Microgranular alginate water-soluble fertilizer prepared by means of melting complexation reaction, and preparation method of microgranular alginate water-soluble fertilizer

A complex reaction, water-soluble fertilizer technology, applied in the directions of nitrate fertilizer, urea compound fertilizer, ammonium orthophosphate fertilizer, etc., can solve the problems of unfavorable agricultural sustainable development, short fertilizer period, short effective action time, etc., to enhance crops. Vegetative growth and reproductive growth ability, increased water and nutrient capacity, beneficial effect of crop root absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

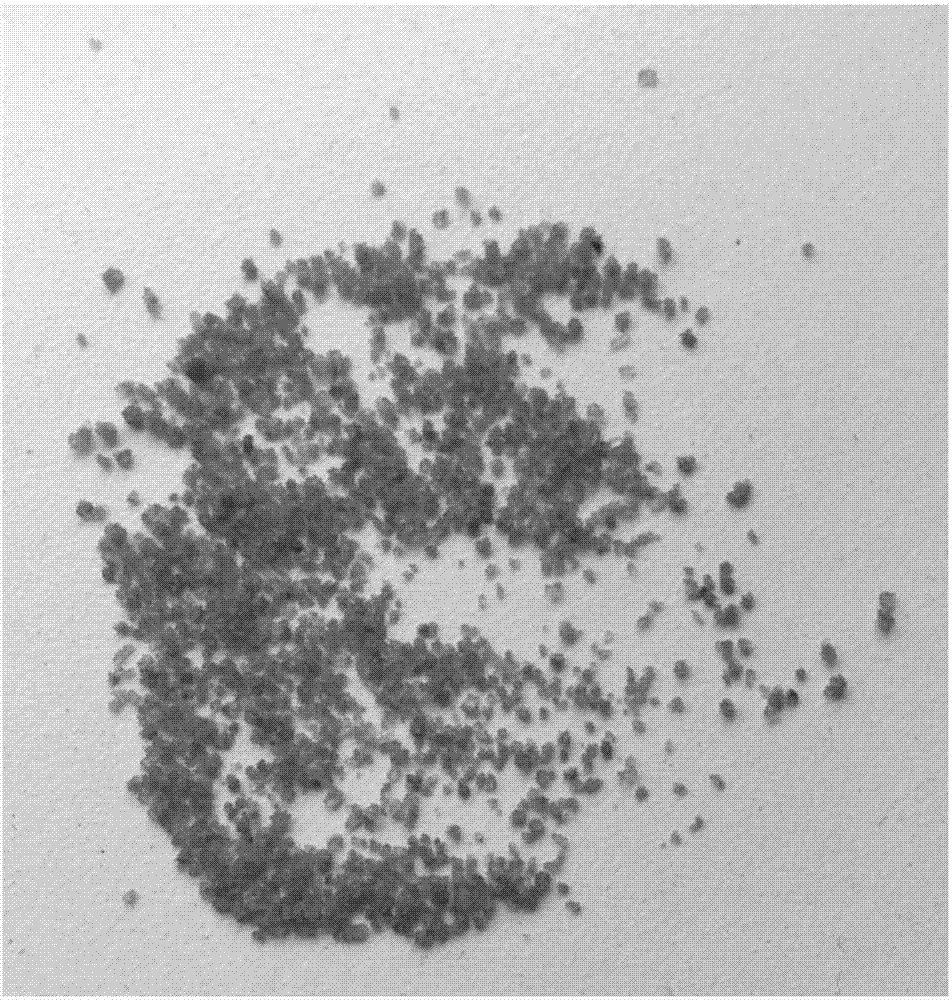

[0031] A kind of microparticle alginic acid water-soluble fertilizer prepared by melt complexation reaction, each component of the raw material is composed as follows according to the weight part:

[0032] 60 parts of nitrogen fertilizer, 40 parts of phosphate fertilizer, 70 parts of potassium fertilizer, 5 parts of alginic acid synergist solution, 10 parts of medium and trace element fertilizer, 3 parts of a mixture of calcium nitrate and calcium carbonate in a mass ratio of 2:3, and 0.5 part of vegetable oil.

[0033] Each component of raw material in the nitrogen fertilizer is composed as follows according to parts by weight: 75 parts of urea, 25 parts of ammonium sulfate; 40 parts of potassium hydrogen; each component of the raw material in the potash fertilizer is composed as follows according to parts by weight: the potash fertilizer is 75 parts of potassium nitrate, 10 parts of potassium hydroxide, and 10 parts of potassium acetate.

[0034] The fermented material obtai...

Embodiment 2

[0037] On the basis of Example 1, different from Example 1, the preparation method of the microparticle alginic acid water-soluble fertilizer prepared by melt complexation reaction specifically includes the following steps:

[0038] (1) High-temperature melting: Take nitrogen fertilizer, phosphate fertilizer, and potassium fertilizer according to the ratio of raw materials, mix and stir them, put them into the melter, control the high-temperature melting temperature to 130°C, and add calcium nitrate and calcium carbonate to the melter after melting for 40 minutes. The mixture composed of a mass ratio of 2:3 continued to melt for 10 minutes;

[0039](2) Complexation reaction: put the melted slurry into the complexation reactor, and at the same time put alginic acid synergist liquid and medium and trace element fertilizer into the complexation reactor, and control the complexation reaction temperature to 120 °C. Combined 50min;

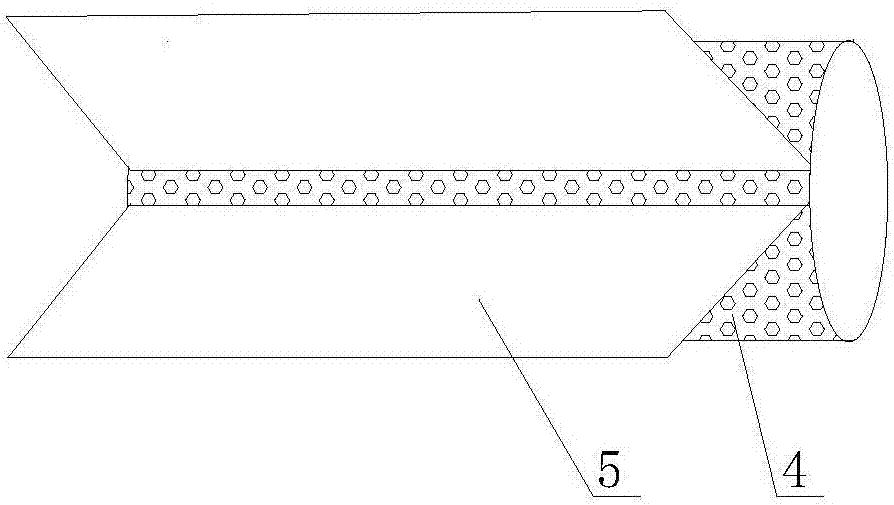

[0040] (3) Granulation: Adjust the pressure of t...

Embodiment 3

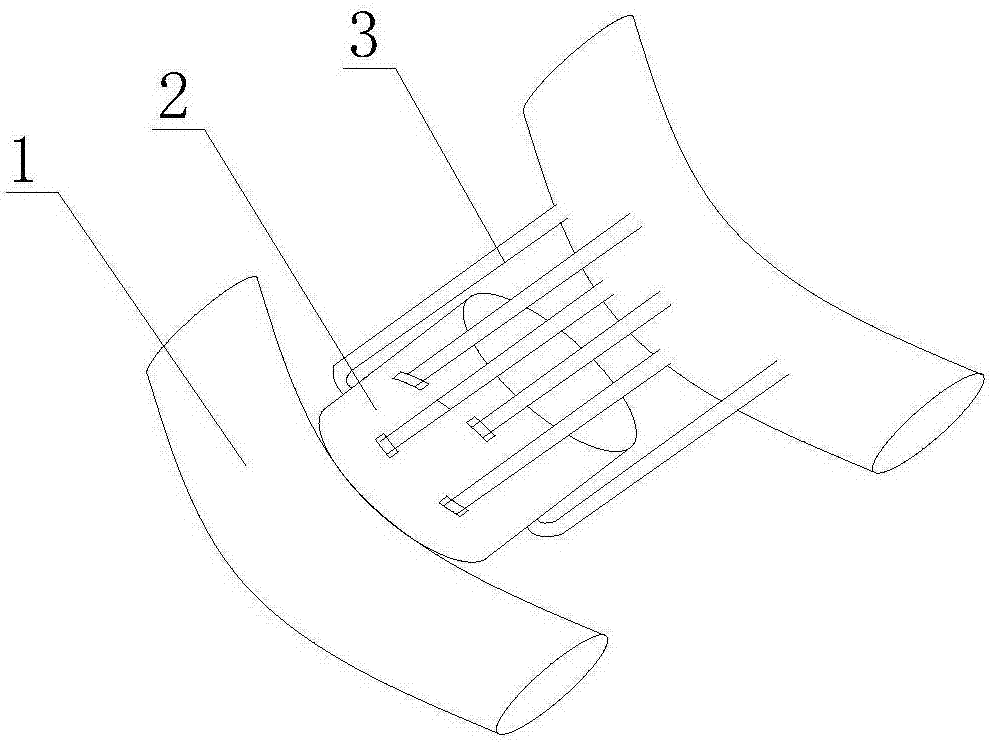

[0044] Such as figure 1 As shown, a kind of microparticle alginic acid water-soluble fertilizer prepared by melt complexation reaction, each component of the raw material is composed as follows according to parts by weight:

[0045] 80 parts of nitrogen fertilizer, 50 parts of phosphate fertilizer, 80 parts of potassium fertilizer, 10 parts of alginic acid synergist solution, 15 parts of medium and trace element fertilizer, 5 parts of a mixture of calcium nitrate and calcium carbonate in a mass ratio of 2:3, and 1 part of vegetable oil.

[0046] Each component of raw material in the nitrogen fertilizer is composed as follows according to parts by weight: 80 parts of urea, 30 parts of ammonium sulfate; 60 parts of potassium hydrogen; each component of the raw material in the potassium fertilizer is composed as follows according to parts by weight: the potassium fertilizer is 80 parts of potassium nitrate, 20 parts of potassium hydroxide, and 15 parts of potassium acetate.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com