A kind of organic-inorganic compound fertilizer and preparation method thereof

A compound fertilizer and inorganic technology, applied in fertilization devices, fertilizer mixtures, agriculture, etc., can solve the problems of complex production process, neglect of active ingredient content, and restriction of the use of humic acid. The effect of restoration and prevention of soil degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

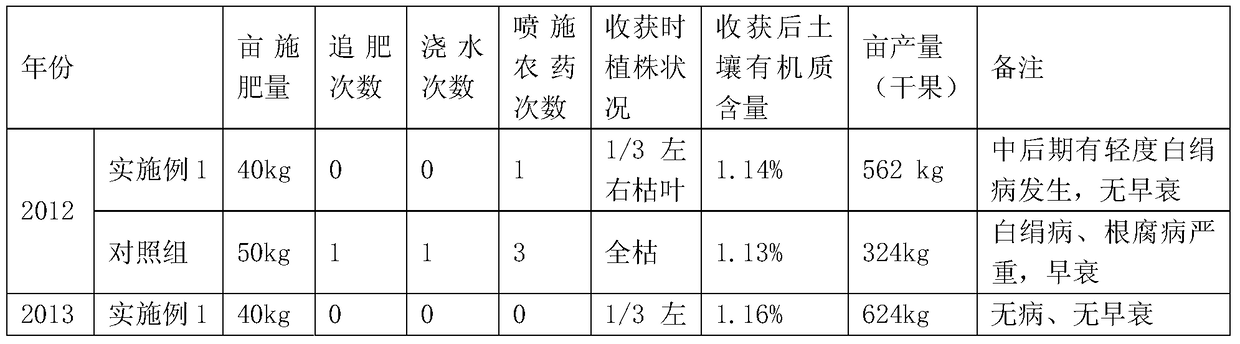

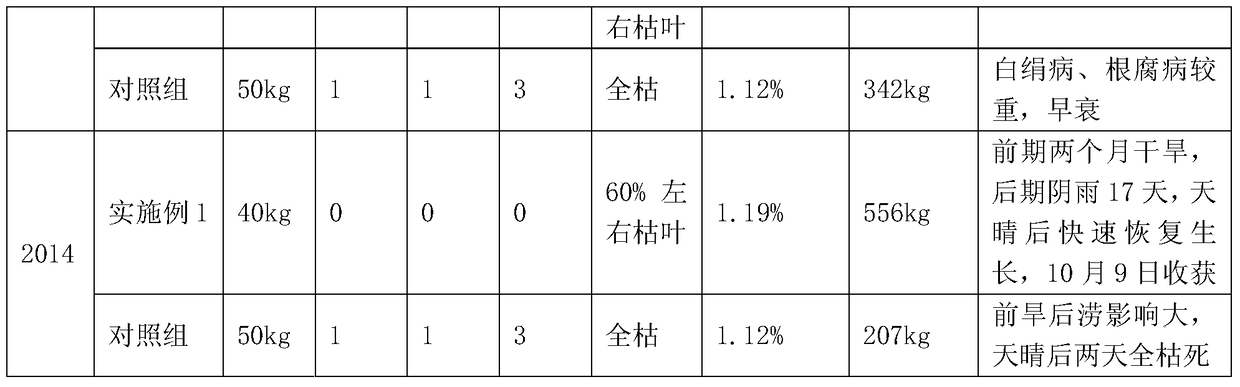

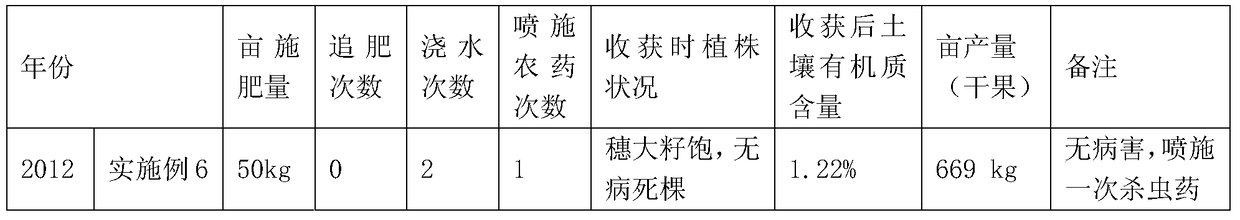

Examples

Embodiment 1

[0040] An organic-inorganic compound fertilizer, its raw material weight percent composition is as follows: 18% of mineral source humic acid, 10% of biochemical humic acid, 10% of Jinyisheng, 6% of organic material, 20% of monoammonium phosphate fertilizer, and 14.5% of potassium chloride fertilizer , urea 21.5%.

[0041] The preparation method of above-mentioned organic-inorganic compound fertilizer, comprises the following steps:

[0042] (1) Weigh the raw materials according to the above formula, mix them evenly in the mixer, then transport them to the pulverizer for pulverization, after pulverization, transport them to the rotary drum steam granulator for humidification until the water content of the material is 13%, and heat To 52 ℃ to make it partially dissolved, complexation reaction, forming fine loose;

[0043] (2) Transport the fine and loose powder into the dryer for melting, complexation reaction, gluing and granulation, and drying. The temperature is 270°C and t...

Embodiment 2

[0047] An organic-inorganic compound fertilizer, its raw material weight percent composition is as follows: 17% of mineral source humic acid, 10% of biochemical humic acid, 10% of Jinyisheng, 5% of organic material, 20% of monoammonium phosphate fertilizer, 6% of potassium chloride fertilizer , Potassium sulfate fertilizer 10.5%, urea 21.5%.

[0048] The preparation method of the above-mentioned organic-inorganic compound fertilizer, the humidification described in the step (1) is humidification until the material humidity is 15%, the heating is heating to a temperature of 53°C, and the complexation reaction granulation time is 8 minutes, In step (2), the inlet temperature of the dryer is 265°C, and the outlet temperature is 65 ℃, complexation reaction granulation time 13 minutes, drying time 20 minutes, the rest are the same as in Example 1.

[0049] The organic-inorganic compound fertilizer that present embodiment obtains, the total nutrient content of nitrogen, phosphorus ...

Embodiment 3

[0051] An organic-inorganic compound fertilizer, its raw material weight percent composition is as follows: mineral source humic acid 13%, biochemical humic acid 7%, gold benefit 3.5%, organic material 3%, monoammonium phosphate fertilizer 10%, potassium chloride fertilizer 6% , potassium sulfate fertilizer 27.5%, urea 30%.

[0052] In the preparation method of the above-mentioned organic-inorganic compound fertilizer, the humidification described in the step (1) is humidification until the material humidity is 18%, and the heating is heating to a temperature of 55° C., and the complexation reaction time is 7 minutes; step (2) The inlet temperature of the medium dryer is 270° C., the outlet temperature is 75° C., the complexation reaction granulation time is 14 minutes, and the drying time is 22 minutes. The rest are the same as in Example 1.

[0053] The organic-inorganic compound fertilizer that present embodiment obtains, the total nutrient content of nitrogen, phosphorus a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com