A method for preparing para-aramid paper with para-aramid precipitated fiber

A technology of para-aramid paper and para-aramid fiber, which is applied in the directions of fiber dispersant addition and paper, etc., can solve the problems of weak dimensional stability, limited wide application, poor evenness, etc. Surface activity, the effect of improving interfacial affinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

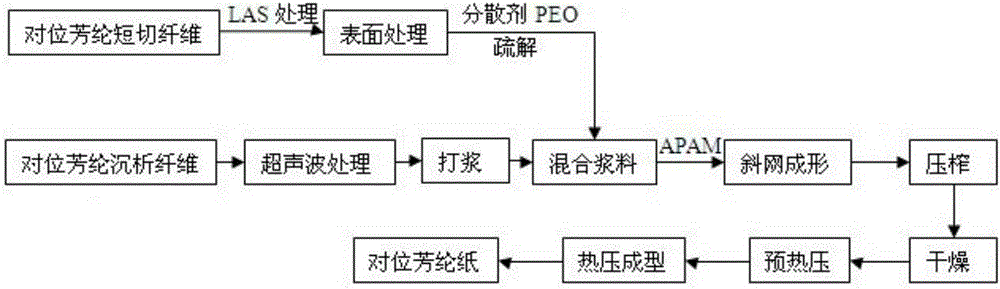

Method used

Image

Examples

Embodiment 1

[0037] The para-aramid precipitated fiber was pretreated for 10 minutes with an ultrasonic processor at a power of 200W and an intermittent time of 5s, and then beating was performed with a trough beater, and the degree of beating was controlled at 35°SR; the aramid chopped fiber was The mass-molar concentration used is 1.5×10 -3 mol / L, the temperature is 40 ℃ sodium dodecylbenzene sulfonate aqueous solution for washing pretreatment, and then washed with water, and then treated with low temperature plasma for 1min under the conditions of pressure 30Pa, power 60W; Add the treated para-aramid chopped fiber and 0.1% dispersant PEO to the beater, fully decompose, then add para-aramid precipitated fiber according to the ratio of 3:7, add APAM, fully decompose and disperse, and obtain Aramid fiber slurry; the prepared slurry is formed on an inclined wire paper machine, pressed and dried; the obtained aramid base paper is preheated and pressed at 100°C for 10s, and further hot-presse...

Embodiment 2

[0039] The para-aramid precipitated fiber was pretreated for 15 minutes with an ultrasonic processor at a power of 800W and an intermittent time of 7s, and then beating was performed with a trough beater, and the degree of beating was controlled at 40°SR; the aramid chopped fiber was Utilize a mass-molar concentration of 2.0×10 -3 mol / L, the temperature is 60 ℃ sodium dodecylbenzene sulfonate aqueous solution for washing pretreatment, and then washed with water, and then treated with low temperature plasma for 2min under the conditions of pressure 50Pa, power 70W; Add the treated para-aramid chopped fiber and 0.3% dispersant PEO to the beater, fully decompose, then add para-aramid precipitated fiber according to the ratio of 5:5, add APAM, fully decompose and disperse, and obtain Aramid fiber slurry; the prepared slurry is formed on an inclined wire paper machine, pressed and dried; the obtained aramid base paper is preheated and pressed at 120°C for 20s, and further hot press...

Embodiment 3

[0041] The para-aramid precipitated fiber was pretreated for 20 minutes with an ultrasonic processor at a power of 1500W and an intermittent time of 8s, and then was beaten with a trough beater, and the beating degree was controlled at 45°SR; the aramid chopped fiber was used The mass-molar concentration is 2.5×10 -3 mol / L, the temperature is 70 ℃ sodium dodecylbenzene sulfonate aqueous solution for washing pretreatment, and then washed with water, and then treated with low temperature plasma for 3min under the conditions of pressure 70Pa, power 80W; Add the treated para-aramid chopped fiber and 0.7% dispersant PEO to the beater, fully decompose, then add para-aramid precipitated fiber according to the ratio of 7:3, add APAM, fully decompose and disperse, and obtain Aramid fiber slurry; the prepared slurry is formed on an inclined wire paper machine, pressed and dried; the obtained aramid base paper is preheated and pressed at 150°C for 30s, and further hot pressed on a hot pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com