Light high-strength ABS wood-plastic foamed board and preparation method thereof

A technology of wood-plastic foaming and ABS resin, which is applied in the field of wood-plastic boards, can solve the problems of high flame retardant, high density and lack of elastic properties, and achieve blending promotion, excellent corrosion resistance and mildew resistance, and strong applicability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

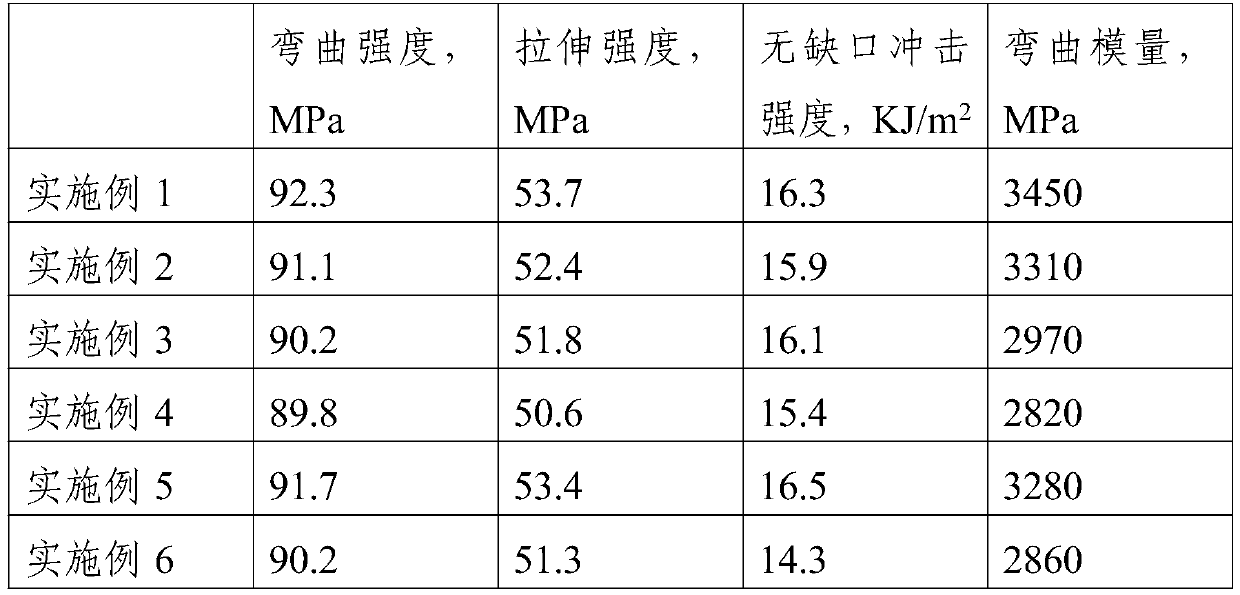

Examples

Embodiment 1

[0027] A light-weight high-strength ABS wood-plastic foam board, made of the following parts by weight: 25 parts of ABS resin particles, 20 parts of maleic anhydride grafted ABS resin particles, 60 parts of wood powder, and coated flame-retardant polypropylene 8 parts of fiber, 7 parts of modifier, 4 parts of foaming agent.

[0028] Wherein: the maleic anhydride grafting ratio in the maleic anhydride grafted ABS resin particle is 2.27wt%.

[0029] Wood flour includes rice husk, straw, and cypress branches, and the mass ratio of the three is 3:5:2. The preparation method of wood flour is as follows: firstly, the materials are taken according to the mass ratio, and the rice husk, straw, and cypress branches are crushed and blended, and then added to the Add 1wt% starch aqueous solution until submerged, stir and mix at 50°C for 20-30min, vacuum dry at 60°C until the water content is less than 5%, and crush to obtain wood flour.

[0030] The preparation method of the coated flame...

Embodiment 2

[0039] A light-weight high-strength ABS wood-plastic foam board, which is made of the following parts by weight: 30 parts of ABS resin particles, 20 parts of maleic anhydride grafted ABS resin particles, 50 parts of wood powder, and coated flame-retardant polypropylene 10 parts of fiber, 5 parts of modifier, 4 parts of foaming agent.

[0040] Wherein: the maleic anhydride grafting rate in the maleic anhydride grafted ABS resin particle is 2.3wt%.

[0041] Wood flour includes rice husk, straw, and cypress branches, and the mass ratio of the three is 3:5:2. The preparation method of wood flour is as follows: firstly, the materials are taken according to the mass ratio, and the rice husk, straw, and cypress branches are crushed and blended, and then added to the Add 1wt% starch aqueous solution until submerged, stir and mix at 50°C for 20-30min, vacuum dry at 60°C until the water content is less than 5%, and crush to obtain wood flour.

[0042] The preparation method of the coat...

Embodiment 3

[0051] A light-weight high-strength ABS wood-plastic foam board, which is made of the following parts by weight: 20 parts of ABS resin particles, 15 parts of maleic anhydride grafted ABS resin particles, 50 parts of wood powder, and coated flame-retardant polypropylene 5 parts of fiber, 5 parts of modifier, 2 parts of foaming agent.

[0052] Wherein: the maleic anhydride grafting rate in the maleic anhydride grafted ABS resin particle is 2.2wt%.

[0053] Wood flour includes rice husk, straw, and cypress branches, and the mass ratio of the three is 3:5:2. The preparation method of wood flour is as follows: firstly, the materials are taken according to the mass ratio, and the rice husk, straw, and cypress branches are crushed and blended, and then added to the Add 1wt% starch aqueous solution until submerged, stir and mix at 50°C for 20-30min, vacuum dry at 60°C until the water content is less than 5%, and crush to obtain wood flour.

[0054] The preparation method of the coate...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com