Flame-retardant and ablation-resistant filler, and preparation method and application thereof

An ablation-resistant and reaction-resistant technology, applied in the field of flame-retardant materials, can solve problems such as limited application range, difficulty in expanding production, and inability to control and adjust product shape, and achieve the effects of simple production process, slow burning, and good sphericity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Add 12.81g of resorcinol and 18.96g of formaldehyde solution (concentration: 37ωt%) into 50mL of deionized water, and stir at a constant speed of 200rpm at room temperature until the solution is clear to obtain solution A.

[0036] Add 14.70g of melamine and 28.38g of formaldehyde solution (concentration: 37ωt%) into 100mL of deionized water, and stir at a constant speed of 200rpm at 85°C until the solution is clear to obtain solution B.

[0037] After solution B dropped to normal temperature, pour solution A into solution B, continue stirring for 5 min, and dilute the solution to 300 mL with deionized water to obtain solution C.

[0038] Heat solution C to 85°C, keep it for 2 hours, then cool to room temperature, pour out the supernatant, wash with deionized water for 3 times, filter and dry in an electric blast drying oven at 85°C for 24 hours to obtain a flame retardant Ablative filler.

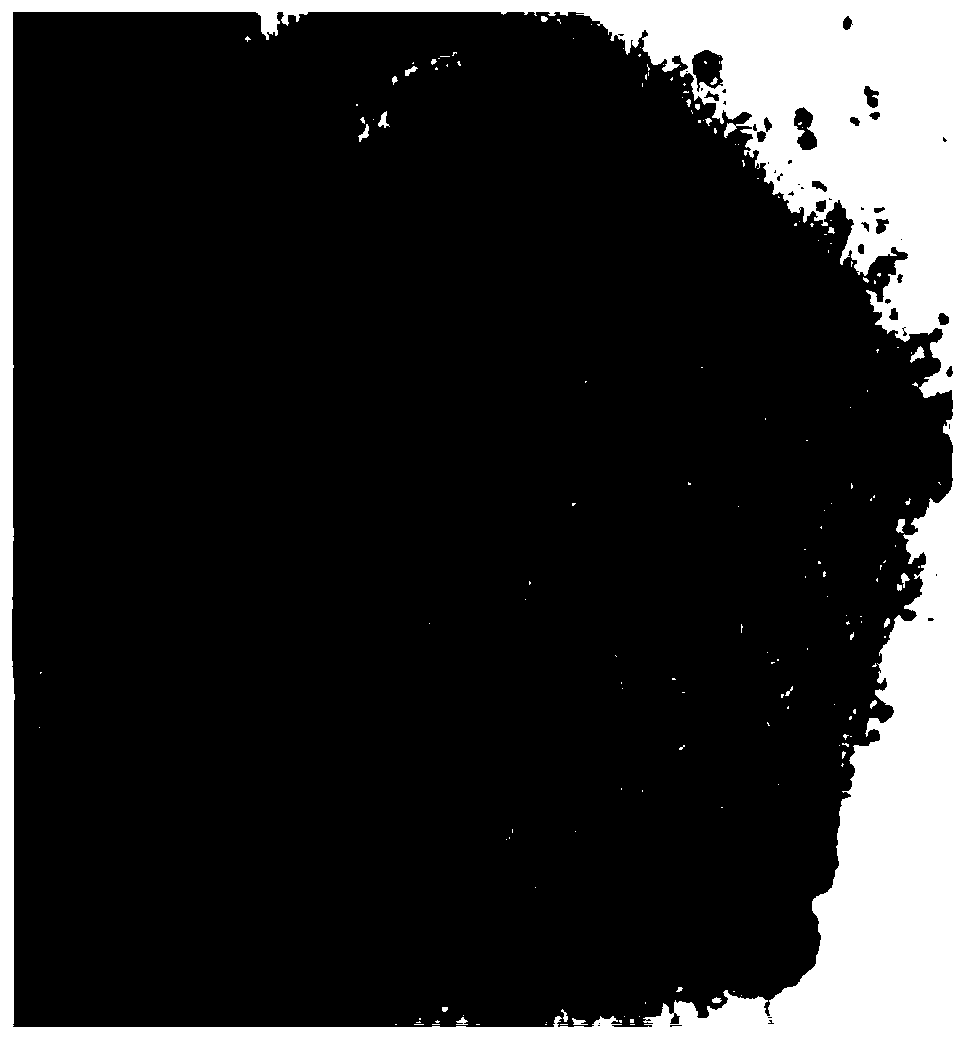

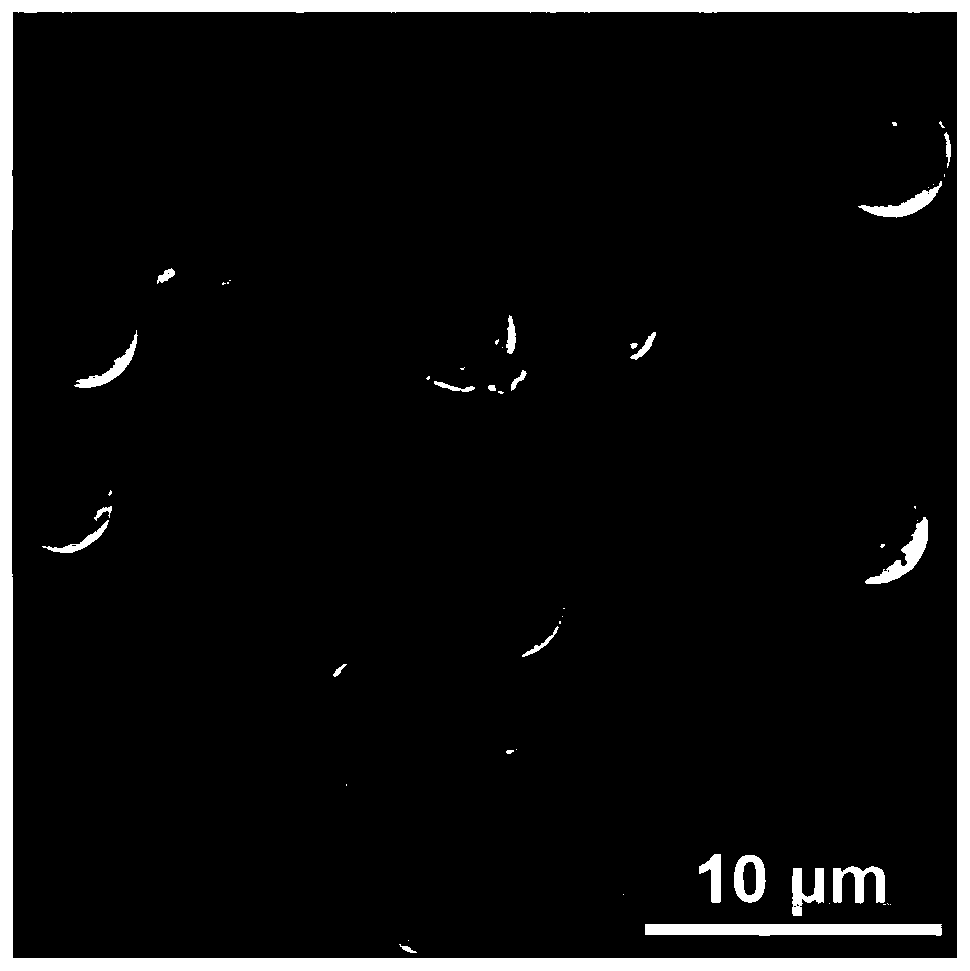

[0039] Such as Figure 1-2 As shown, the flame-retardant and ablation-resista...

Embodiment 2

[0043] Add 17.82g of resorcinol and 26.28g of formaldehyde solution (concentration: 37ωt%) into 50mL of deionized water, and stir at a constant speed of 200rpm at room temperature until the solution is clear to obtain solution A.

[0044] Add 10.20 g of melamine and 19.62 g of formaldehyde solution (concentration: 37ωt%) into 100 mL of deionized water, and stir at a constant speed of 200 rpm at 85° C. until the solution becomes clear to obtain solution B.

[0045] After solution B dropped to normal temperature, pour solution A into solution B, continue stirring for 5 min, and dilute the solution to 300 mL with deionized water to obtain solution C.

[0046] Heat solution C to 85°C, keep it for 2 hours, then cool to room temperature, pour out the supernatant, wash with deionized water for 3 times, filter and dry in an electric blast drying oven at 85°C for 24 hours to obtain a flame retardant Ablative filler.

[0047] The flame-retardant and ablation-resistant filler obtained i...

Embodiment 3

[0049] Add 8.22g of resorcinol and 12.18g of formaldehyde solution (concentration: 37ωt%) into 50mL of deionized water, and stir at a constant speed of 200rpm at room temperature until the solution is clear to obtain solution A.

[0050] Add 18.84g of melamine and 36.30g of formaldehyde solution (concentration: 37ωt%) into 100mL of deionized water, and stir at a constant speed of 200rpm at 85°C until the solution is clear to obtain solution B.

[0051] After solution B dropped to normal temperature, pour solution A into solution B, continue stirring for 5 min, and dilute the solution to 300 mL with deionized water to obtain solution C.

[0052] Heat solution C to 85°C, keep it for 2 hours, then cool to room temperature, pour out the supernatant, wash with deionized water for 3 times, filter and dry in an electric blast drying oven at 85°C for 24 hours to obtain a flame retardant Ablative filler.

[0053] The flame-retardant and ablation-resistant filler obtained in this examp...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

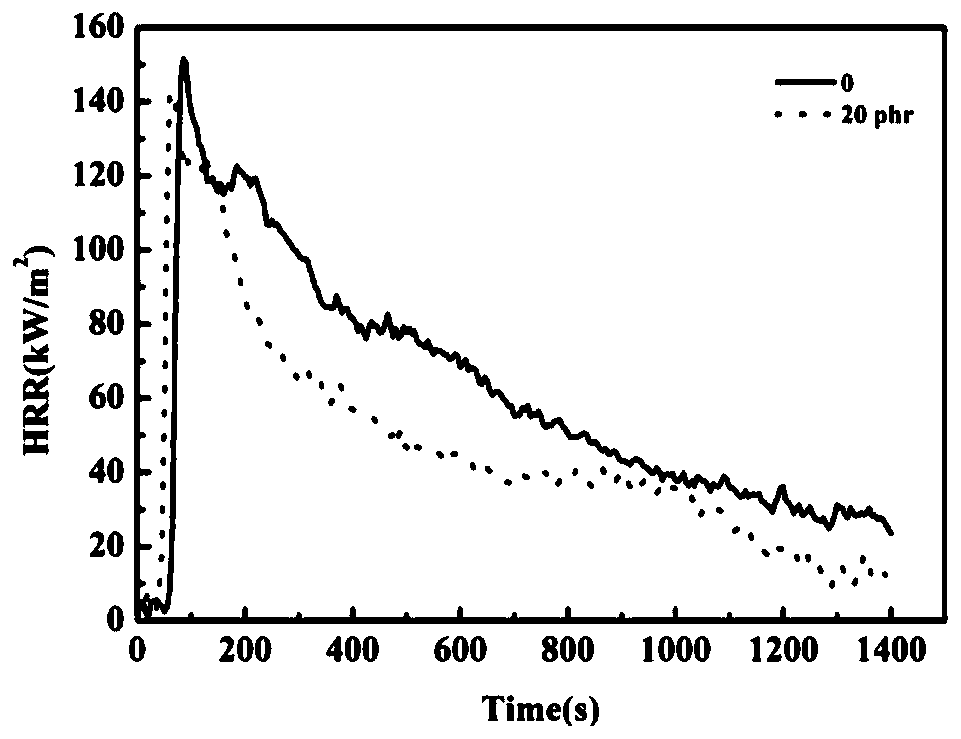

| heat release rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com