Antistatic polyurethane shoe material and manufacturing method thereof

A polyurethane, anti-static technology, applied in footwear, applications, clothing and other directions, can solve the problems of static carry away, can not be used in anti-static occasions, high resistance value, reduce surface energy, improve interface affinity, improve anti-static The effect of electrostatic properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

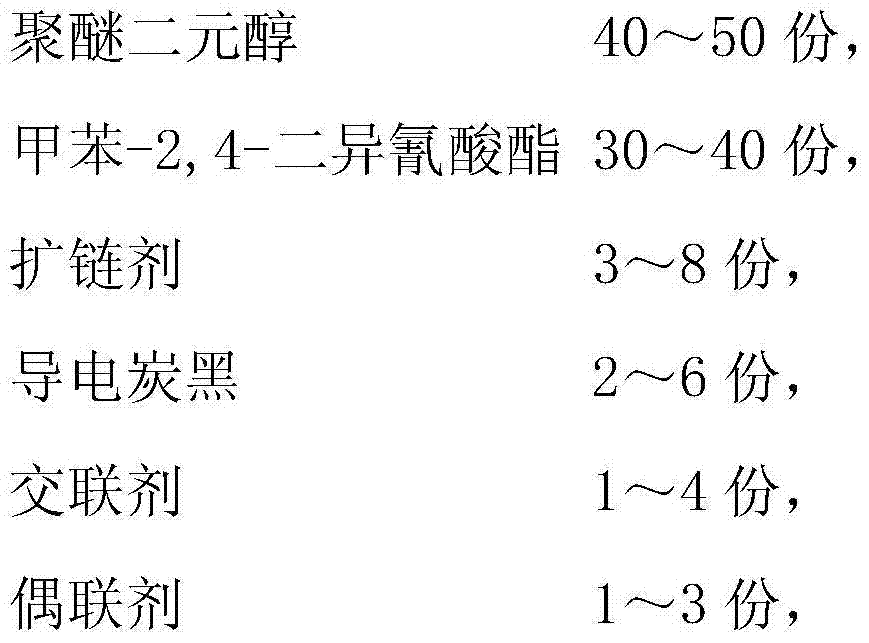

[0024] A kind of antistatic polyurethane shoe material, its parts by weight consist of:

[0025]

[0026] Its manufacturing method comprises the following steps:

[0027] (1) Evenly disperse the coupling agent in ethanol, add conductive carbon black and stir for 10 minutes, leave the mixed liquid after stirring uniformly at room temperature for 2 hours, filter and dry to obtain modified carbon black powder;

[0028] (2) Utilize polyether diol and toluene-2,4-diisocyanate to prepare a prepolymer, then use a chain extender to extend the chain, mix and stir to obtain polyurethane;

[0029] (3) Add the modified carbon black powder and other components to the polyurethane, dissolve and stir to obtain the composite;

[0030] (4) Casting the composite material obtained in step (3) to obtain an antistatic polyurethane shoe material.

Embodiment 2

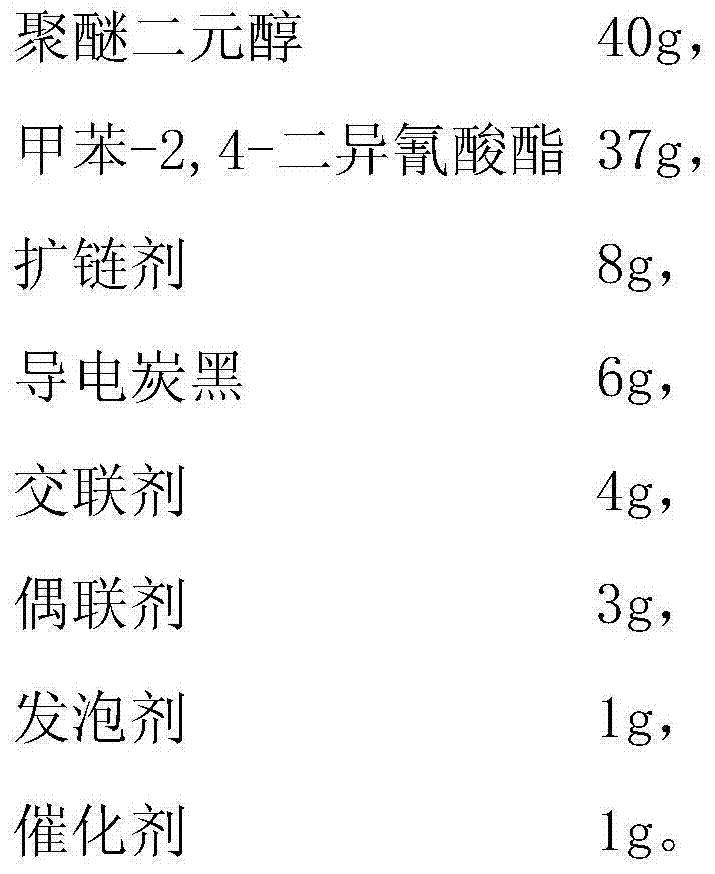

[0032] A kind of antistatic polyurethane shoe material, its parts by weight consist of:

[0033]

[0034] Its manufacturing method comprises the following steps:

[0035] (1) Evenly disperse the coupling agent in ethanol, add conductive carbon black and stir for 10 minutes, leave the mixed liquid after stirring uniformly at room temperature for 2 hours, filter and dry to obtain modified carbon black powder;

[0036] (2) Utilize polyether diol and toluene-2,4-diisocyanate to prepare a prepolymer, then use a chain extender to extend the chain, mix and stir to obtain polyurethane;

[0037] (3) Add the modified carbon black powder and other components to the polyurethane, dissolve and stir to obtain the composite;

[0038] (4) Casting the composite material obtained in step (3) to obtain an antistatic polyurethane shoe material.

Embodiment 3

[0040] A kind of antistatic polyurethane shoe material, its parts by weight consist of:

[0041]

[0042]

[0043] Its manufacturing method comprises the following steps:

[0044] (1) Evenly disperse the coupling agent in ethanol, add conductive carbon black and stir for 10 minutes, leave the mixed liquid after stirring uniformly at room temperature for 2 hours, filter and dry to obtain modified carbon black powder;

[0045] (2) Utilize polyether diol and toluene-2,4-diisocyanate to prepare a prepolymer, then use a chain extender to extend the chain, mix and stir to obtain polyurethane;

[0046] (3) Add the modified carbon black powder and other components to the polyurethane, dissolve and stir to obtain the composite;

[0047] (4) Casting the composite material obtained in step (3) to obtain an antistatic polyurethane shoe material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com