Patents

Literature

100 results about "Polyamide epoxy" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

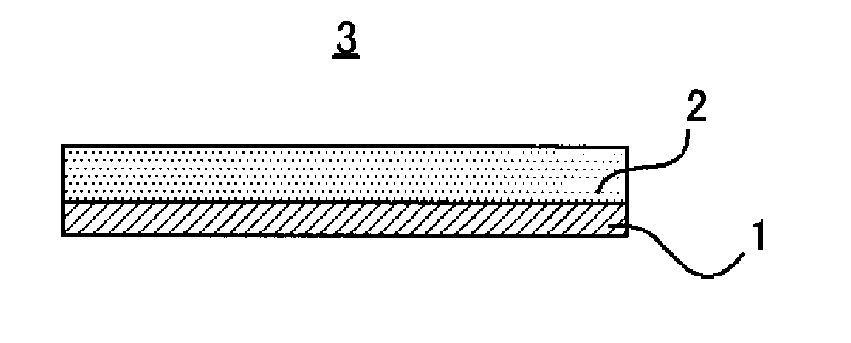

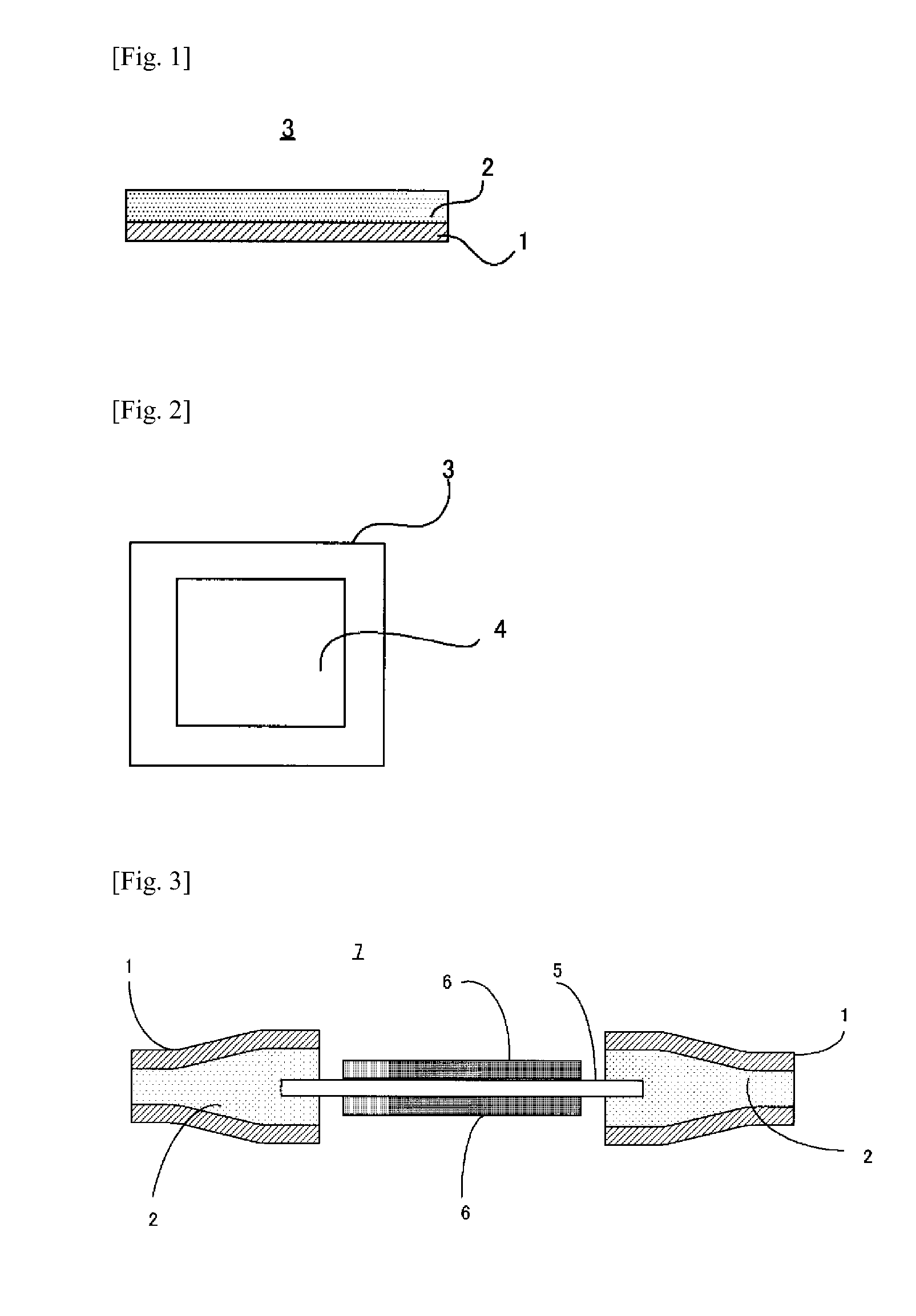

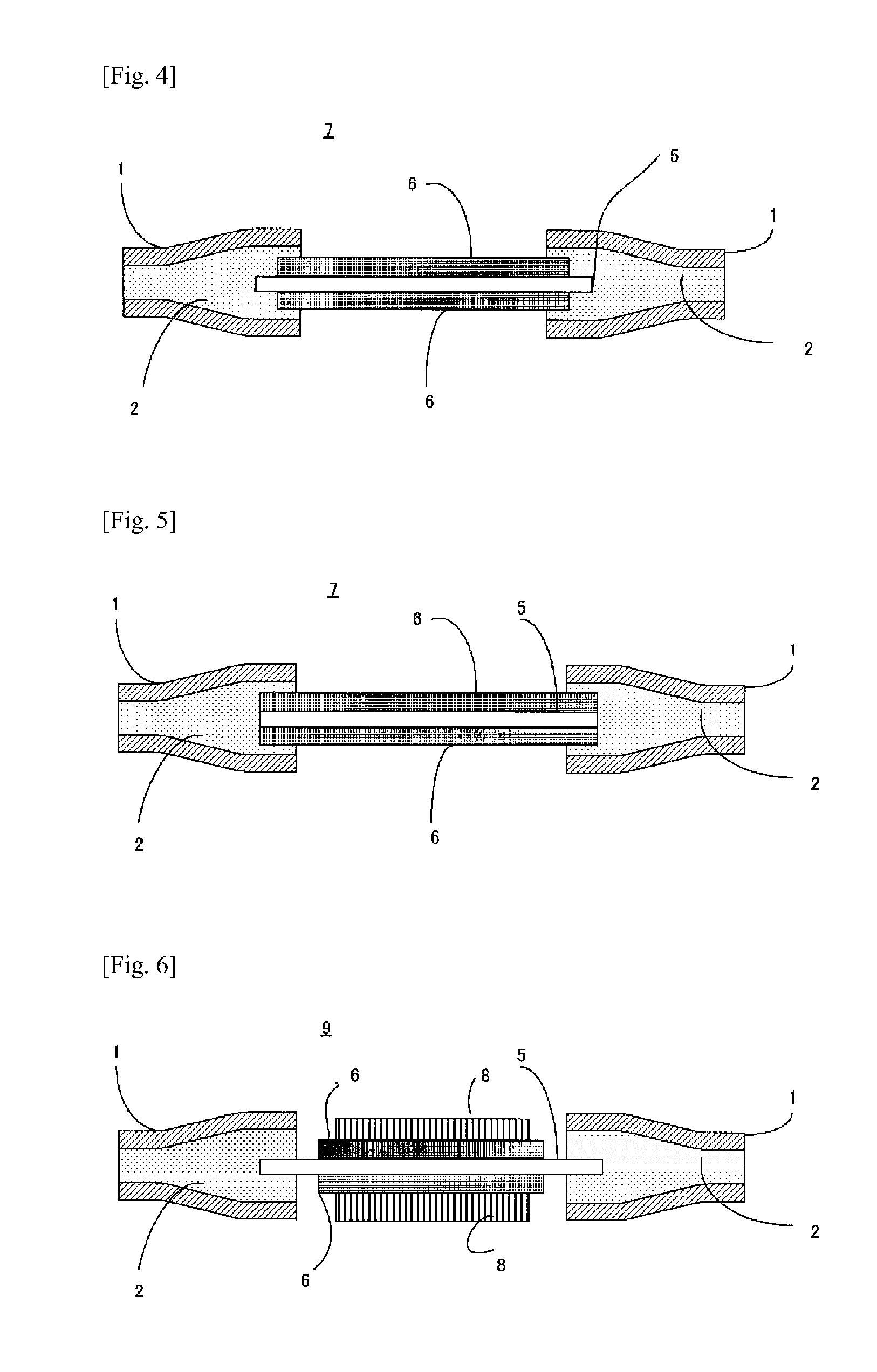

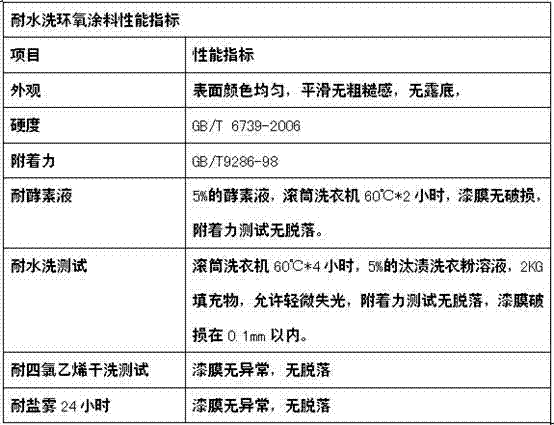

Ultra-low permeation hose and method of manufacture

InactiveUS20040040609A1Outstanding resistanceImprove adhesionFlexible pipesRigid pipesHeat resistanceRefrigerant

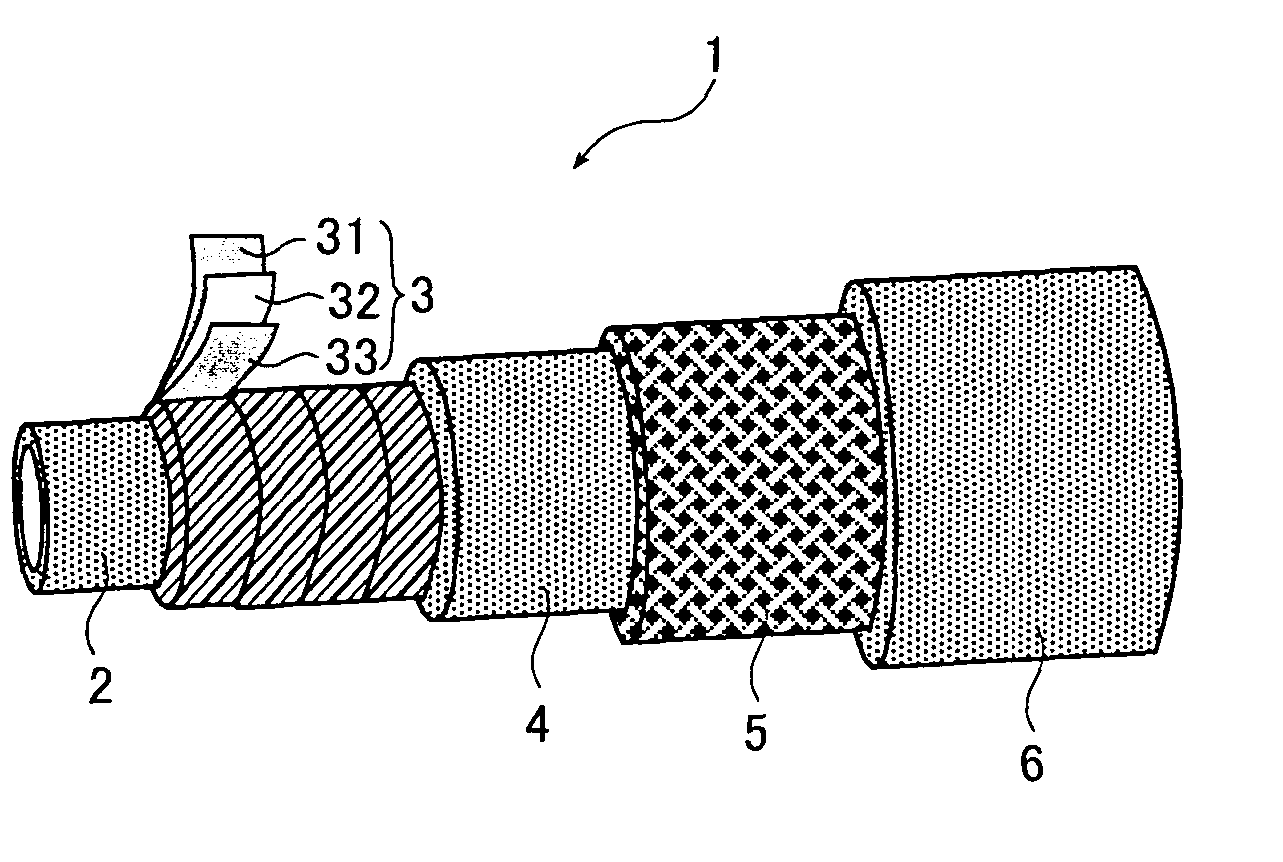

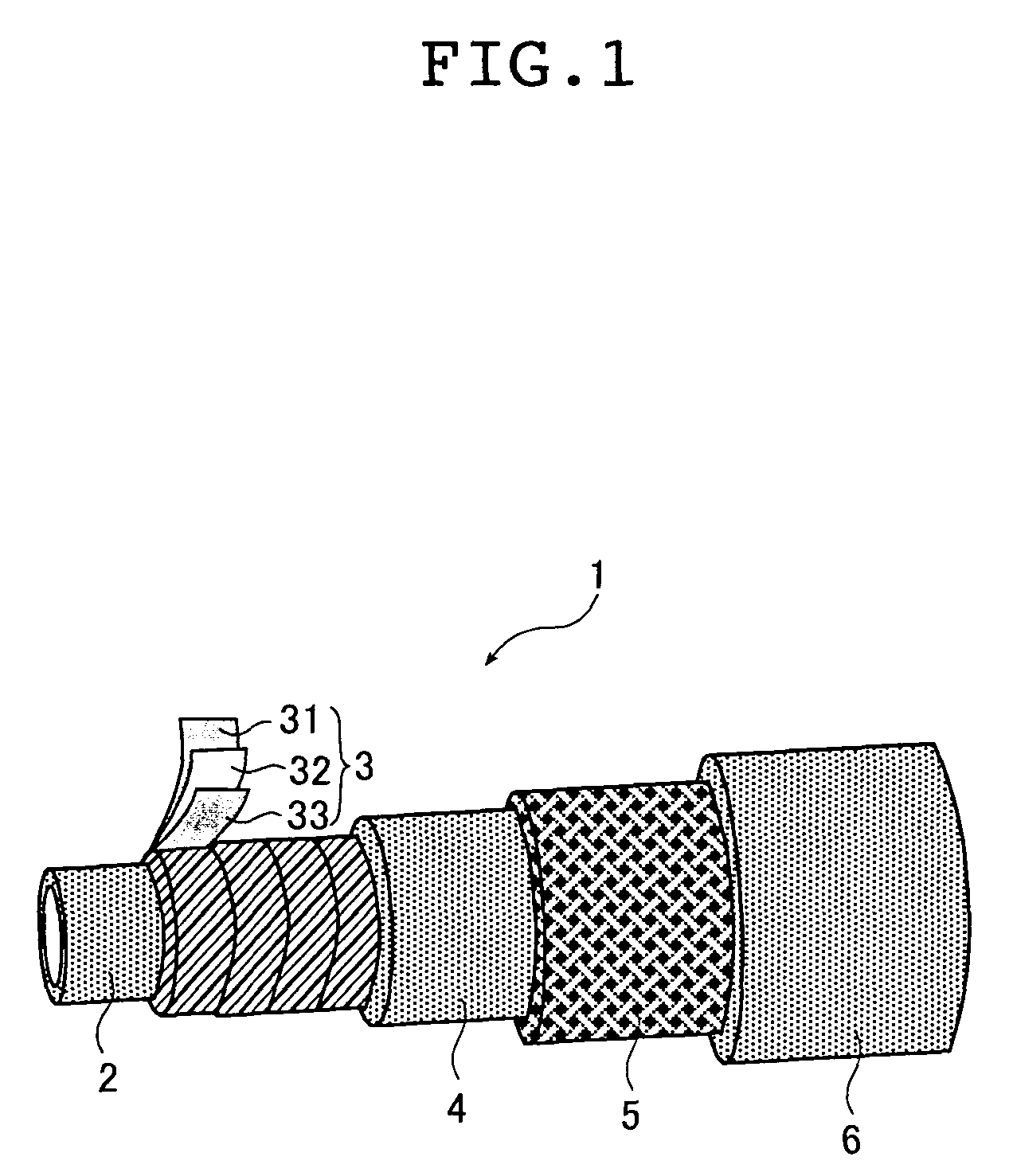

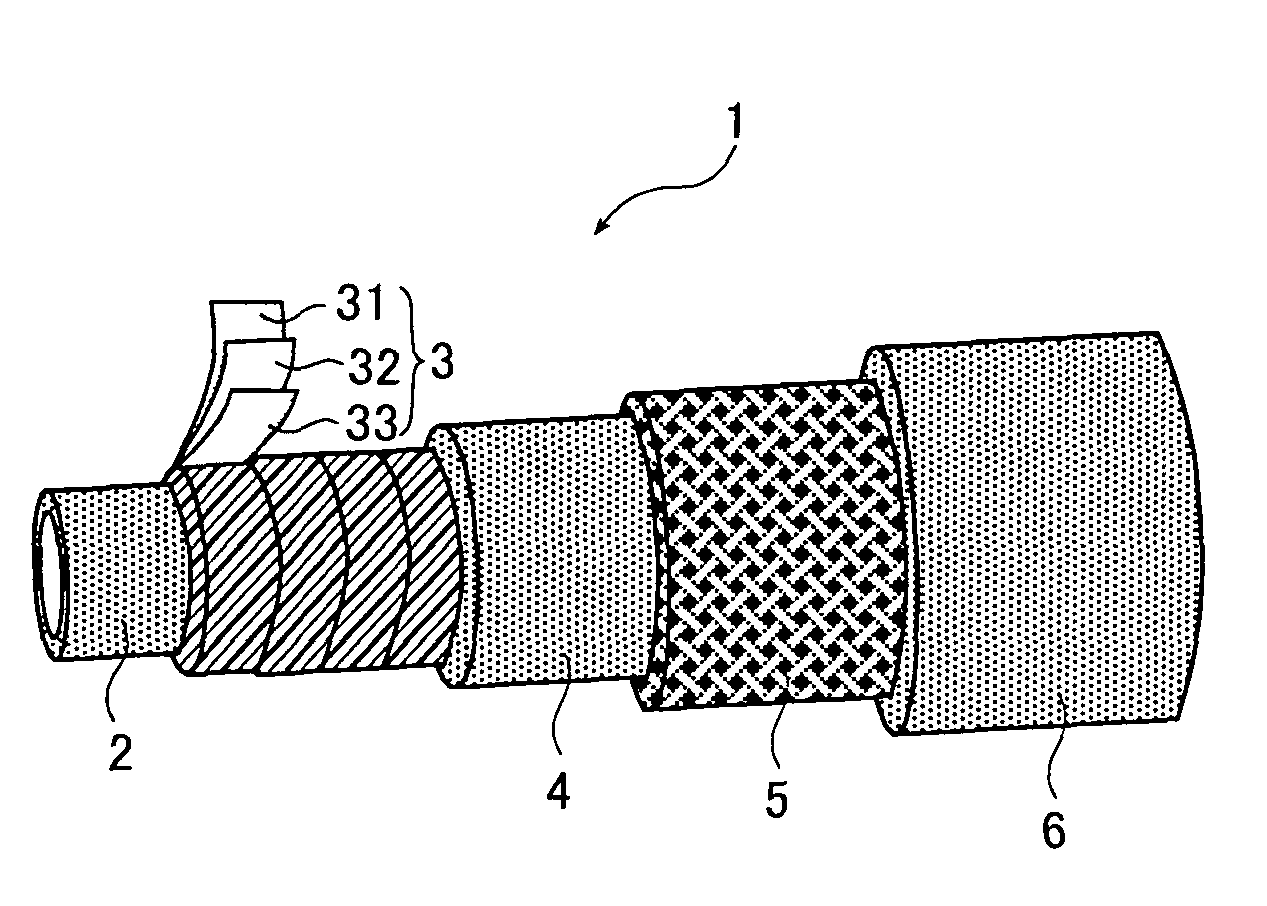

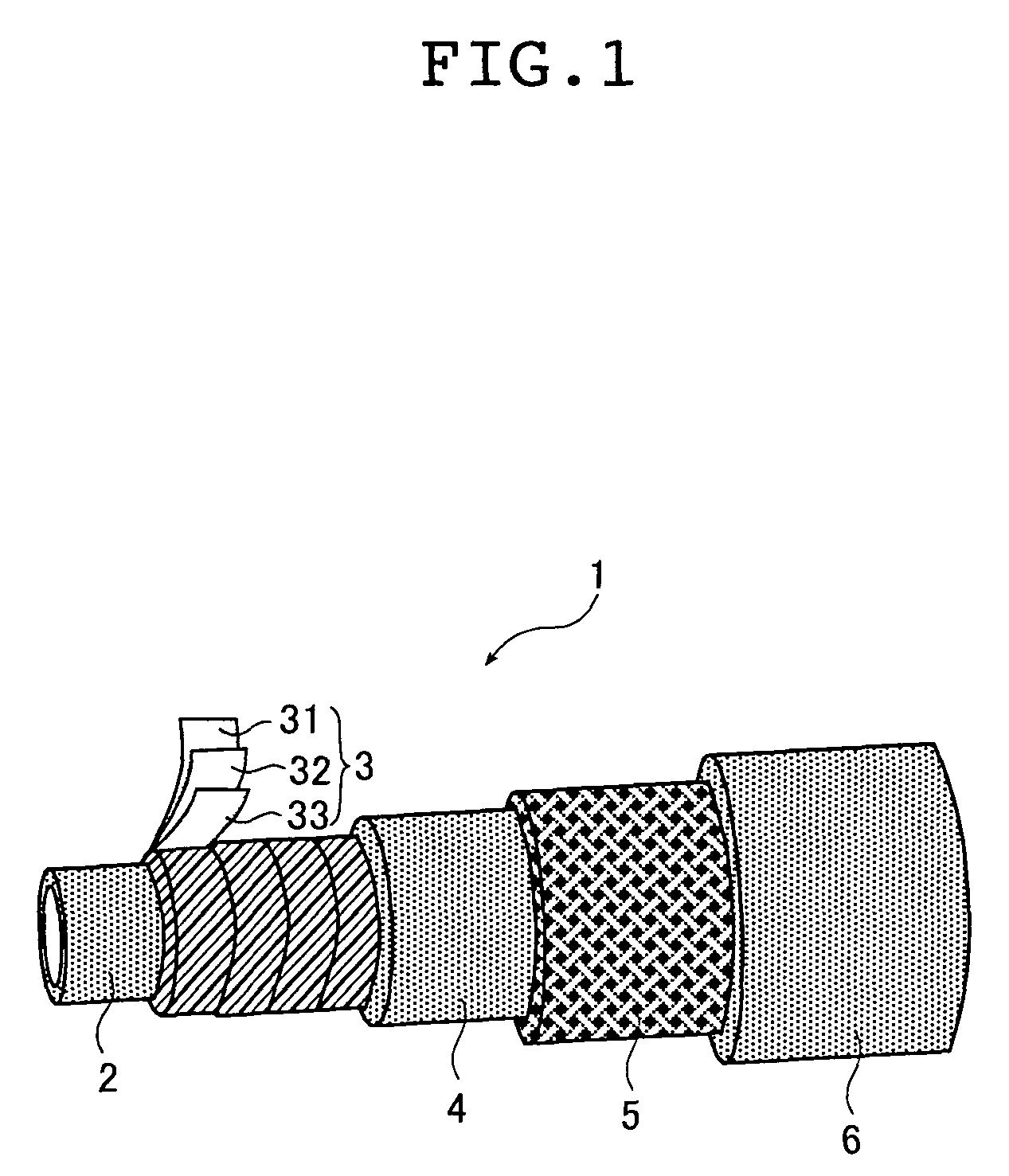

An object of the present invention is to provide ultra-low permeation hoses which have at the interior thereof a refrigerant barrier layer that consists in large part of a metal layer and is capable of conforming to hose deformation, which have an excellent resistance to refrigerant permeation (i.e., barrier properties to refrigerants), particularly an excellent CO2 permeation resistance and an excellent heat resistance when CO2 is used as the refrigerant. The object can be accomplished by an ultra-low permeation hose having at least a refrigerant barrier layer and a rubber layer and / or a resin layer; wherein the refrigerant barrier layer is a laminated film comprising a resin layer and, on the outside thereof, a metal layer, which the resin layer and the metal layer are bonded together by a polyamide-epoxy reactive adhesive.

Owner:YOKOHAMA RUBBER CO LTD +1

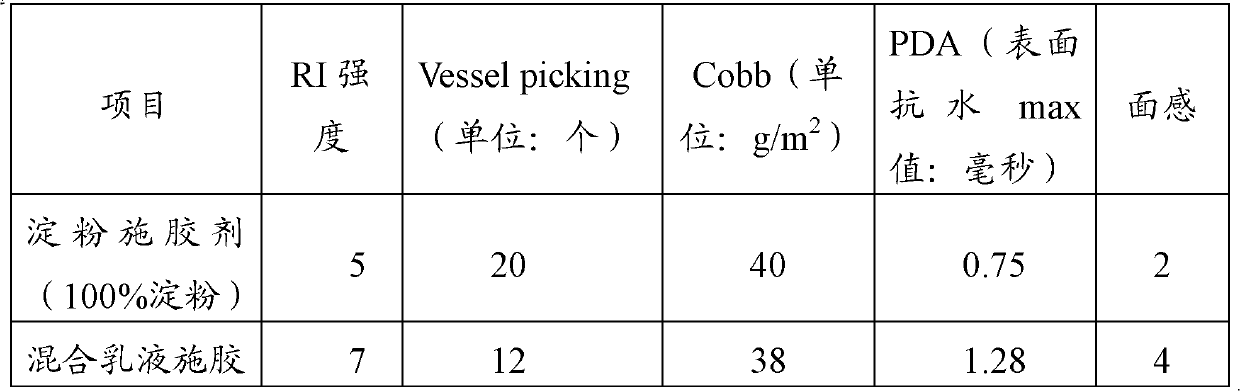

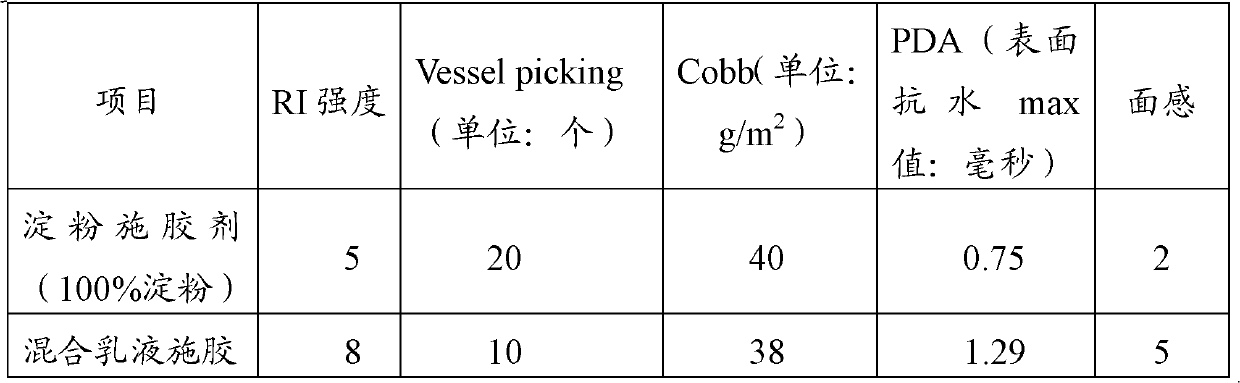

Method for making raw paper of heat sublimation transfer printing paper

InactiveCN102767120AEasy to useOptimize copying parametersSpecial paperWater-repelling agents additionPulp and paper industryAlum

The invention discloses a method for making raw paper of heat sublimation transfer printing paper. The method comprises the following steps of: slurrying a needle leaf wood-pulp board and a broad leaf wood-pulp board, and respectively beating the needle leaf wood-pulp board and the broad leaf wood-pulp board to 15 to 25 degrees SR and 18 to 28 degrees SR; then mixing the two beaten pulps, mixing the mixture and chemimechanical pulp (CTMP) which is beaten to 22 to 32 degrees SR in advance, and uniformly stirring the mixture with wet strength agent polyamide epoxy resin (PAE), white alum and sizing agent cation rosin size to obtain paper pulp; and putting the paper pulp onto a net, controlling the net part to be dehydrated and molded, and performing squeezing, surface sizing and drying to obtain the heat sublimation transfer printing paper. The indexes of the finished paper can meet the requirement of the heat sublimation transfer printing paper by optimizing the beating degree, the using amounts of various additives during papermaking and making parameters of a paper maker.

Owner:ZHEJIANG JINCHANG SPECIALTY PAPER CO LTD

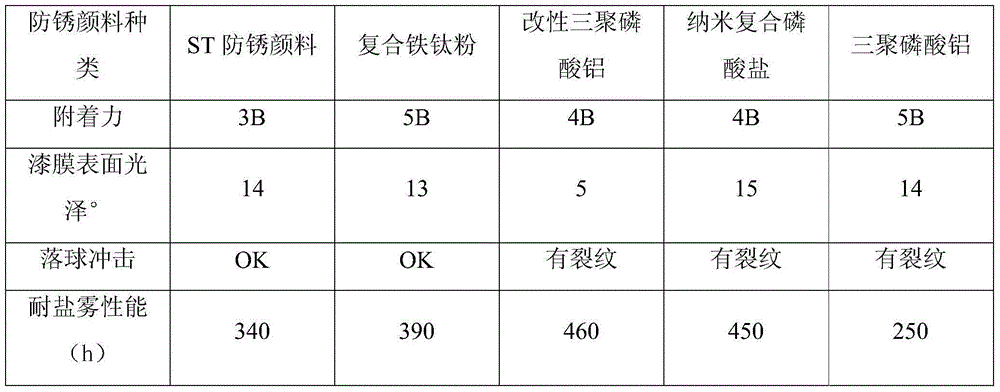

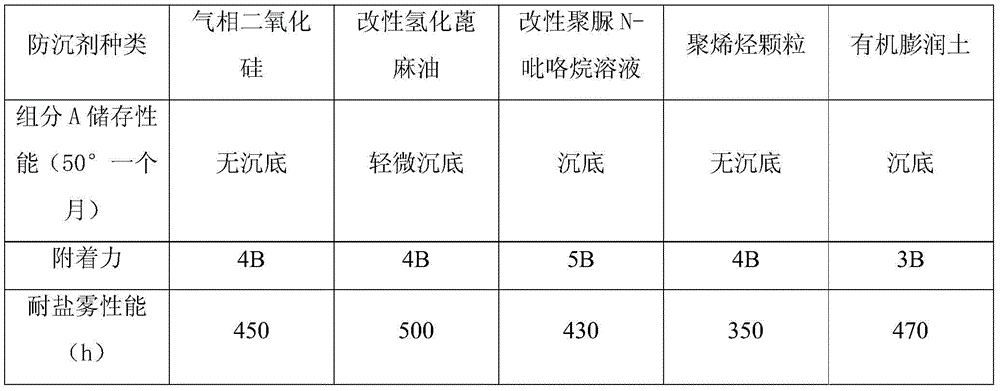

Bi-component corrosion-proof dope

InactiveCN101100578AGood oil resistanceImprove water resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

A titanium-nickel nanometer alloy powder contains A and B components; A components consist of epoxy-resin, titanium-nickel nanometer alloy powder, antirust pigment, filler corrosion stabilizer and anti-sagging accessory; B components consist of composite curing agent with cashew nut shell modified phenolic amine curing agent and polyamide epoxy curing agent; the proportion of A and B is 10:1. It has excellent adhesion and physical performance and better oil, water, acid-alkali and salt fog resistances and mating ability. It can be used as universal base coat and used for various substrate materials such as steel, aluminum and stainless steel etc.

Owner:中国人民解放军海军装备技术研究所

Ultra-low permeation hose and method of manufacture

InactiveUS6988515B2Improve the immunityImprove heat resistanceFlexible pipesRigid pipesHeat resistanceRefrigerant

An object of the present invention is to provide ultra-low permeation hoses which have at the interior thereof a refrigerant barrier layer that consists in large part of a metal layer and is capable of conforming to hose deformation, which have an excellent resistance to refrigerant permeation (i.e., barrier properties to refrigerants), particularly an excellent CO2 permeation resistance and an excellent heat resistance when CO2 is used as the refrigerant. The object can be accomplished by an ultra-low permeation hose having at least a refrigerant barrier layer and a rubber layer and / or a resin layer; wherein the refrigerant barrier layer is a laminated film comprising a resin layer and, on the outside thereof, a metal layer, which the resin layer and the metal layer are bonded together by a polyamide-epoxy reactive adhesive.

Owner:THE YOKOHAMA RUBBER CO LTD +1

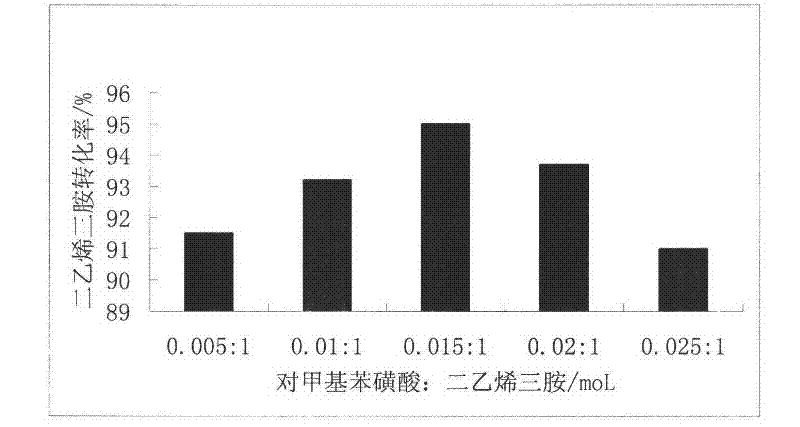

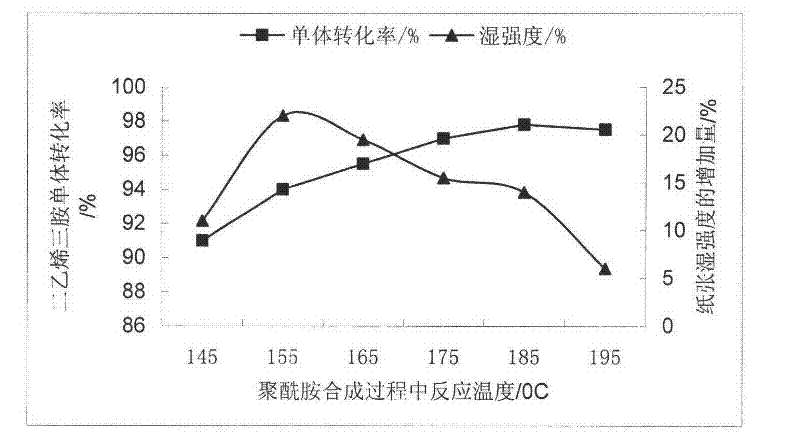

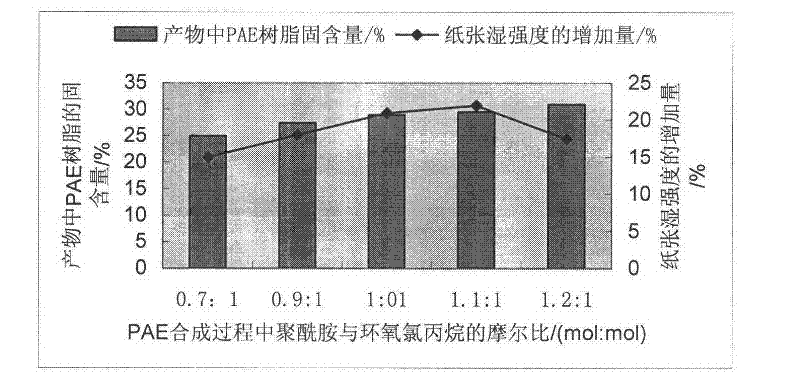

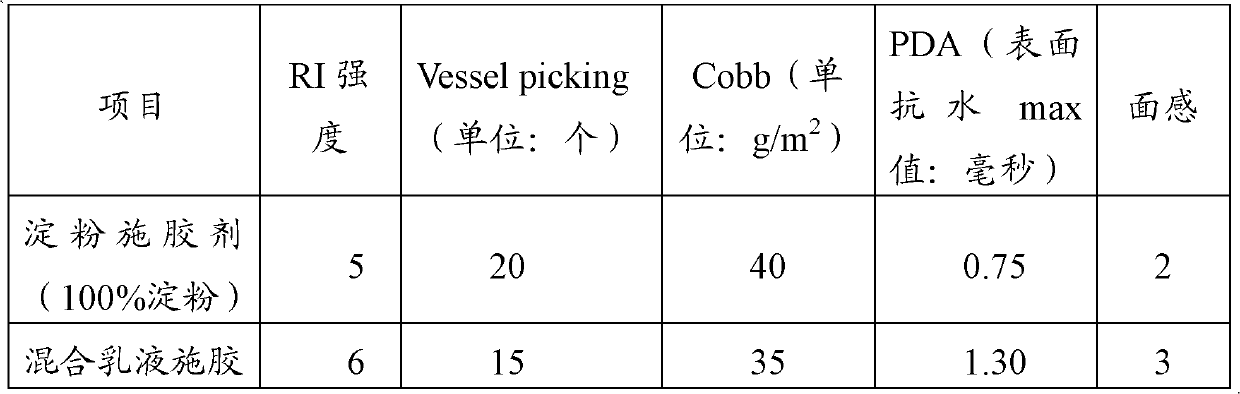

Preparation method of permeation resistant addition agent with functions of reinforcing stiffness and wet-strength

The invention discloses a preparation method of a permeation resistant addition agent with functions of reinforcing stiffness and wet-strength. The preparation method comprises the following main operating steps of: (1) firstly synthesizing midbody polyamide, then carrying out epoxidation on the polyamide and chloroepoxy propane to obtain polyamide epoxy chloropropane resin; (2) firstly synthesizing seed emulsion, then synthesizing a shell, obtaining a product which is fluorine containing acrylic ester core-shell emulsion; (3) carrying out composition modification on polyamide epoxy chloropropane and the fluorine containing acrylic ester core-shell emulsion to obtain the permeation resistant addition agent with the functions of reinforcing stiffness and wet-strength. According to the preparation method, the fluorine containing acrylic ester core-shell emulsion is used for carrying out composition modification on the PAE (Polyamide Epoxy chloropropane resin) so that the periphery of the emulsion particles are adsorbed and coated by macromolecules of the PAE (Polyamide Epoxy chloropropane resin) to prepare the cationization PAE (Polyamide Epoxy chloropropane resin) modified fluorinecontaining acrylic ester core-shell emulsion; the modified PAE (Polyamide Epoxy chloropropane resin) is a stable multifunctional papermaking addition agent and has the characteristic of wet-strength sizing.

Owner:GUANGXI UNIV

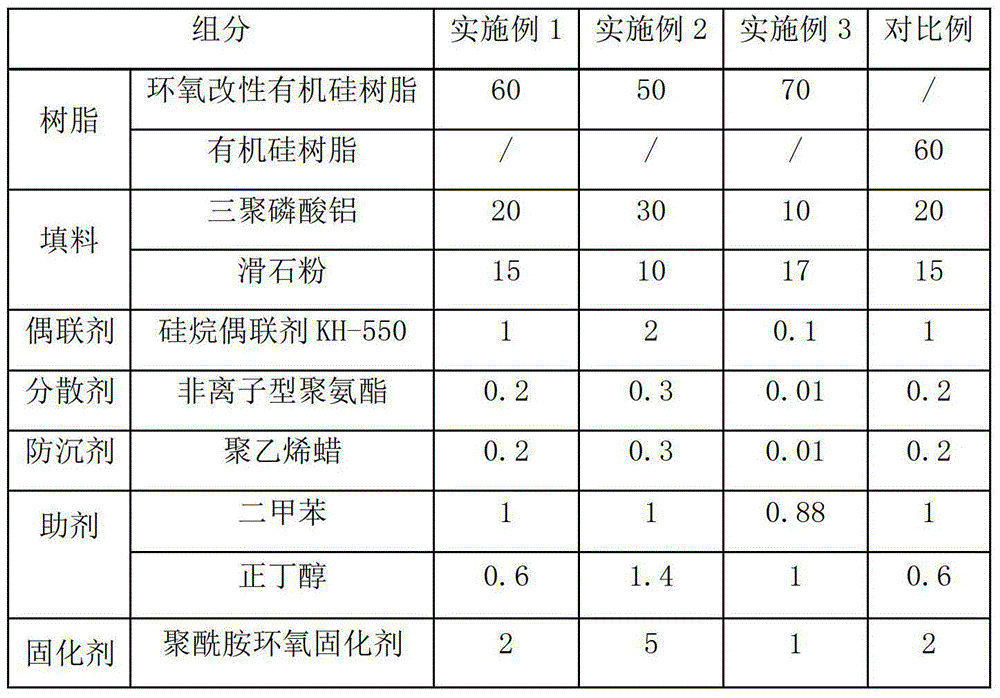

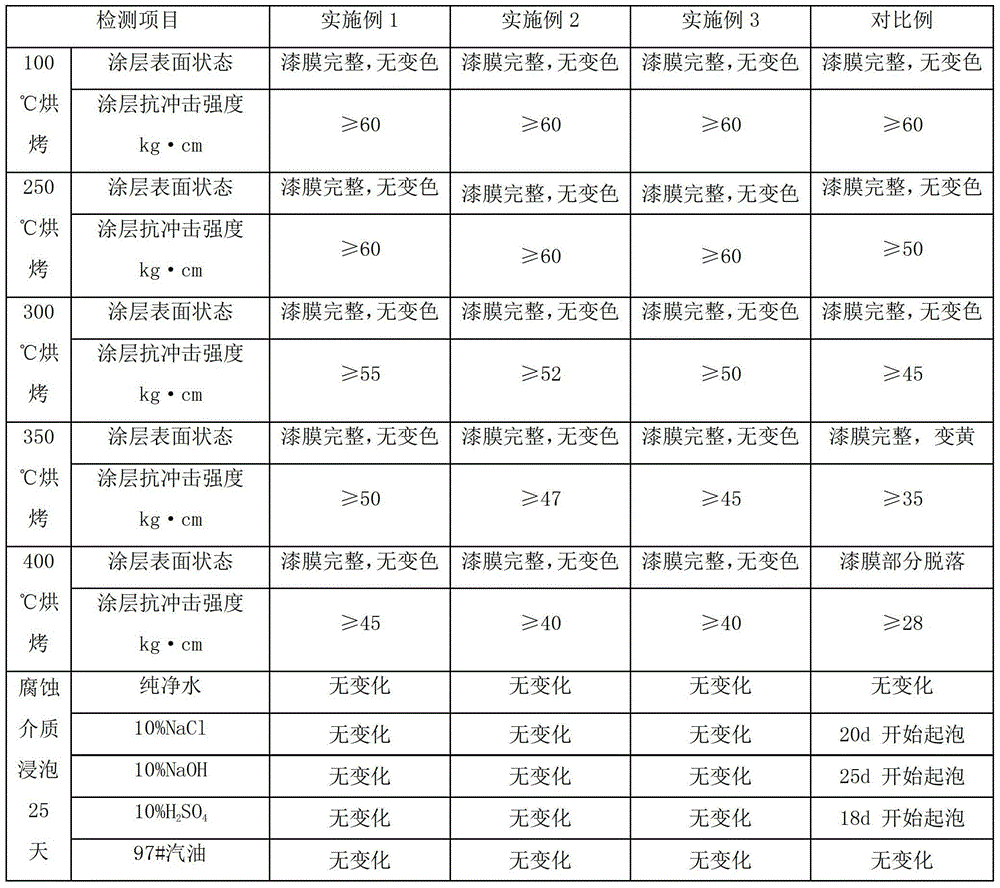

Corrosion-resistant high-temperature insulation paint

InactiveCN103333607AImprove corrosion resistanceImprove aging resistanceAnti-corrosive paintsEpoxyPolyamide

The invention provides corrosion-resistant high-temperature insulation paint which comprises a component A and a component B, wherein the component A comprises the following raw materials in parts by mass: 50-70 parts of epoxy modified organic silicon resin, 10-30 parts of corrosion-resistant filler, 1-10 parts of talcum powder, 0.1-2 parts of silane coupling agent, 0.01-0.3 part of nonionic dispersant, 0.01-0.3 part of anti-settling agent and the balance of assistant; and the component B comprises the following raw material in parts by mass: 10-20 parts of curing agent, and the curing agent is a polyamide epoxy curing agent. The corrosion-resistant high-temperature insulation paint provided by the invention has favorable comprehensive performance, good insulativity and favorable corrosion resistance.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

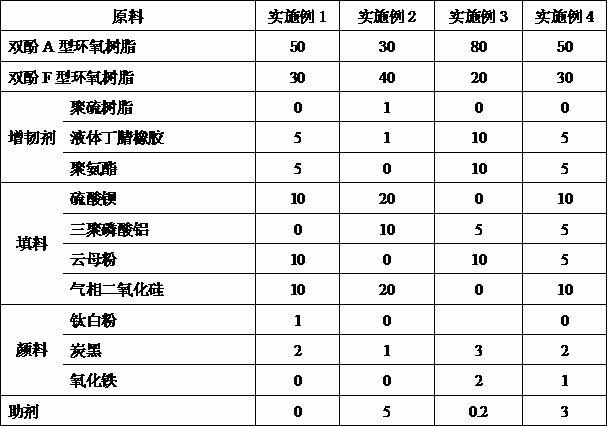

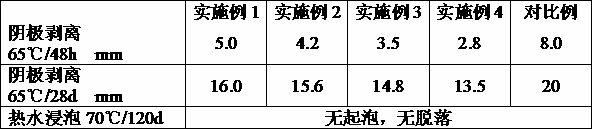

Solvent-free epoxy primer for corrosion protection of 3 polypropylene (PP) at craters of steel pipelines

InactiveCN102367354AReduce pollutionIncrease productivityAnti-corrosive paintsEpoxy resin coatingsPolymer scienceSolvent free

The invention discloses a solvent-free epoxy primer for corrosion protection of 3 PP at craters of steel pipelines. The primer comprises, by mass, 50 to 80% of component A and 20 to 50% of component B, wherein, the component A comprises, by weight, 30 to 80 parts of a bisphenol A type epoxy resin, 20 to 40 parts of a bisphenol F type epoxy resin, 2 to 20 parts of a flexibilizer, 15 to 50 parts of a filling material and 1 part to 5 parts of pigments, and the component B is a polyamide epoxy hardener. According to the invention, the solvent-free epoxy primer for corrosion protection of 3 PP at craters of steel pipelines ensures good bond performance, i.e., high bonding strength, between the primer and PP, and good bond performance between 3 PP and a hot melt adhesive as well.

Owner:JIANGSU DASHENG HEAT SHRINKABLE MATERIALS

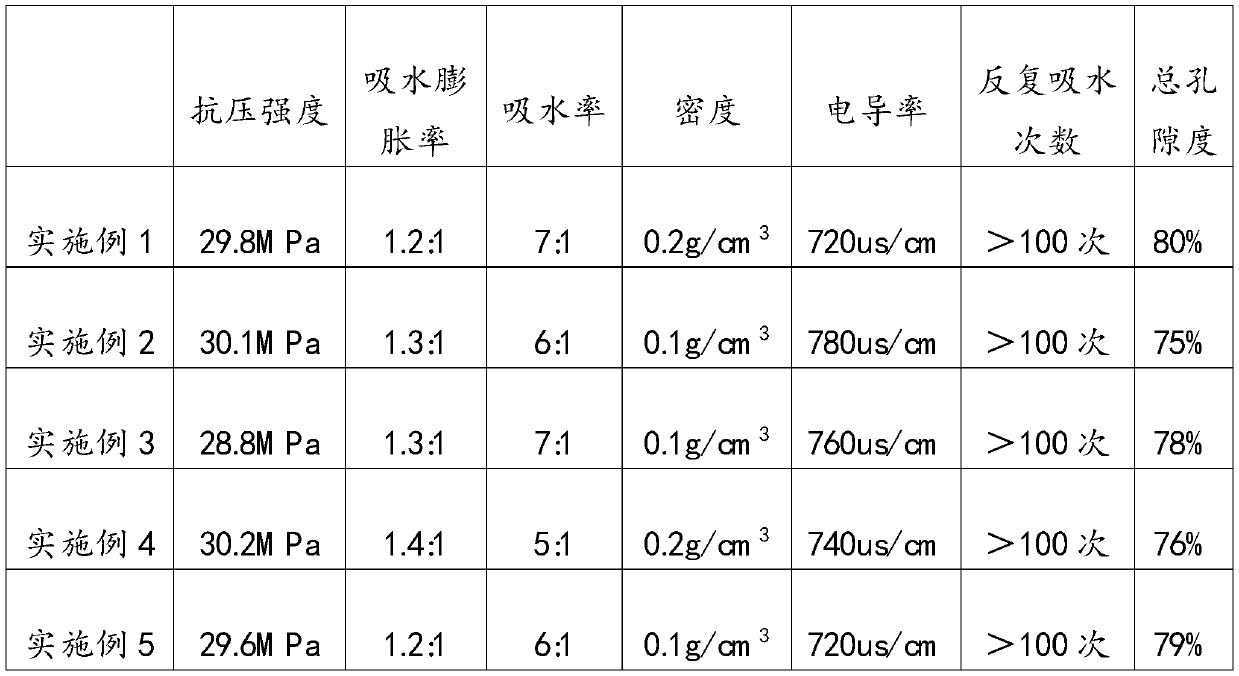

High density fibrous filter plate and manufacturing method

InactiveCN1562442AHigh filtration precisionFiltration accuracy is higher than or excellentFibreboardStationary filtering element filtersPorosityEpoxy

A high-density filtering fibreboard is prepared from sepiolite wool, paper pulp fibre, adhesive (polyvinyl alcohol or epoxy resin), wet strengthening agent (polyvinylimine, polyamide epoxy resin, or cyanuramide), and dry strengthening agent (carboxymethyl cellulose or polyacrylamide) through preparing pulp, mixing shaping, baking, and shearing by needed sizes. It has high porosity and filtering throughput.

Owner:HEBEI UNIV OF TECH

Sizing agent and preparation method therefor

InactiveCN103374857AImprove stabilityNot easy to layerWater-repelling agents additionCross-linkAluminum silicate

Provided are a sizing agent and a preparation method therefor. The method comprises the following steps. First, some starch is taken. Second, a pigment weighing 20-120% of absolute dry weight of the starch are taken, the pigment can be mineral formed by hydrated aluminum silicates, and the content of the mineral with a particle size of less than 1 micron is 95-99%, or the pigment is talcum powder with a sheet structure and processed by electric charges, and the content of the talcum powder with a particle size of less than 2 microns is not less than 95%, or the pigment is heavy calcium carbonate, and the content of heavy calcium carbonate with a particle size of less than 2 microns is not less than 60%, or the pigment is light calcium carbonate with an average particle size of 0.35-0.45 micron. Third, cross-linking agents weighing 0.2-3% of absolute dry weight of the starch are taken, and the cross-linking agents are amino resin, ammonium zirconium carbonate, polyamide epoxy resin, polyamide polyamine epichlorohydrin resin, polyamide polyurea resin, glyoxal and melamine glyoxal. Fourth, the starch, the pigments and the cross-linking agents and water are mixed and boiled together at the temperature of 100-130 DEG C for 40-60 min.

Owner:GOLD EAST PAPER JIANGSU

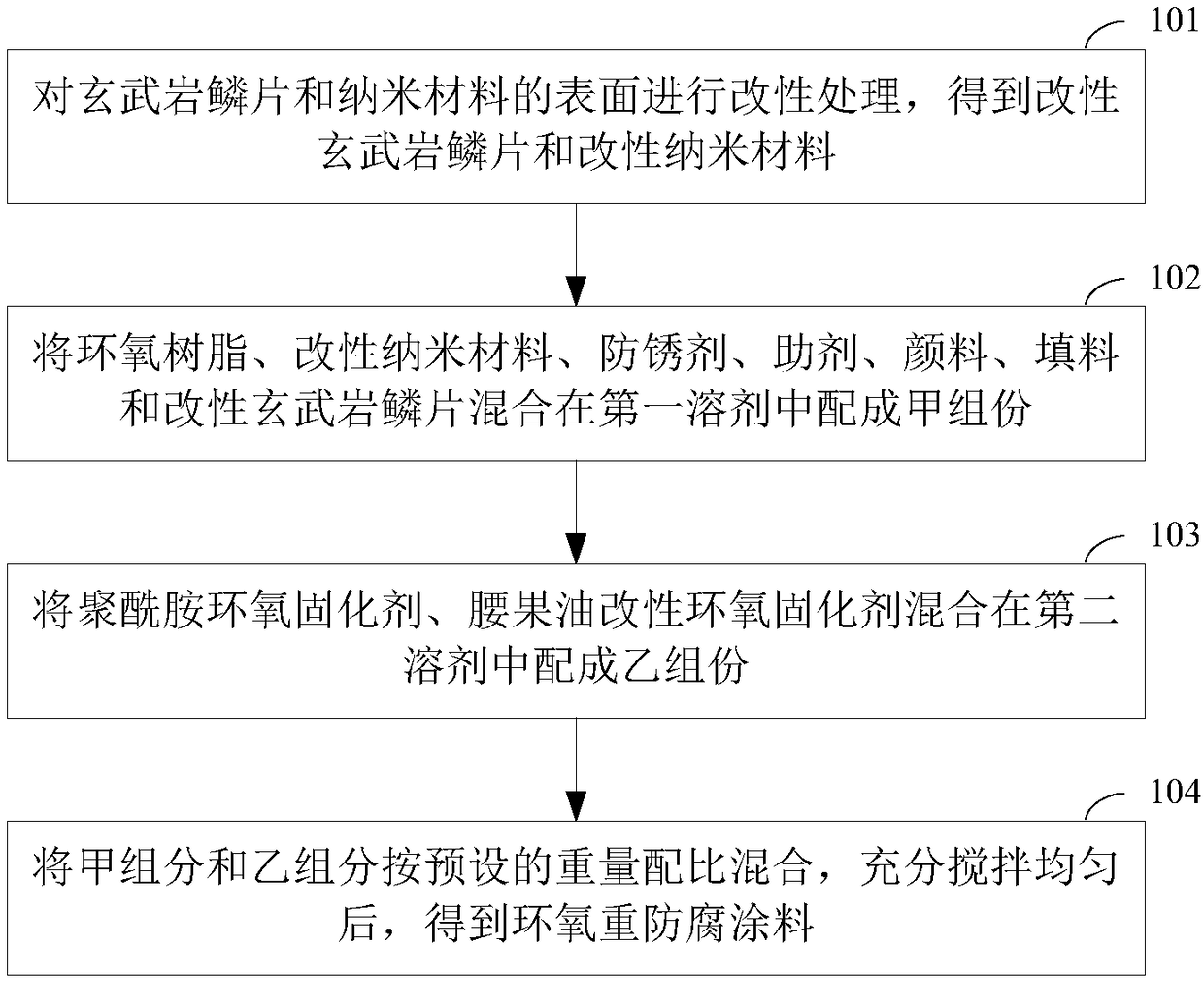

Preparation method of epoxy heavy duty anticorrosion coating

InactiveCN108129949AImprove penetration resistanceImprove shielding effectAnti-corrosive paintsEpoxy resin coatingsEpoxySolvent

The invention provides a preparation method of an epoxy heavy duty anticorrosion coating. The preparation method comprises following steps: basalt scale and a nanometer material are subjected to surface modification treatment so as to obtain modified basalt scale and a modified nanometer material; epoxy resin, the modified nanometer material, an antirust agent, an auxiliary agent, a pigment, a filling material, and modified basalt scale are mixed in a first solvent so as to obtain a component A; a polyamide epoxy hardener, and a cashew oil modified epoxy hardener are mixed in a second solventso as to obtain a component B; the component A and the component B are mixed at a preset weight ratio, full stirring is carried out so as to obtain the epoxy heavy duty anticorrosion coating. The preparation method is capable of improving the compactibility, the corrosion resistance, and the durability of the epoxy heavy duty anticorrosion coating.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

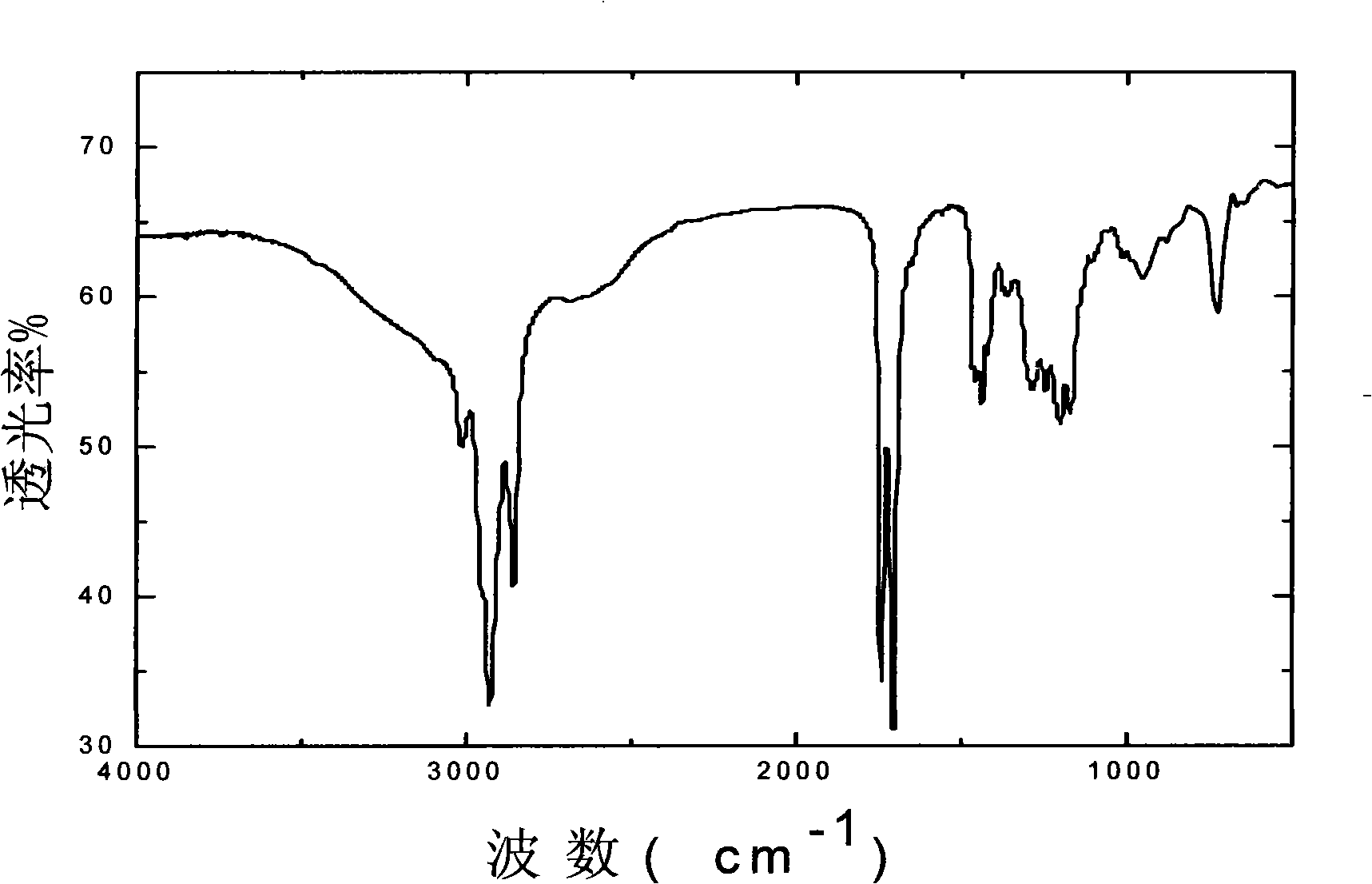

Method for preparing C21dicarboxylic acid polyamide epoxy hardener from methyl eleostearate

The invention belongs to the preparation field of epoxy curing agents and discloses a method of preparing C21 dicarboxylates polyamide epoxy curing agent with methyl eleostearate as follows: the first step: 100 molar portions of methyl eleostearate, 20.6-30.9 molar portions of acrylic acid, and inhibitor accounting for 0.5% to 1.5% mass of the acrylic acid are processed with addition reaction at 160 to 180 DEG C for 2 to 3 hours; then the non-reactant is removed through vacuum distillation and the reactant is decolorized through depigmenting agent so as to obtain C21 dicarboxylic acid monomethyl ester. The second step: 1 mol of C21 dicarboxylic acid monomethyl ester obtained from the first step is added drop by drop into 1.5-2 mol of polyamine which is of 140 DEG C within 0.5 hour, then the mixture liquid is processed with amidation at 170 to 200 DEG C for 3 to 6 hours; later, water and free amine are removed through vacuum distillation, so the C21 dicarboxylates polyamide epoxy curing agent is obtained. The methyl eleostearate of the invention has an 85% yield, high reactivity and low energy consumption needed in the reactions; the prepared C21 dicarboxylates polyamide epoxy curing agent and the epoxy solid products have high strength and modulus and good heat-resistant performance.

Owner:INST OF CHEM IND OF FOREST PROD CHINESE ACAD OF FORESTRY

Soybean-protein-containing aldehyde-free adhesive and preparation method thereof

InactiveCN106905919AImprove crosslink strengthImprove water resistanceNon-macromolecular adhesive additivesProtein adhesivesPolymer scienceAdhesive

To overcome the defects of a soybean adhesive in the prior art, the invention provides a soybean-protein-containing aldehyde-free adhesive and a preparation method thereof, and belongs to the technical field of an aldehyde-free adhesive used for timber. The aldehyde-free adhesive takes soybean protein as a main component, and contains a surfactant, the weight of which is 1-10% of that of soyabean protein, an alkaline compound, the weight of which is 3-15% of that of soyabean protein, metal oxide, the weight of which is 5-20% of that of soyabean protein, polyamide epoxy haloalkane resin, the weight of which is 3-20% of that of soyabean protein, and water the weight of which is 2-5 times of that of soyabean protein. Soybean protein is taken as a substrate, and the surfactant, the modifier of metal oxide and hydroxide and a cross-linking agent are used for comprehensive modification of soybean protein, so that the adhesive strength and water proofness of the soybean protein adhesive are improved.

Owner:UNIV OF SCI & TECH LIAONING

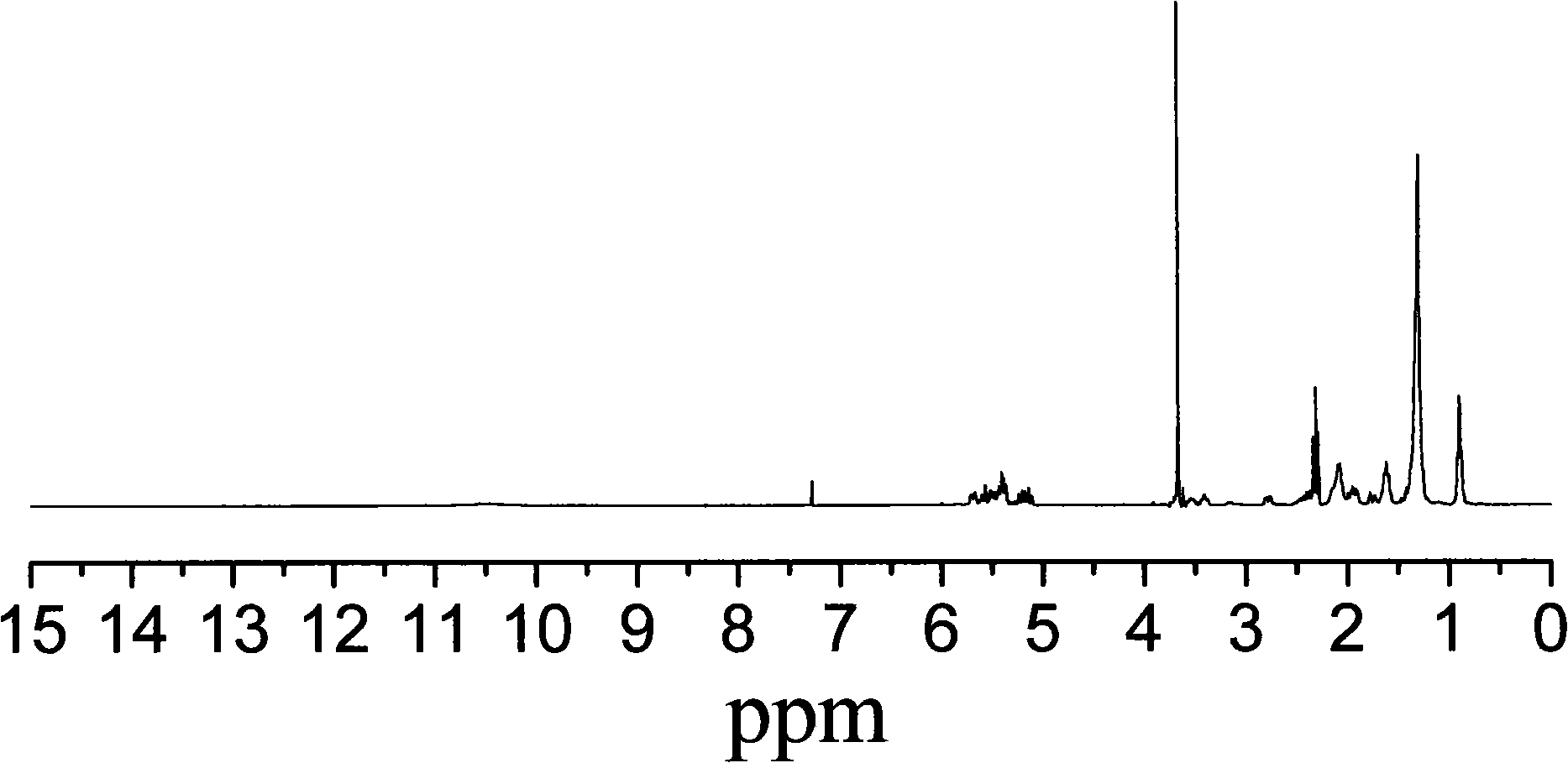

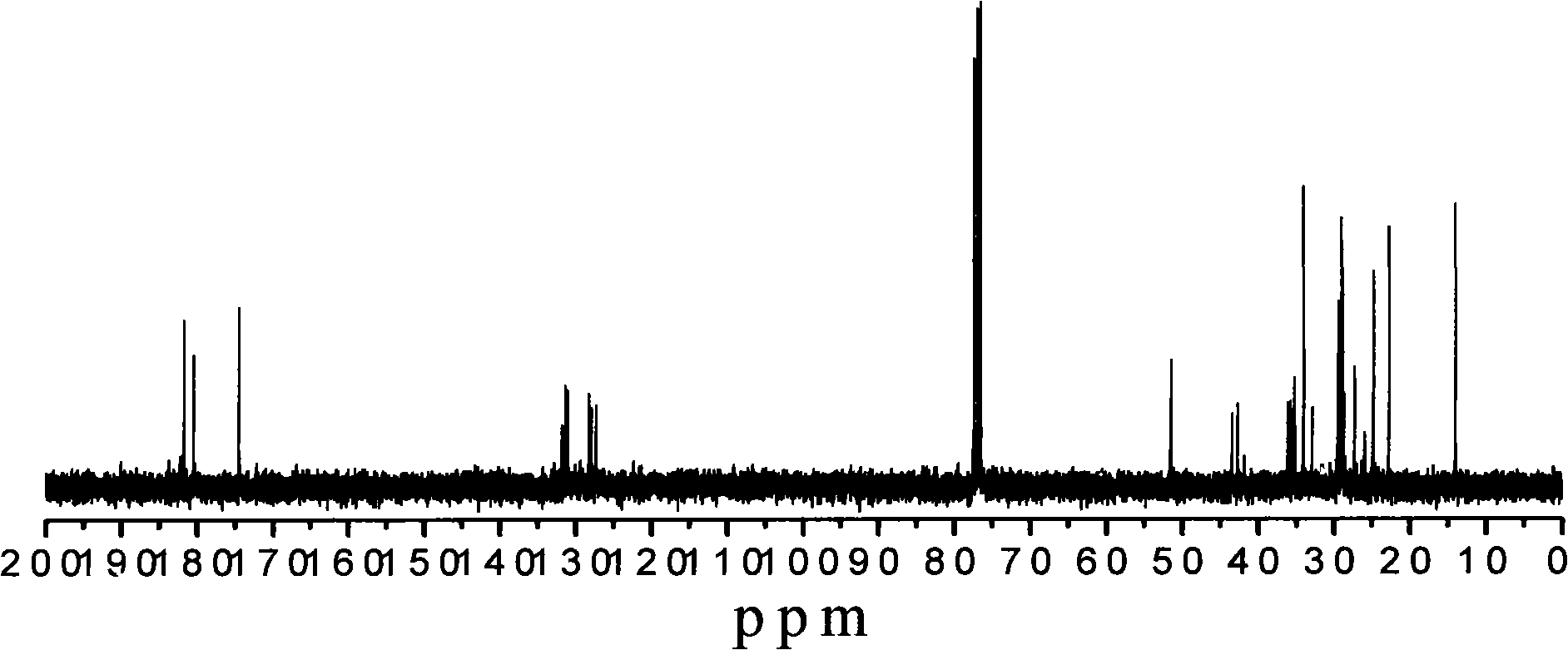

Reinforcing material for solid polymer fuel cell, and cohesive/adhesive composition for use in same

InactiveUS20140127608A1Improve adhesionStably retain adhesion forceFilm/foil adhesivesCell component detailsPolyamidePolyamide epoxy

Owner:DAI NIPPON PRINTING CO LTD

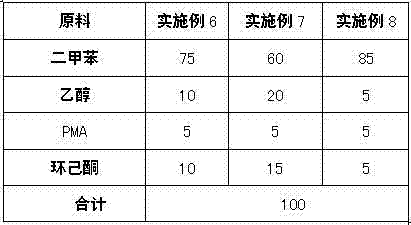

Railway transit aqueous epoxy double-component coating and preparation method thereof

ActiveCN104817929ASmall particle sizeImprove salt spray resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyZinc phosphate

The invention belongs to the field of coating preparation and especially relates to a railway transit aqueous epoxy double-component coating and a preparation method thereof. The coating includes a component A and a component B, wherein the component A comprises 3-6 parts of a coalescing agent 2,2,4-Trimethyl-1,3-pentanediol monoisobutyrate, 0.5-1 part of an aqueous epoxy dispersing agent, 0.5-1 part of a chelating-type aqueous coupling agent, 15-20 parts of iron oxide red, 15-20 parts of talcum powder, 4-6 parts of high-molecular-modified zinc phosphate, 3-4 parts of modified aluminium triphosphate, 20-25 parts of high-molecular epoxy resin, 2 parts of an emulsifier containing epoxy groups, 0.1-0.5 parts of an aqueous wetting agent, 0.1-0.5 parts of an aqueous defoaming agent, 1 part of an anti-settling agent, 1 part of an anti-flash-rust agent, 0.3 parts of an aqueous anti-sag agent and 20-30 parts of deionized water; and the component B comprises 80 parts of an aqueous polyamide epoxy curing agent and 20 parts of deionized water.

Owner:常州勤邦新材料科技有限公司

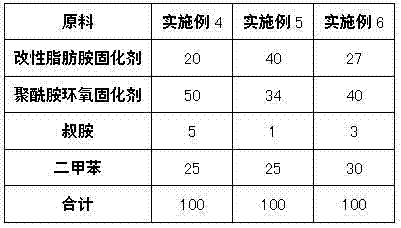

Washing-resistant epoxy paint, and preparation method and application thereof

ActiveCN102850906AImprove washing resistanceUniform colorLiquid surface applicatorsEpoxy resin coatingsEpoxyWax

The invention discloses washing-resistant epoxy paint, and a preparation method and an application thereof. The washing-resistant epoxy paint is mainly composed of a component A and a component B according to a volume ratio of 3:1. The component A is compose of epoxy resin with epoxy equivalent of 450-500, epoxy resin with epoxy equivalent of 180-190, plasticized resin, an organic solvent, an adhesion-promoting agent, an auxiliary agent, wax powder, and a toner. The component B is composed of a modified aliphatic amine epoxy curing agent, a polyamide epoxy curing agent, a tertiary amine curing accelerator, and xylene. The washing-resistant epoxy paint provided by the invention is suitable to be used in metal zipper workpiece coating. The metal zippers processed with the coating treatment have the advantages of smooth surfaces and uniform color. A dried paint film has good enzyme solution resistance and excellent washing resistance.

Owner:CHINA PAINT MFG CO SHENZHEN

Waterproof packing cardboard and producing method thereof

InactiveCN101037854AHigh strengthImprove toughnessFlexible coversMechanical working/deformationEpoxyCardboard

The present invention relates to a waterproof and antirust packaging paperboard and a manufacturing method thereof. Said method comprises coating one side of a waterproof paperboard with a layer of surface water-resistance agent, wherein said waterproof paperboard is made of a paper board containing a composite water-resistance agent prepared by mixing alkyl ketene dimmer and polyamide epoxy resin with a proportion of 4-6:1 by weight. The beneficial effects in accordance with the present invention are as follows: 1, the waterproof paperboard manufactured by a multi-layer recombination not only exhibit better intensity, tenacity and impact resistance, but also has excellent waterproof and damp proof insulation performances, and further exhibits better antirust performance after being coated with a vapor phase inhibitor, then said paperboard has excellent packaging performances which is stable, and the packaging requests and outdoor storage requests can be satisfied by packaging steel (coil) sheet materials with the waterproof paperboard in accordance with the present invention; 2, the manufacturing cost is low ans the source of the raw material is extensive; 3, said waterproof paperboard can be recovered and recycled easily, and is naturally degradable, and then is environment-friendly.

Owner:武汉市江夏区江南实业有限公司 +1

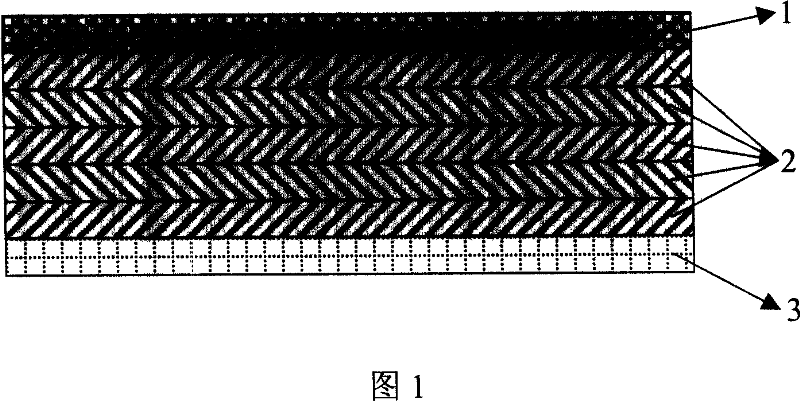

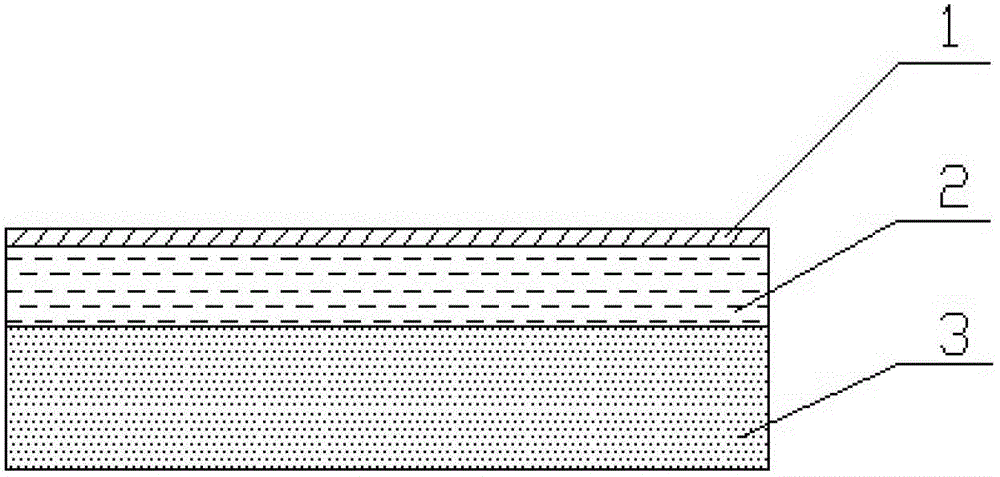

Marine pumping corrosion protection layer and spray coating method thereof

InactiveCN103753911AImprove work efficiencyNot easy to influenceSynthetic resin layered productsPretreated surfacesEpoxyPolyamide

The present invention provides a marine pumping corrosion protection layer and a spray coating method thereof, wherein the marine pumping corrosion protection layer comprises a primer layer, an intermediate paint layer and a top coat layer, the primer layer is prepared by mixing an epoxy resin and a curing agent according to a volume ratio of 3:2, the intermediate paint layer is prepared by mixing a polyamide epoxy paint and a curing agent according to a volume ratio of 3:1, the top coat layer is prepared by mixing a polyurethane surface paint and a curing agent according to a volume ratio of 6:1, 0.1-0.3% of a coupling agent and 10-20% of a filler are respectively mixed in the primer layer, the intermediate paint layer and the top coat layer, the coupling agent is vinyl triethoxysilane or isopropyl triisostearyl titanate, and the filler is one or a plurality of materials selected from titanium dioxide powder, corundum powder, wollastonite powder, carbon black powder and quartz powder. According to the present invention, the pollution of the marine pumping corrosion protection layer on the environment can be solved so as to further increase the marine pumping work efficiency.

Owner:NINGBO YINZHOU YONGJIA ELECTRICAL TOOLS

Mould corrosion prevention method

The invention relates to a mould corrosion prevention method. The mould corrosion prevention method is characterized by including the following steps: (1) subjecting the surface of a mould to pretreatment; (2) subjecting the mould to spray coating with epoxy-tar anti-corrosive paint, thick paste type aluminium-powder epoxy-tar anti-corrosive paint or polyamide epoxy resin, wherein the thickness of the coating is 0.8-0.95mm. The mould corrosion prevention method has the advantages that the whole method is simple and easy to operate; cost is low, corrosion prevention effect is good, and the treated mould can be used for a long time even if in the humid environment or acid-base environment.

Owner:滁州市艾德模具设备有限公司

Method for preparing water-resistant paper product glue by taking soybean protein powder as raw material

InactiveCN102888206ASimple production processEasy to operateProtein adhesivesGlue/gelatin preparationPreservativePolyamide

The invention discloses water-resistant paper product glue which consists of the following components in parts by weight: 0-90 parts of water, 10-30 parts of soybean protein powder, 1-90 parts of polyamide epoxy chloropropane, 1-10 parts of tackifier, 0-15 parts of pH modifier and 0.05-5 parts of sterilization preservative. The water-resistant paper product glue is prepared by the following steps of: mixing the soybean protein powder with water; sequentially adding the polyamide epoxy chloropropane, the tackifier, the pH modifier and the sterilization preservative; and finally stirring and mixing. According to the invention, the technology is simple, pollution and discharge are avoided, the water resistance of the product is much higher than that of the similar products such as water glass, starch glue and the like, and damping is prevented. The water-resistant paper product glue is green, environment-friendly and convenient to use.

Owner:谷神生物科技集团有限公司

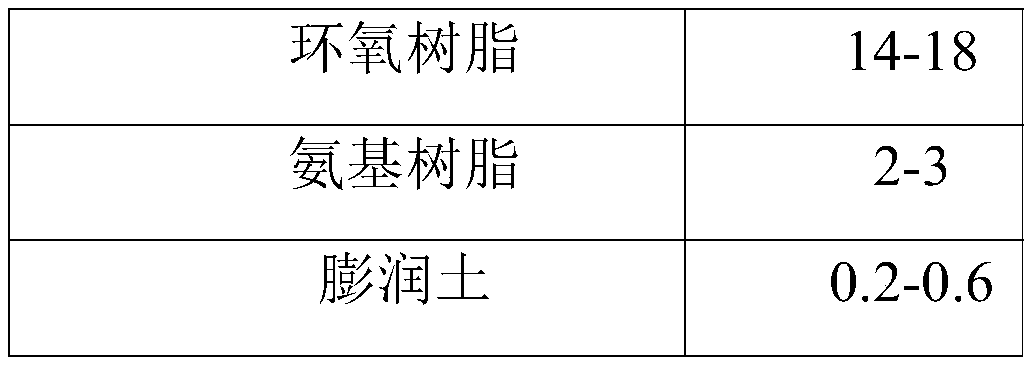

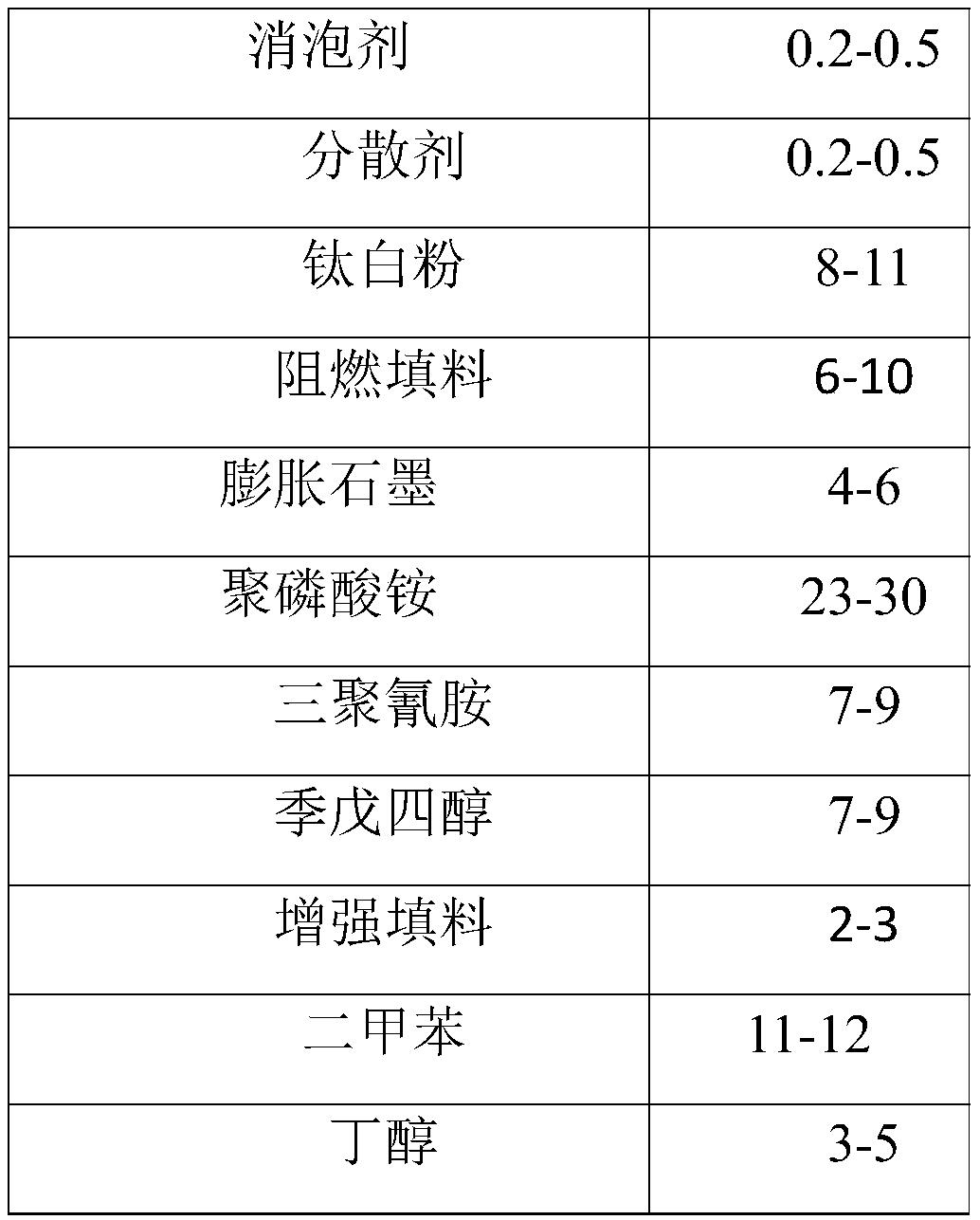

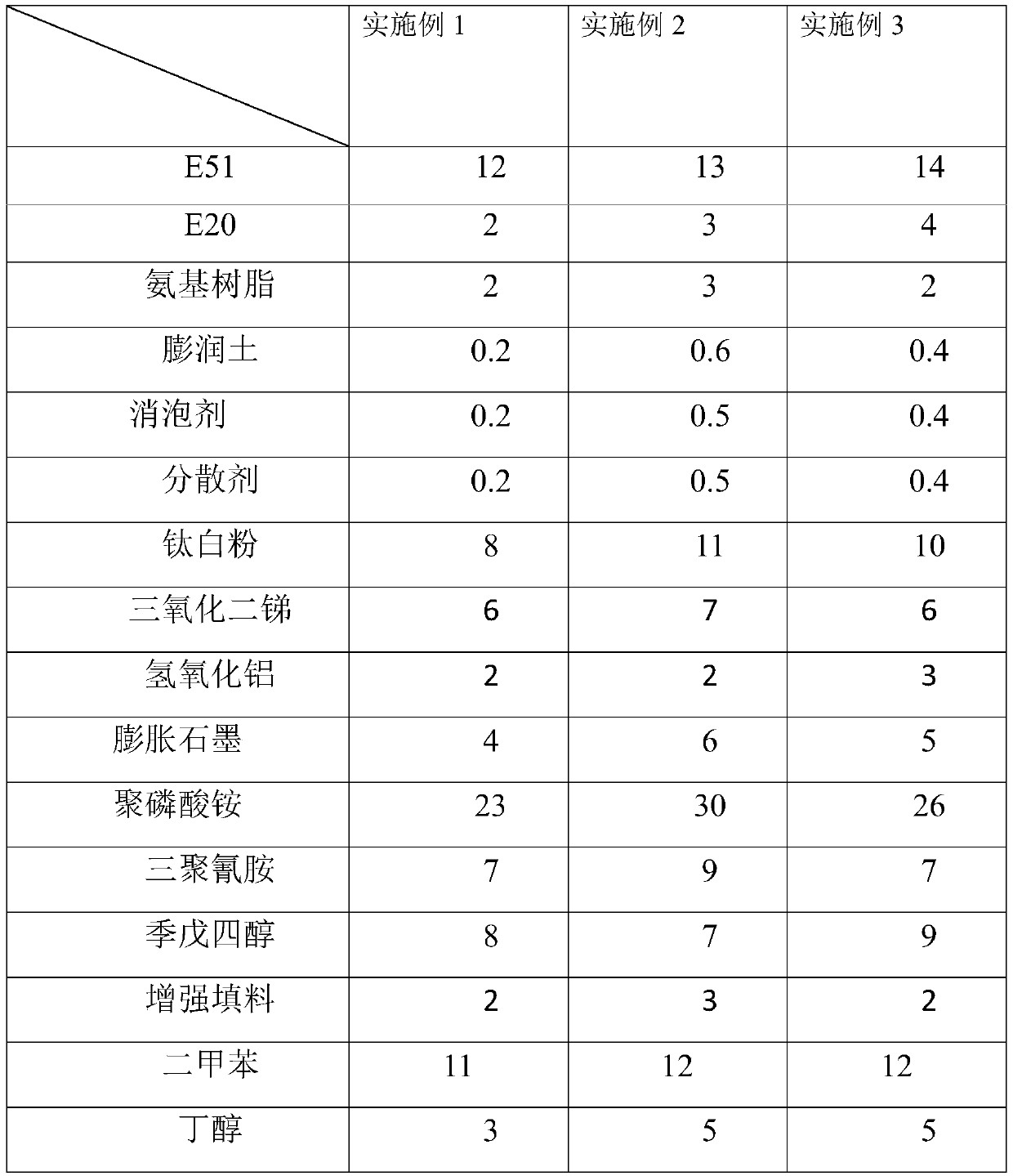

Double-component expansion type fireproof coating and preparation method thereof

InactiveCN110591502AStrong adhesionImprove cohesionFireproof paintsEpoxy resin coatingsEpoxyDefoaming Agents

The invention discloses a double-component expansion type fireproof coating which consists of a component A and a component B, wherein the component A consists of the following raw materials in partsby weight: 14-18 parts of an epoxy resin, 2-3 parts of an amino resin, 0.2-0.6 part of bentonite, 0.2-0.5 part of a defoaming agent, 0.2-0.5 part of a dispersant, 8-11 parts of titanium dioxide, 6-10parts of flame-retardant filler, 4-6 parts of expanded graphite, 20-30 parts of Ammonium Polyphosphate, 5-9 parts of melamine, 5-9 parts of pentaerythritol, 2-3 parts of reinforcing filler, 11-12 parts of xylene and 3-5 parts of butanol; and the component B is a modified polyamide epoxy curing agent. The fireproof coating is excellent in flame retardancy, high in mechanical strength and excellentin water resistance.

Owner:石家庄市油漆厂

Bi-component corrosion-proof dope

InactiveCN100526406CEasy curingStrong adhesionAnti-corrosive paintsEpoxy resin coatingsEpoxyPolyamide

A titanium-nickel nanometer alloy powder contains A and B components; A components consist of epoxy-resin, titanium-nickel nanometer alloy powder, antirust pigment, filler corrosion stabilizer and anti-sagging accessory; B components consist of composite curing agent with cashew nut shell modified phenolic amine curing agent and polyamide epoxy curing agent; the proportion of A and B is 10:1. It has excellent adhesion and physical performance and better oil, water, acid-alkali and salt fog resistances and mating ability. It can be used as universal base coat and used for various substrate materials such as steel, aluminum and stainless steel etc.

Owner:中国人民解放军海军装备技术研究所

Epoxy micaceous iron sealing agent for cold sprayed zinc and preparation method of epoxy micaceous iron sealing agent

InactiveCN105017935AImprove auxiliary forceNot easy to producePaints with free metalsEpoxy resin coatingsEpoxyCoating system

The invention discloses an epoxy micaceous iron sealing agent for cold sprayed zinc. The sealing agent comprises a first component and a second component. The weight ratio of the first component to the second component is 6:1. The first component comprises, by weight, 10-20 parts of epoxy resin, 30-50 parts of micaceous iron oxide, 10-20 parts of talcum powder, 1-2 parts of aluminum powder, 1-5 parts of anti-settling agents, 0.1-0.2 part of defoaming agents and 10-35 parts of diluents. The second component is a polyamide epoxy curing agent. The invention further discloses a preparation method of the epoxy micaceous iron sealing agent for cold sprayed zinc. The sealing agent is applied to a cold sprayed zinc three-coating system to serve as an intermediate paint sealing agent, can be applied to an epoxy zinc-rich primer and serves as a sealing agent in an inorganic zinc-rich primer system. The epoxy micaceous iron sealing agent for the cold sprayed zinc is used for increasing adhesive force of the cold sprayed zinc, avoids the sagging phenomenon, and facilitates construction. When the sealing agent is used, bubbles are not easily generated, and the defoaming effect is good.

Owner:WUXI HUADONG ZINDN TECH

Thiourea modified polyamide epoxy curing agent and preparation method

InactiveCN106995525AImprove performanceImprove toughnessAnti-corrosive paintsEpoxy resin coatingsPolymer scienceThiourea

The invention discloses a thiourea modified polyamide epoxy curing agent and a preparation method thereof. The thiourea modified polyamide epoxy curing agent is prepared from polyamide and thiourea. The thiourea modified polyamide epoxy curing agent disclosed by the invention is prepared through an optimal raw material ratio screened by a lot of experiments. According to the preparation method, polyamide is prepared firstly through an optimum scheme and the thiourea modified polyamide epoxy curing agent with an excellent performance is prepared by taking the polyamide and thiourea at a preferable ratio to react. An experiment result shows that the thiourea modified polyamide epoxy curing agent prepared by the preparation method enables epoxy resin to be rapidly cured at low temperature of -10 DEG C and an epoxy resin cured thin film has excellent toughness and adhesive force; the surface of the film does not easily absorb moisture and the corrosion-resisting and drug-resisting performances are excellent; requirements on application of low-temperature environment epoxy heavy-duty anticorrosive paint can be met. Compared with other curing agents, the thiourea modified polyamide epoxy curing agent has more excellent performances and very good technical effects are obtained.

Owner:江苏三木化工股份有限公司 +1

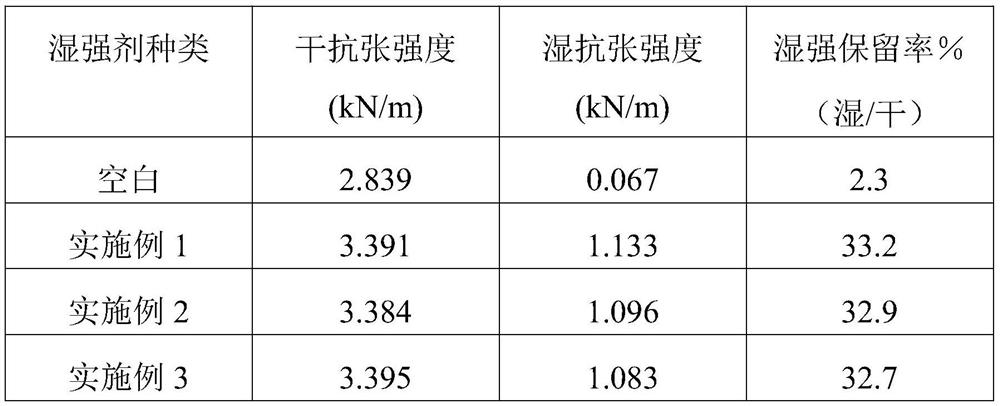

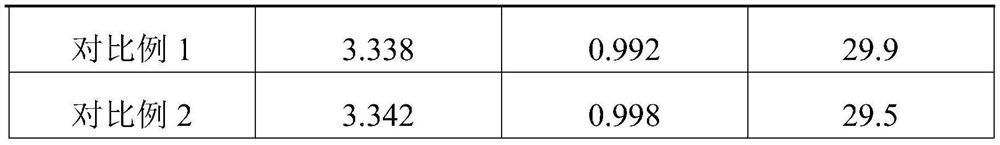

Preparation method of environment-friendly low-chlorine wet strength agent

ActiveCN112647351AHigh cationic degreeImprove retentionReinforcing agents additionPolyamideEngineering

The invention discloses a preparation method of an environment-friendly low-chlorine wet strength agent. The method comprises the following steps: adding polybasic acid which accounts for 0.05-5% of the weight of polyethylene polyamine and has the functionality greater than or equal to 3 into a polycondensation reaction system of dicarboxylic acid and polyethylene polyamine for copolymerization; then adding epoxy chloropropane for modification to obtain polyamide epoxy resin; and then mixing with enzymolysis hydroxypropyl guar gum to obtain the environment-friendly low-chlorine wet strength agent. A branched structure is formed during first-stage polymerization, the branching degree is high, and the reaction temperature in the polymerization stage is low; and mixed reaction with a natural environment-friendly enzymolysis guar gum derivative is carried out, residual epichlorohydrin in polyamide epoxy resin is consumed, and thus the final product has low organochlorine content and more excellent application performance, and the obtained paper has better wet strength and wet strength retention rate.

Owner:SHANGHAI DONGSHENG NEW MATERIALS +1

Insulation coating material for electric power device

InactiveCN105199453AImprove the ability to adapt to the environmentStrong adhesionAnti-corrosive paintsPolyesterEpoxy

The invention discloses an insulation coating material for an electric power device, and belongs to the technical field of a coating material, which solves the problems that the existing insulation coating material is poor in adhesive force and poor in corrosion resistance. The insulation coating material is prepared from the following raw materials in parts by weight: 30 to 40 parts of organic silicon resin, 10 to 20 parts of epoxy resin, 5 to 10 parts of dimethyl siloxane, 3 to 5 parts of methylbenzene, 13 to 18 parts of n-butyl alcohol, 1 to 3 parts of dimethyl terephthalate, 1 to 2 parts of polyethylene, 1 to 3 parts of butyl acrylate, 1 to 3 parts of hydroxyethyl acrylate, 5 to 10 parts of polyethylene wax, 0.5 to 1 part of polyamide epoxy curing agent, 1 to 3 parts of modified polyester silane, 2 to 5 parts of silicon nitride, 1 to 3 parts of magnesium oxide and 0.3 to 1 part of polyether modified organic silicon defoaming agent. The insulating coating material can be used for a majority of electric power devices and is particularly suitable for the electric power device working in a dirty and wet environment.

Owner:STATE GRID SHANDONG ELECTRIC POWER +1

Terrace with solvent type anti-static epoxy finishing coat

The invention discloses a terrace with a solvent type anti-static epoxy finishing coat. The terrace comprises a foundation, wherein cement is paved on the foundation and the solvent type anti-static epoxy finishing coat is paved on the cement. The solvent type anti-static epoxy finishing coat is formed by stirring auxiliaries such as epoxy resin, dimethylbenzene, methylisobutylketone, padding, color paste and a defoaming agent, conductive powder and a polyamide epoxy curing agent. Due to adoption of the mode, the terrace with the solvent type anti-static epoxy finishing coat is uniform in ground color, attractive in appearance and good in anti-static effect and is suitable for semiconductor industries and precision industries.

Owner:SUZHOU MINGXUAN FLOORING COATINGS

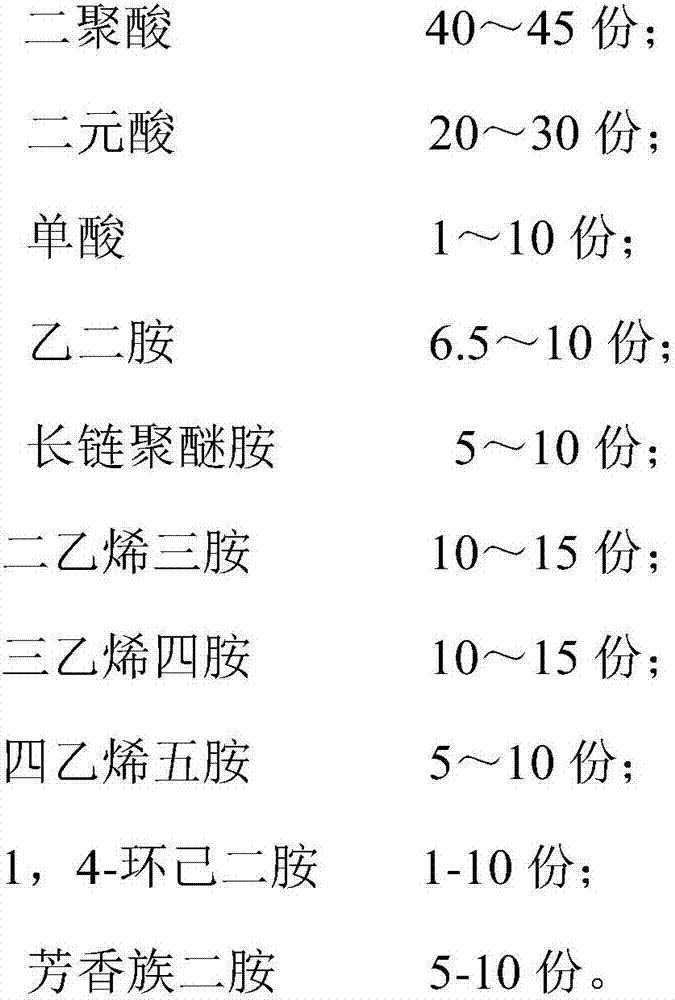

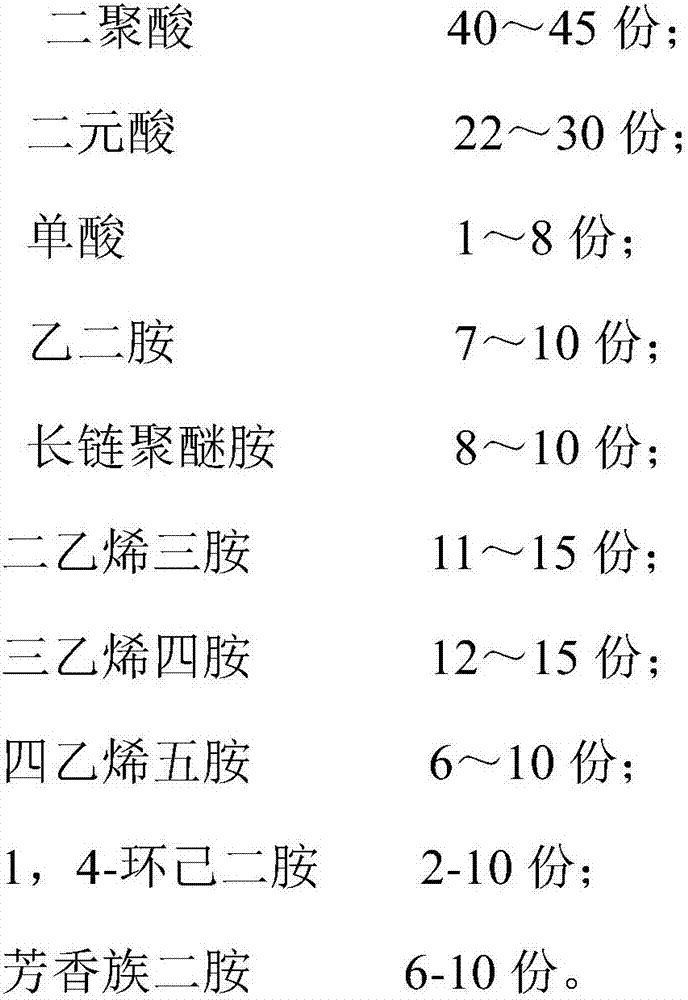

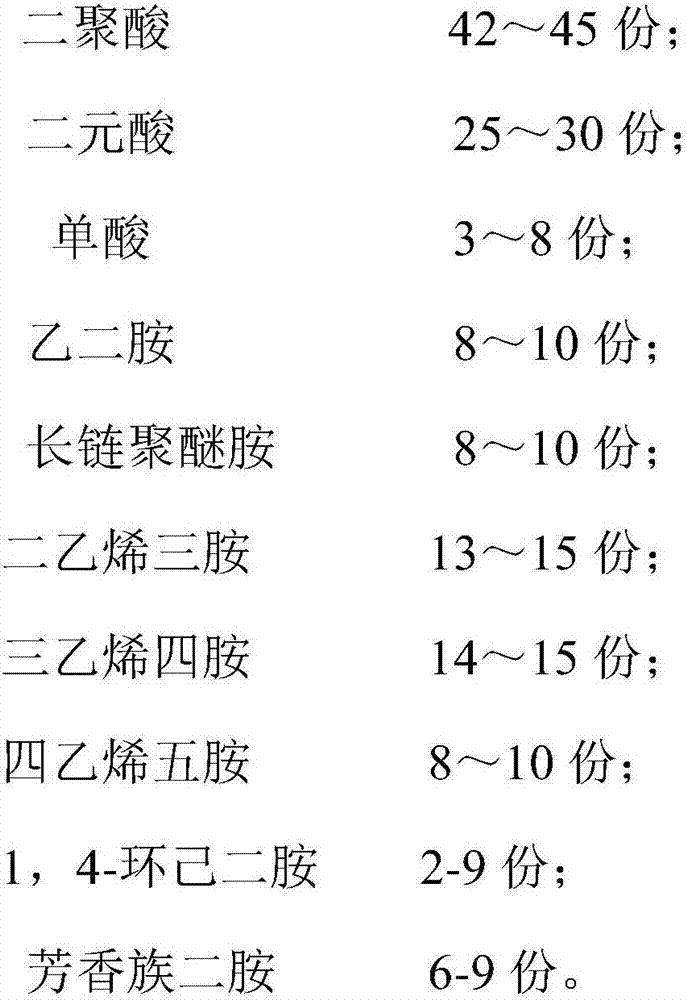

Polyamide epoxy resin curing agent

The invention relates to the technical field of curing agents, in particular to a polyamide epoxy resin curing agent. The polyamide epoxy resin curing agent is prepared from, by weight, 40-45 parts of dimer acid, 20-30 parts of binary acid, 1-10 parts of momomer acid, 6.5-10 parts of quadrol, 5-10 parts of long-chain polyether amine, 10-15 parts of diethylenetriamine, 10-15 parts of triethylene tetramine, 5-10 parts of tetraethylenepentamine, 1-10 parts of 1,4-cyclohexanediamine and 5-10 parts of aromatic diamine. Compared with the prior art, the polyamide epoxy resin curing agent is prepared through the steps that acid and amine are subjected to a polymerization reaction to prepare amide and regarded as a reaction system, and 1,4-cyclohexanediamine is added into the reaction system, and the polyamide epoxy resin curing agent modified by 1,4-cyclohexanediamine has the excellent low-temperature resistance, and is quite good in obtained flexibility and toughness, moderate in hardness and high in curing speed.

Owner:东莞市舜天实业有限公司

Nano-modified epoxy heavy-duty anti-corrosion coating

InactiveCN111004557AClose contactImprove penetration resistanceAnti-corrosive paintsEpoxy resin coatingsPolymer sciencePolyamide

The invention provides a nano-modified epoxy heavy-duty anti-corrosion coating which comprises a component A and a component B at a mass ratio of (8-10): 1, wherein the component A comprises the following raw materials in parts by mass: 35-50 parts of epoxy resin, 2-10 parts of a modified nano material, 5-20 parts of modified scale aggregate, 6-10 parts of a mixed solvent, 5-15 parts of a silane coupling agent, 2-8 parts of an antirust agent, 1-5 parts of an auxiliary agent, 5-10 parts of a filler and 3-12 parts of a pigment; and the component B comprises the following raw materials in parts by mass: 15-30 parts of a polyamide epoxy curing agent, 10-15 parts of a cashew nut oil modified epoxy curing agent and 35-50 parts of a mixed solvent. By applying the above formula, the compactness ofthe coating can be effectively improved, the corrosion resistance of the coating is enhanced, and the durability of the coating is improved.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP

Straw greening brick and preparing method thereof

ActiveCN110192476AWith strengthRich in nutrientsSingle unit pavingsGrowth substratesLand resourcesBrick

The invention discloses a straw greening brick and a preparing method thereof. The straw greening brick comprises crop straw, animal waste, an inorganic complex, sodium polyacrylate, amino acid, polyamide epoxy chloropropane, ferrous sulfate, magnesium sulfate and borax. The straw greening brick has the advantages that the straw greening brick can provide rich nutrients for seed germination and plant growth, the straw greening brick can have certain water absorption strength due to the contained polyamide epoxy chloropropane and sodium polyacrylate, the straw greening brick is light in handfeel and loose in texture and has quite good water absorption property, water retention property and permeability, is good in forming and free of looseness and can be directly spread on the ground surface or half-buried in the ground surface, seeds and a brick body are press-formed at a time or the seeds are scattered in planting grooves, germination and growth can be directly realized after wateringor raining, the traditional turf spreading maintenance link is replaced, the rapid greening aim is realized, wind erosion can be rapidly stopped, the improvement of desertification saline-alkali soilis gradually realized, and land resources are saved.

Owner:SHENYANG AGRI UNIV +1

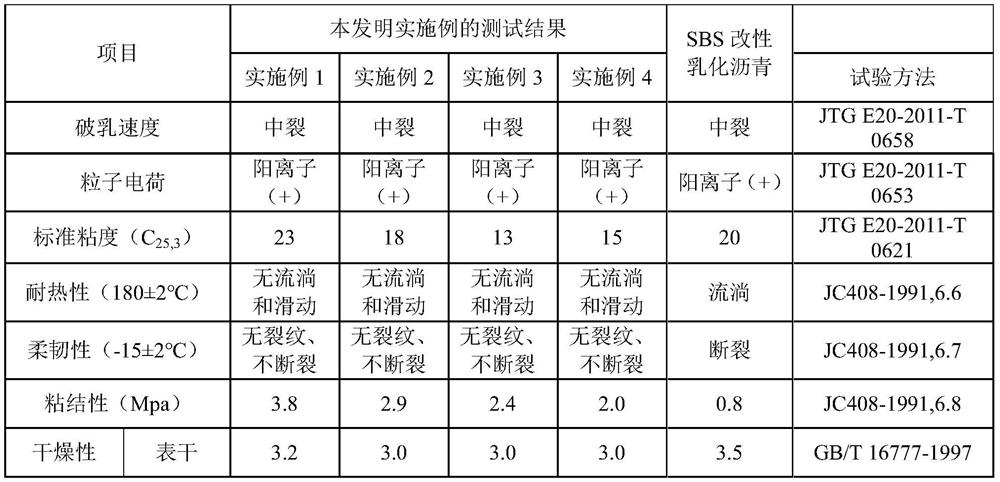

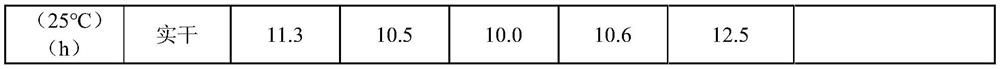

Emulsified asphalt cold-recycling layer interface bonding material as well as preparation method and application thereof

ActiveCN112210344AGuaranteed stabilityGuaranteed not to crackIn situ pavingsNon-macromolecular adhesive additivesXylylenePhosphoric acid

The invention relates to an emulsified asphalt cold-recycling layer interface bonding material which is prepared from the following raw materials: a component A, a component B, a component C, a component D and a component E. The component A is waterborne epoxy resin; the component B is a polyamide epoxy curing agent; the component C is formed by mixing a stabilizer and water; the component D is formed by mixing solid SBS, xylene, a compound emulsifier, a defoaming agent and water; the component E is formed by mixing asphalt, a medium-crack emulsifier, phosphoric acid and water; the emulsifiedasphalt cold-recycling layer interface bonding material comprises following components in parts by mass: 3-25 parts of the component A, 3-25 parts of the component B, 3-15 parts of the component C, 5-10 parts of the component D and 40-90 parts of the component E, the interface bonding performance between the emulsified asphalt cold-recycling layer and the upper layer is improved, the water damageresistance and the durability of the pavement are improved, and the product is non-toxic, high in stability, high in bonding strength, high in shear strength, good in waterproof performance and good in durability.

Owner:山西工程科技职业大学 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com