Hot melt adhesive for polyolefin and application thereof

A technology of hot-melt adhesives and polyolefins, applied in the direction of adhesives, non-polymer adhesive additives, adhesive additives, etc., can solve the problems that are difficult to meet, and ordinary adhesives cannot meet the bonding requirements of polyolefin difficult-to-bond materials, etc. problem, to achieve good bonding, stable chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

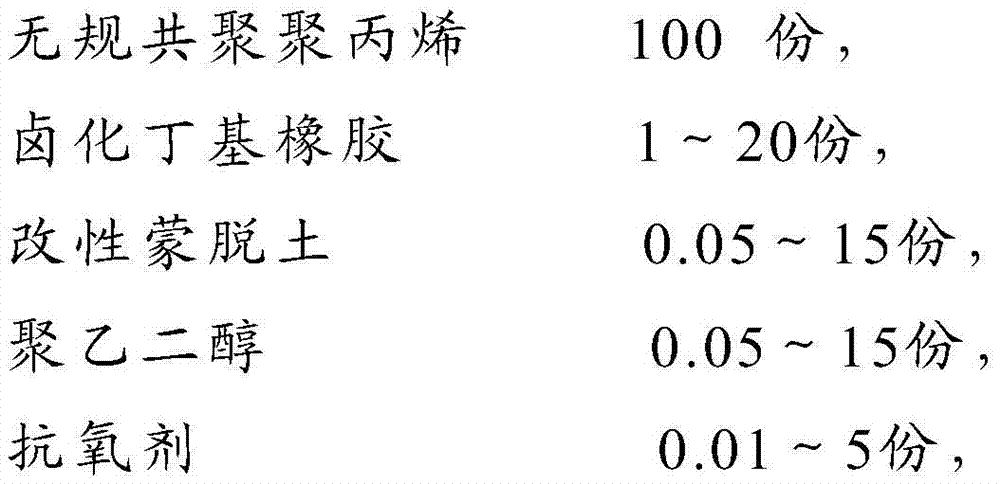

[0077] The preparation method of described hot melt adhesive comprises the following steps:

[0078] (A.1) Melt blending modified montmorillonite with random copolymerized polypropylene, halogenated butyl rubber, polyethylene glycol, and antioxidant;

[0079] (A.2) Discharging and cutting into granules to obtain the product hot melt adhesive;

[0080] In a preferred embodiment, in step (A.1), the modified montmorillonite is mixed with random copolymerized polypropylene, halogenated butyl rubber, polyethylene glycol, and antioxidant at 145°C to 190°C Melt blending for 5 minutes to 20 minutes.

[0081] In a further preferred embodiment, in step (A.1), the modified montmorillonite, random copolymerized polypropylene, halogenated butyl rubber, polyethylene glycol, and antioxidant are melted at 155°C to 180°C Blending for 10 minutes to 15 minutes;

[0082] Among them, the melting point of random copolymerized polypropylene is 125°C to 140°C, which determines that the preparation...

Embodiment 1

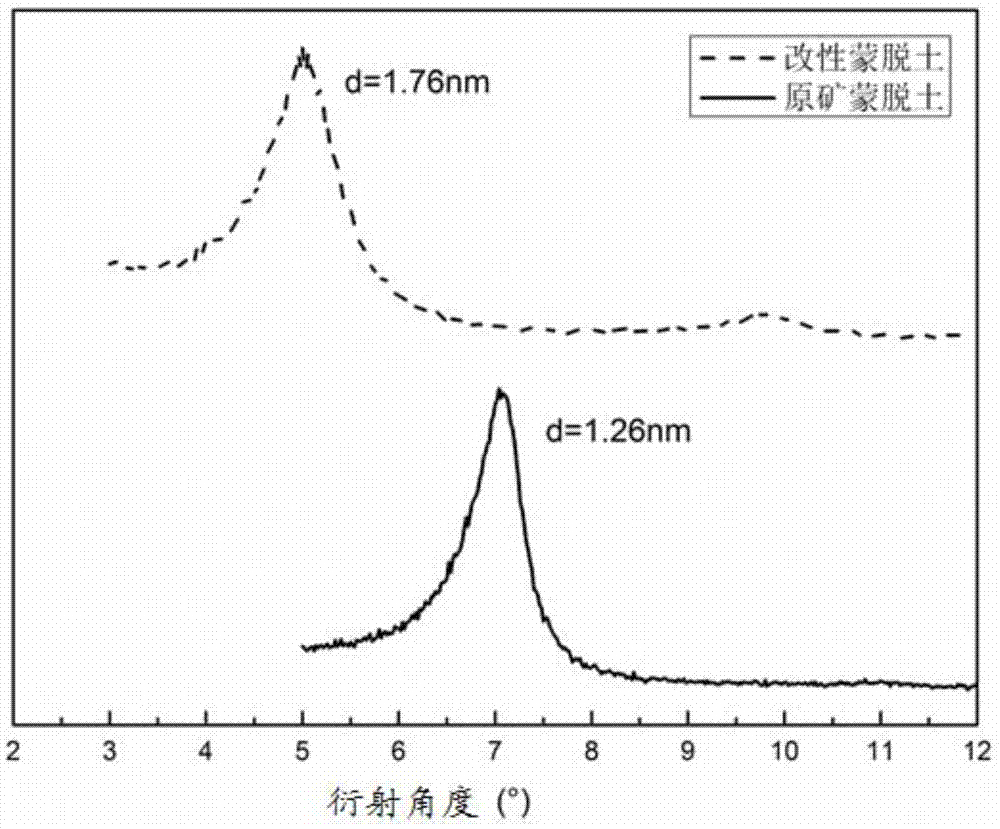

[0131] Preparation of modified montmorillonite by solution method

[0132] Take 25g of polyethylene glycol 8000, dry it in vacuum at 50°C for 12 hours, add the dried polyethylene glycol 8000 into 4000g of absolute ethanol, heat and stir at 60°C for 30 minutes, add 50g of raw ore to the obtained polyethylene glycol solution Montmorillonite, heated at 60°C, stirred for 3 hours, centrifuged the obtained suspension at 1000g for 5 minutes at room temperature, vacuum-dried the obtained centrifugal precipitate at 45°C, ground and sieved to obtain modified montmorillonite, the average The particle size is 200 mesh.

Embodiment 2

[0134] Preparation of Montmorillonite Modified by Melting Method

[0135] Take 25g of polyethylene glycol 8000, dry it in vacuum at 50°C for 8 hours, mix the dried polyethylene glycol 8000 with 30g of raw ore montmorillonite, grind it, then mechanically stir it at 70°C for 6 hours, let it stand for cooling at room temperature, and finally grind it and sieving to obtain modified montmorillonite with an average particle size of 200 mesh.

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com