Preparation method and application of novel modified rubber seed shell biochar material

A technology for modifying rubber and rubber seed shells, which is applied in chemical instruments and methods, carbon compounds, ion exchange water/sewage treatment, etc., can solve the problems of high cost, high price, secondary pollution, etc., and achieve improved porosity, removal The effect of high efficiency and promotion of complexation reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

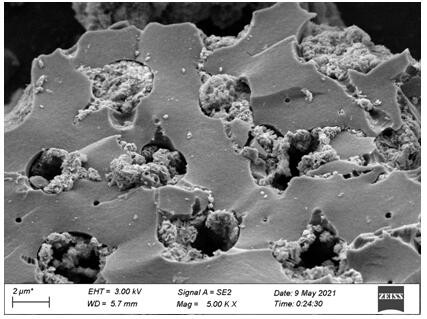

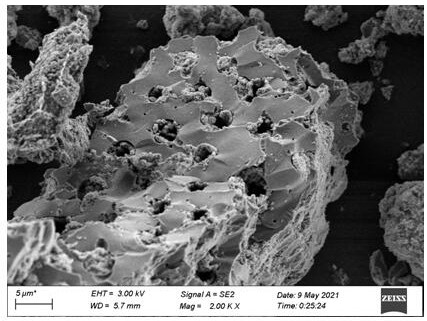

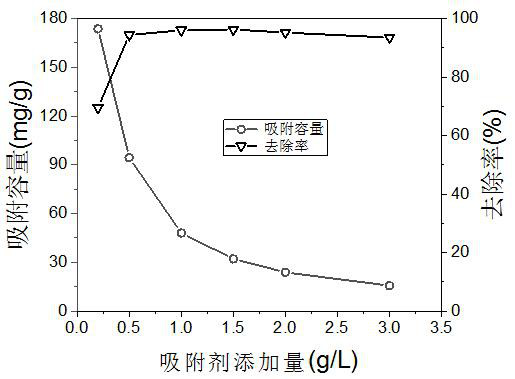

Image

Examples

Embodiment 1

[0025] Preparation method and application of a novel modified rubber seed shell biochar material

[0026] (1) Crushing the rubber seed shell, passing the crushed rubber seed shell through a 40-mesh sieve to obtain rubber seed shell particles, and drying at 60° C. for 12 hours.

[0027] (2) The rubber seed shell particles dried in step (1) were pre-carbonized in a tube furnace, and the temperature was raised to a calcination temperature of 300°C at a constant rate of 5°C / min and then calcined at a constant temperature for 1h.

[0028] (3) Add the pre-carbonized material in step (2) to 100mL KMnO 4 solution beaker, here KMnO 4 The mass ratio of rubber seed shell carbon to rubber seed shell carbon was 1:1, and the above beaker was ultrasonically treated in an ultrasonic instrument for 1 h, and the mixture was dried in an oven at 60 °C after the ultrasonic was completed.

[0029] (4) Place the dried mixture in step (3) again in the tube furnace at a constant rate of 5°C / min to t...

Embodiment 2

[0031] Example 2: Preparation method and application of a novel modified rubber seed shell biochar material

[0032] (1) Crushing the rubber seed shell, passing the crushed rubber seed shell through a 60-mesh sieve to obtain rubber seed shell particles, and drying at 80° C. for 12 hours.

[0033] (2) The rubber seed shell particles dried in step (1) were pre-carbonized in a tube furnace, and the temperature was raised to a calcination temperature of 500°C at a constant rate of 5°C / min and calcined at a constant temperature for 1h.

[0034] (3) Add the pre-carbonized material in step (2) into 100mL KMnO 4 solution in the beaker, here KMnO 4 The mass ratio of rubber seed shell carbon to rubber seed shell carbon is 1:2. The above-mentioned beaker is ultrasonicated in an ultrasonic instrument for 1 hour, and the mixture is dried in an oven at 80°C after ultrasonication.

[0035] (4) Place the dried mixture in step (3) again in the tube furnace at a constant rate of 5°C / min to a ...

Embodiment 3

[0037] Example 3: Preparation method and application of a novel modified rubber seed shell biochar material

[0038] (1) Crushing the rubber seed shell, passing the crushed rubber seed shell through a 40-mesh sieve to obtain rubber seed shell particles, and drying at 70 °C for 12 h.

[0039] (2) The rubber seed shell particles dried in step (1) were pre-carbonized in a tube furnace, and the temperature was raised to a calcination temperature of 400 °C at a constant rate of 5 °C / min and then calcined at a constant temperature for 1 h.

[0040] (3) Add the pre-carbonized material in step (2) into 100mL KMnO 4 solution in the beaker, here KMnO 4 The mass ratio of rubber seed shell carbon to rubber seed shell carbon is 1:3, and the above beaker is ultrasonicated in an ultrasonic instrument for 1 hour, and the mixture is dried in an oven at 70°C after the ultrasonication is completed.

[0041] (4) Place the dried mixture in step (3) again in the tube furnace at a constant rate of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com