Ultra-low temperature spraying non-curing rubber asphalt waterproof coating

A kind of asphalt waterproof coating, non-curing rubber technology, applied in the direction of asphalt coating, coating, conjugated diene coating, etc., can solve the problems of high energy consumption, high pollution, etc., to improve creep performance, improve flow performance, avoid The effect of high energy consumption and high pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

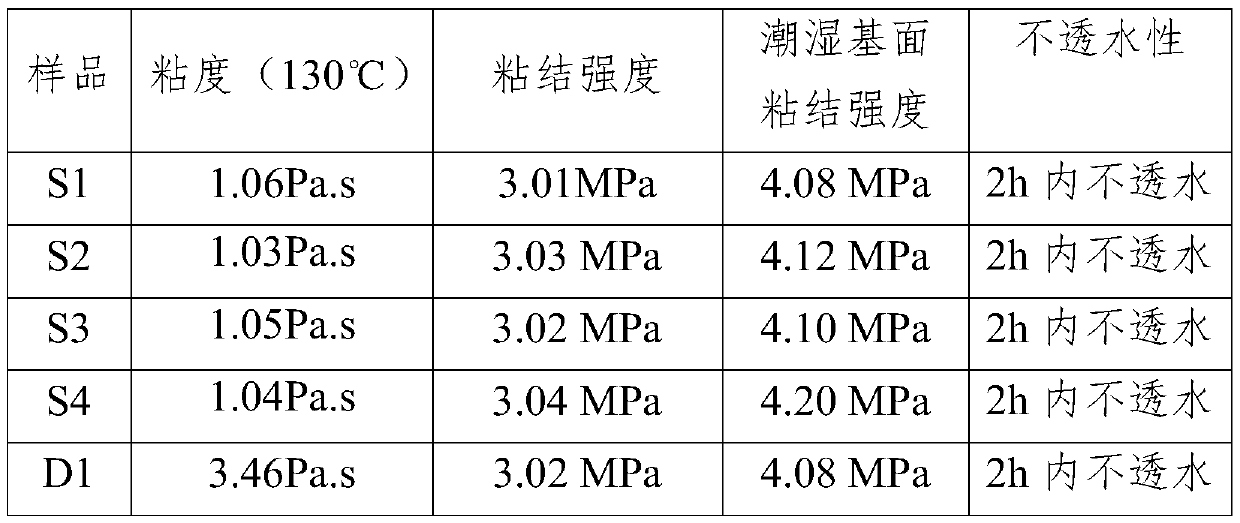

Examples

Embodiment 1

[0032] This embodiment provides a kind of ultra-low temperature spraying non-curing rubber asphalt waterproof coating and its preparation method, comprising the following steps:

[0033] Add 45 parts by weight of asphalt into a 1000L reactor, turn on the heating device, heat the asphalt to 130-150°C, add 2 parts by weight of thermoplastic styrene-butadiene rubber, 8 parts by weight of styrene-isoprene-styrene Segment copolymer, 5 parts by weight of ethylene-vinyl acetate copolymer, 5 parts by weight of styrene-butadiene rubber, 4 parts by weight of α-pinene+β-pinene, heat up while stirring, and keep the temperature after heating up to 185-195°C Keep the temperature constant, stir until fully mixed, cool down to 165-175°C, add 6 parts by weight of grafted fumed silica, 9 parts by weight of polyamide epoxy curing agent, 3 parts by weight of phosphating nano-silicon oxide and 4 parts by weight. Lauryl alcohol ester in parts by weight, heat-preserved and stirred for 1.0-1.5 hours ...

Embodiment 2

[0035] This embodiment provides a kind of ultra-low temperature spraying non-curing rubber asphalt waterproof coating and its preparation method, comprising the following steps:

[0036] Add 50 parts by weight of asphalt into a 1000L reactor, turn on the heating device, heat the asphalt to 130-150°C, add 2 parts by weight of thermoplastic styrene-butadiene rubber, 2 parts by weight of styrene-isoprene-styrene Segment copolymer, 3 parts by weight of ethylene-vinyl acetate copolymer, 3 parts by weight of styrene-butadiene rubber, 7 parts by weight of α-pinene+β-pinene, heat up while stirring, and keep the temperature after heating up to 185-195°C Keep the temperature constant, stir until fully mixed, cool down to 165-175°C, add 9 parts by weight of grafted fumed silica, 8 parts by weight of polyamide epoxy curing agent, 6 parts by weight of phosphating nano-silicon oxide and 6 parts by weight. Lauryl alcohol ester in parts by weight, heat-preserved and stirred for 1.0-1.5 hours ...

Embodiment 3

[0038] This embodiment provides a kind of ultra-low temperature spraying non-curing rubber asphalt waterproof coating and its preparation method, comprising the following steps:

[0039] Add 55 parts by weight of asphalt into a 1000L reactor, turn on the heating device, heat the asphalt to 130-150°C, add 1 part by weight of thermoplastic styrene-butadiene rubber, 4 parts by weight of styrene-isoprene-styrene Segment copolymer, 4 parts by weight of ethylene-vinyl acetate copolymer, 6 parts by weight of styrene-butadiene rubber, 5 parts by weight of α-pinene+β-pinene, heat up while stirring, and keep the temperature after heating up to 185-195°C Keep the temperature constant, stir until fully mixed, cool down to 165-175°C, add 8 parts by weight of grafted fumed silica, 6 parts by weight of polyamide epoxy curing agent, 5 parts by weight of phosphating nano-silicon oxide and 3 parts by weight. Lauryl alcohol ester in parts by weight, heat-preserved and stirred for 1.0-1.5 hours t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| penetration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com