6) sleeves on the floating shaft (3), a conveyor belt pulley (7) is disposed at one end of the floating shaft (3). The bank note verifier of the invention is capable of collecting magnetic data of bank notes stably and reliably.

Owner:SHENZHEN YIHUA COMP

A passive piston volumetric tube with flip valve plug

ActiveCN108168639BSmall pressure lossReduce shockContracting/expanding measuring chambersCylinder blockExtreme position

The invention discloses an overturning valve plug-type passive piston volume pipe, relating to a passive piston volume pipe which belongs to the field of liquid flow measurement. The overturning valveplug-type passive piston volume pipe comprises a cylinder body, a piston system and a return mechanism. The overturning valve plug-type passive piston volume pipe further comprises a lower ejection rod and an upper ejection rod. The lower ejection rod is used for ejecting an overturning valve plug open when the piston system moves at the downstream extreme position. The upper ejection rod enablesthe overturning valve plug to be closed when the piston system moves at the upstream extreme position. The piston system can operate in the cylinder body in a reciprocating manner so that continuousmeasurement of flow is achieved. The piston system comprises an overturning valve plug mechanism, a piston, a piston rod and a piston sealing part. The overturning valve plug mechanism comprises a torsion spring, the overturning valve plug, a rotary shaft and a sealing ring. In order to resolve the technical problem, loss of pressure and state transition impact during operation of the passive piston volume pipe are reduced and a return process is prevented from climbing. Therefore, the requirement for measurement accuracy of the passive piston volume pipe is ensured and service lifetime of equipment is prolonged.

Owner:BEIJING CHANGCHENG INST OF METROLOGY & MEASUREMENT AVIATION IND CORP OF CHINA

Dyeing and finishing process of a four-way stretch fabric based on antimony-free polyester

ActiveCN113186741BIncrease elasticityStress reliefHeating/cooling textile fabricsTextile treatment machine arrangementsColour fastnessPolyester

The invention discloses a dyeing and finishing process of a four-way stretch fabric based on antimony-free polyester, which includes a pre-treatment process, a dyeing process and a post-treatment process in sequence; the pre-treatment process includes a tension-free pre-shrinking process and a presetting process; the dyeing The dyeing agents used in the process include dyeing auxiliaries and dyes; dyeing auxiliaries include dyeing optimizer TF‑256, dyeing synergist TF‑257 and spandex degreasing agent TF‑109A; post-treatment process includes sequential high-temperature drying process , soaping process and low-temperature setting process; the low-temperature setting process uses a moisture-absorbing and sweat-wicking finishing agent to carry out setting treatment on the soaped fabric; the soaping aids used in the soaping process include Yakesai RC and acidity slip agent VS . The invention can not only ensure that the processed fabric has better elasticity and resilience, but also make the color fastness and other technical indicators of the fabric meet higher requirements, and can also endow the fabric with better moisture absorption and perspiration function.

Owner:SHENGHONG GRP CO LTD

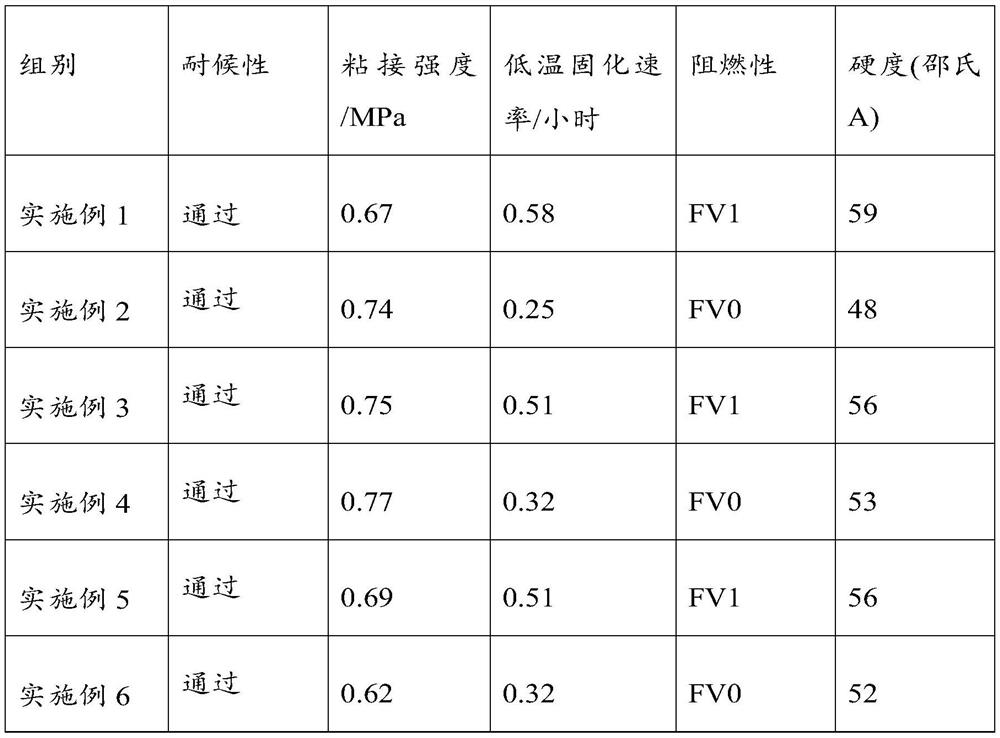

A kind of electric composite insulator repair adhesive and preparation method thereof

ActiveCN110003843BGood weather resistanceImprove adhesionNon-macromolecular adhesive additivesPolyether adhesivesPolymer sciencePtru catalyst

The invention discloses a power composite insulator repair adhesive and a preparation method thereof, and relates to the technical field of adhesives. Power composite insulator repair glue, by weight, its raw materials include polysiloxane 80-200 parts, silane-modified polyether prepolymer 5-40 parts, white carbon black 2-30 parts, flame retardant 40-40 parts 280 parts, 5-30 parts of crosslinking agent, 10-50 parts of coupling agent and 0.1-3 parts of catalyst; preferably, polysiloxane is hydroxyl-terminated polydimethylsiloxane. The preparation method of the power composite insulator repair glue uses the above formula as the raw material, and the prepared repair glue has good weather resistance and good adhesion, can be quickly cured at low temperature, and is compatible with the composite insulator body material better.

Owner:BEIJING GUODIAN FUTONG SCI & TECH DEV

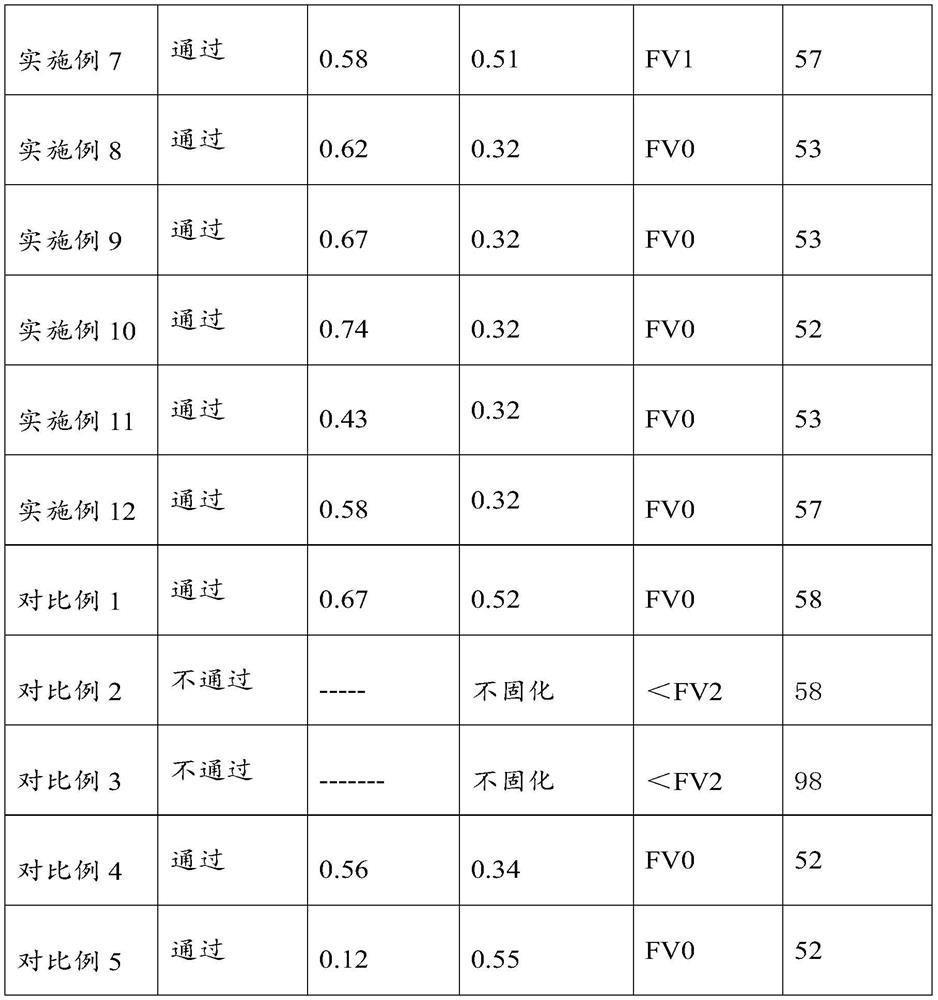

Precompression device for polymer compression spring

The invention relates to a precompression device for a polymer compression spring. The precompression device is characterized by comprising a base and a guiding cylinder which are connected through a fixing rod, wherein the polymer compression spring is arranged inside the guiding cylinder, connecting parts of series connection structure joints of elastic balls of the polymer compression spring are respectively provided with a pair of locating sleeves, a gland is arranged inside the guiding cylinder at the top of the polymer compression spring, and a compression rod is arranged above the gland; each pair of locating sleeves are in mechanical connection by means of a bulge and groove structure, or are in adsorption connection by magnets, or are connected by tightening rings arranged at the outer races of the locating sleeves. The precompression device provided by the invention has simple and ingenious structure arrangement; the elastic balls of the polymer compression spring obtained after precompression have identical compression ratio and uniform diameter; and the polymer compression spring does not generate a destabilization phenomenon and a subsequent machining process is omitted. Therefore, the precompression device can be widely used in a manufacturing process of the polymer compression spring.

Owner:北京隆轩橡塑有限公司

A production line for processing pipettes with dovetail grooves at intervals

ActiveCN110341159BConvenient distanceImprove cooling and shaping effectMetal working apparatusMouth pieceProcess engineering

Owner:义乌市城西机械有限公司

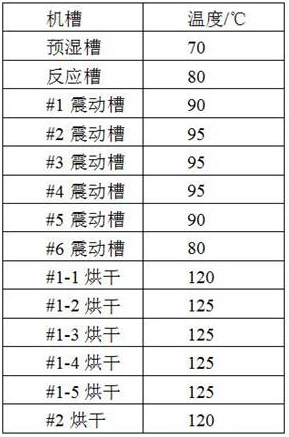

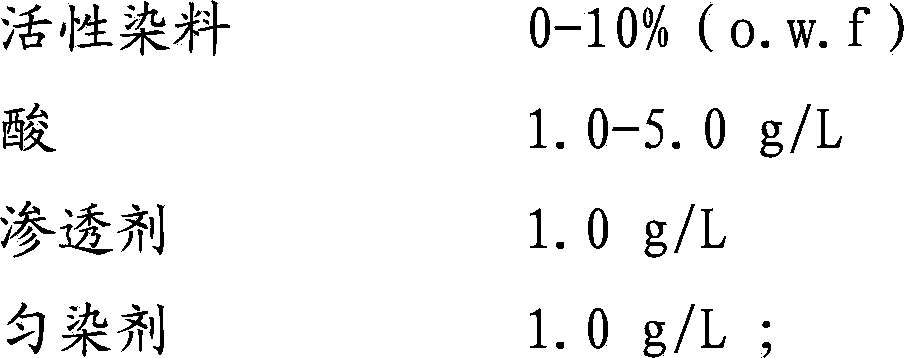

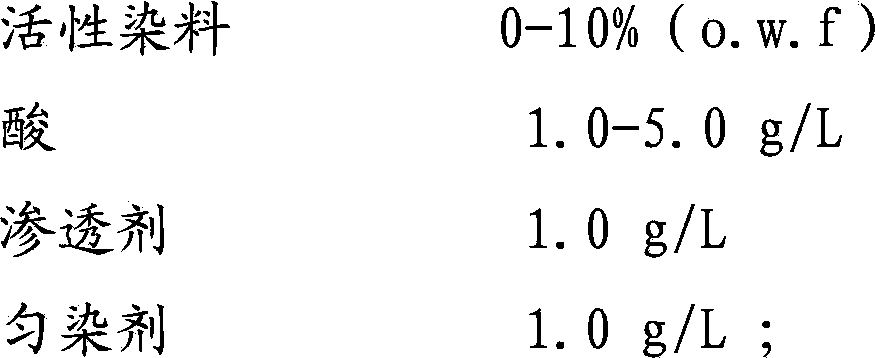

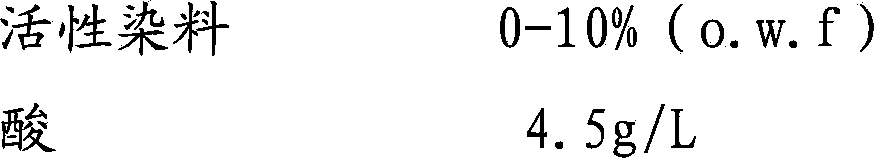

Dyeing method for cheese made of nylon stretch yarns

InactiveCN102733203BConsistent colorConsistent elasticityFibre treatmentDyeing processYarnTextile technology

The invention belongs to the technical field of textiles, and particularly relates to a dyeing method for cheese made of nylon stretch yarns, and the method comprises the following steps of: loose winding, pre-treatment, dyeing, post-treatment and dewatering, and is characterized in that the steps of elasticity lowering, dewatering and loose secondary winding are added between pre-treatment and dyeing, so that the whole process comprises loose winding, pre-treatment, elasticity reducing, dewatering, loose secondary winding, dyeing, post-treatment and dewatering. The dyeing method has the beneficial effects that the steps of elasticity reducing, dewatering and loose secondary winding are added between pre-treatment and dyeing, so that the interior and exterior of the cheese are uniform in color and elasticity, the success rate for one dyeing is high, and the problems brought by the conventional method are avoided.

Owner:TIANJIN TIANGE TEXTILE

Coating cloth processing method

InactiveCN106436330AReduce processShorten the timePretreated surfacesCoatingsWater basedPore distribution

The invention relates to a coating cloth processing method, which comprises the following steps that 1, a water-based PU (poly urethane) pulp layer is formed on the surface of non-woven cloth; 2, the water-based PU pulp layer is in contact with a coagulating agent in a sealed chamber; the coagulating agent is pressed into the water-based PU pulp layer through high-temperature and high-pressure means, so that the whole water-based PU pulp layer is in full contact with the coagulating agent; 3, drying is performed for removing moisture in the water-based PU pulp layer, so that the water-based PU pulp layer is formed into a water-based PU film layer. The water-based PU film layer has uniform pore distribution, consistent elasticity and flexibility, and good anti-stripping intensity; the thickness of the water-based PU film layer trends to be consistent; the thickness of the water-based PU film layer at least maintains 95 percent to 99 percent of the thickness of the water-based PU pulp layer; the water-based PU film layer does not collapse.

Owner:张庆州

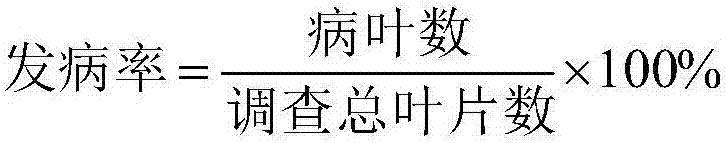

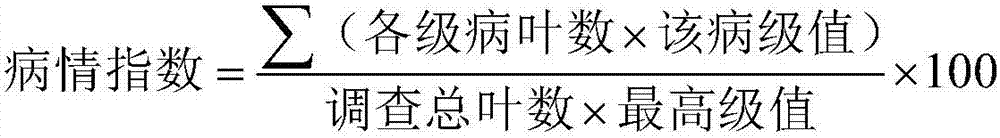

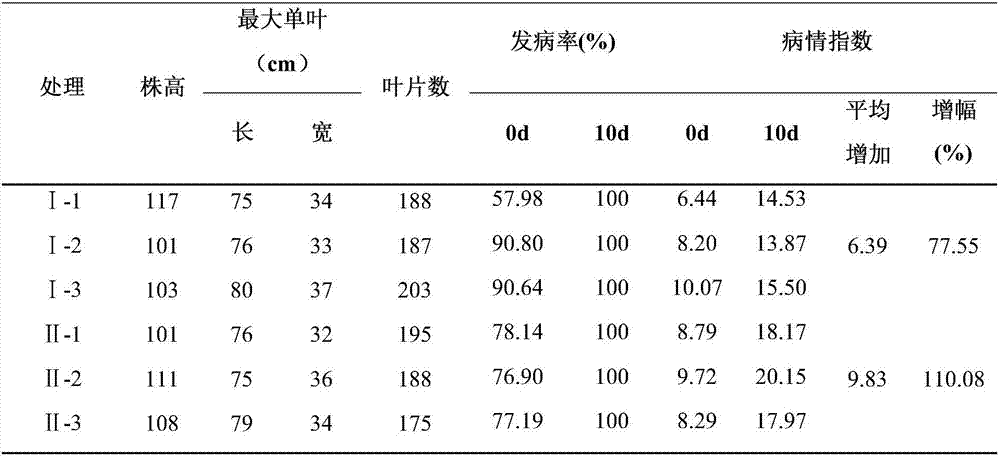

Tobacco yellowing synergism compound mixture and use method thereof

PendingCN107141075AInhibit or reduce absorptionSolve the problem of nutrient deficiency in the later stage of growthBiocidePlant growth regulatorsDiseaseAdditive ingredient

The invention discloses a tobacco yellowing synergism compound mixture and a use method thereof. The mixture comprises a compound A and a compound B, wherein the compound A is an onion and garlic liquid mixture which is used in the maturation stage of tobacco and can inhibit or reduce nitrogen absorption of plants, and the compound B is P2O5 or K2O or ZnSO4 or MnSO4 or other mineral elements and can solve the problem of nutrient deficiency in the later growth stage of crops and promote tobacco yellowing synergism in cooperation with the onion and garlic liquid mixture. The compound mixture can improve the nutritional resistance of plants, enhance the disease resistance, relieve leaf diseases, reduce the color difference between leaves at the same portions of tobacco plants and ensure the uniformity of tobacco maturing and yellowing; cured tobacco has high elasticity and toughness, orange tobacco is obtained, the color and luster are improved, and the oil content is high; the proportion of green tobacco is substantially reduced, the quality and yield of tobacco are improved, and the economic benefit is significant. The effective ingredients of the compound mixture are plant tissue extracts and are free of environmental pollution, safe and environmentally friendly.

Owner:郑州惠农有害生物防治有限公司

a communication tower

The invention discloses a communication iron tower which comprises four forward spiral frameworks distributed in an axial array and four backward spiral frameworks distributed in an axial array , wherein the backward spiral frameworks are wound on the forward spiral frameworks, and fixedly connected with the forward spiral frameworks via locking pieces, so as to form a cage-shaped tower body; eight foot margin embedding parts are arranged on the lower side of the tower body; a platform mounting part is arranged on the upper side of the tower body; the foot margin embedding parts are embedded in a cement tower base; a bearing platform is mounted in the platform mounting part; a combined hand rail is mounted at the upper end of the platform mounting part. The communication iron tower has the advantages that the number of components is small; the integrity and the intensity are high; the mounting is convenient; the tower body is relatively high in tenacity and elasticity; the intensity distribution of the tower body is uniform; the capabilities of resisting side forces in all directions are the same; the stability is high; lateral stress can be dispersed; the side force impact can be buffered; the damage resisting capacity is high.

Owner:YANGZHOU RUNYUAN LAMP DECORATION CO LTD

Automatic elasticity balancing device of hanger

ActiveCN102874131BConsistent elasticityThe overall structure is light in weightTrolley linesDrive shaftEngineering

Owner:李东生

Process for machining isolated steel belt of slewing bearing steel ball

ActiveCN102152080BAvoid Polygonal CirclesConsistent elasticityLaser beam welding apparatusButt weldingLaser cutting

The invention discloses a process for machining an isolated steel belt of a slewing bearing steel ball, comprising the steps of: machining strip materials by the procedures of feeding bar materials, leveling and milling end faces; roughly rounding: roughly rounding the strip materials to process arced strip materials with the radiuses approaching that of product rings; welding: carrying out butt welding on the arced strip materials to obtain rings with the radiuses approaching that of the product rings; finely rounding: finely rounding the rings till a finally required cylindricity of a product is obtained; cutting orifices: sequentially carrying out laser cutting on the finely rounded rings to obtain rolling-body orifices; and boring: boring and trimming the rolling-body orifices to obtain the diameter of the orifice required finally. In the invention, because the process is regulated in that the rolling-body orifices are subjected to laser cutting after fine rounding is carried out,the strength of the strip materials is consistent along the length direction; elastic deformation and plastic deformation of the materials are uniform and consistent in the processes of roughly rounding and finely rounding and no inflection points are generated along an arc direction, so that ribbed roundness of a workpiece is effectively avoided; and reshaping is not needed so that the cylindricity precision of products is ensured.

Owner:SHANDONG GOLDEN EMPIRE PRECISION MACHINERY TECH CO LTD

Floating mechanism of currency detection apparatus and currency detection apparatus

The invention discloses a floating mechanism of a currency detection apparatus and a currency detection apparatus. The floating mechanism includes a rack (1), two shrapnels (2) and a floating shaft (3). The left and right ends of the floating shaft (3) are separately sleeved with a flange bearing (4). The rack (1) includes two supporting plates (11) which are parallel to each other and a fixing plate (12) which is disposed between the two supporting plates (11). The left end of the floating shaft (3) is installed on the corresponding supporting plate (11) through the corresponding flange bearing (4). One end of respective shrapnel (2) is fixed on the fixing plate (12), and the other end of respective shrapnel (2) abuts against one side of the corresponding flange bearing (4) approaching the fixing plate (12). The floating mechanism can work normally and stably. The currency detection apparatus includes a magnetic sensor (5) and the aforementioned floating mechanism. The floating shaft (3) is sleeved with a floating roller (6). One end of the floating shaft (3) is provided with a transmission belt pulley (7). The currency detection can acquire magnetic data of paper currency in a stable and reliable manner.

Owner:SHENZHEN YIHUA COMP

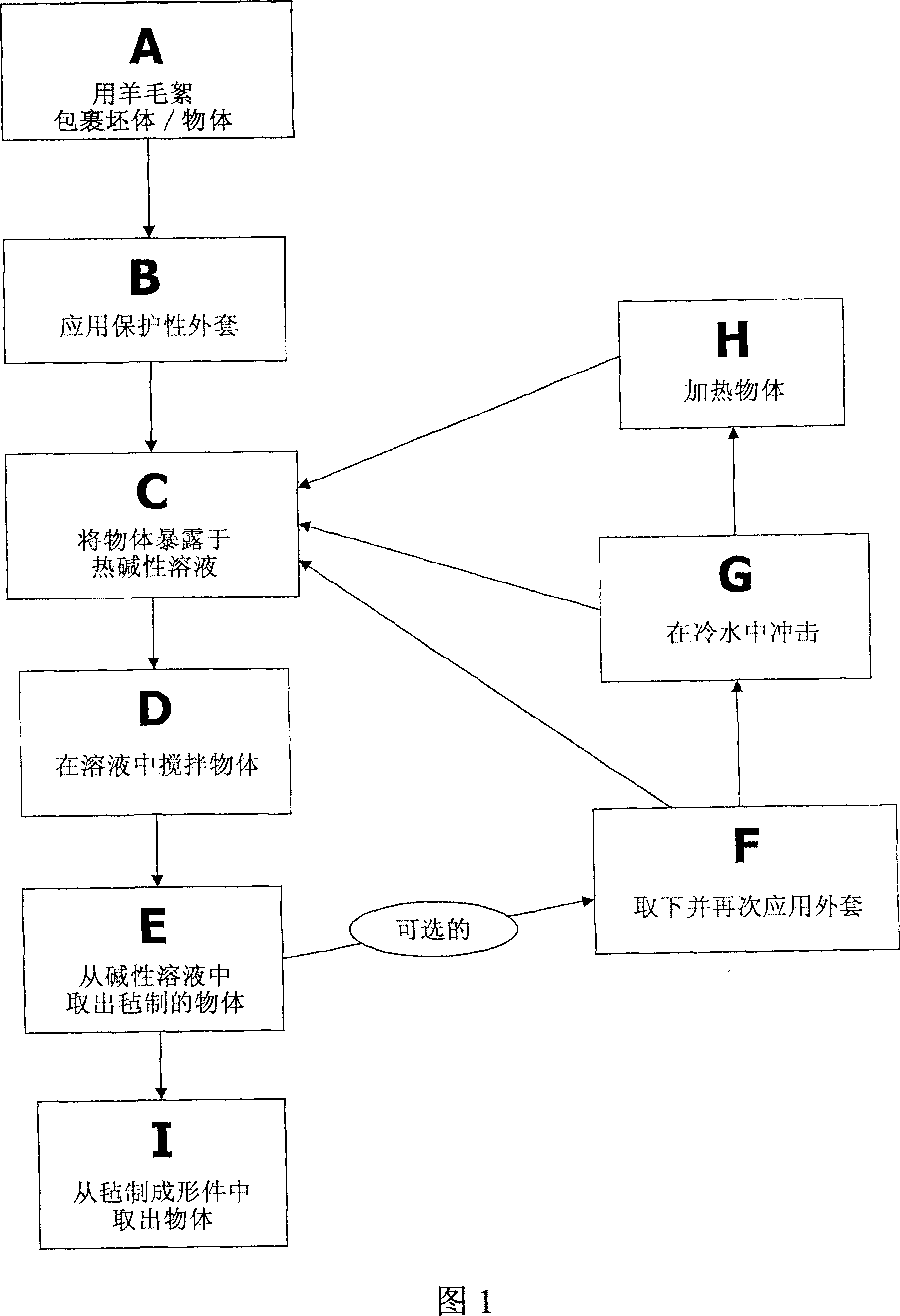

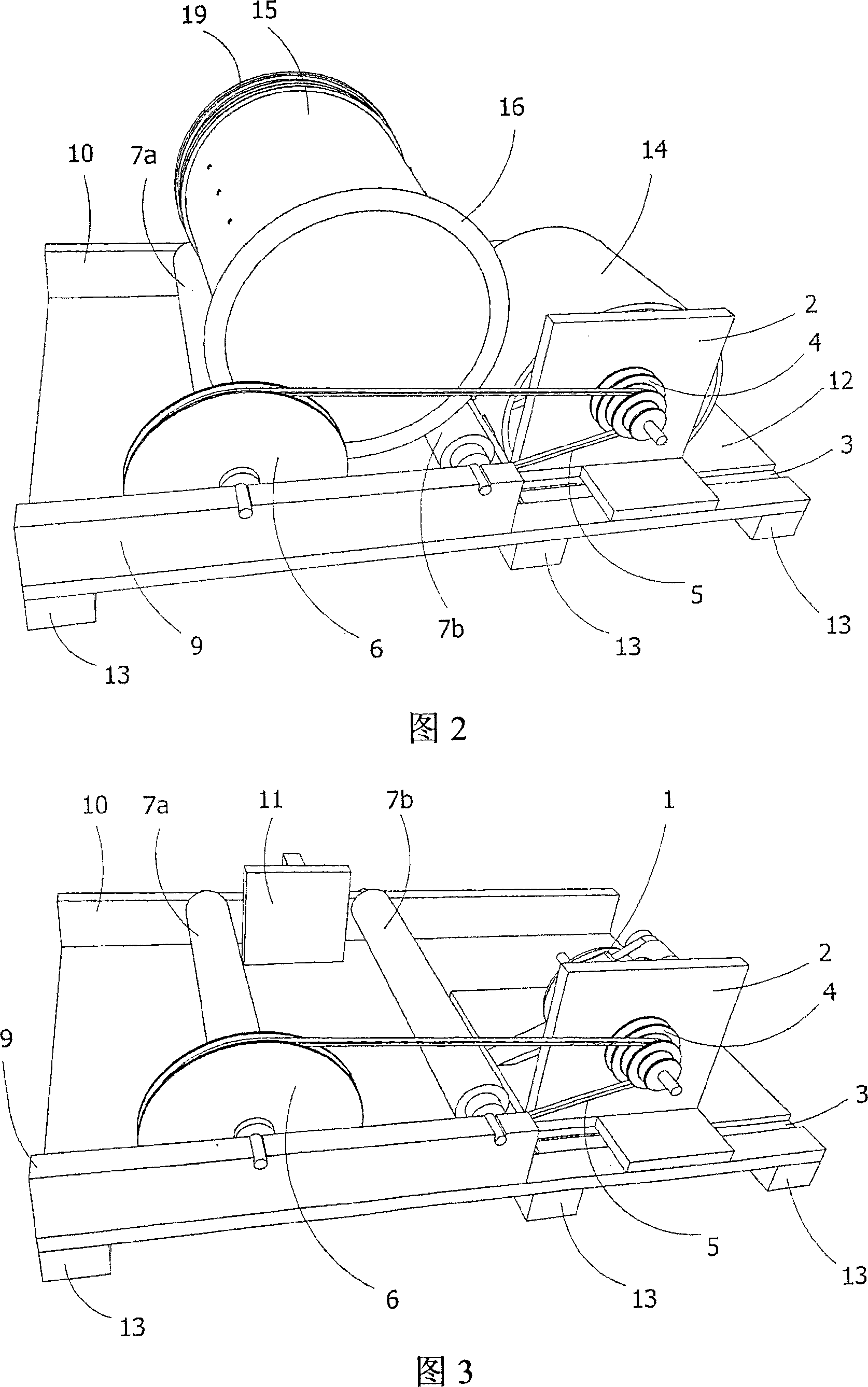

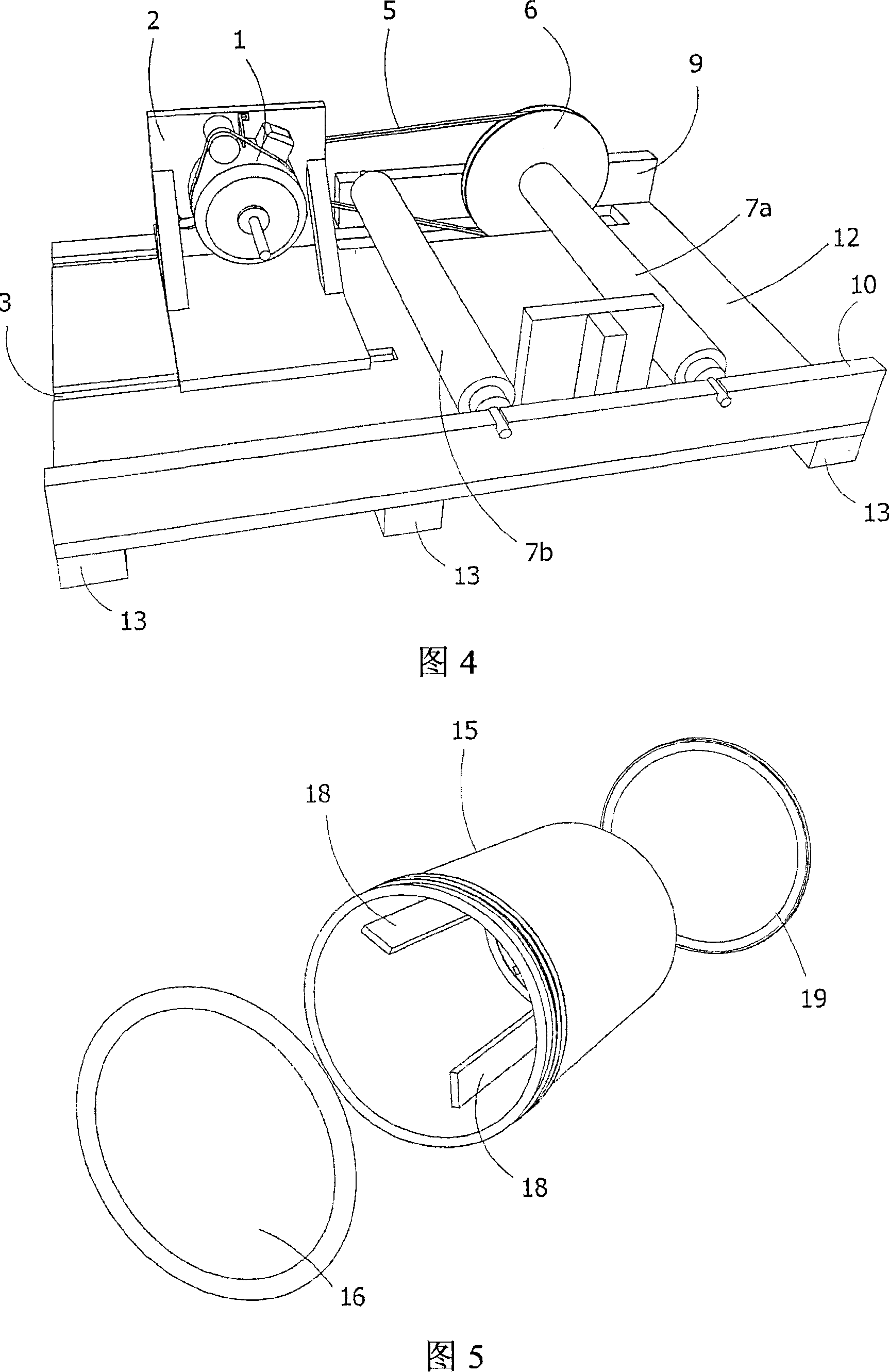

Method and apparatus for felting three-dimensional objects

InactiveCN101160424AEfficient preparationConsistent densityFibre treatmentFelting apparatusVolumetric Mass DensityEngineering

A method and apparatus for felting three-dimensional objects is disclosed. The method involves wrapping a three-dimensional object with wool, and agitating the encased object within a drum in the presence of heated alkaline solution. The process may be repeated to achieve the desired felt consistency. An apparatus is provided for use with the method. Products produced in accordance with the invention have consistent texture, resiliency, and density throughout, with no visible seams or rough edges.

Owner:德博拉罗克萨姆科尔

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com