Patents

Literature

86results about How to "Consistent proportion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

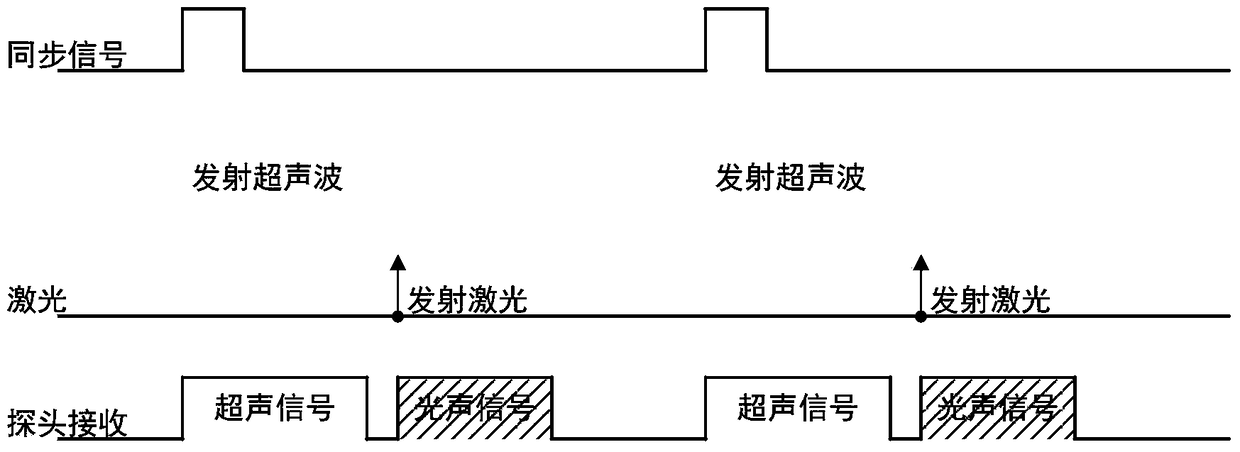

Opto-acoustic and ultrasonic bimodal synchronous imaging system and method

ActiveCN105395170AExclude different bitsComprehensive evaluationOrgan movement/changes detectionDiagnostic recording/measuringData acquisition moduleData processing

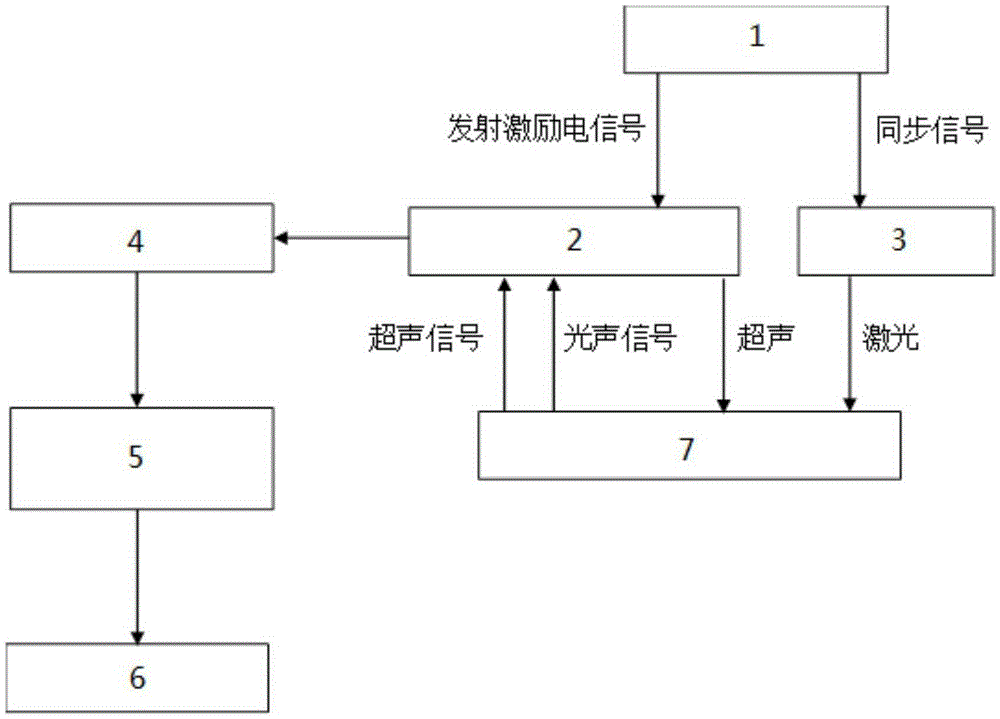

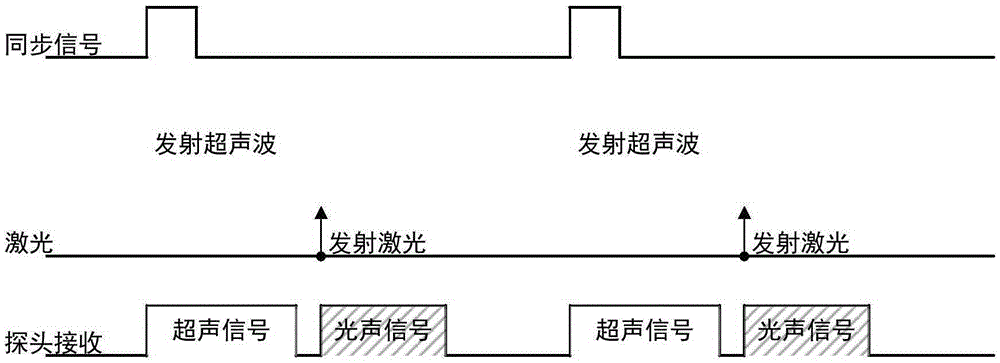

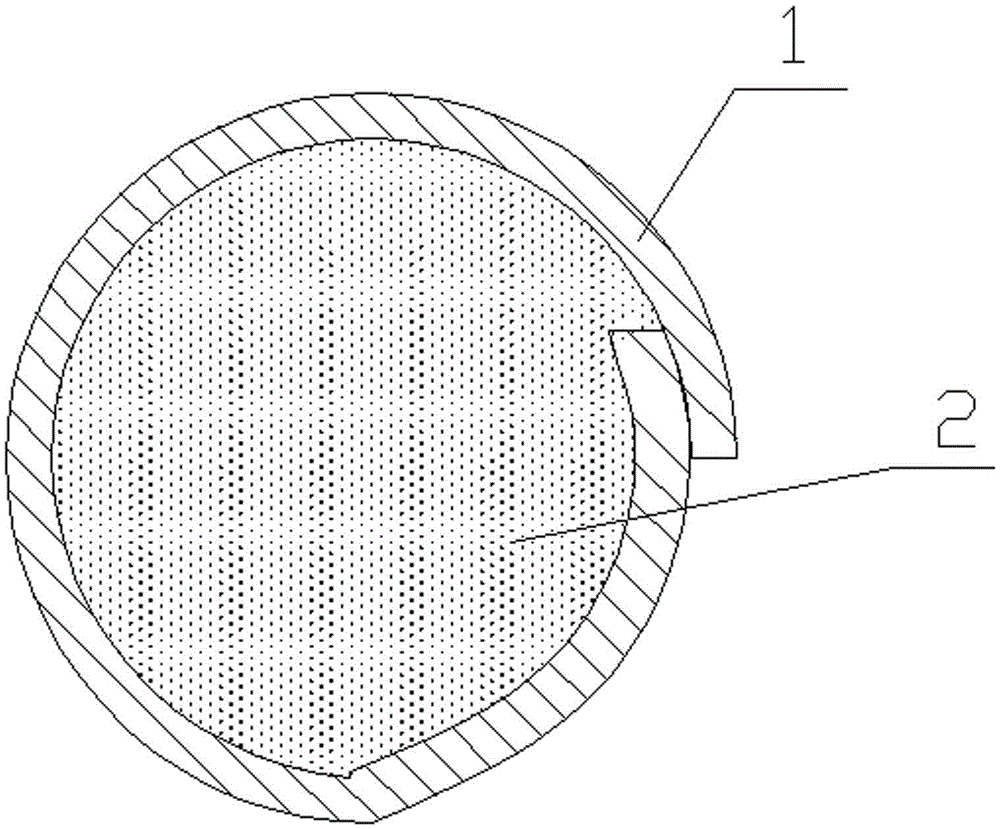

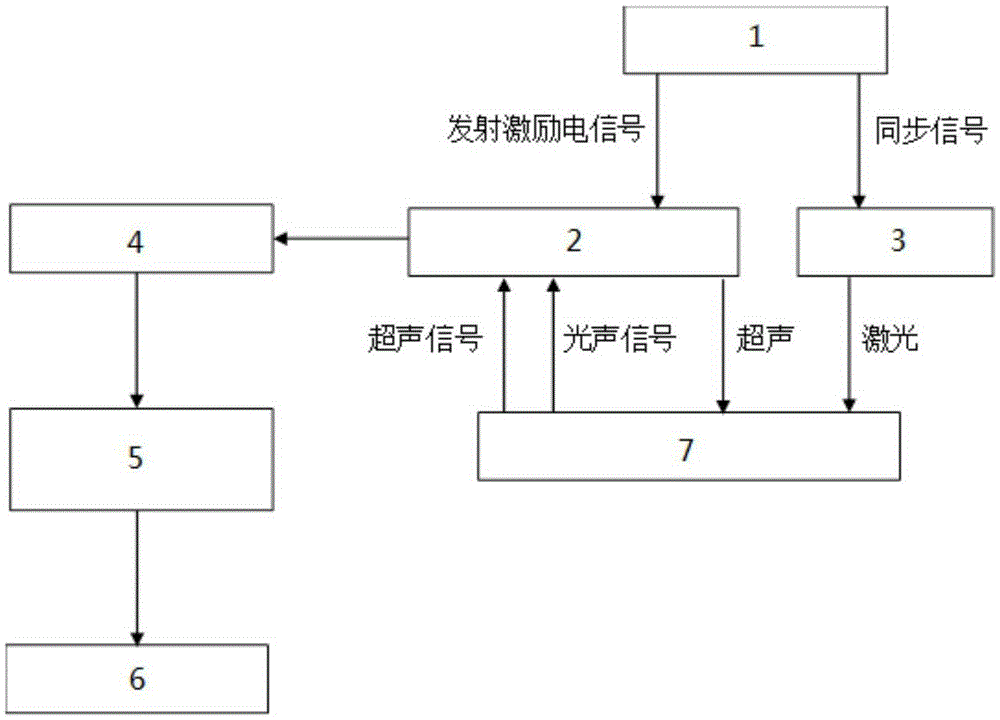

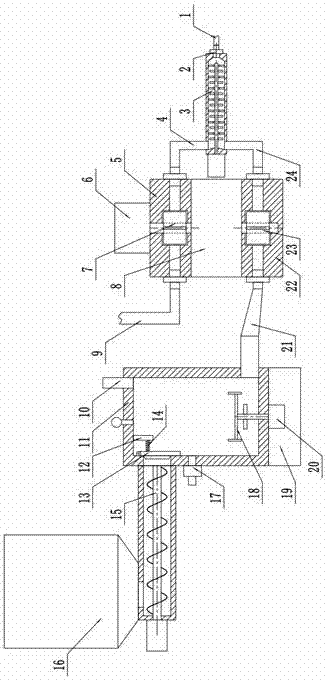

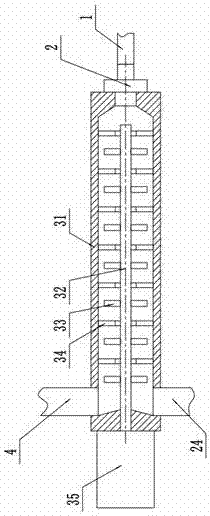

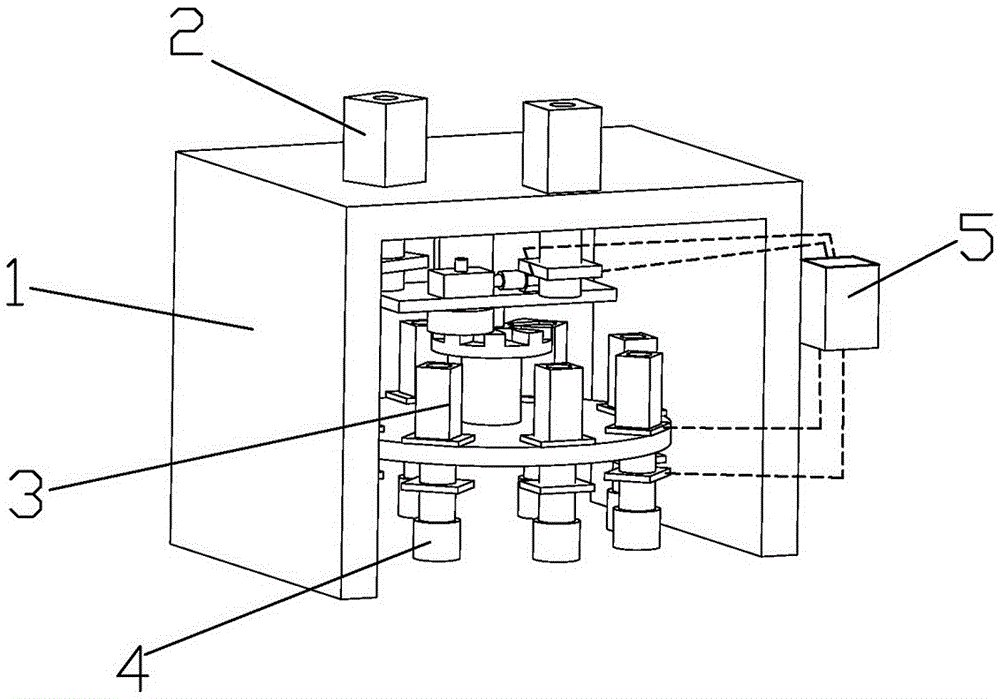

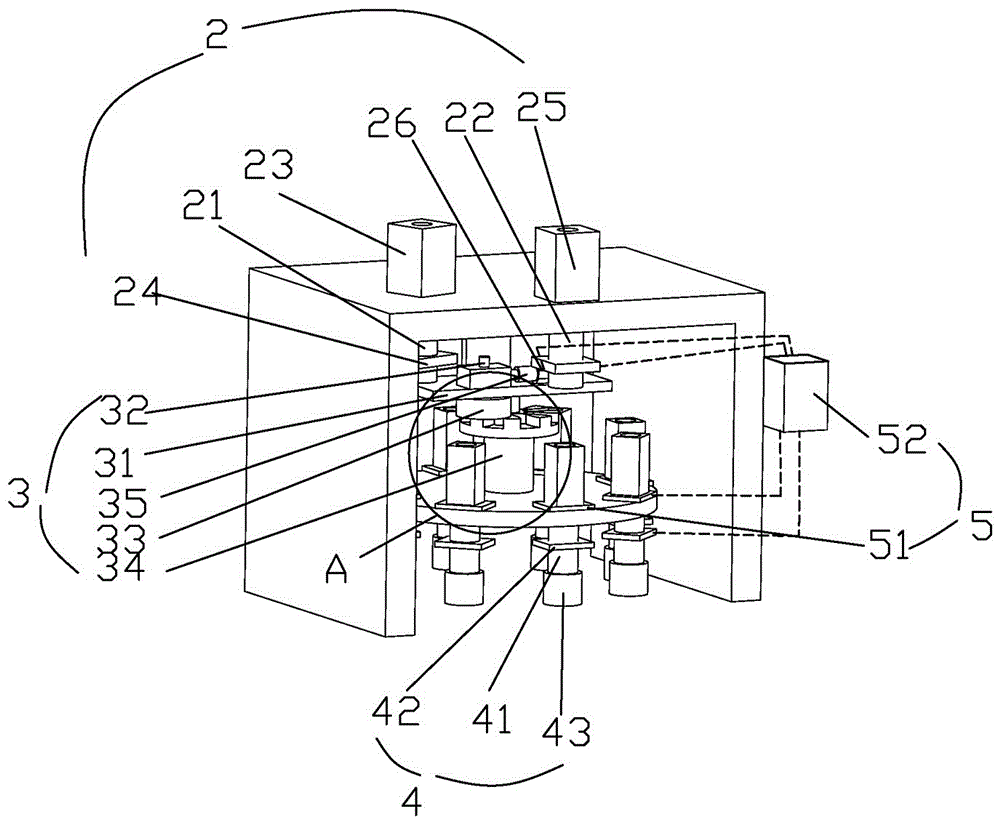

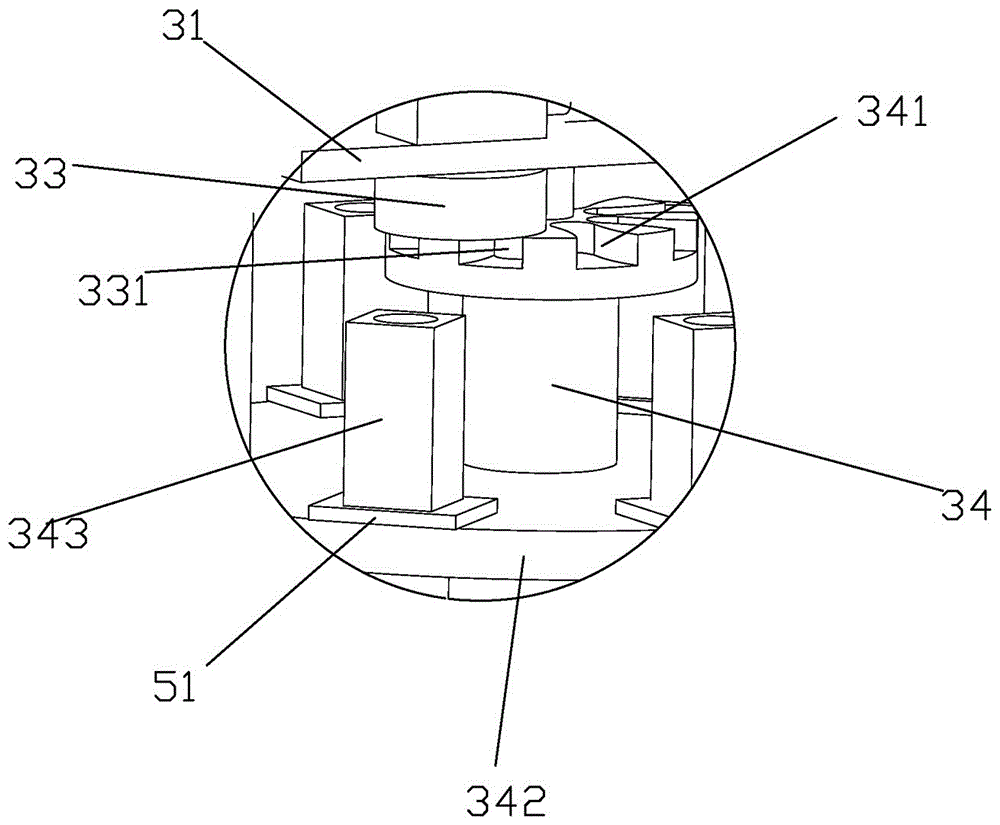

The invention relates to an opto-acoustic and ultrasonic bimodal synchronous imaging system, which is applied to diagnostic imaging of tested tissues in the medical field. The imaging system comprises a host machine, a pulse laser, as well as a multi-channel ultrasonic probe, a data acquisition module, a data processing and image reconstruction module and a display module which are sequentially connected, wherein the host machine is connected to the multi-channel ultrasonic probe and the pulse laser; the multi-channel ultrasonic probe clings to the tested tissues; and the pulse laser is opposite to the tested tissues. Compared with the prior art, the imaging system disclosed by the invention has the advantages of being synchronous, precise, consistent in proportion and the like.

Owner:TONGJI UNIV +1

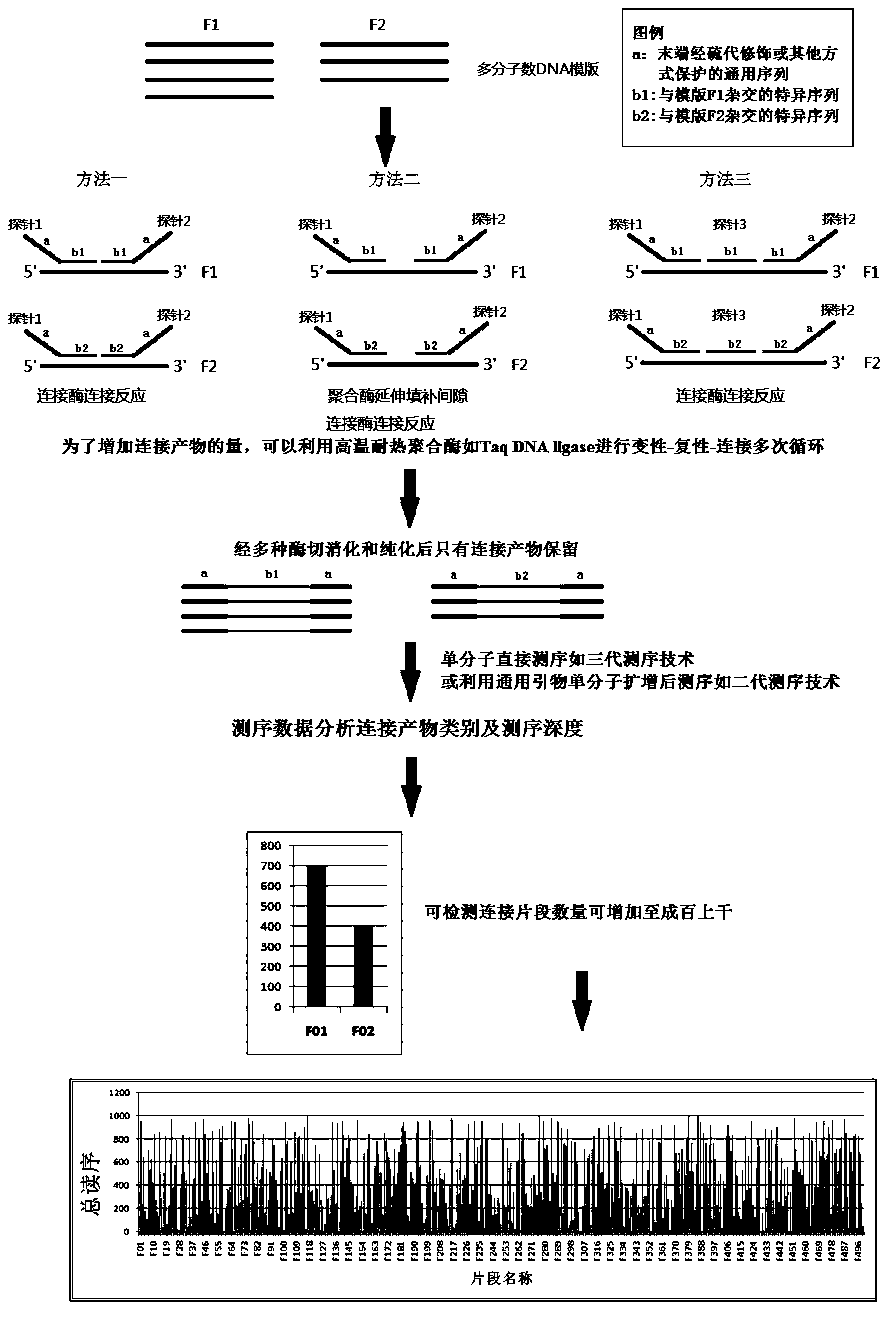

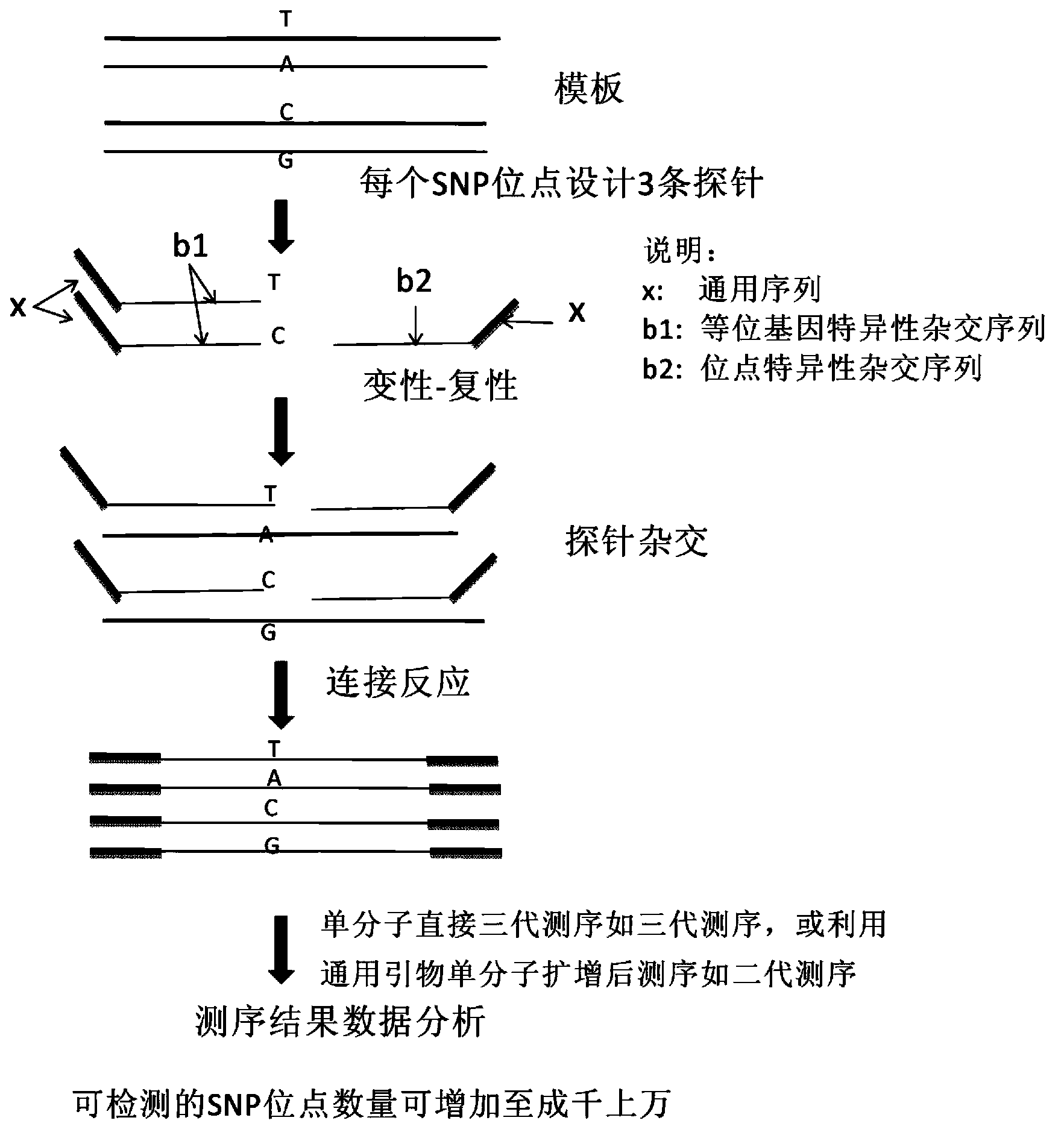

High-flux nucleic acid analysis method and application thereof

ActiveCN103898199AReduce testing costsQuick buildMicrobiological testing/measurementHigh fluxBinding domain

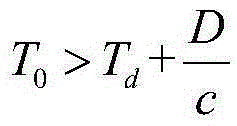

Disclosed are a method for analyzing high-throughput nucleic acid and an application thereof. Among n nucleic acid fragments to be analyzed, for each target nucleic acid fragment, at least two specific probes bound to different binding domains of the target nucleic acid fragment are provided, each specific probe has a specific binding domain and a universal sequence domain, a sequence of the specific binding domain and a sequence of the binding domain of the target nucleic acid fragment are complementary, and a sequence of the universal sequence domain is corresponding to a sequence of a sequencing primer.

Owner:GENESKY TECH (SUZHOU) INC +1

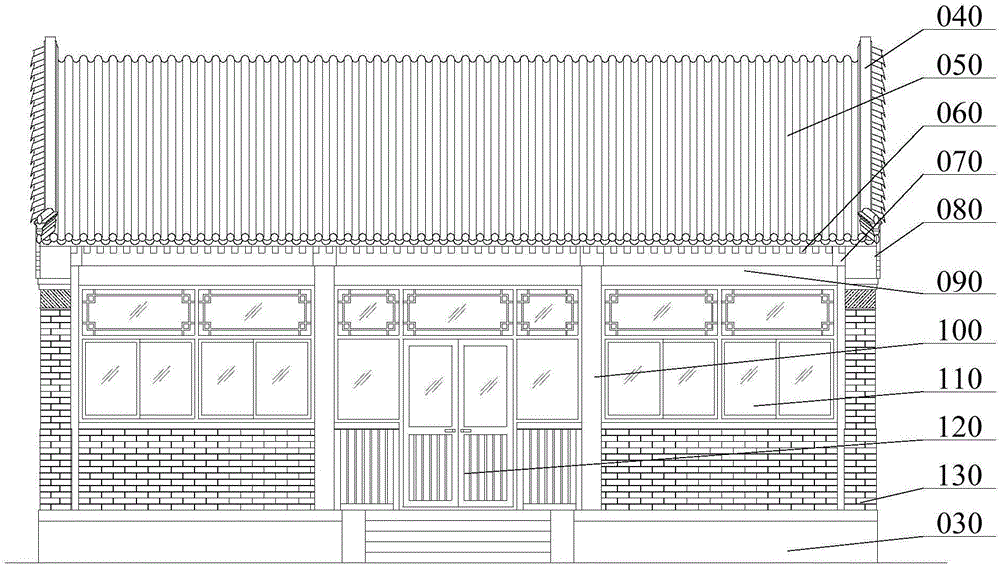

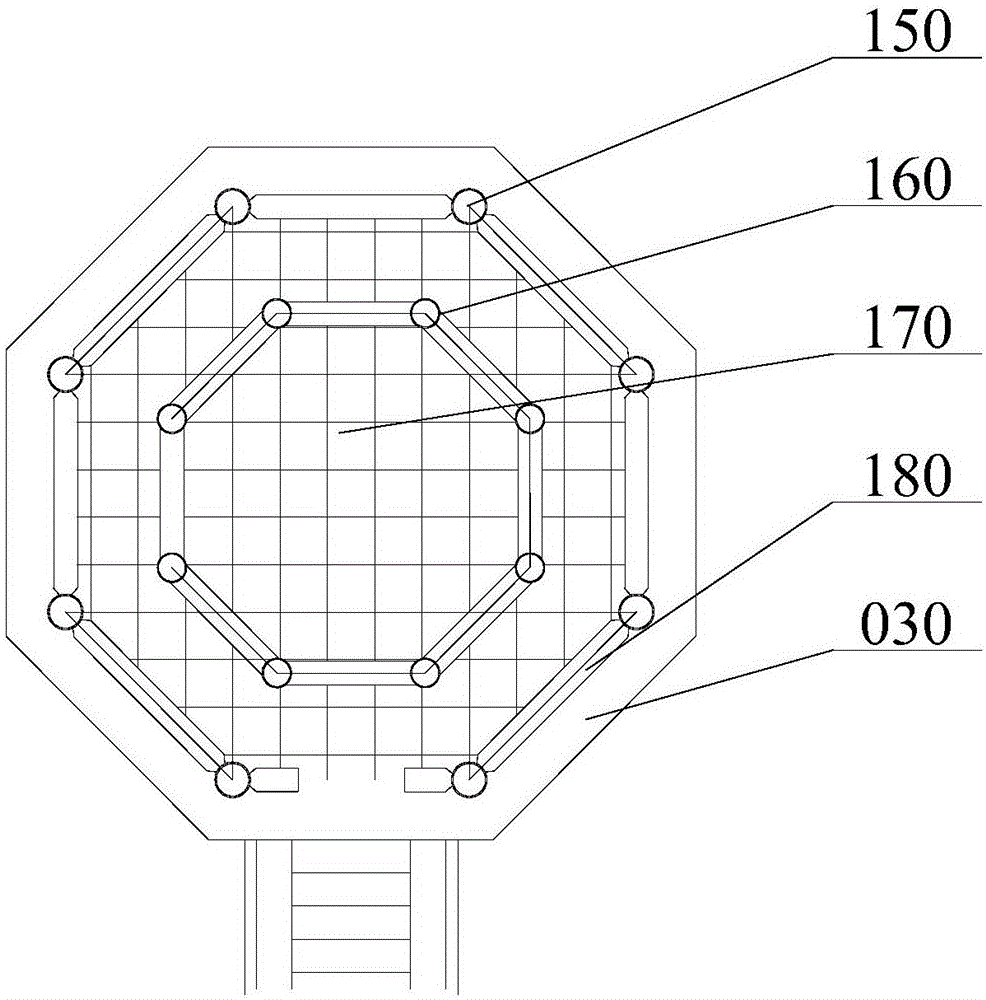

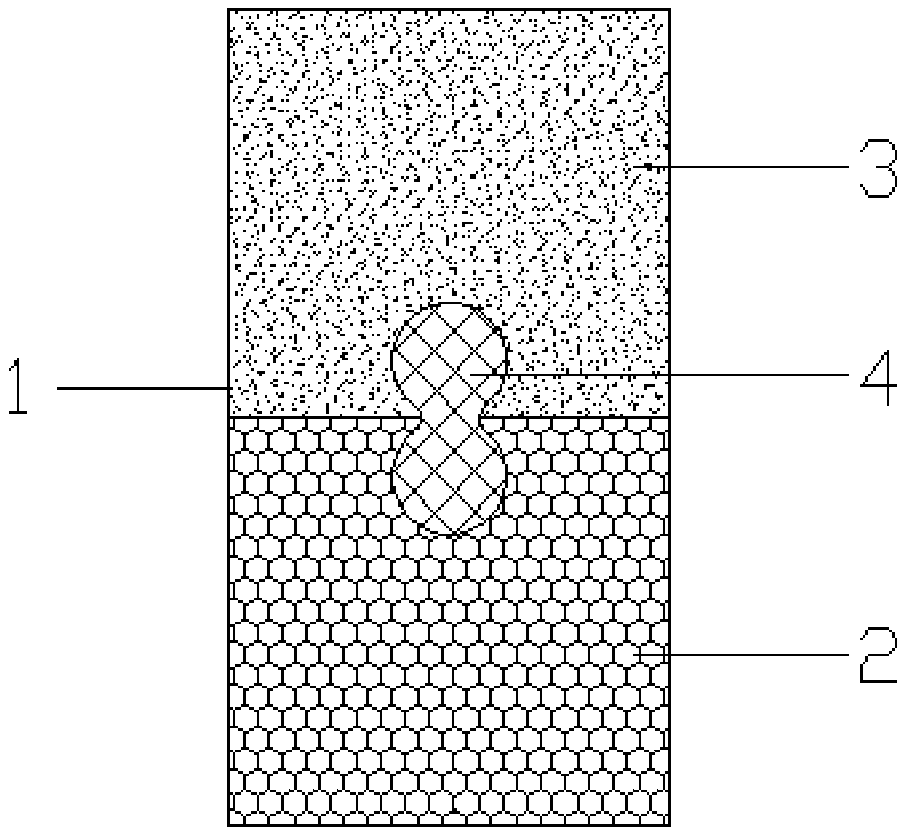

Archaistic building and manufacturing method thereof

ActiveCN106382023AConstruction rationalizationStable physical propertiesBuilding roofsRoof covering using tiles/slatesWater seepageBuilding construction

The invention provides an archaistic building and a manufacturing method thereof, relating to the technical field of manufacturing of historic buildings. The archaistic building comprises a ground foundation, a main body steel structure, archaistic upright pillars and archaistic joint tiles, wherein the archaistic joint tiles and the archaistic upright pillars are made of modified cement and are factory prefabricates with lifelike forms and excellent assembling and archaistic effects. Besides, the steps of the manufacturing method are simple, and the manufactured archaistic joint tiles are scientific in physical dimension design and reasonably butted and have the advantages that water seepage and rain leakage are avoided, the texture is real, the durability is good, and the appearance and the proportion are accordant with traditional tiles. According to the manufacturing method, the technical problems of long construction cycle and short service life in the prior art are solved, the construction of the archaistic building is relatively reasonable, and the application of the archaistic building is relatively wide.

Owner:BEIJING JUXING COMPOSITE MATERIAL TECH DEV

Human papillomaviruse type hybrid virus-like particles and preparation method thereof

ActiveCN102747047AIncrease production costProne to cross protectionViral antigen ingredientsInactivation/attenuationDiseaseHuman papillomavirus

The present invention relates to human papillomavirus (HPV) type hybrid virus-like particles and a preparation method thereof. The virus-like particles can be used for preventions two or more HPV infections and diseases caused by HPV infections. The present invention further relates to uses of the protein and the virus-like particles in preparations of drug compositions or vaccines, wherein the drug compositions or the vaccines are provided for preventions of HPV infections and diseases caused by HPV infections, and the diseases comprise cervical cancer, condyloma acuminatum, and the like.

Owner:XIAMEN UNIV +1

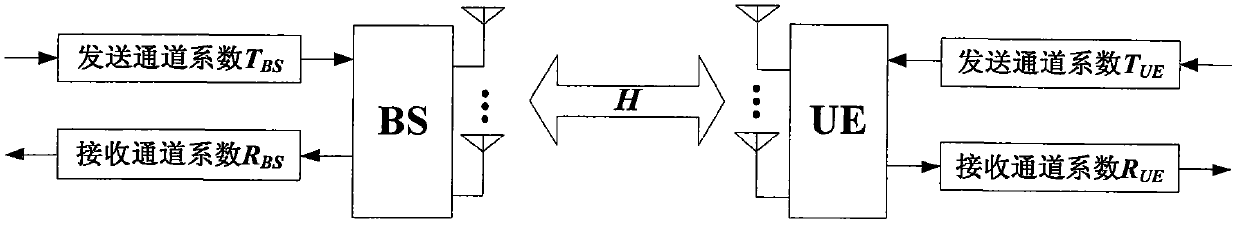

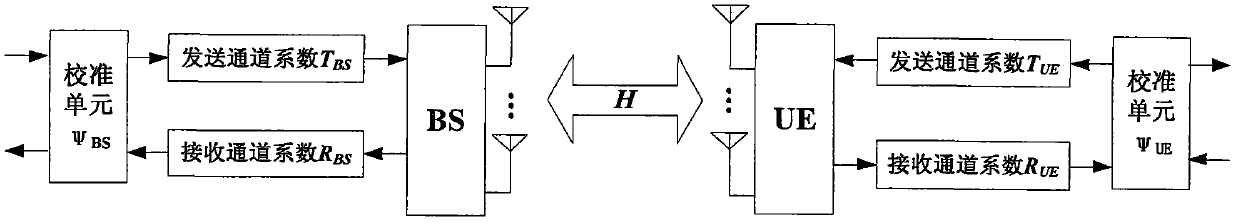

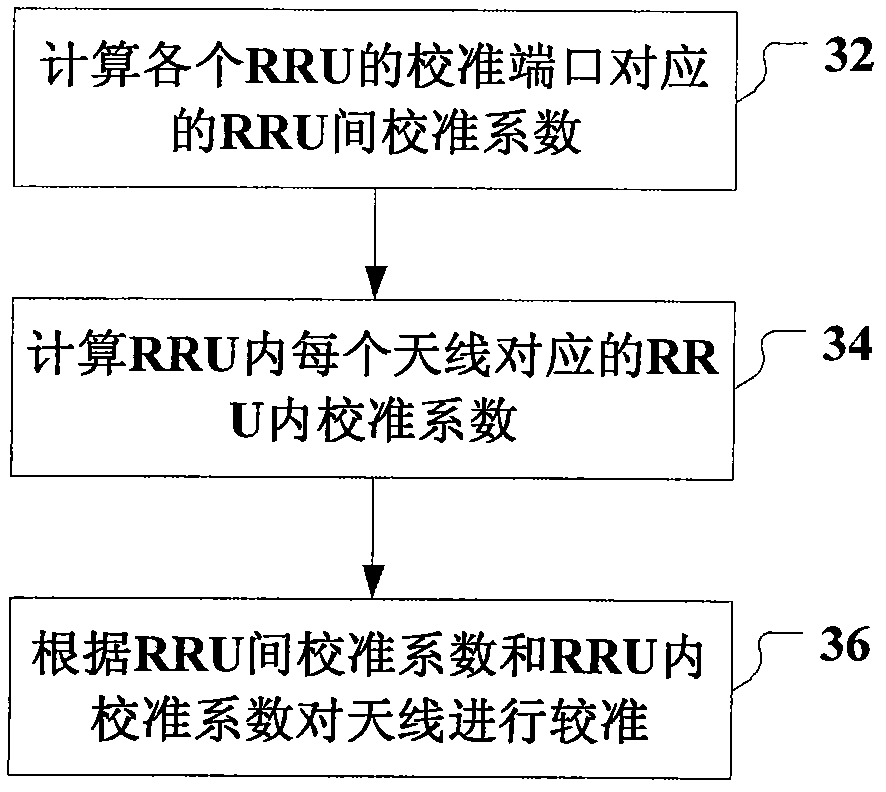

RRU antenna calibration method, apparatus and system

ActiveCN103378886AGuaranteed reciprocityHigh precisionSpatial transmit diversityAntenna calibrationPhysics

The invention discloses an RRU antenna calibration method, an apparatus and a system. The method comprises the steps of calculating a corresponding calibration coefficient among RRUs to each calibration port according to different RRU calibration ports through calibration signals in interconnected transmission; calculating a corresponding calibration coefficient in a RRU to each antenna in the RRU according to different antennas in the RRUs and the calibration signals transmitted by the calibration ports; and calibrating antenna transmitting channels and antenna receiving channels according to the calibration coefficients among the RRUs and the calibration coefficients in the RRUs so that the proportions of the antenna transmitting channels and the antenna receiving channels are same. The RRU antenna calibration method, the apparatus and the system calibrate different RRU calibration ports through interconnection among the RRUs or side connection of the antennas, and then calibrate the antennas in the RRUs by using the calibration ports, thereby enabling the calibration of the antennas among the RRUs and guaranteeing reciprocity of uplink and downlink channels of a TDD system with high accuracy, less improvement on equipment and lower cost.

Owner:CHINA MOBILE COMM GRP CO LTD

Method for duplicating and enlarging sculpture

InactiveCN104015535ASolve difficult crafting puzzlesConsistent proportionModel makingEngraving3d printer

The invention belongs to the technical field of statue engraving, and relates to an engraving method, in particular to a method for duplicating and enlarging a sculpture. The method overcomes the defects in the prior art, and saves time and labor, the enlarged sculpture is not distorted, and the method can be used for producing large products. According to the technical scheme, a model of a large sculpture is scanned in a three-dimension scanner to form an electronic model, the model is sliced to be processed and then is processed through a flat carving machine, and processed slices are bonded and then ground and corrected to be molded. Compared with a traditional sculpture enlarging method, the large sculpture is sliced to be processed, and then the processed slices are bonded, so that a manufactured sculpture is larger, the size of the sculpture is far beyond the largest range of a 3D printer and a circular carving machine, and the problem that a large sculpture is hard to manufacture is solved.

Owner:SHANXI BIMU MOER BUILDING TECH CO LTD

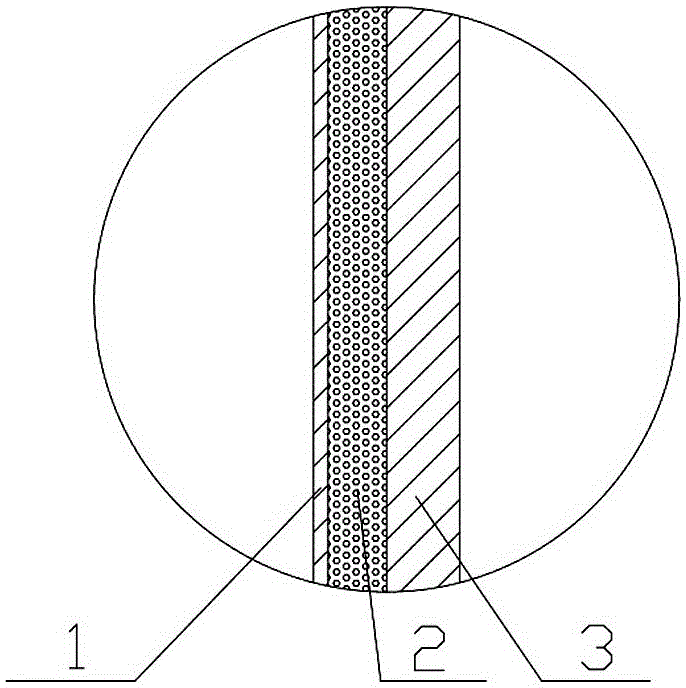

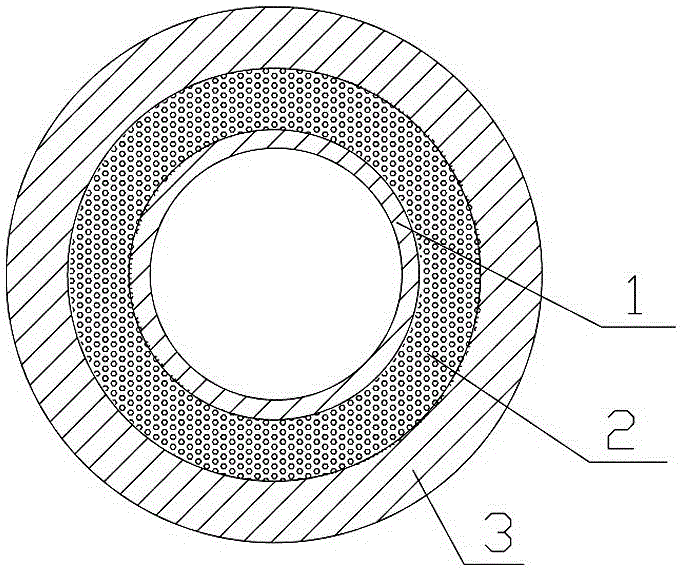

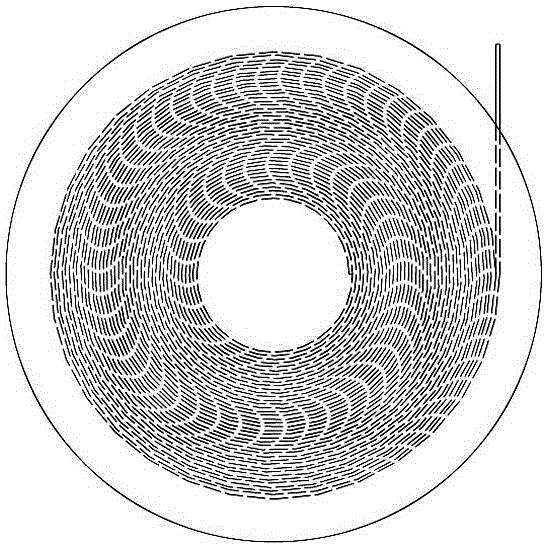

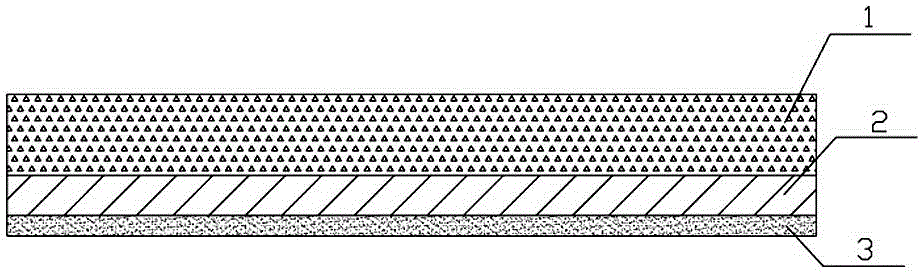

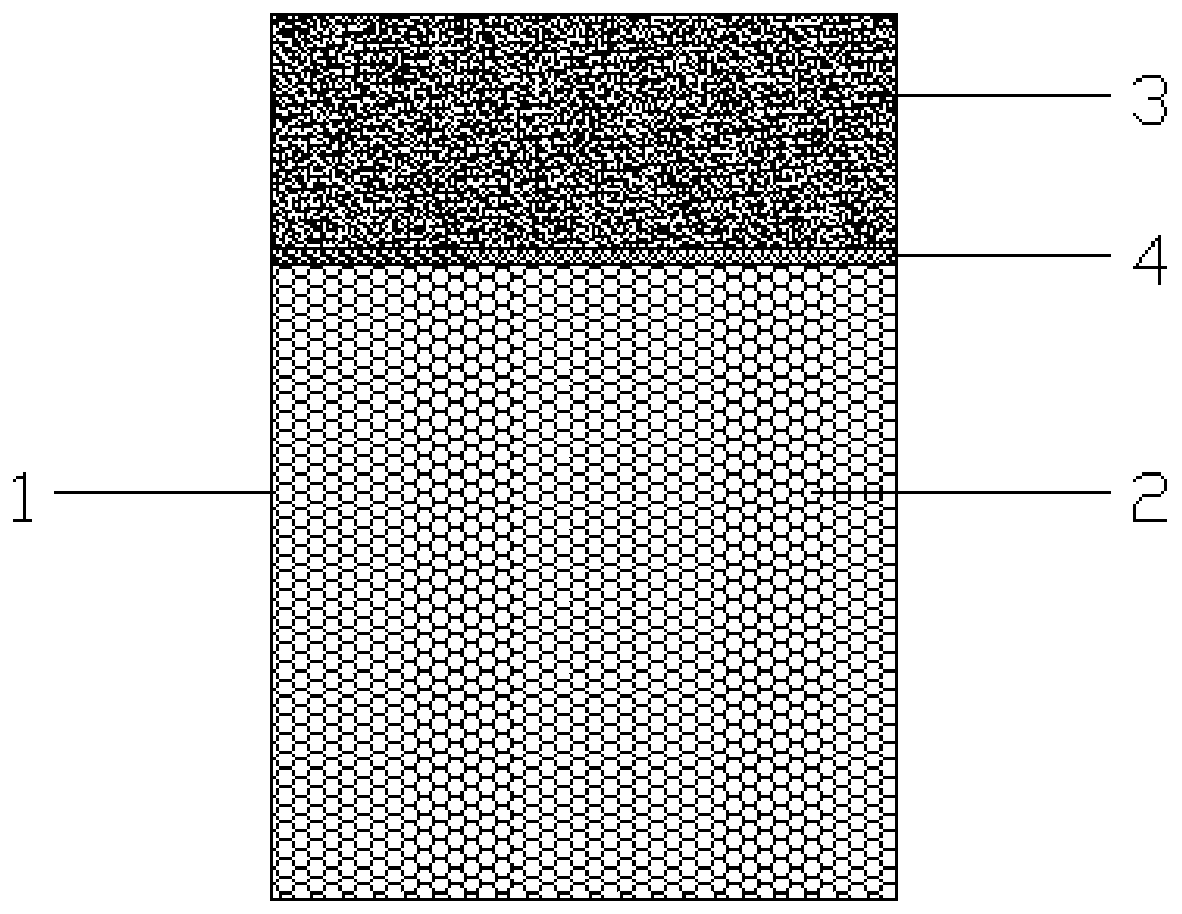

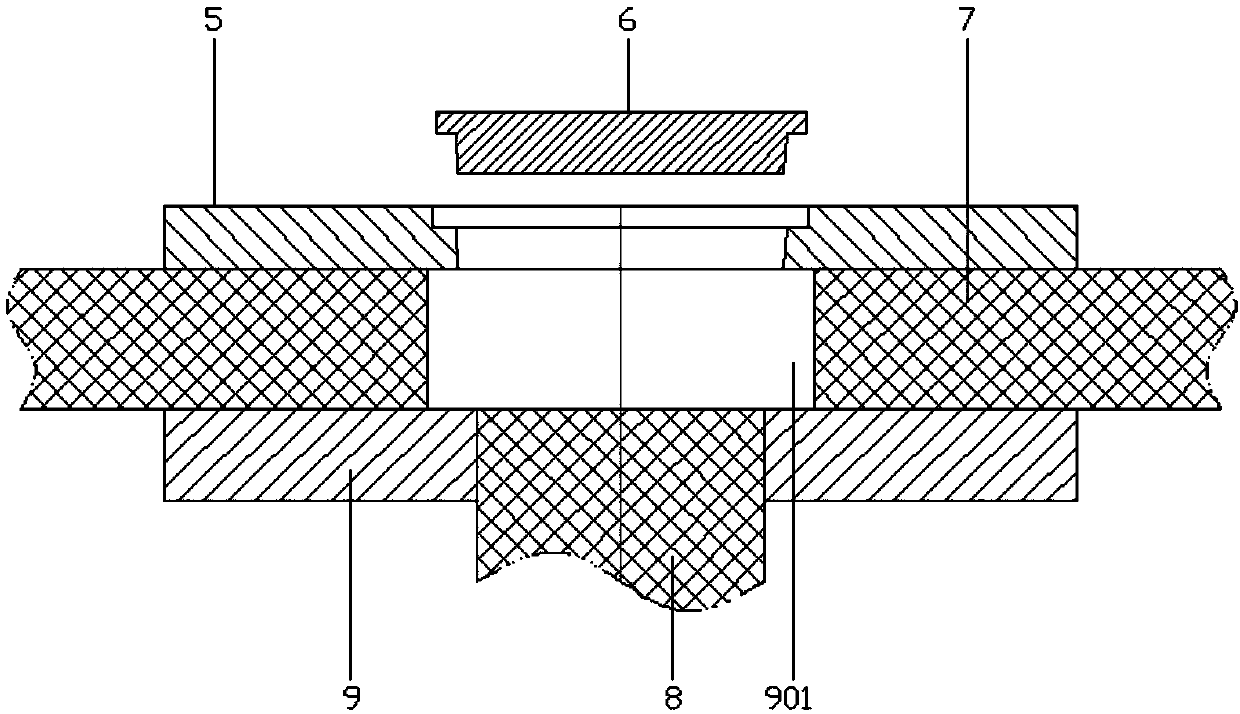

Layered composite brazing coating material and preparation method thereof

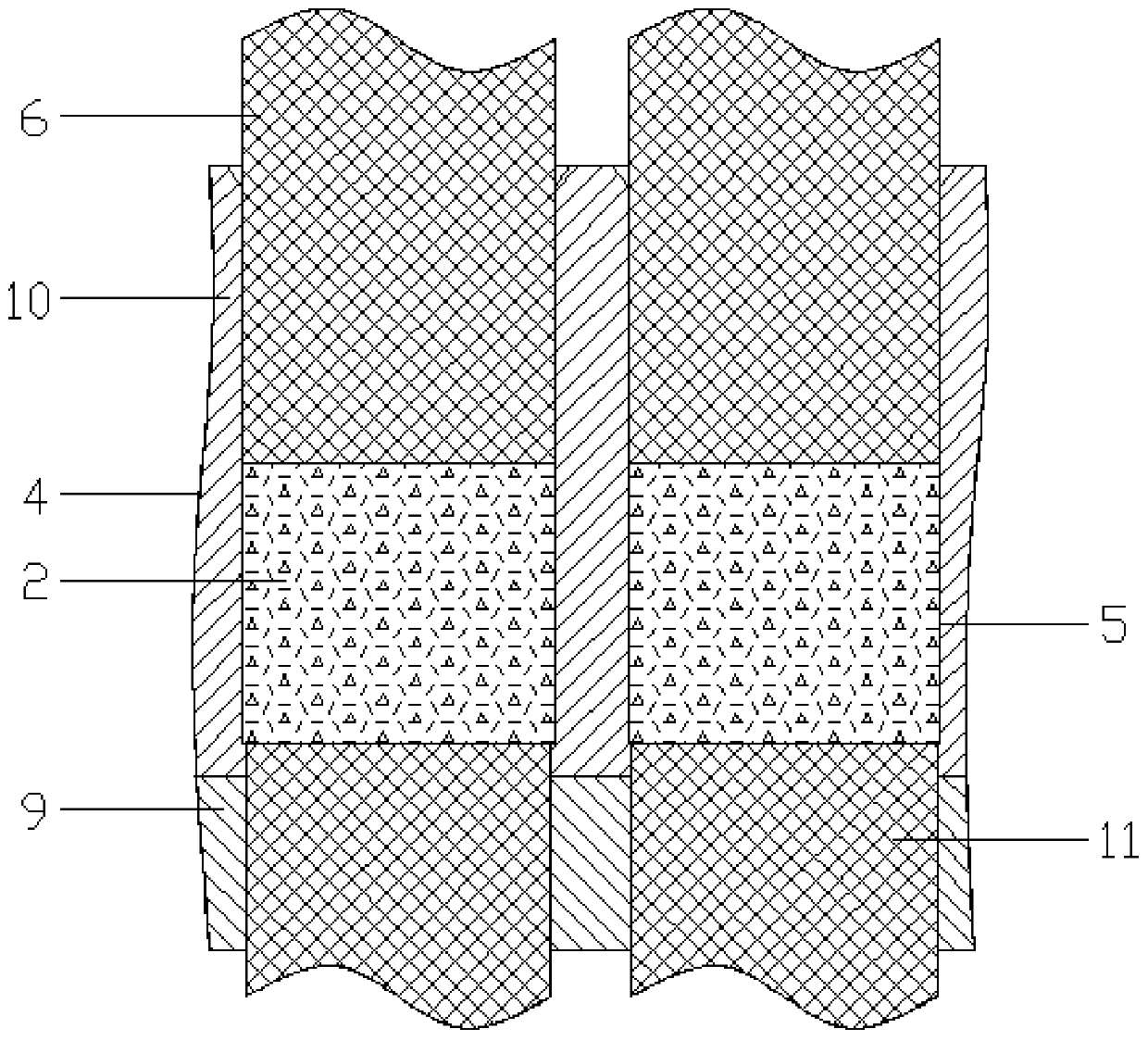

ActiveCN106112307AImplement automatic additionConsistent proportionLaminationLamination apparatusCemented carbideFiller metal

The invention discloses a layered composite brazing coating material. The layered composite brazing coating material is a belt-shaped structure consisting of a brazing filler metal alloy inner layer, a mixture middle layer including hard alloy particles and a brazing flux and a brazing filler metal alloy outer layer, or a drawn pipe-shaped structure. The brazing filler metal alloy inner layer is 0.01-1 mm thick; the mixture middle layer is 0.1-4 mm thick; and the brazing filler metal alloy outer layer is 0.1-2 mm thick. In the mixture middle layer, the weight percentage of the hard alloy particles is 80-99%. The layered composite brazing coating material has the brazing flux, is excellent in formability, and realizes quantitative and automatic adding of the brazing flux; the brazing filler metal alloy and the hard alloy are consistent in proportion to effectively guarantee the brazing coating quality; the rolled layered composite brazing coating material can be wound as a disc or a shaft; and the automatic production can be realized in the brazing coating process. Compared with a traditional suspension pulp-shaped brazing coating material or a piece-shaped brazing coating material, the layered composite brazing coating material is simple in preparation process, is convenient for storage and transportation, and can realize automatic production in the brazing coating process.

Owner:CHINA INNOVATION ACADEMY OF INTELLIGENT EQUIP CO LTD

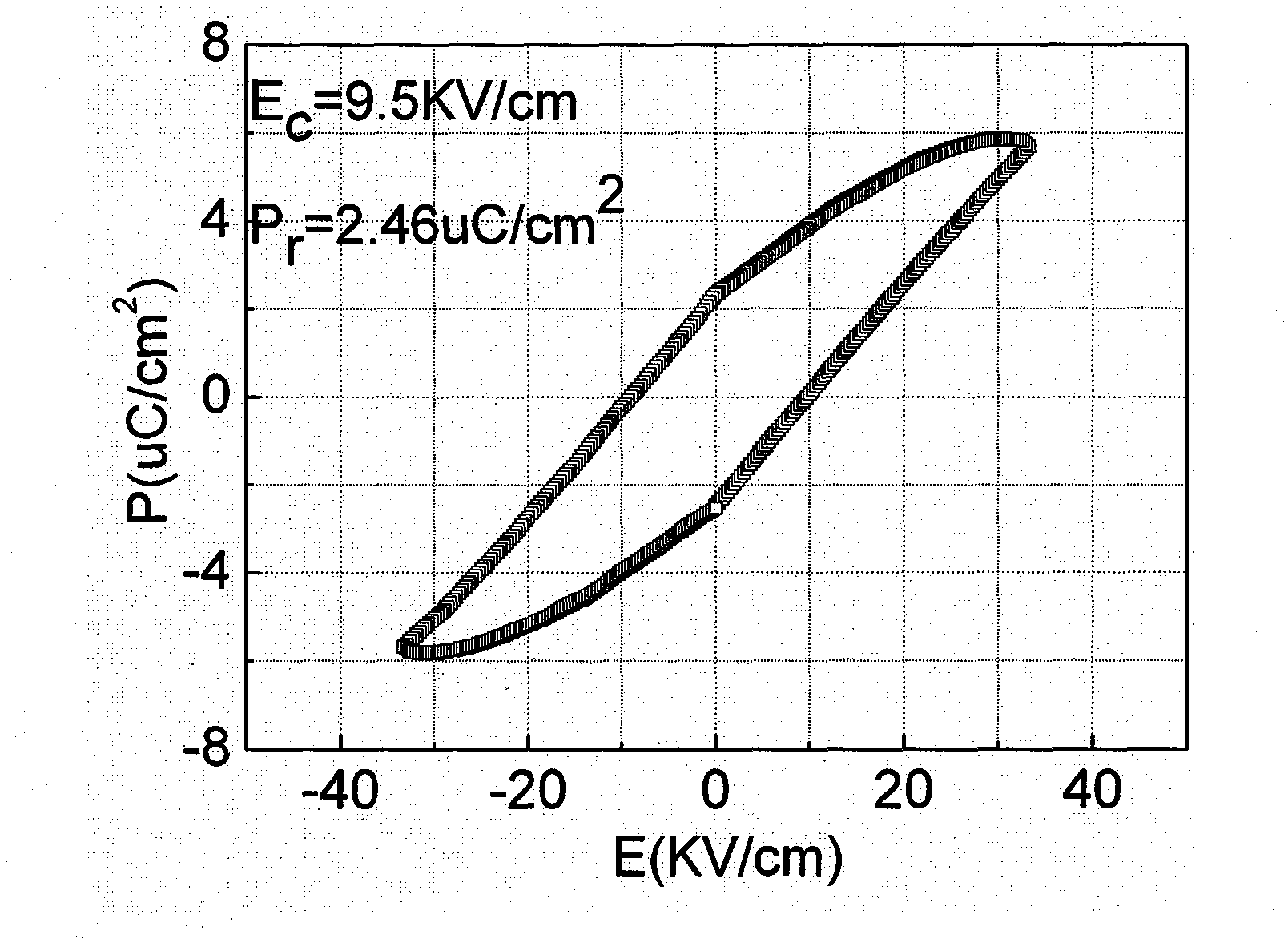

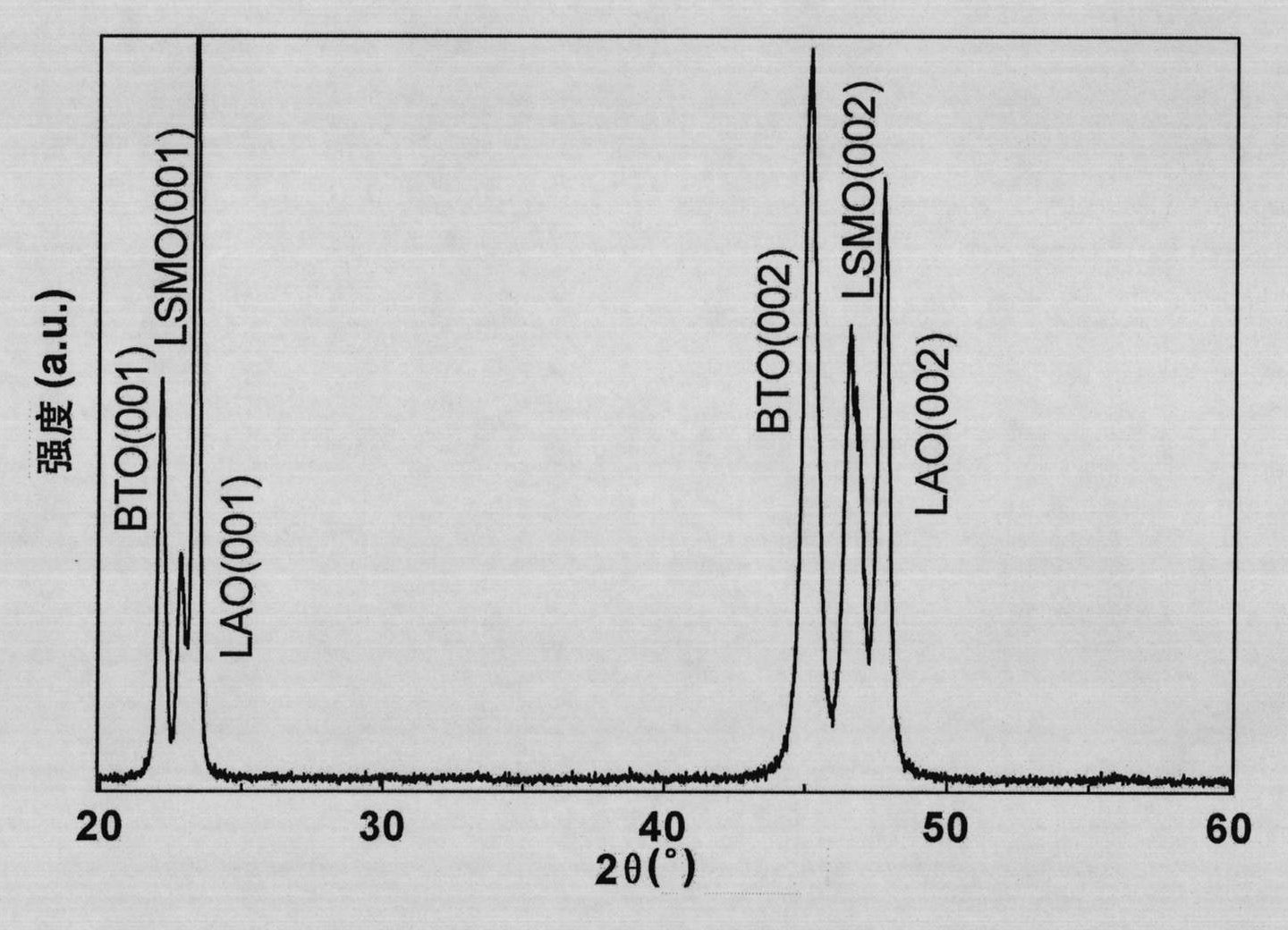

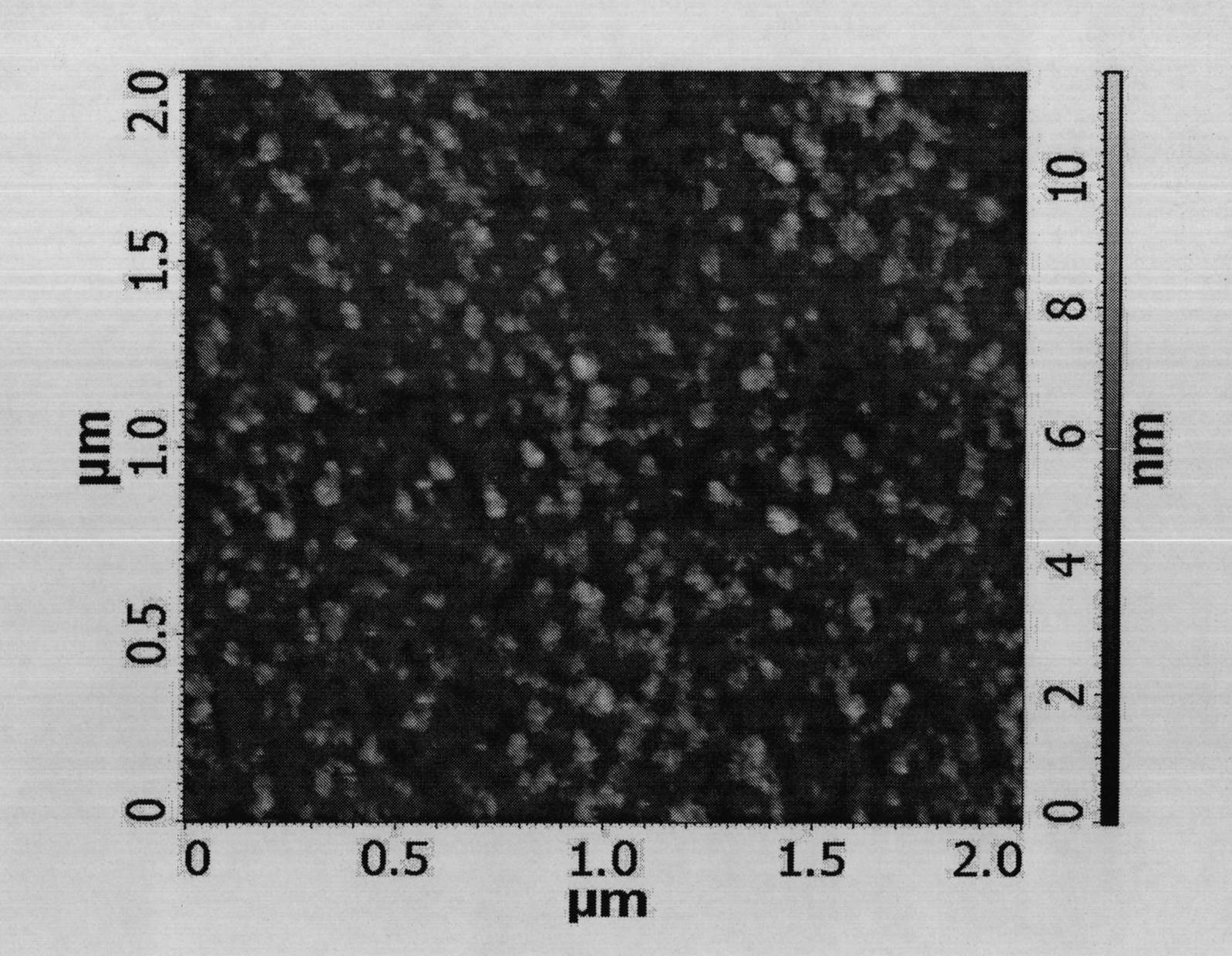

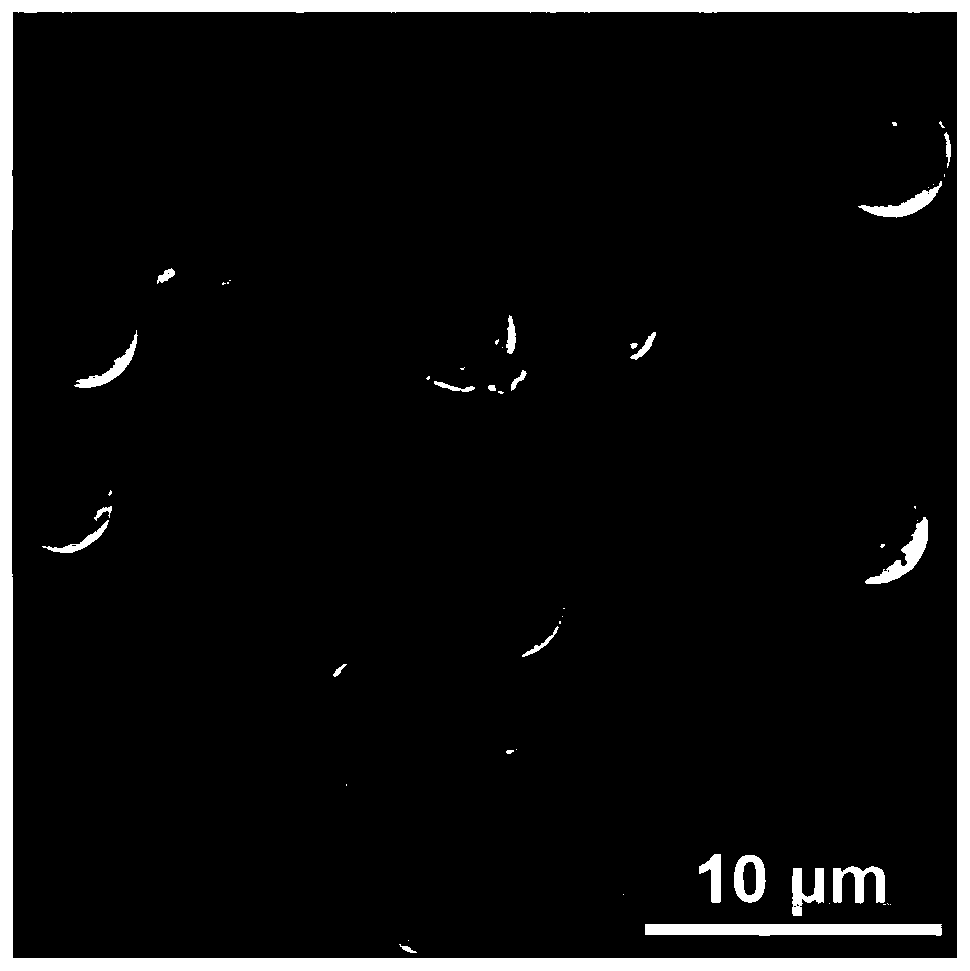

All-perovskite multiferroic magnetoelectric compound film and preparation method thereof

InactiveCN102071399AIdeal chemical ratioConsistent proportionVacuum evaporation coatingSputtering coatingSingle crystal substrateSingle crystal

The invention discloses an all-perovskite multiferroic magnetoelectric compound film and a preparation method thereof, belonging to the technical field of films. The La2 / 3Sr1 / 3MnO3 / BaTiO3 multiferroic magnetoelectric compound film with an all-perovskite structure is deposited on the surface of a LaAlO3 (001) single crystal substrate, and successively comprises a La2 / 3 Sr1 / 3MnO3 film and a BaTiO3 ferroelectric film from bottom to top; and the thickness of the La2 / 3Sr1 / 3MnO3 ferromagnetic film is 400-800nm, and the thickness of the BaTiO3 ferroelectric film is 400nm. The preparation method is as follows: deposing a La2 / 3Sr1 / 3MnO3 film and a BaTiO3 film on the LaAlO3 single crystal substrate by using pulse laser; and then annealing at the temperature of 850 DGE C. By using the preparation method, the ferromagnetic and ferroelectric properties of the La2 / 3Sr1 / 3MnO3 and BaTiO3 can be effectively improved, and the magnetoelectric effect of the compound film can also be improved.

Owner:BEIJING UNIV OF TECH

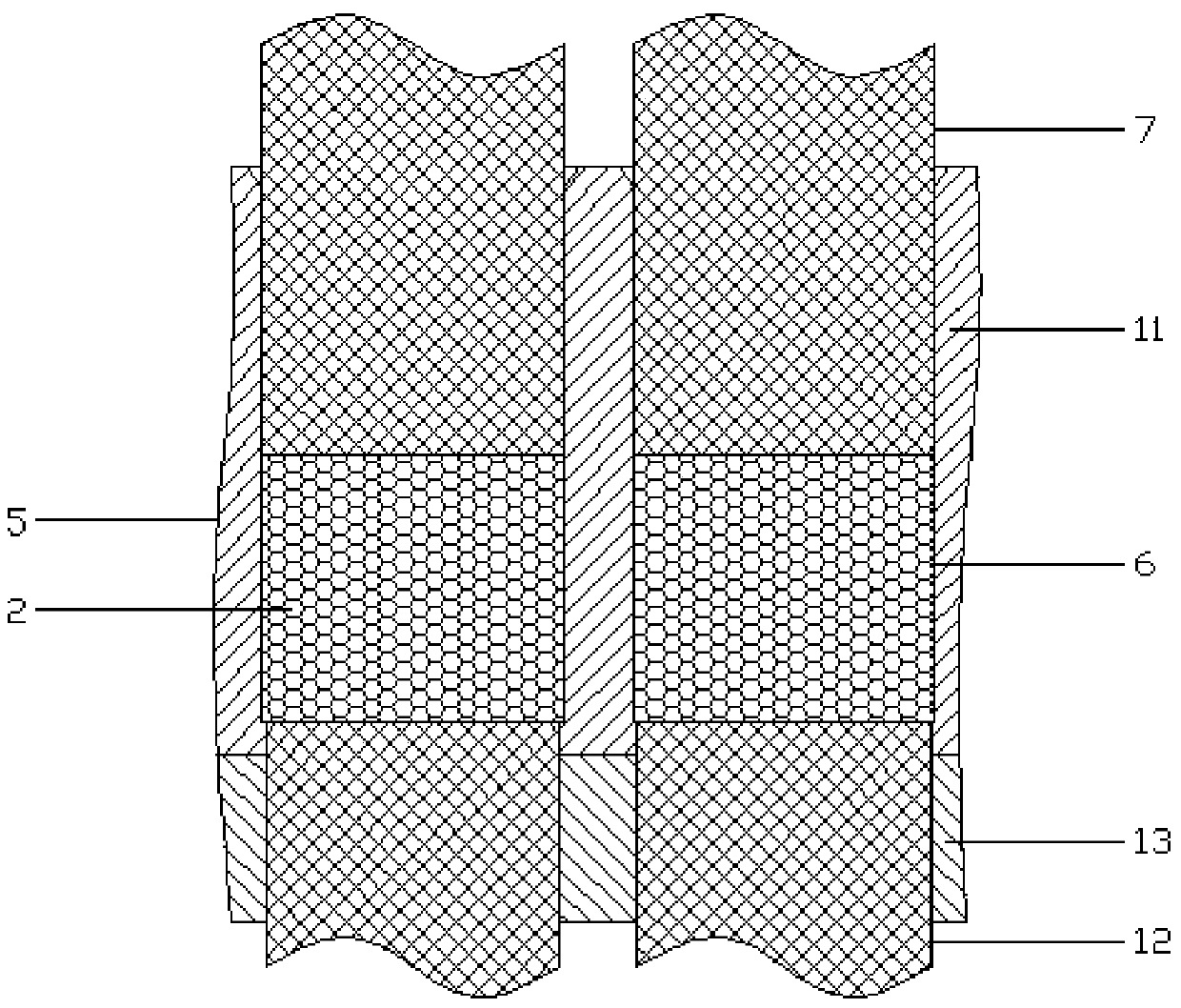

Tubular braze coating material

InactiveCN105382439ASimple preparation processGood formabilityWelding/cutting media/materialsSoldering mediaCemented carbideAdhesive

The invention discloses a tubular braze coating material. The tubular braze coating material is of a double-layer filament-shaped or strip-shaped structure shaped like a belt core, the outer layer is a brazing alloy wrapping layer, and the inner layer is composed of mixtures of hard alloy particles and brazing flux. The mixtures are composed of, by weight, the hard alloy particles of 80-90% and the balance brazing flux. Compared with traditional suspending slurry braze coating materials or sheet braze coating materials formed by powdery brazing filler metal, hard alloy particles, adhesives, organic matter and the like, the tubular braze coating material has the advantages that the brazing flux is contained internally, quantitative and automatic addition of the brazing flux is realized in the braze coating process, the proportion of brazing alloy and the proportion of the hard alloy particles are uniform, the hard alloy particles are uniformly distributed after braze coating, and storage, transportation and use are convenient.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

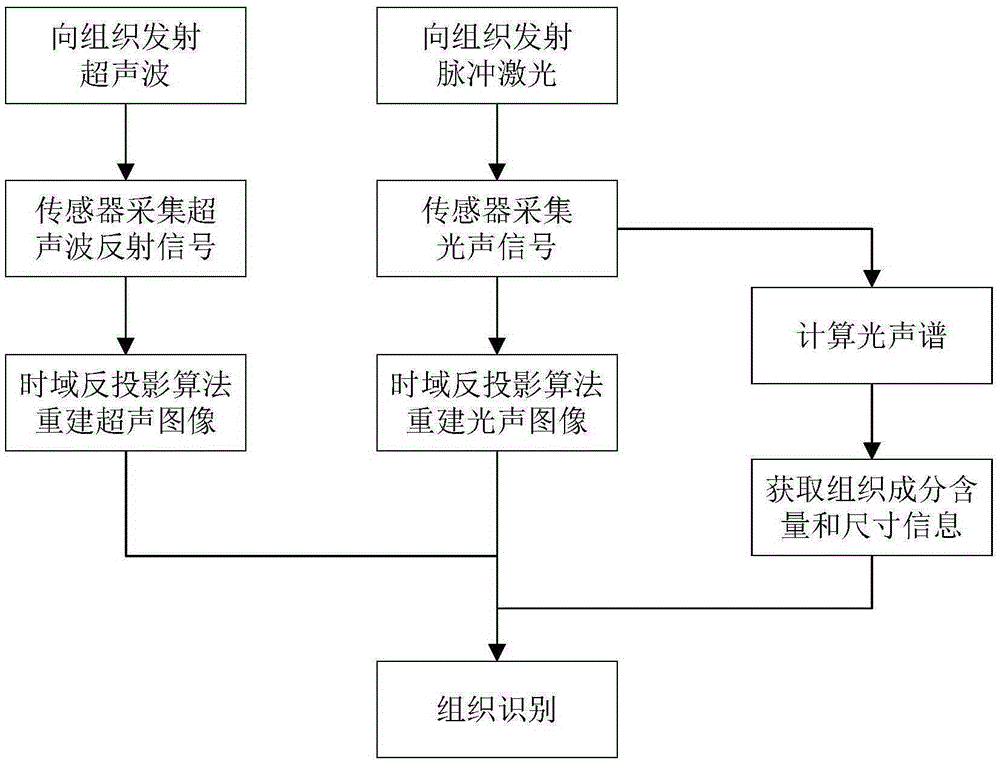

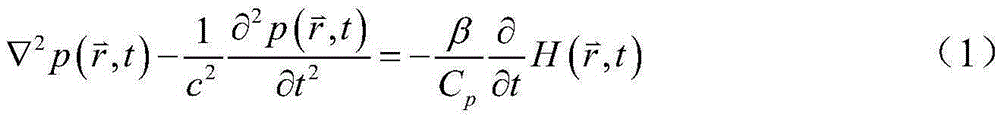

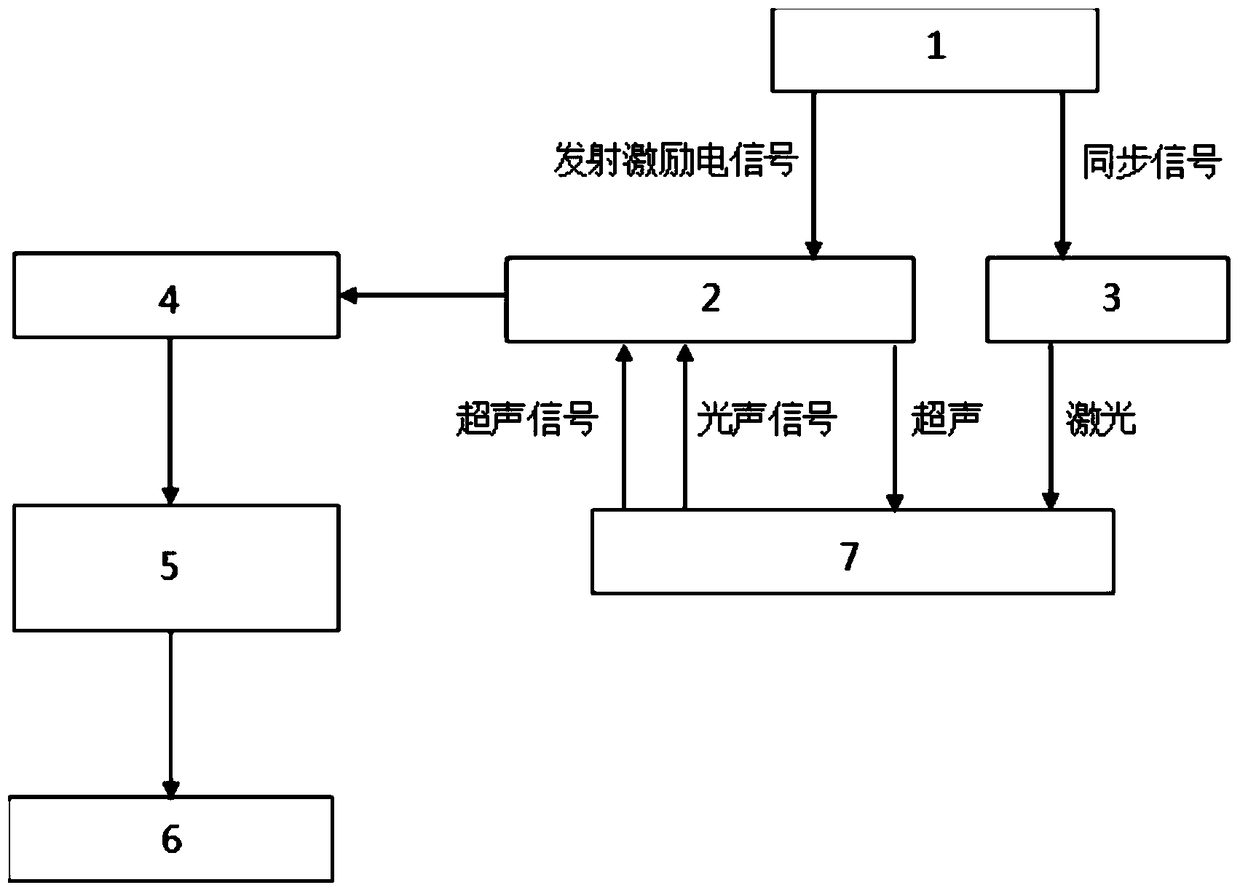

Ultrasonic, opto-acoustic and opto-acoustic spectrometry tri-modal imaging system and method

ActiveCN105395219AHigh resolutionThree-modal imaging implementationOrgan movement/changes detectionUltrasonic/sonic/infrasonic dianostic techniquesSonificationUltrasonic sensor

The invention relates to an ultrasonic, opto-acoustic and opto-acoustic spectrometry tri-modal imaging system, which is applied to identification of ingredient content and dimension equivalent of a tissue. The system comprises a host machine, a pulse laser, as well as an array ultrasonic sensor, a data acquisition module, a data processing and image reconstruction module and a display module which are sequentially connected, wherein the host machine is connected to the array ultrasonic sensor and the pulse laser; the array ultrasonic sensor clings to the tested tissues; and the pulse laser is opposite to the tested tissues. Compared with the prior art, the imaging system disclosed by the invention has the advantages of achieving tri-modal imaging as well as synchronous and equal-proportion imaging and the like.

Owner:TONGJI UNIV

Preparation method of high-heat-conduction aluminum nitride thick film

InactiveCN103173727AImprove thermal conductivityFast depositionVacuum evaporation coatingSputtering coatingAluminum IonEpoxy

The invention relates to a preparation method of a high-heat-conduction aluminum nitride thick film, belongs to the technical field of surface coating preparation and application and mainly solves the technical problems that an aluminum nitride thick film can not be prepared, the deposition speed is low, commercialization is difficult to realize and the like in the prior art. According to the method, the aluminum nitride thick film is deposited through arc ion plating, the nitrogen / aluminum ratio in the film is uniform, the thickness of the prepared AlN high-heat-conduction film can be up to 3-10mu m, and a large bonding force can be generated between the film and a substrate, wherein the involved substrate material can be metal such as stainless steel, iron, copper, aluminum and the like, or can be an inorganic non-metal material such as ceramic, glass and the like, or can be a high-molecular organic polymer such as epoxy resin, polyimide and the like. The preparation method comprises the following steps: performing surface treatment on the substrate material; and by selecting pure aluminum as a cathode target material and using pure nitrogen gas as reacting gas, forming the AlN high-heat-conduction film through reaction between aluminum ions obtained by ionization and the nitrogen gas, wherein the purity of the aluminum target material is 99.99%, and the purity of the nitrogen gas is 99.999%. Thus, the method is applicable to multiple fields such as electronic measuring instruments, computer equipment, measurement and control systems, airplanes, precision weapons and the like.

Owner:辽宁法库陶瓷工程技术研究中心

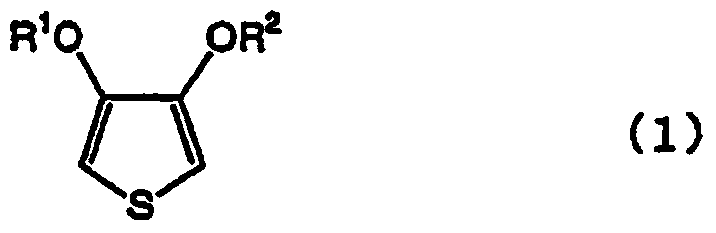

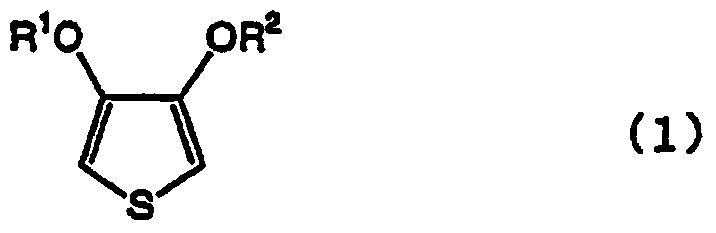

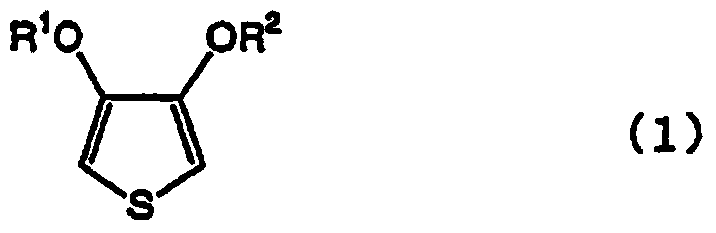

Polythiophene derivative aqueous dispersion and preparation method thereof

The invention discloses a preparation method of a polythiophene derivative aqueous dispersion. The preparation method comprises the following polymerization processes: firstly mixing an oxidant aqueous solution with 3,4-dialkoxythiophene shown in a formula (1) in the specification; dropwise adding the solution obtained after mixing to a solution containing polyanions, carrying out high-shear stirring for 24 hours to polymerize 3,4-dialkoxythiophene, then adding cation-anion resins, stirring the materials for 12 hours and filtering the product, thus obtaining the polythiophene derivative aqueous dispersion. The preparation method has the beneficial effects that the preparation method has the advantage that the proportion of an oxidant to EDOT (3,4-ethylenedioxythiophene) can be always kept consistent, so that the dispersion liquid with good stability is obtained; the preparation method is simple and is mild in production conditions and low in requirements of instruments and equipment; through changes of the factors such as preparation conditions, aftertreatment modes or additives and the like, the parameters such as solid content, acidity, viscosity, granularity and the like of the aqueous dispersion and the parameters such as electrical conductivity or light transmittance and the like can be adjusted, thus being suitable for different application requirements.

Owner:SHENZHEN CAPCHEM TECH

Method for preparing super-simulative fake breast

ActiveCN103144231AConsistent softnessConsistent elasticityHuman Mammary GlandsBiomedical engineering

The invention belongs to the technical field of plastic and aesthetic surgery and especially relates to a method for preparing a super-simulative fake breast. The method comprises the following steps of: (1) atomizing a release agent on the surface of a mold for preparing the fake breast, and then putting the mold in an oven for drying; (2) atomizing liquid silicon rubber on the surface of the mold in step (1), and then removing bubbles through vacuum equipment, and then putting the mold in the oven for solidification; (3) repeating step (2) three to six times, pouring liquid silica gel in the gap part of the mold for vulcanization, and then solidifying the mold in the oven; and (4) pouring the liquid silicon rubber on the outer layer of the product formed in step (3), then removing bubbles, drying and demoulding to finally obtain the super-simulative fake breast. The super-simulative fake breast prepared through the above-mentioned steps basically keeps consistent with the breast tissue of a human body in softness, elasticity, specific gravity and colour and lustre, and is more authentic and closer to the human body skin than the traditional silicon gel fake breast. Especially in touch aspect, the advantage of the product is well displayed.

Owner:DONGGUAN LANKE SILICONE TECH

Composite braze coating material and preparation method thereof

InactiveCN106271178AStrong combinationImprove cleanlinessWelding/cutting media/materialsSoldering mediaBrazingCarbide coating

The invention discloses a composite braze coating material which comprises a strip or platy braze coating material body with a three-layer structure, wherein the braze coating material body sequentially comprises a hard alloy coating, a brazing alloy layer and a brazing flux coating. The thicknesses of the hard alloy coating, and the brazing alloy layer and the brazing flux coating are adjusted between 0.001mm and 20mm. When the composite braze coating material is prepared, brazing alloy strips or plates are rolled according to design thickness, the upper surfaces of the brazing alloy strips or plates are coated with hard alloy particles in a cold spraying manner, the lower surfaces of the brazing alloy strips or plates are coated with brazing fluxes in a hot spraying manner, a certain sizes of composite braze coating material formed by the hard alloy coating, the brazing alloy layer and the brazing flux coating is prepared. The proportion of brazing alloys and the hard alloy particles is consistent, stability and consistency of braze coating quality can be effectively ensured, the brazing fluxes are quantitatively and automatically added and firmly deposited on the surfaces of the brazing alloys in a hot spraying manner, and the composite braze coating material is simple in preparation process, good in formability and convenient to store, transport and use.

Owner:ZHENGZHOU RES INST OF MECHANICAL ENG CO LTD

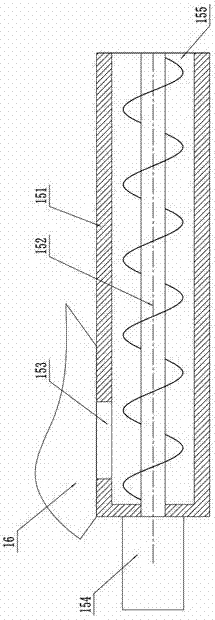

Farmland-garden water and fertilizer integrated irrigation equipment

ActiveCN107484483ATotal controlImprove the effect of real-time mixingPressurised distribution of liquid fertiliserImpellerInlet valve

The invention discloses farmland-garden water and fertilizer integrated irrigation equipment which comprises an irrigation pipeline, a connection head, a mixing device, a first connection pipe, a first shell, a first motor, a first impeller, a speed reducer, a water inlet pipe, a high-pressure air pipe, a preprocessing tank, a fixed stopping block, a sealing cover, a spring, a quantitative conveying device, a fertilizer storage tank, a water inlet value, a stirring paddle, a base, a second motor, a conveying pipe, a second shell, a second impeller and a second connection pipe. The farmland-garden water and fertilizer integrated irrigation equipment disclosed by the invention has the advantages of reasonable and simple structure, low production cost and convenience in installation. Firstly, the quantitative conveying device can convey a fertilizer stored in the fertilizer storage tank into the preprocessing tank; then the water inlet valve is started to add the defined proportion of water into the preprocessing tank; then compressed air is sent into the preprocessing tank by the high-pressure air pipe; the arranged speed reducer can guarantee that the output proportions of the water and the fertilizer are the same; finally, the water and the fertilizer are further mixed by the mixing device and then conveyed into the irrigation pipeline to irrigate farmland and gardens.

Owner:YANTAI ZHIXING INTPROP CONSULTATION SERVICES CO LTD

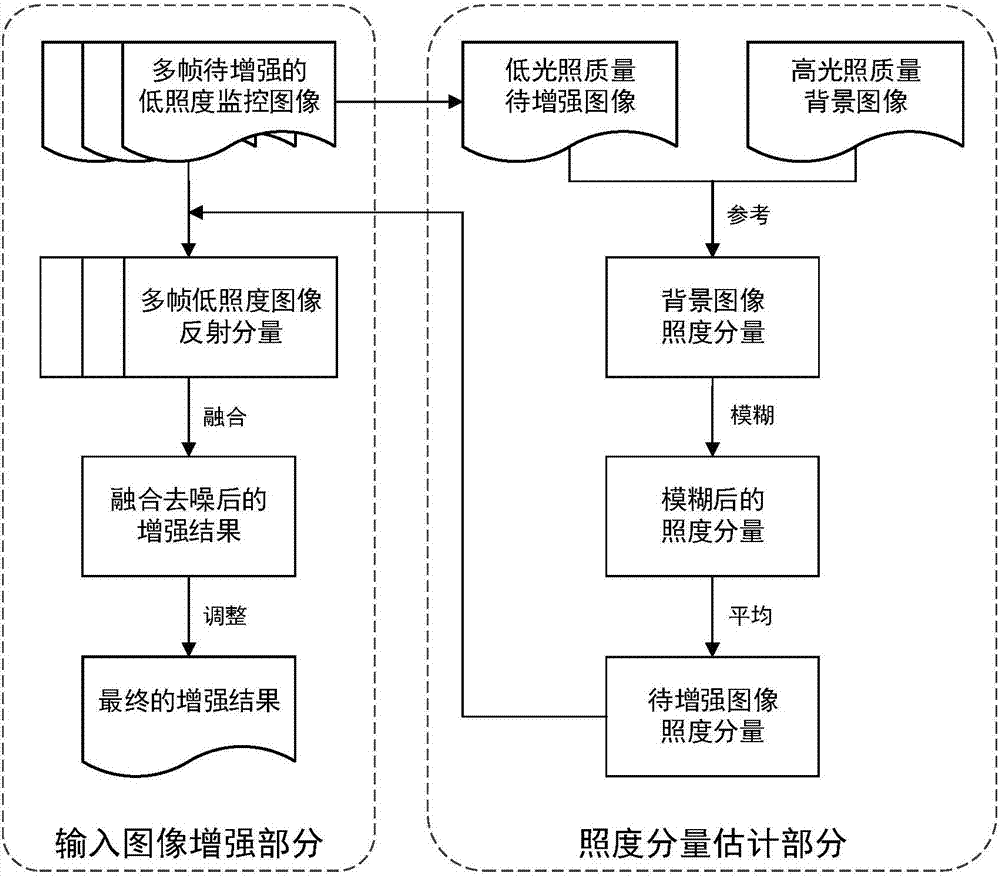

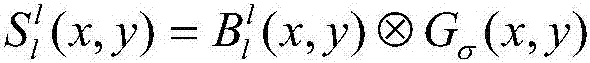

Reference frame-based low illumination monitoring image enhancement method

ActiveCN107392879AHigh color fidelityAccurate illuminance component estimationImage enhancementImage analysisGlobal illuminationImage enhancement

The invention provides a reference frame-based low illumination monitoring image enhancement method comprising the following steps: a reference frame and a low illumination image to be enhanced are obtained from a monitoring video, neighboring frames of the low illumination image is extracted, an illumination component of a background image is calculated, an illumination component of the image to be enhanced is calculated, reflection components of the low illumination image and a plurality of the neighboring frames are extracted, and an enhancement result of the low illumination image to be enhanced can be obtained after denoising operation via fusing operation. Via the reference frame-based low illumination monitoring image enhancement method, the illumination component of the image to be enhanced can be estimated accurately, color fidelity of the enhancement result can be improved, noise interference can be lowered, sharpness and a recognizable degree of the low illumination monitoring image can be improved, and forceful support can be provided for the monitoring image to assist criminal investigation.

Owner:WUHAN UNIV

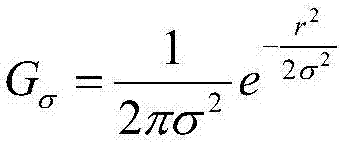

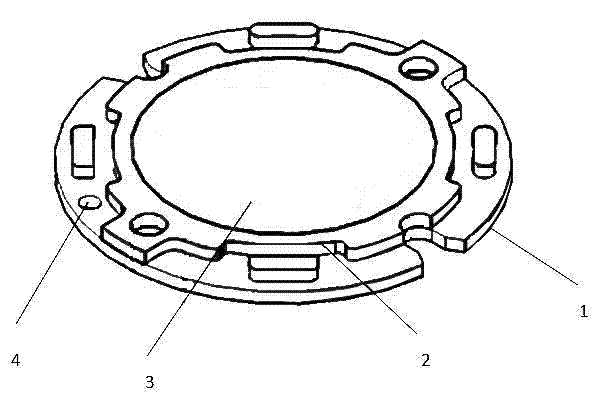

Novel LED (light emitting diode) integrated light source module and preparation method thereof

InactiveCN102738372AControl Volume and Thickness UniformityControl the light effectSemiconductor devicesEngineeringLight-emitting diode

The invention discloses a novel LED integrated light source module. The novel LED integrated light source module comprises a substrate body, and LED chips arranged on the substrate body, wherein rubber barrier walls are arranged on the substrate body to enclose an LED chip fixing region on the substrate body to at least one closed region; the LED chips are arranged in the closed region; the rubber barrier walls can stop a phosphor powder glue mixed layer in the LED chip region from flowing out of the light emitting region due to fluid dynamics and can also improve the light emitting efficiency and light uniformity of the LED chip. The invention also discloses a processing method of the above LED integrated light source module.

Owner:FOSHAN EVERCORE OPTOELECTRONICS TECH

Microgranular alginate water-soluble fertilizer prepared by means of melting complexation reaction, and preparation method of microgranular alginate water-soluble fertilizer

InactiveCN107445705APromote complexation reactionFacilitate root absorption of cropsCalcareous fertilisersAlkali orthophosphate fertiliserNutrientNitrogen fertilizer

The invention discloses microgranular alginate water-soluble fertilizer prepared by means of melting complexation reaction, and a preparation method of the microgranular alginate water-soluble fertilizer. The microgranular alginate water-soluble fertilizer is prepared from the following raw material components in parts by weight: 60-80 parts of nitrogen fertilizer, 40-50 parts of phosphorus fertilizer, 70-80 parts of potassium fertilizer, 5-10 parts of an alginate synergistic solution, 10-15 parts of medium-trace element fertilizer, 3-5 parts of a mixture obtained by mixing calcium nitrate and calcium carbonate according to a mass ratio of 2 to 3, and 0.5-1 part of vegetable oil. The balance and stability of nutrient components of the fertilizer are guaranteed; nitrogen-phosphorus-potassium base fertilizer contains weak acid radicals, so that the complexation reaction is better promoted, and the fertilizer is easily absorbed by the crop root system; chelating medium-trace elements are easy to absorb; the calcium carbonate can improve the hardness of fertilizer microparticles and adjust the acid soil; the alginate synergistic solution contains small active substances and has an adhesive effect when being dissolved in water, so that the solubility of the microgranular alginate water-soluble fertilizer is better than that of the common water-soluble fertilizer after the alginate synergistic solution is complexed with molten nitrogen, phosphorus and potassium elements; the microgranular alginate water-soluble fertilizer is dissolved in a way of sol swelling, so that the fertilizer is convenient to disperse and absorb, and the crop yield is further increased.

Owner:SHANDONG ENBAO BIOTECH

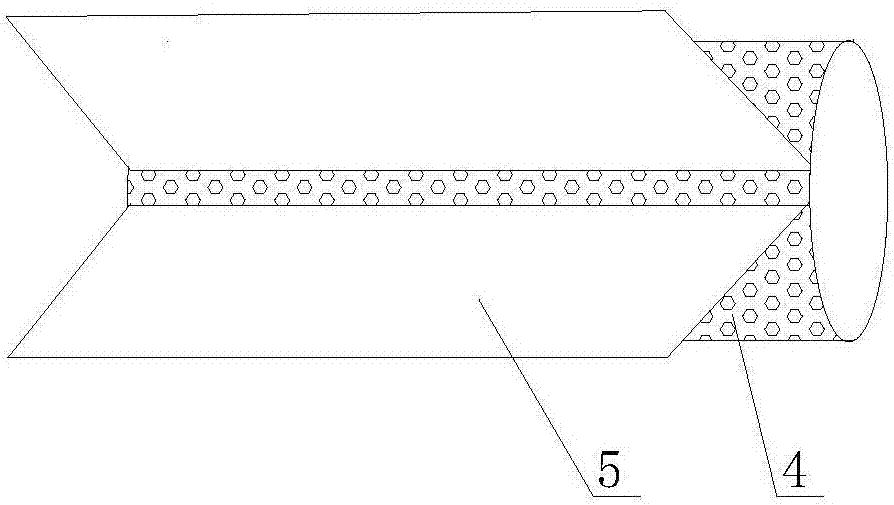

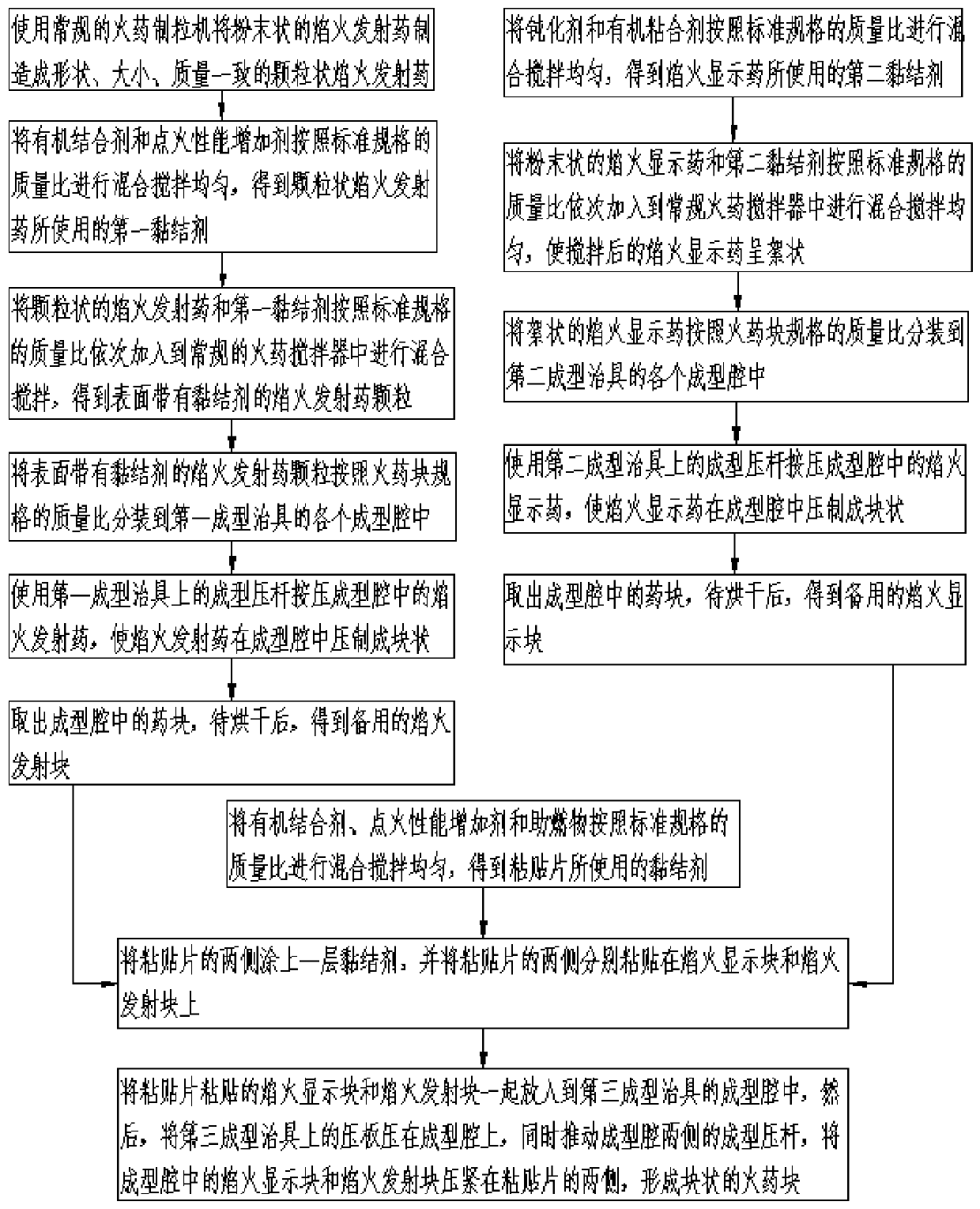

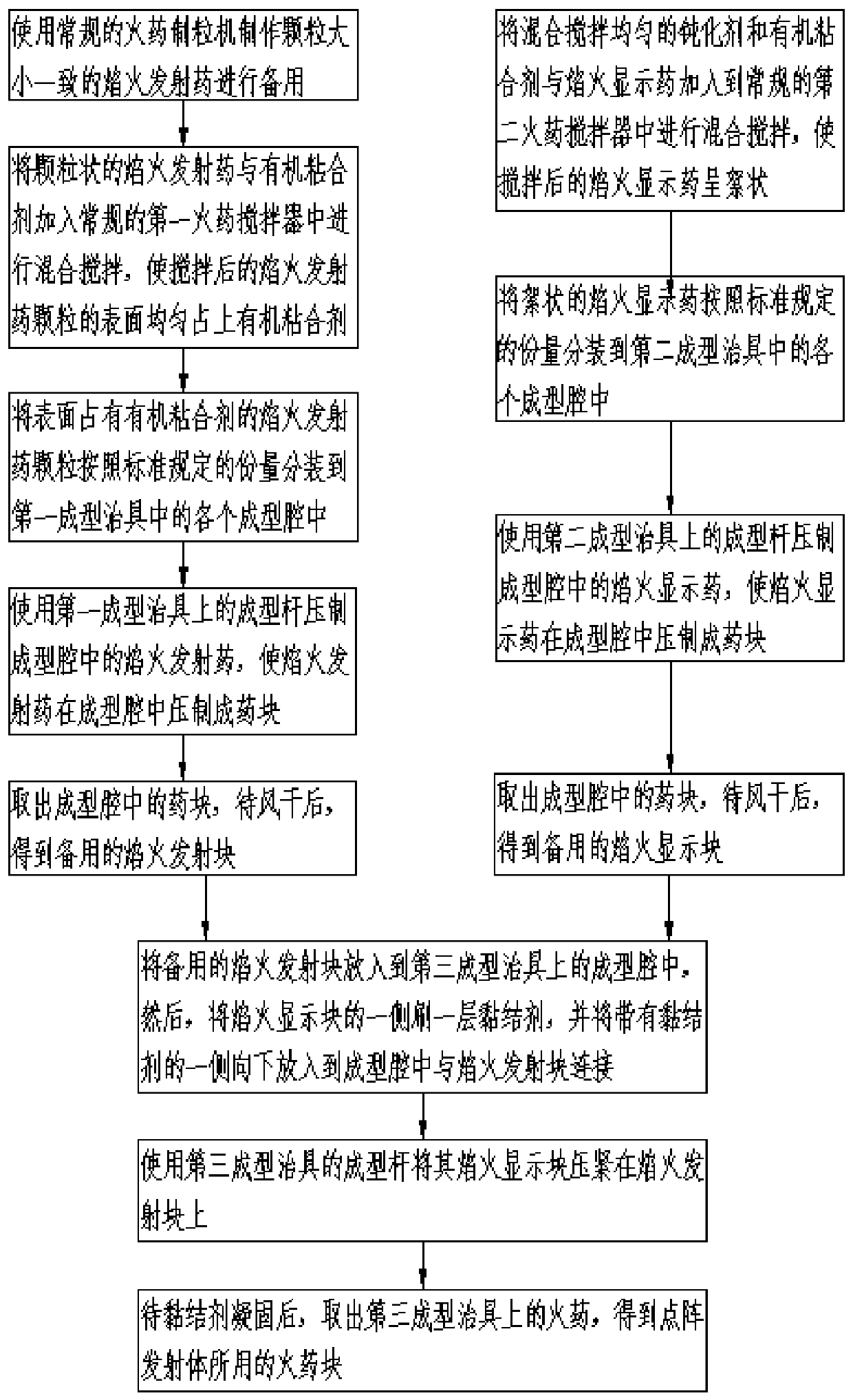

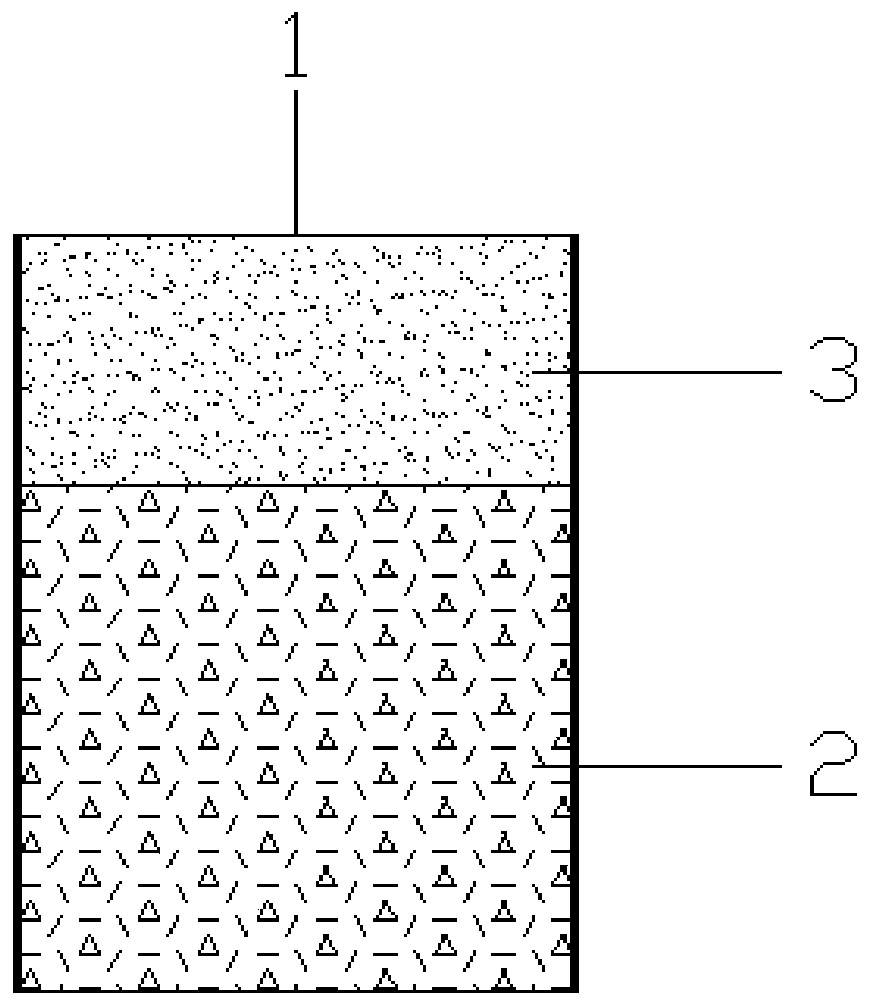

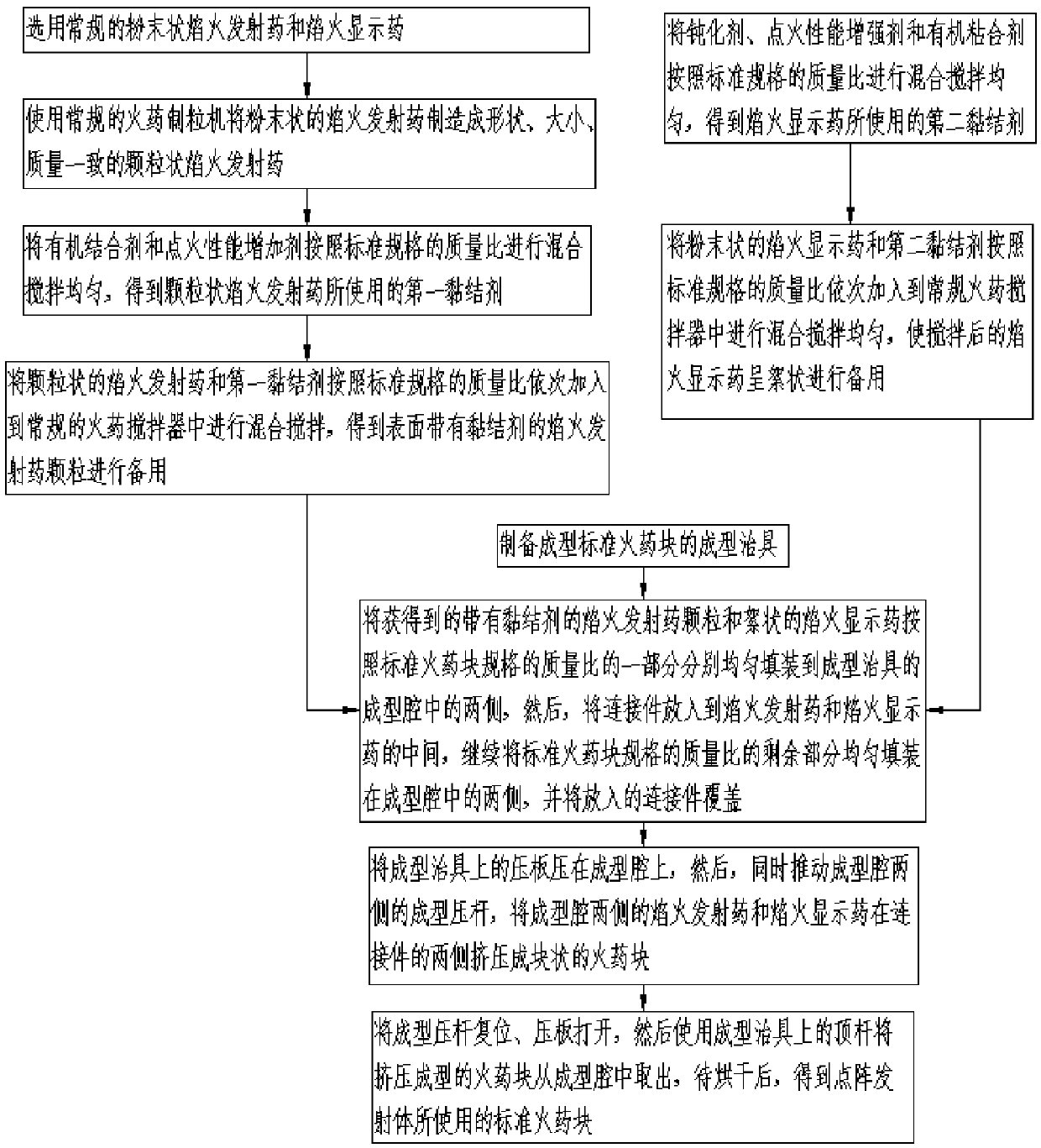

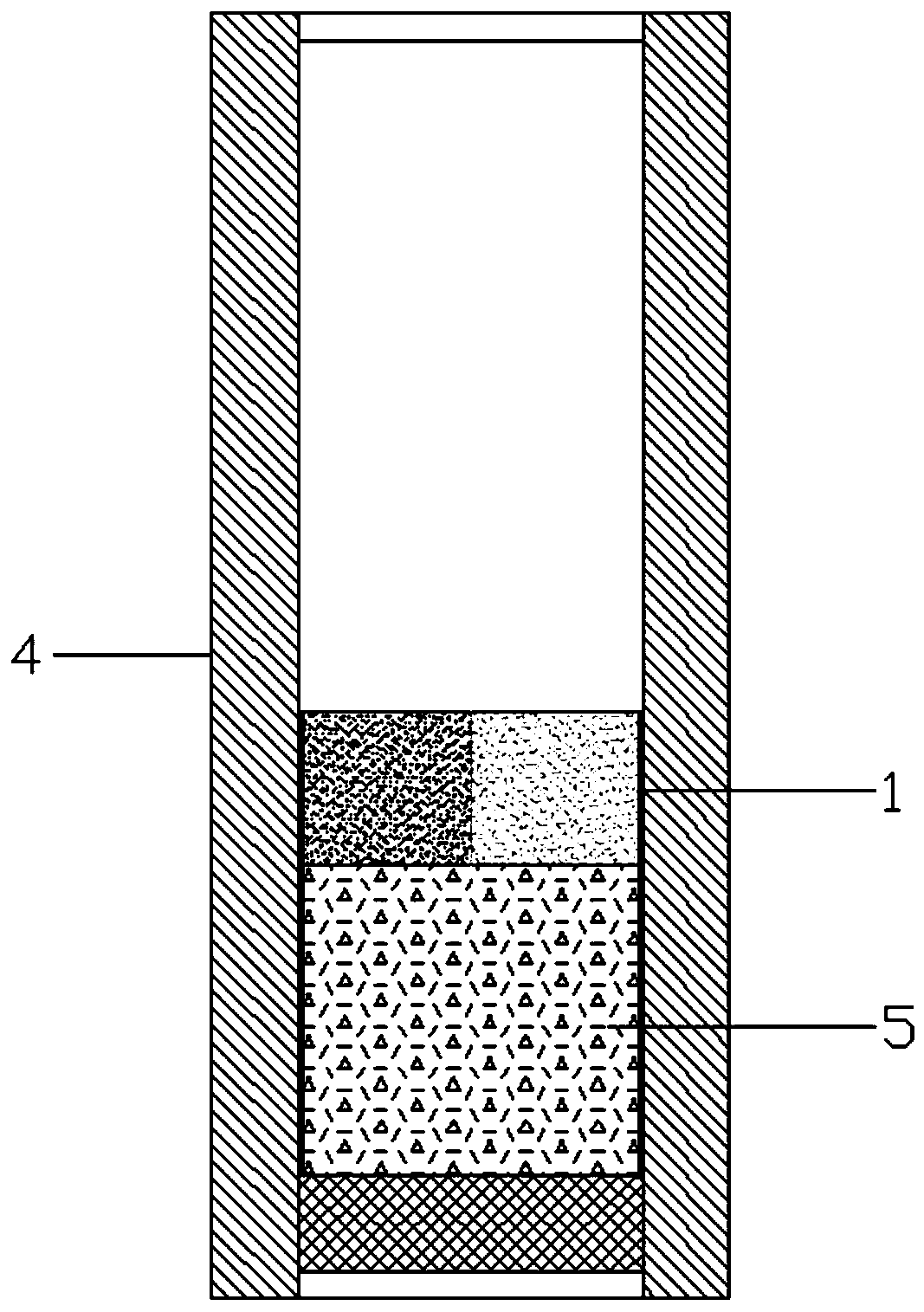

Special gunpowder block for graphic fireworks dot matrix emitter and preparation method thereof

ActiveCN109708533AReduce burning rateEasy to makeExplosive working-up apparatusFireworksGunpowderAdhesive

The invention discloses a special gunpowder block for a graphic fireworks dot matrix emitter and a preparation method thereof. The special gunpowder block for the graphic fireworks dot matrix emittercomprises a gunpowder block, wherein the gunpowder block is arranged as a columnar gunpowder block, which is prepared by bonding a fireworks emitting block and a fireworks display block through a combustion-supporting paste sheet; the combustion-supporting paste sheet comprises a paste sheet and an adhesive arranged on the paste sheet; the fireworks emitting block is a fireworks emitting block prepared by mixing fireworks propellants launched from conventional fireworks in the industry, an ignition performance enhancer and an organic adhesive. The gunpowder block provided by the invention is integrally formed by the fireworks emitting block and the fireworks display block through the combustion-supporting paste sheet, so that the fireworks emitting block and the fireworks display block arenot only clear, but also firmly connected and not easy to separate; the added paste sheet is helpful to slow down the ignition of the fireworks display block during emission; and the ignition performance enhancer and a passivating agent added in the gunpowder block can help the ignition of the fireworks emitting block and slow down the combustion speed of the fireworks display block.

Owner:SUZHOU TIANWEIMU FIREWORKS TECH CO LTD

Carrier of feed additive and preparation method thereof

InactiveCN102178048AImprove liquidityHigh adsorption ratioAnimal feeding stuffAccessory food factorsFood additiveTrace element

The invention relates to a feed, in particular to a carrier of a feed additive and a preparation method thereof. The carrier comprises the following components in percentage: 30-60 percent of maize cob meal, 10-20 percent of calcium carbonate, 5-20 percent of kaolin, 2-25 percent of zeolite powder, 10-40 percent of wheat shorts and 1-5 percent of adhesive. The preparation method comprises the following steps of: mixing the maize cob meal, the calcium carbonate, the kaolin, the zeolite powder, the wheat shorts and the adhesive at a temperature of 35 plus or minus 1 DEG C for 5-15 minutes according to the ratio for later use; adding water into a mixed substance, stirring the mixture, and regulating the pH value of the mixture into the range of 6-8; pelletizing the regulated mixture for 5-10minutes, and then drying at a temperature of 60-120 DEG C and sieving to obtain the carrier of the feed additive. The carrier obtained by using the preparation method is prepared by using high-quality rare minerals as main raw materials and refining the components through a special process, contains various mineral substances and trace elements and does not contain heavy metals and toxic and harmful materials.

Owner:BENXI JUKANG BIOLOGICAL DEV

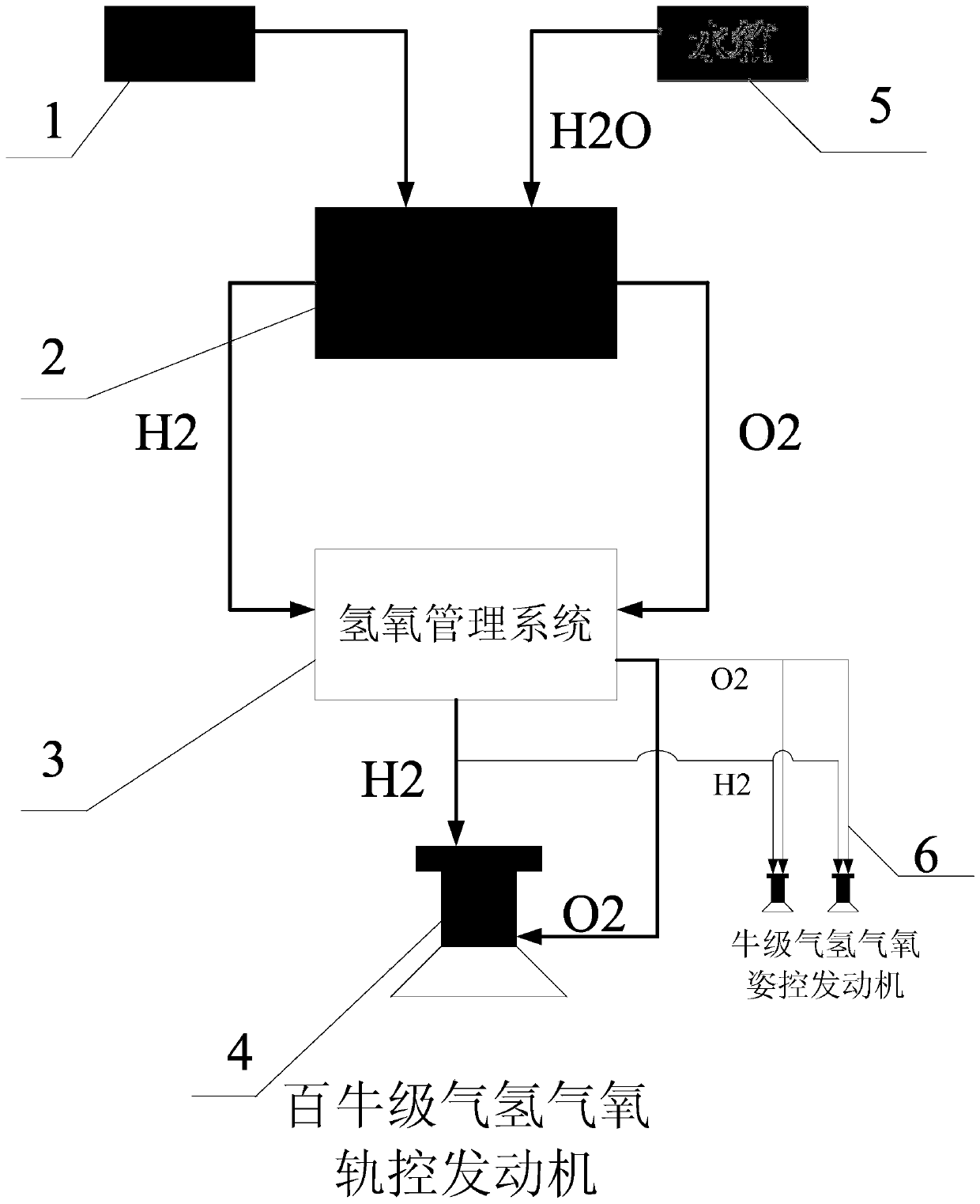

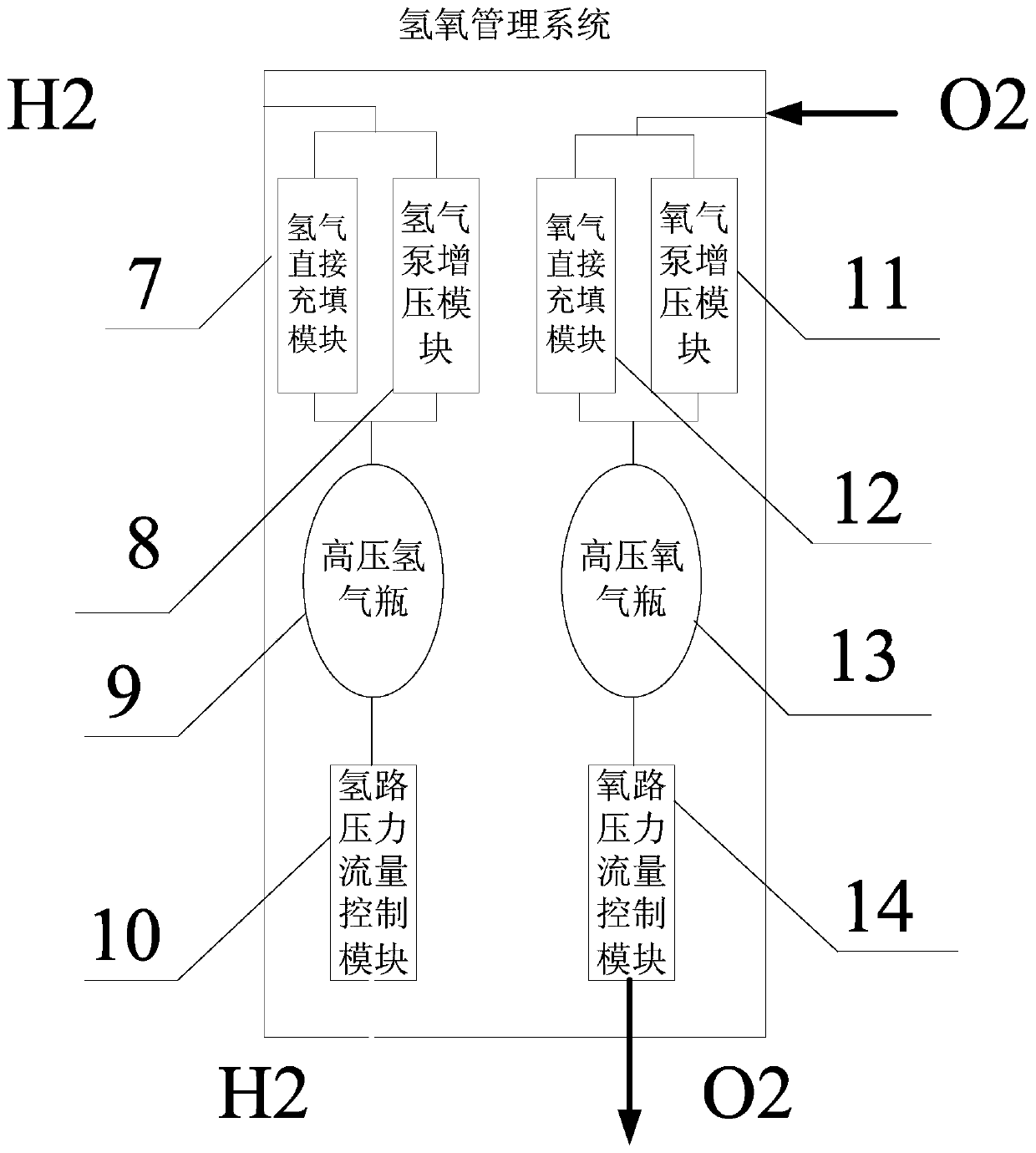

Water-based propulsion system and method applied to high orbit satellite

ActiveCN110127089AExtended life on orbitImprove reliabilityCosmonautic vehiclesCosmonautic propulsion system apparatusWater basedNatural satellite

The invention discloses a water-based propulsion system and method applied to a high orbit satellite. The water-based propulsion system comprises a power source, a water tank, a static water supply proton exchange membrane electrolysis tank, a hydrogen and oxygen management system, a hecto-Newton scale gaseous hydrogen gaseous oxygen track control engine, and a Newton scale gaseous hydrogen gaseous oxygen attitude control engine. According to the water-based propulsion system and method applied to the high orbit satellite, the problems that hydrogen and oxygen gases are difficult to be managedon a long-term basis in the space environment and that the hydrogen and oxygen gases with an equivalent mixing ratio are difficult to be efficiently utilized are solved, and engineering practicability of a hydrogen and oxygen propulsion system in a space flight platform is improved.

Owner:BEIJING INST OF CONTROL ENG

Mixed scented tea processing and packaging machine

ActiveCN106516197AImprove efficiencyEnsure consistencyPackaging automatic controlSolid materialEngineeringMechanical equipment

The invention relates to the technical field of mechanical equipment, in particular to a mixed scented tea processing and packaging machine. The mixed scented tea processing and packaging machine comprises a machine frame and further comprises a feeding component, a mixing component and a discharging component, wherein the feeding component is arranged on the top of the machine frame, the mixing component is arranged below the feeding component, and the discharging component is arranged at the bottom o the mixing component. Raw materials of mixed scented tea enter the mixing component from the feeding component to be mixed, and the mixed scented tea is discharged out of the discharging component and packaged. According to the mixed scented tea processing and packaging machine, the structure is simple, operation is convenient, subpackaging and mixing can be automatically carried out, the packaging efficiency can be improved, the mixing proportion is uniform after packaging, the quality uniformity is ensured, and automation is achieved.

Owner:山东振承农业发展股份有限公司

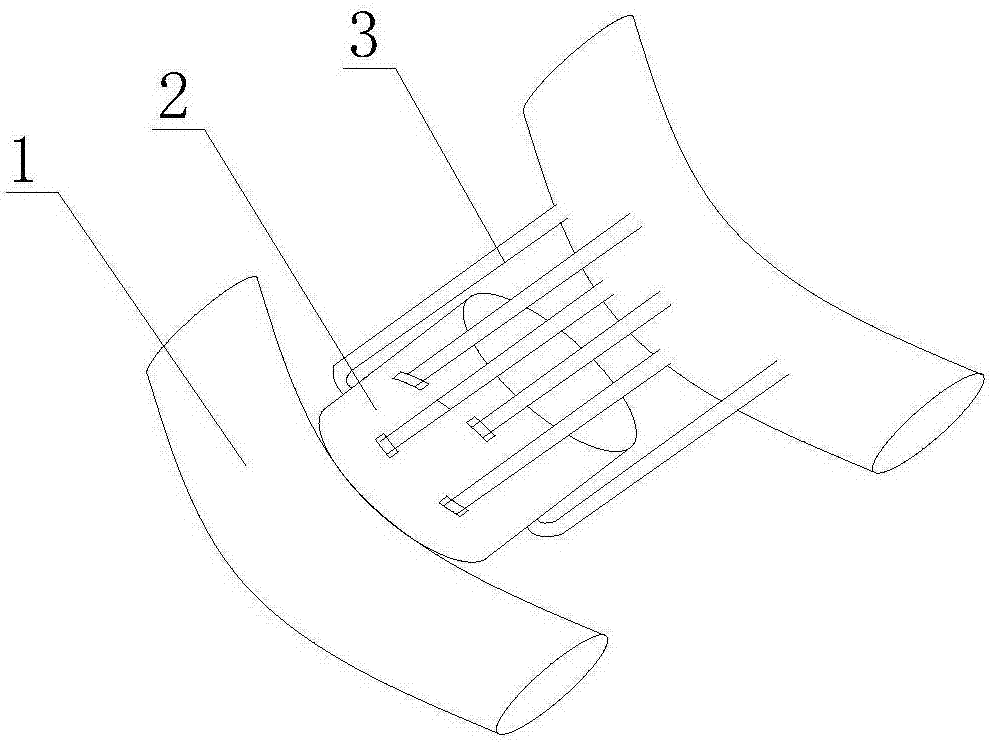

A photoacoustic ultrasound dual-mode simultaneous imaging system

ActiveCN105395170BComprehensive evaluationConsistent proportionOrgan movement/changes detectionDiagnostic recording/measuringDiagnostic Radiology ModalitySonification

The invention relates to an opto-acoustic and ultrasonic bimodal synchronous imaging system, which is applied to diagnostic imaging of tested tissues in the medical field. The imaging system comprises a host machine, a pulse laser, as well as a multi-channel ultrasonic probe, a data acquisition module, a data processing and image reconstruction module and a display module which are sequentially connected, wherein the host machine is connected to the multi-channel ultrasonic probe and the pulse laser; the multi-channel ultrasonic probe clings to the tested tissues; and the pulse laser is opposite to the tested tissues. Compared with the prior art, the imaging system disclosed by the invention has the advantages of being synchronous, precise, consistent in proportion and the like.

Owner:TONGJI UNIV +1

Special gunpowder block for graph-text firework lattice launcher and preparation method thereof

InactiveCN109928857ASimple processEasy to manufactureExplosive working-up apparatusFirecrackerFireworks

The invention discloses a special gunpowder block for a graph-text firework lattice launcher and a preparation method thereof. The special gunpowder block comprises a gunpowder block, the gunpowder block is a columnar gunpowder block, the columnar gunpowder block is prepared by bonding a firework launching block and a firework display block through a bonding agent; the bonding agent is formed by mixing and stirring an organic binding agent and an ignition performance enhancer; and the firework launching block is columnar particles prepared from conventional firework and firecracker blast-off gunpowder in the industry. The gunpowder block has the advantages that the production efficiency is high, the cost is low, the manufacturing process is simple and convenient, the standardized design isfacilitated, and the cost of graph-text fireworks is reduced, so that the graph-text fireworks can meet the public use; due to the adoption of uniform gunpowder blocks, the setting-off effects of thegraph-text firework lattice structures are consistent.

Owner:SUZHOU TIANWEIMU FIREWORKS TECH CO LTD

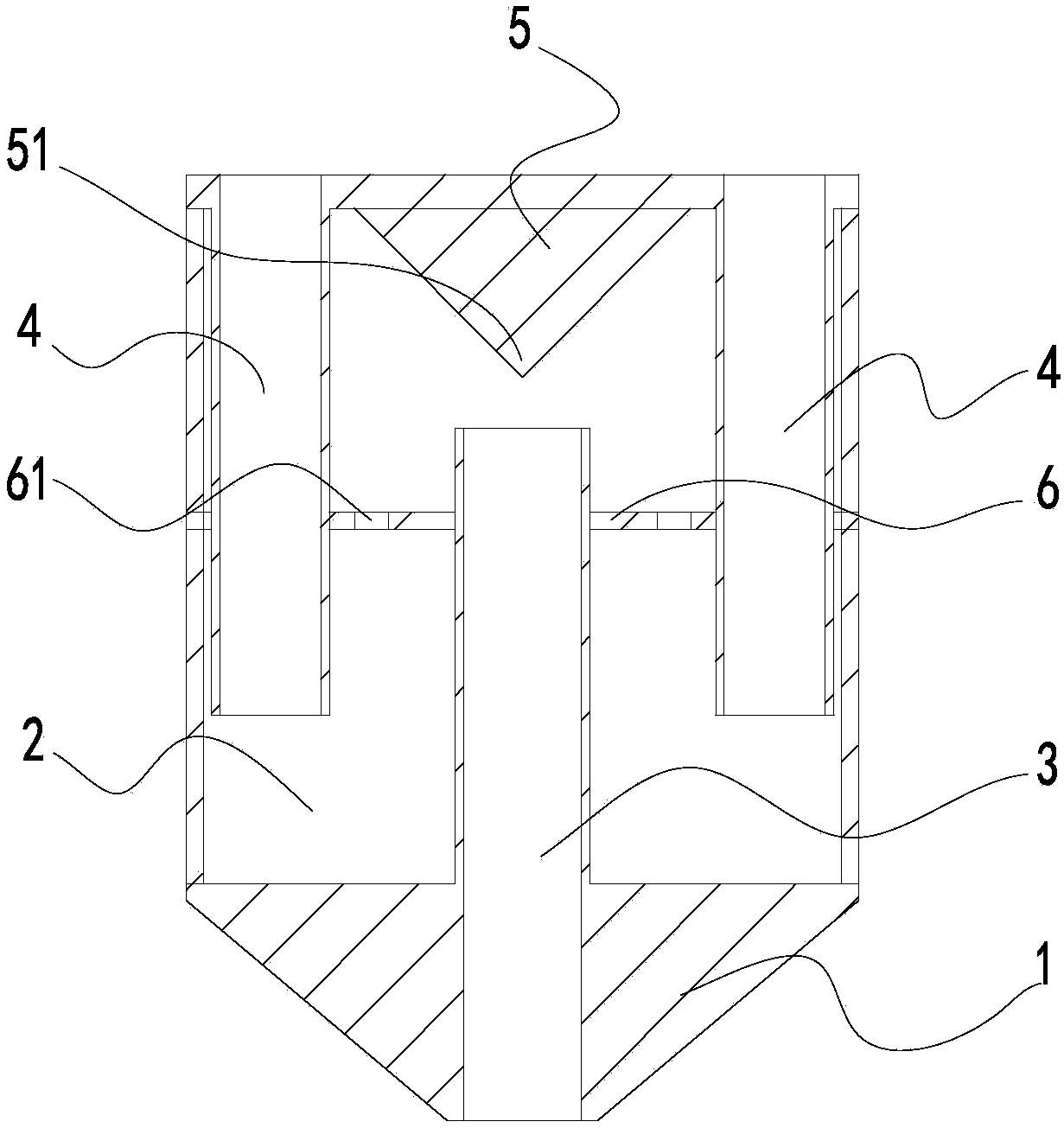

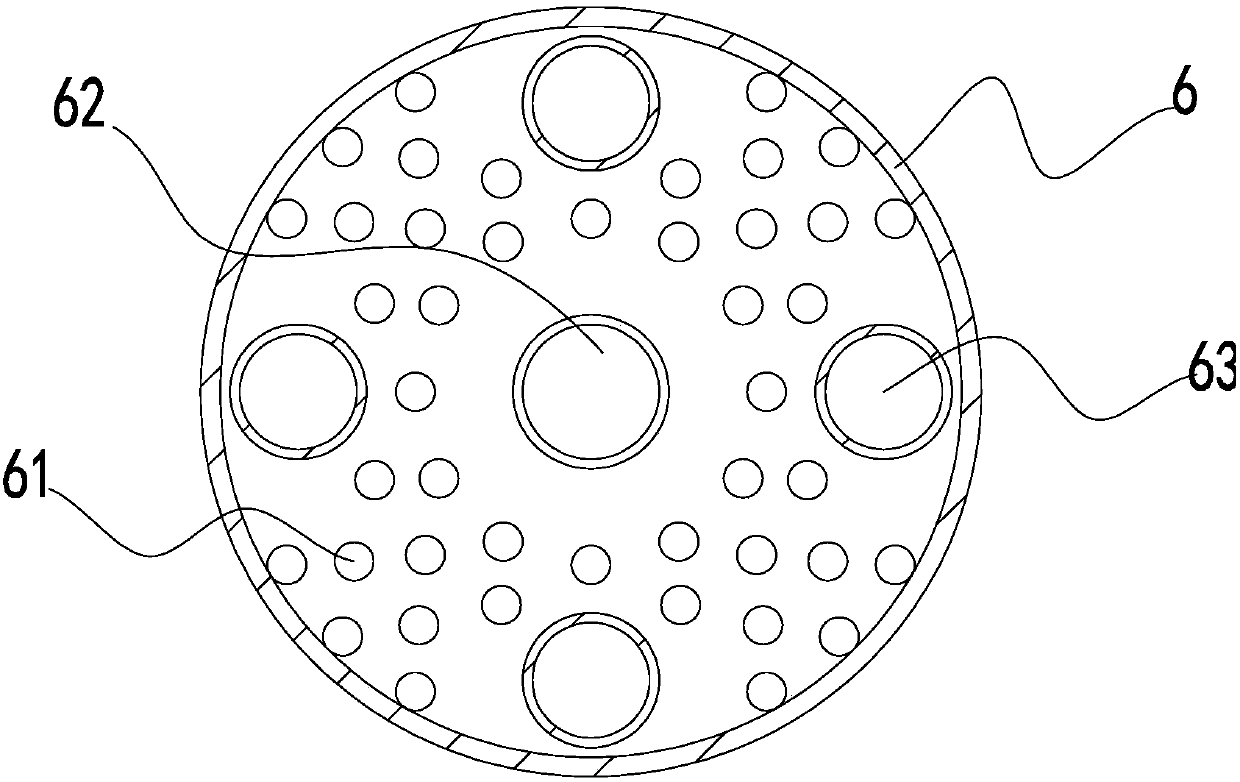

Distributor, heat exchanger device and air conditioner

InactiveCN108050688AImprove heat transfer effectConsistent proportionMechanical apparatusSpace heating and ventilation detailsGas phaseHigh energy

The invention provides a liquid distributor, a heat exchanger device and an air conditioner. According to the distributor, a uniform flow part is arranged in a liquid storage cavity and is provided with a sharp part, and the sharp part is arranged towards a main inlet pipe. The top point of the sharp part and the center line of the main inlet pipe are aligned. Refrigerant fluid flowing out of themain inlet pipe impacts on the sharp part and then is evenly scattered in the liquid storage cavity in various directions, accordingly, the refrigerant fluid stored at the bottom of the liquid storagecavity is in a uniform mixing state and is conveyed into a heat exchanger through a branch flow dividing pipe, accordingly, it is guaranteed that the proportion of a gas-phase refrigerant and a liquid-phase refrigerant in various refrigerant branches in the heat exchanger is consistent, and the heat exchange capability of the heat exchanger is better improved. The distributor is arranged on the heat exchanger device, and high heat exchange capability is achieved. The air conditioner is provided with the heat exchanger device, and a high energy efficiency coefficient is achieved.

Owner:HISENSE (SHANDONG) AIR CONDITIONING CO LTD

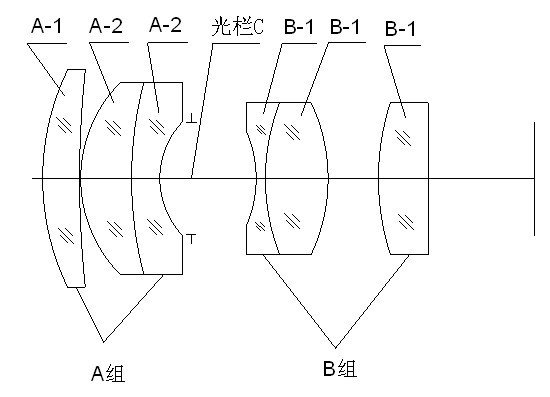

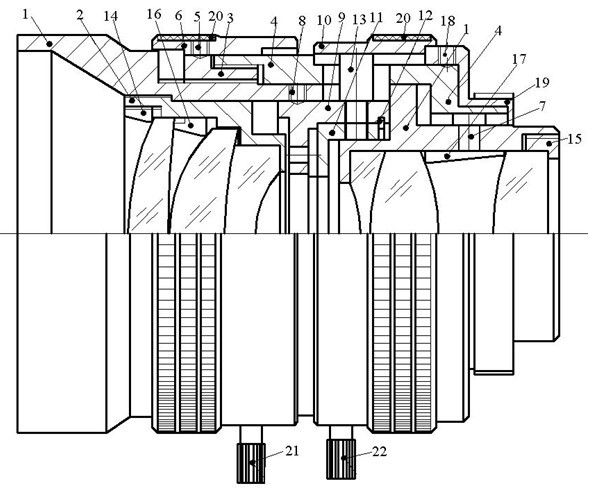

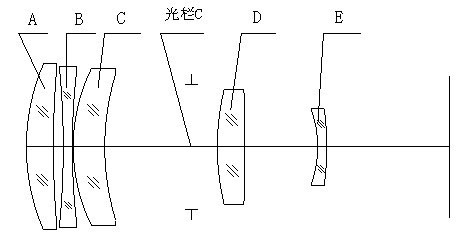

High resolution lens used in automatic detecting device

ActiveCN102193174AGuaranteed concentricity requirementsOptimize assembly processMountingsCamera lensOptoelectronics

The invention relates to a high resolution lens used in an automatic detecting device, comprising a main lens cone. The high resolution lens used in the automatic detecting device is characterized in that the main lens cone is respectively provided with a front lens group A with positive focal power, a variable diaphragm C and a rear lens group B with positive focal power along the incidence direction of light from left to right; the front lens group A is formed by an agglutination group consisting of a positive crescent type lens A-1, a positive crescent type lens A-2 and a negative crescenttype lens A-3 which are closely connected; the rear lens group B is formed by an agglutination group consisting of a negative crescent type lens B-1, a positive crescent type lens B-2 and a flat concave lens B-3. The high resolution lens used in the automatic detecting device has the characteristics of high resolution and small distortion; the lens has functions of focusing and aperture adjustment and is firm and uniform in structure; and each moving component is reliable in movement, good in hand-feeling and beautiful in appearance.

Owner:FUJIAN FORECAM OPTICS CO LTD

Standard powder block special for firework lattice structure body and preparation method of standard powder block

The invention discloses a standard powder block special for a firework lattice structure body and a preparation method of the standard powder block. The standard powder block comprises a standard powder block body. The standard powder block body is arranged to be a column-shaped standard powder block body. The column-shaped standard powder block body is formed by connecting a firework launching block with a firework display block through a connecting piece. The firework display block is produced by mixing industry conventional firework launch burning display powder with an organic binding agent, an ignition performance enhancer and a passivator. The standard powder block body is integrally formed by connecting the firework launching block with the firework display block through the connecting piece, the firework launching block and the firework display block can be distinct, and in addition, the firework launching block and the firework display block can be connected firmly and not likely to be separated; and the ignition performance enhancer and the passivator added to the powder block body can assist in ignition of the firework launching block and decreasing the burning speed ofthe firework display block.

Owner:SUZHOU TIANWEIMU FIREWORKS TECH CO LTD

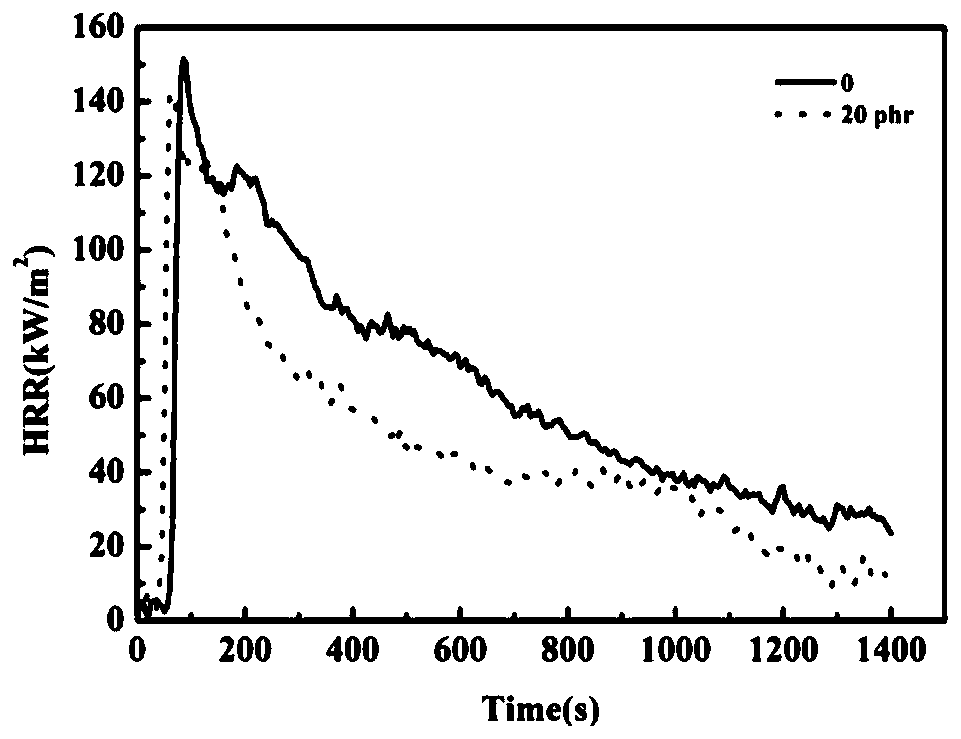

Flame-retardant and ablation-resistant filler, and preparation method and application thereof

The invention relates to a flame-retardant and ablation-resistant filler, and a preparation method and an application thereof. Raw materials of the filler comprise a phenolic compound, an aldehyde compound and an amine compound, and a molar ratio of the phenolic compound to the aldehyde compound to amino groups on the amine compound is X:Y:Z, wherein Y is (1~3)*X + (0.5~2)*Z, the average particlesize of the filler is 120-5000 nm, and the nitrogen content is 5-35 wt%. The preparation method of the filler comprises the following steps: (1) mixing the phenolic compound and the aldehyde compoundin a solvent to obtain a solution A; (2) mixing the amine compound and the aldehyde compound in the solvent to obtain a solution B; (3) mixing the solution A with the solution B to obtain a solution C; and (4) heating, washing and drying the solution C, and grinding the dried solution C. Compared with fillers in the prior art, the filler of the invention has the advantages of simple preparation method, favorable sphericity, uniform granularity, excellent flame retardancy and the like, and can be used as a filler for flame-retardant ablative heatproof composite materials and coatings.

Owner:EAST CHINA UNIV OF SCI & TECH

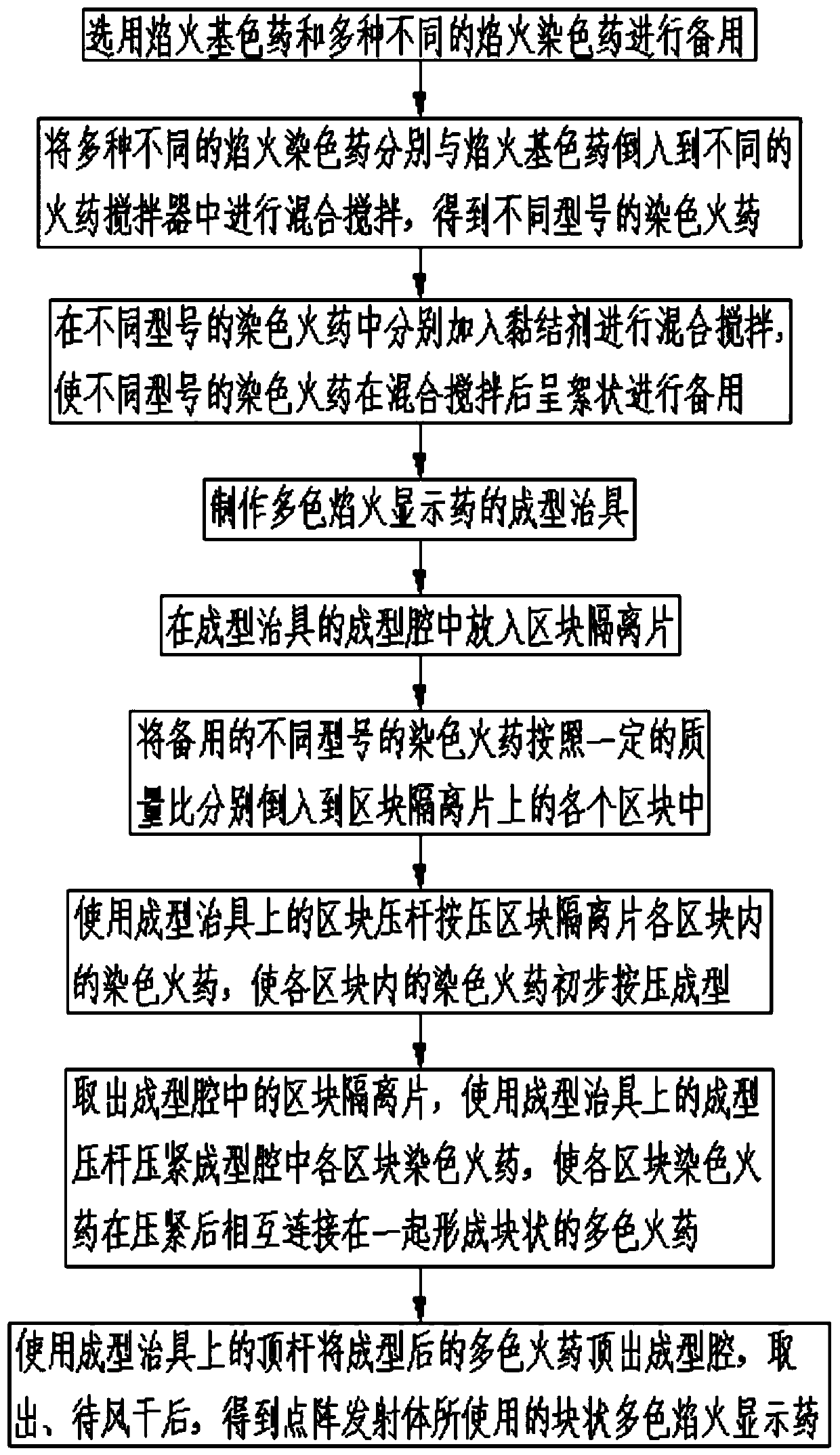

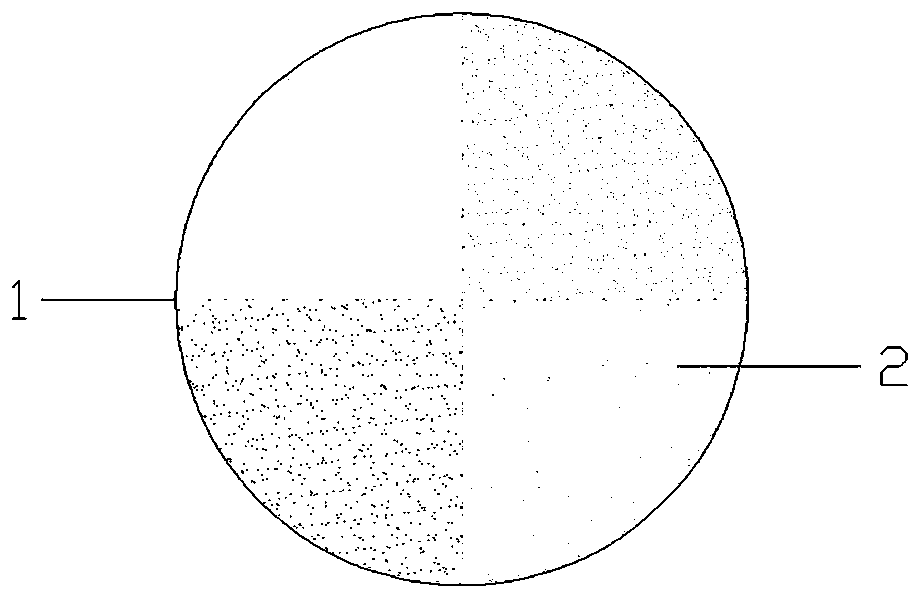

Multi-color firework display powder of image-text firework lattice launcher and preparation method of multi-color firework display powder

The invention discloses multi-color firework display powder of an image-text firework lattice launcher and a preparation method of the multi-color firework display powder. The powder and the method comprises the multi-color firework display powder which is used for being arranged on inner firework propellant powder of the lattice launcher, and the multi-color firework display powder is provided with multiple of areas for setting of flames with different colors, wherein each of the areas is made of firework primary color powder and firework dye powder, and the firework dye powder used in each area can generate the flames with different colors during combustion. According to the powder and the method, the multiple different dye powder are pressed through a forming jig to form the multi-colorfirework display powder, so that the process is simple, manufacturing is convenient, and the batch production can be carried out through the jig; and the size and mass ratio of the produced multi-color firework display powder are basically consistent, so that the time when the multi-color firework display powder is launched to a high altitude for being set off is consistent when the multi-color firework display powder is used in an image-text firework lattice structural body.

Owner:征茂德

High-purity, high-strength and high-conductivity copper-based target and preparation method thereof

ActiveCN111910101AInhibition of segregationConsistent proportionVacuum evaporation coatingSputtering coatingStrontiumZone melting

The invention discloses a high-purity, high-strength and high-conductivity copper-based target and a preparation method thereof. The high-purity, high-strength and high-conductivity copper-based target comprises the following raw materials of, in parts by weight, 0.1-1.0 part of high-purity silver powder, 1-10 parts of high-purity copper-silver-strontium alloy powder, the balance 99-99.9 parts ofcopper powder, and the sum of the weight parts of the silver powder and the copper powder is 100 parts in total, wherein the content of silver in the copper-silver-strontium alloy powder is 0.1% - 1.0%, the content of strontium in the copper-silver-strontium alloy powder is 5ppm - 20 ppm, and the balance copper. According to the high-purity, high-strength and high-conductivity copper-based targetand the preparation method thereof, the copper powder and the silver powder are subjected to cold isostatic pressing blank forming through a powder metallurgy method, it can be guaranteed that the proportion of the copper and the silver is kept consistent, and segregation of the silver in the melting process can be avoided; and according to the preparation method, multi-pass zone melting is carried out before a high-purity billet is prepared to obtain an alloy master billet so that the high purity of a subsequent target finished product can be ensured.

Owner:CENT SOUTH UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com