Interval flower color dovetail groove pipe head sucking pipe machining production line

A dovetail groove and production line technology, applied in metal processing, etc., can solve problems such as hard cutting, straw cooling, and inconvenient operation, and achieve the effects of convenient operation, reduced energy consumption, and improved results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described below in conjunction with the accompanying drawings and embodiments, but not as a basis for limiting the present invention.

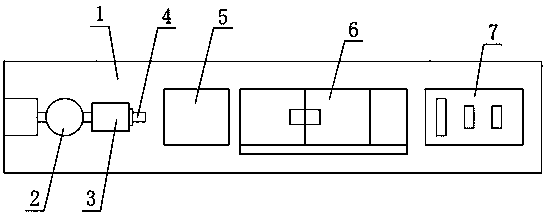

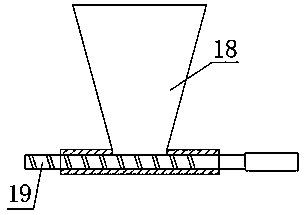

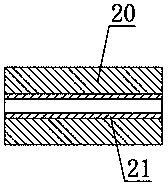

[0031] Example. A production line for processing pipettes with dovetail grooves at intervals, consisting of Figures 1 to 14 As shown, it includes a frame 1, a feeding device 2, a heating device 3, an extrusion mold 4, a vacuum defoaming device 5, a cooling and shaping device 6, and a cutting and blanking device 7 arranged in sequence on the frame 1; cooling and shaping The device 6 includes a cooling box 8 fixedly connected to the frame, and the two ends of the cooling box 8 are respectively provided with a sealed inlet 9 and a sealed outlet 10 with the same height; A sealing transition opening 12 is arranged on the top, and the sealing transition opening 12 has the same height as the sealing feed opening 9 .

[0032] On the cooling box 8, a pinch wheel 13 is arranged at a position corresponding ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com